Condenser

A condenser and refrigerant technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of wasted space in the engine room, large space in the condenser, insufficient gas-liquid separation performance, etc., and achieve space saving , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0032] In the description below, the figure 1 The inside of the paper ( Figure 4 The upper side) is the front, and the opposite side is the back.

[0033] In addition, in the following description, the term "aluminum" includes not only pure aluminum but also aluminum alloys.

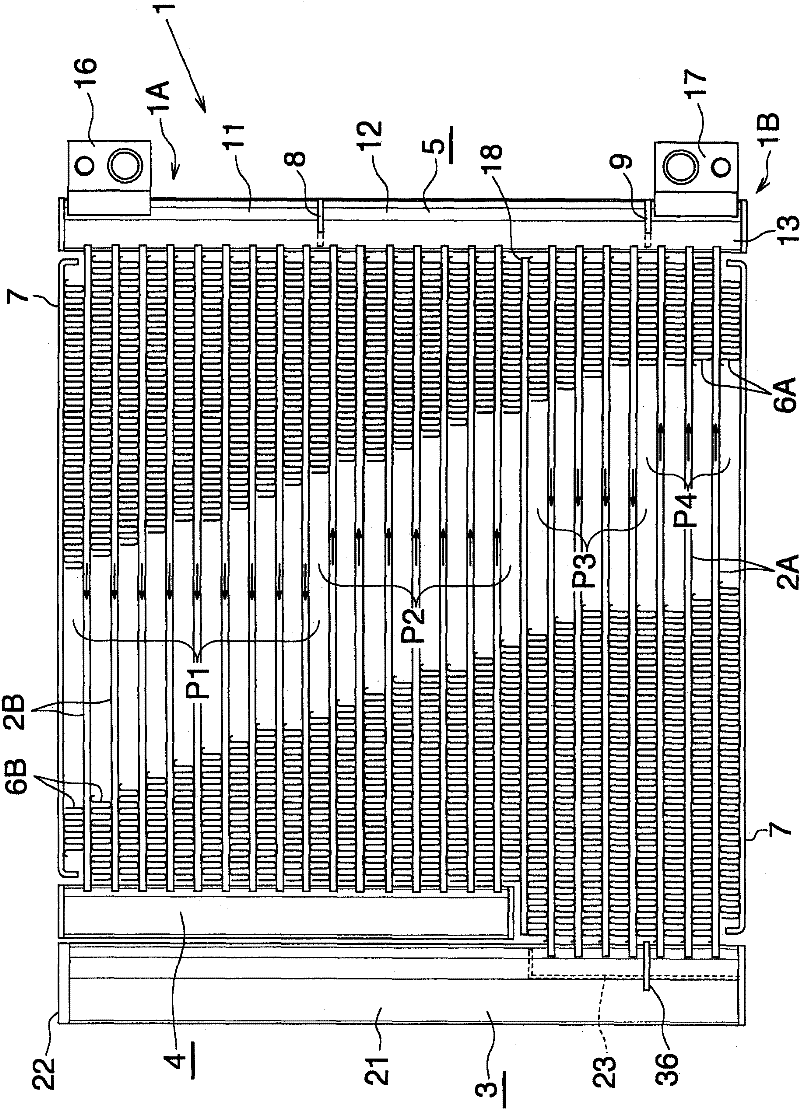

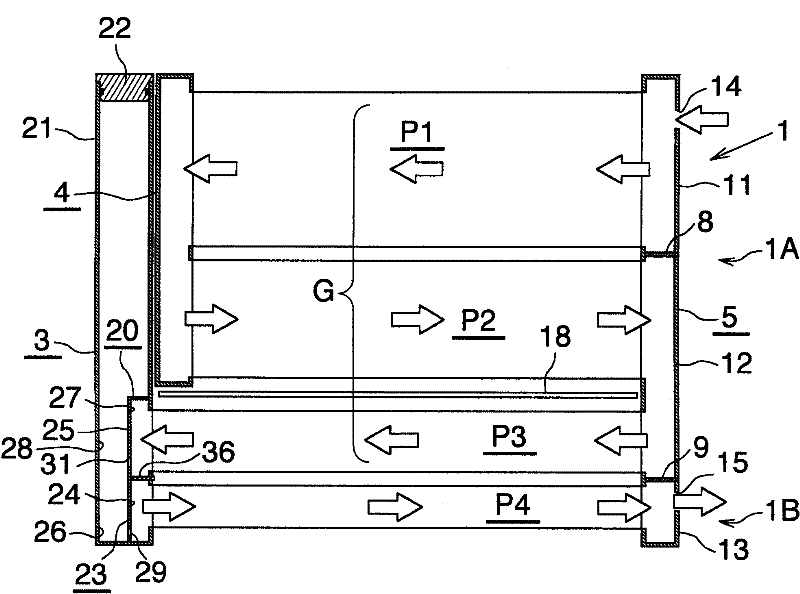

