Condenser

A condenser and refrigerant technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of wasted space in the engine room, large space in the condenser, and other equipment obstacles in the first liquid collection tank, etc., to achieve Space saving, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0032] In the description below, the figure 1 The inside of the paper ( Figure 4 The upper side) is the front, and the opposite side is the back.

[0033] In addition, in the following description, the term "aluminum" includes not only pure aluminum but also aluminum alloys.

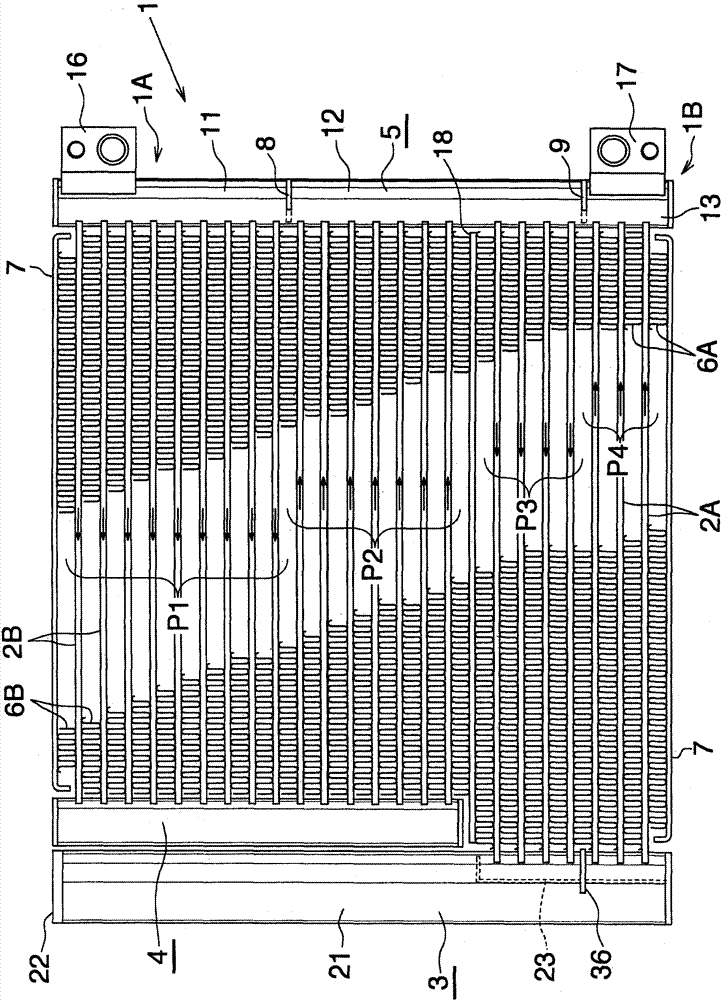

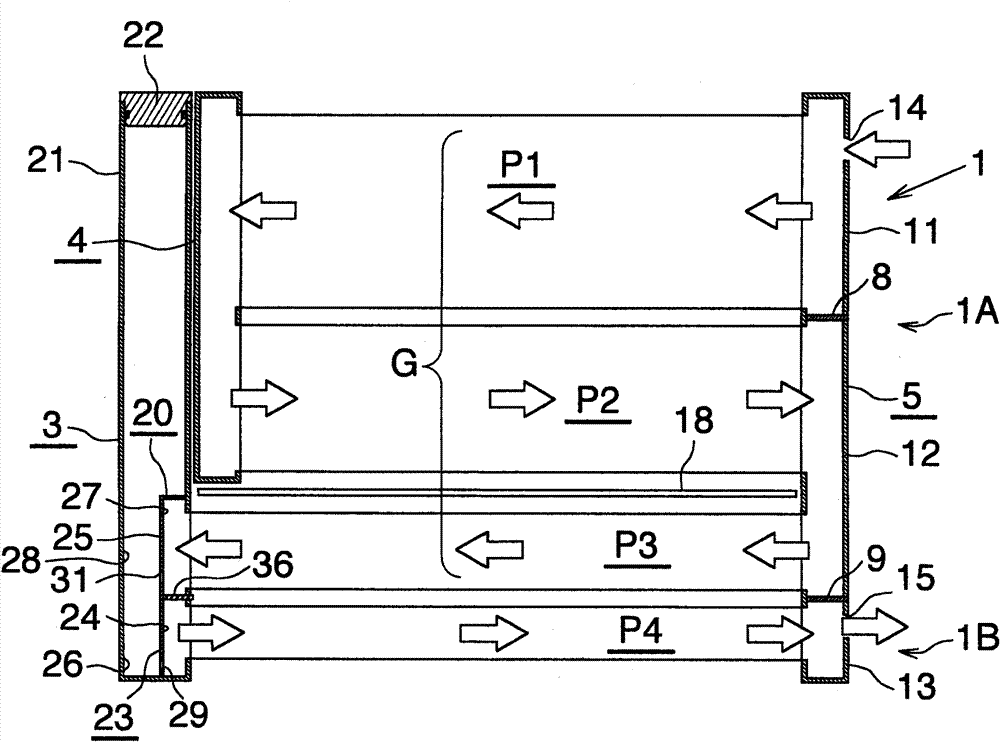

