winding device

A winding and winding end technology, applied in the direction of shape/style/structure of electromechanical devices, electric components, winding conductors, etc., can solve unsatisfactory problems, increase the total cost of stator winding configuration, etc., and achieve total weight reduction and total loss The effect of reducing and increasing the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

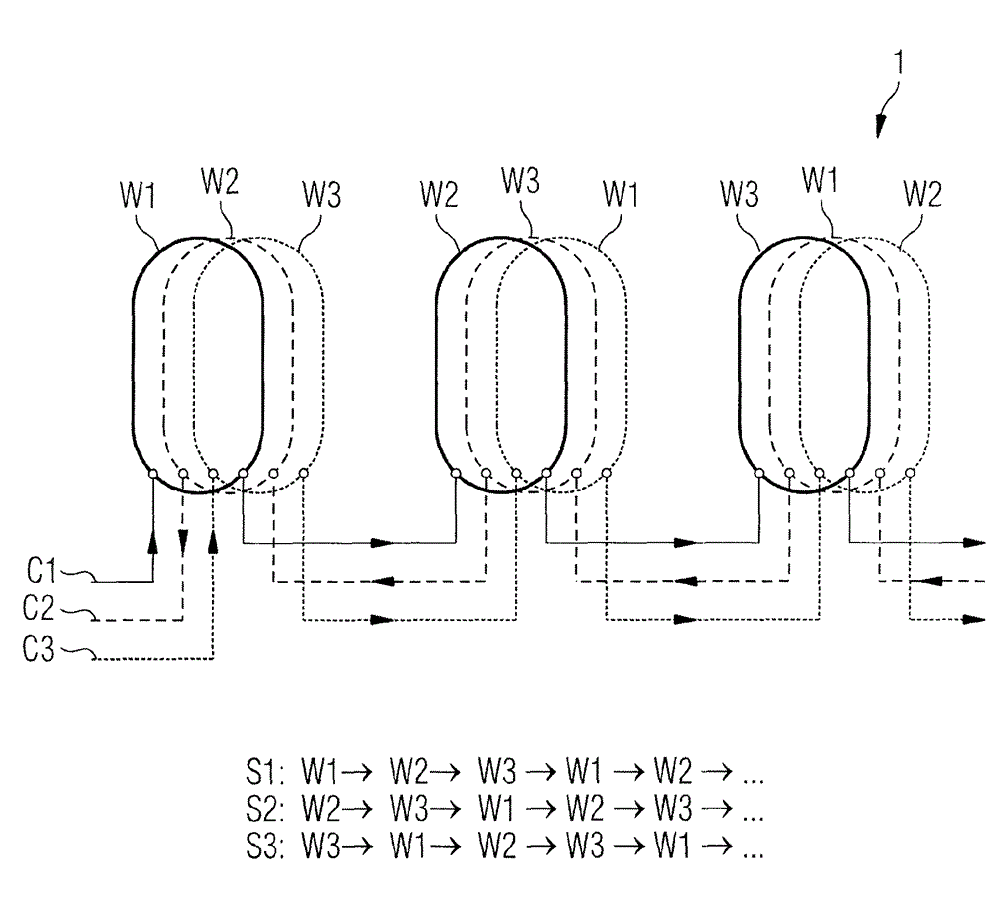

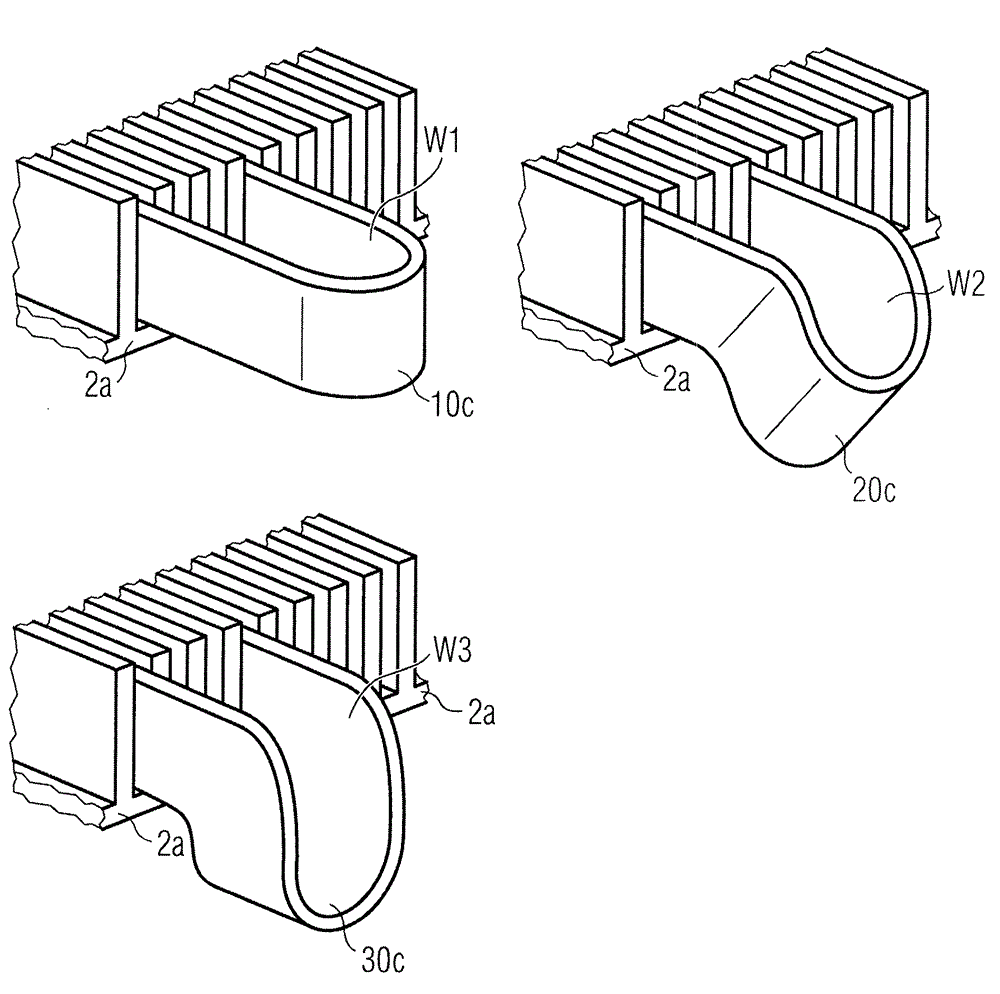

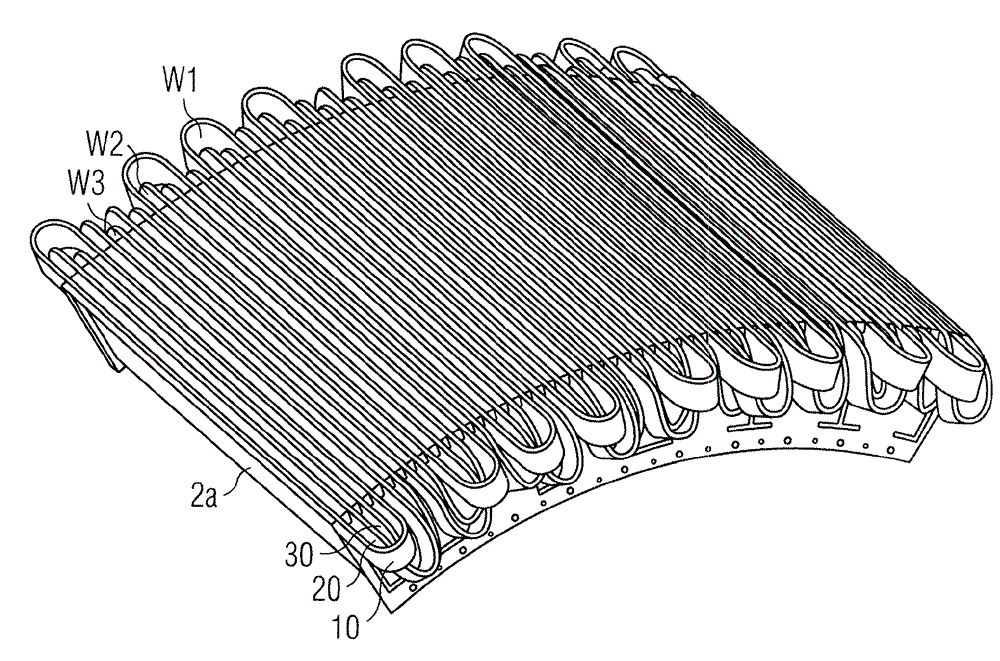

[0027] figure 1A very simple diagram of a generator 4 in a wind turbine 5 is shown. For simplicity, only relevant components are represented, other components such as gearbox, controller etc. are not shown. Pressure applied to the blades 50 of the wind turbine 5 turns the hub 51 or mandrel and thus the rotor 3 . The rotor 3 is surrounded by the stator 2 around which a plurality of coils (not shown) are wound. The generator 4 acts as an induction motor, in which a current is induced in the coils. The principle of operation of such a generator will be clear to a person skilled in the art and thus need not be described in detail here.

[0028] Due to the large currents (eg around 200-500 Amps for a 2-10 MW wind turbine), the windings have to be dimensioned accordingly. For wind turbine stators, the windings are usually made of stacked metal bars or strips with a cross-section of approximately 20 mm × 100 mm. These strips are held in stator slots arranged around the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com