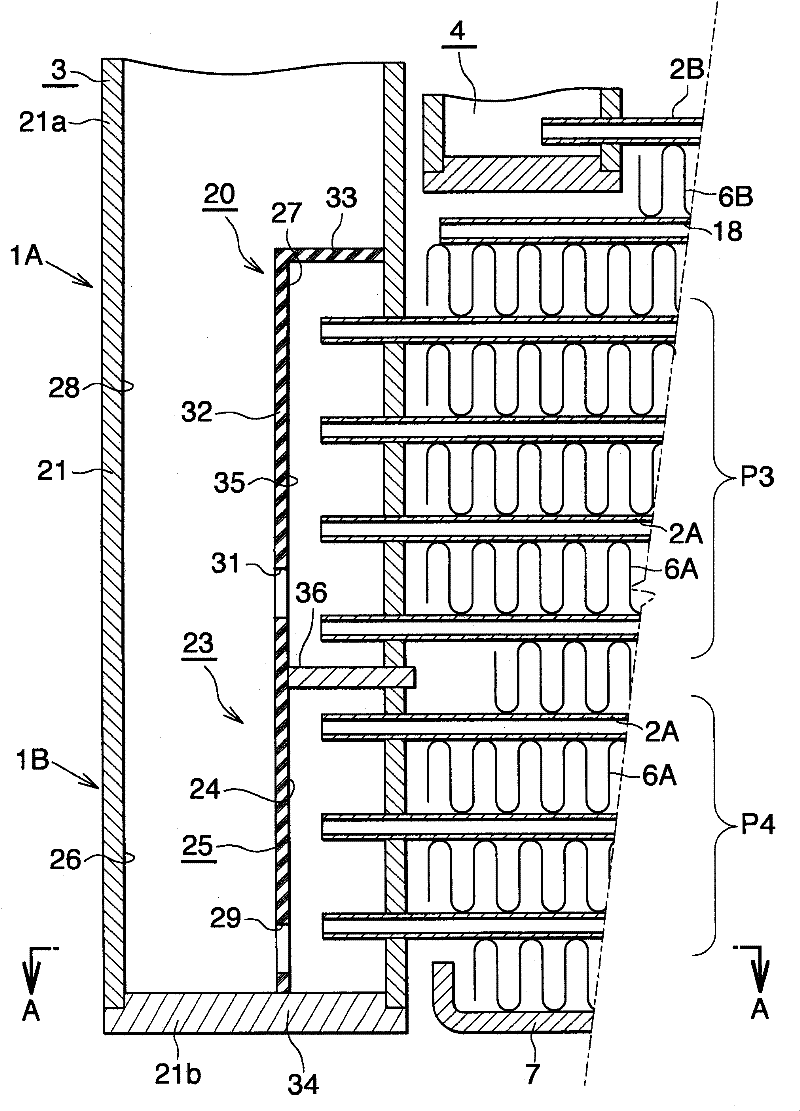

[0034] figure 1 Concretely showing the overall structure of the first embodiment of the condenser of the present invention, figure 2 Schematically express figure 1 the condenser. exist figure 2 In FIG. 2 , the illustration of each heat exchange tube is omitted, and the illustration of corrugated fins, side plates, refrigerant inlet parts, and refrigerant outlet parts is also omitted. in addition, image 3 and Figure 4 express figure 1 The structure of the main part of the condenser.

[0035] exist figure 1 and figure 2 Among them, the condenser 1 has: a plurality of aluminum flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com