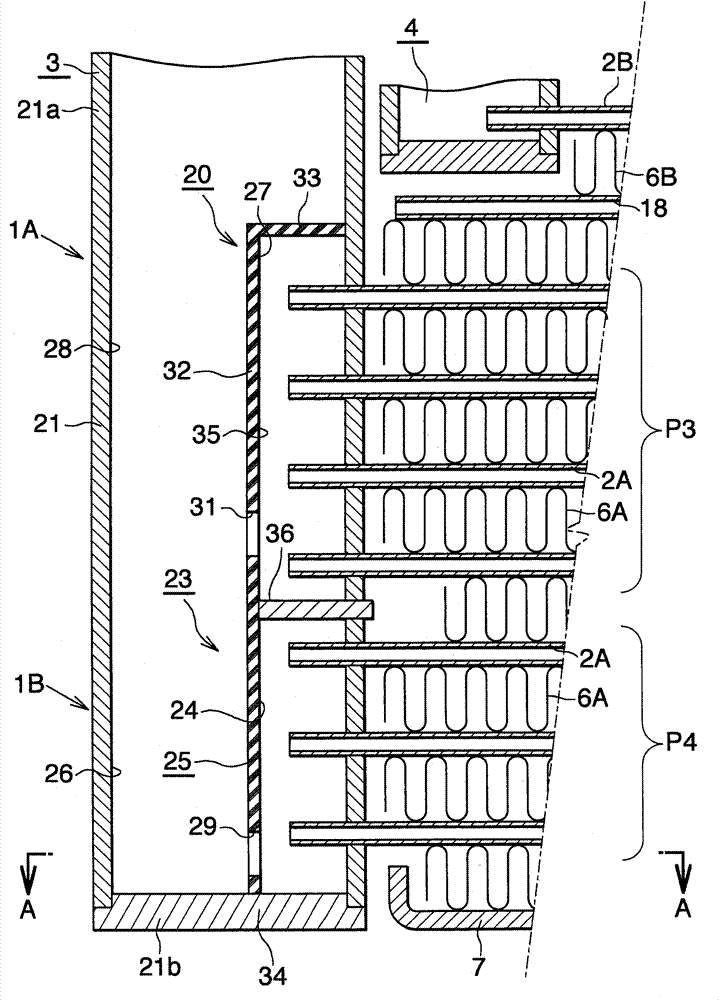

[0034] figure 1 Concretely showing the overall structure of the first embodiment of the condenser of the present invention, figure 2 Schematically express figure 1 the condenser. exist figure 2 In FIG. 2 , the illustration of each heat exchange tube is omitted, and the illustration of corrugated fins, side plates, refrigerant inlet parts, and refrigerant outlet parts is also omitted. in addition, image 3 and Figure 4 express figure 1 The structure of the main part of the condenser.

[0035] exist figure 1 and figure 2 Among them, the condenser 1 has: a plurality of aluminum flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com