Integrated valve with oil circuit selection function for controlling hydraulic motor brake

A technology of hydraulic motors and brakes, which is applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., and can solve problems such as reduced service life, brake wear, and potential safety hazards of the main engine, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

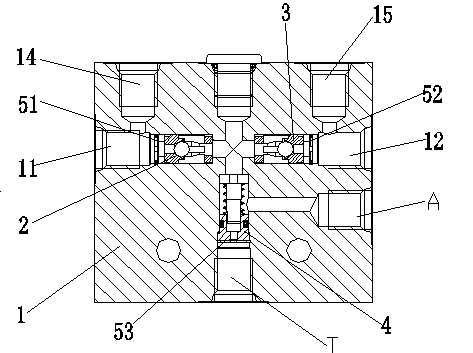

[0030] Figure 1 to Figure 13 Shown is the structural representation of the present invention.

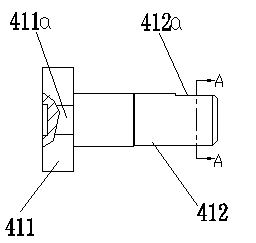

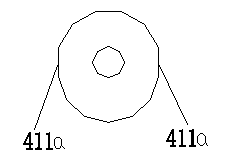

[0031] The reference signs are: valve body 1, main hydraulic chamber 1a, first valve chamber 1b, second valve chamber 1c, third valve chamber 1d, first control oil port 11, second control oil port 12, third Oil hole 13, fourth control oil port 14, fifth control oil port 15, first check valve assembly 2, first valve seat 21, first oil inlet hole 21a, first valve ball 22, first ball seat 23 , the first radial hole 23a, the first axial hole 23b, the second one-way valve assembly 3, the second valve seat 31, the second oil inlet hole 31a, the second valve ball 32, the second ball seat 33, the second Radial hole 33a, second axial hole 33b, throttle assembly 4, valve core 41, valve head 411, first damping hole 411a, valve stem 412, second damping annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com