Spooling device of wire rod

A winding device and wire technology, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of rising unit price of devices, expensive servo motors, and large-scale devices, so as to reduce gaps and avoid random winding. , the effect of easy high-speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the best mode for carrying out the present invention will be described based on the drawings.

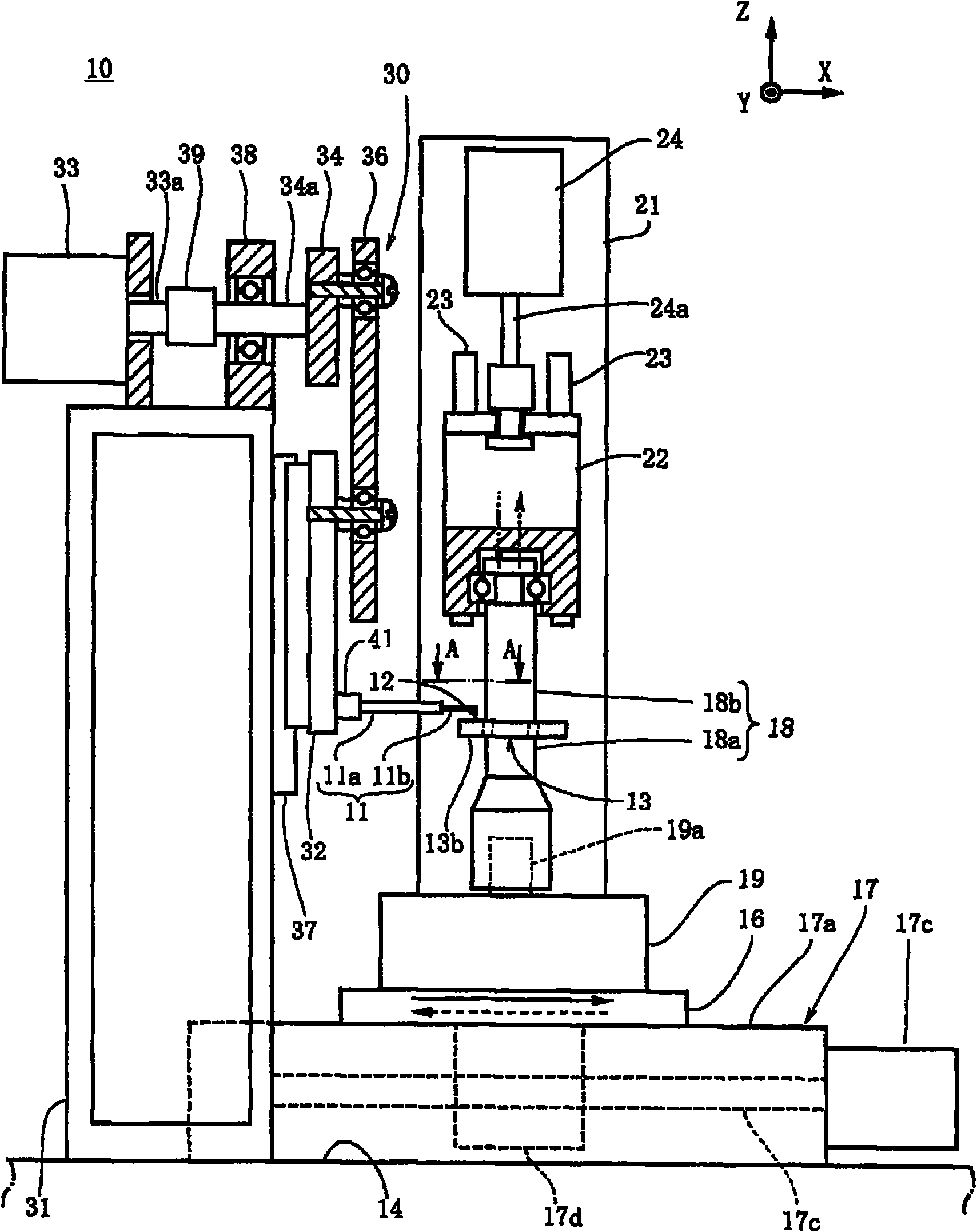

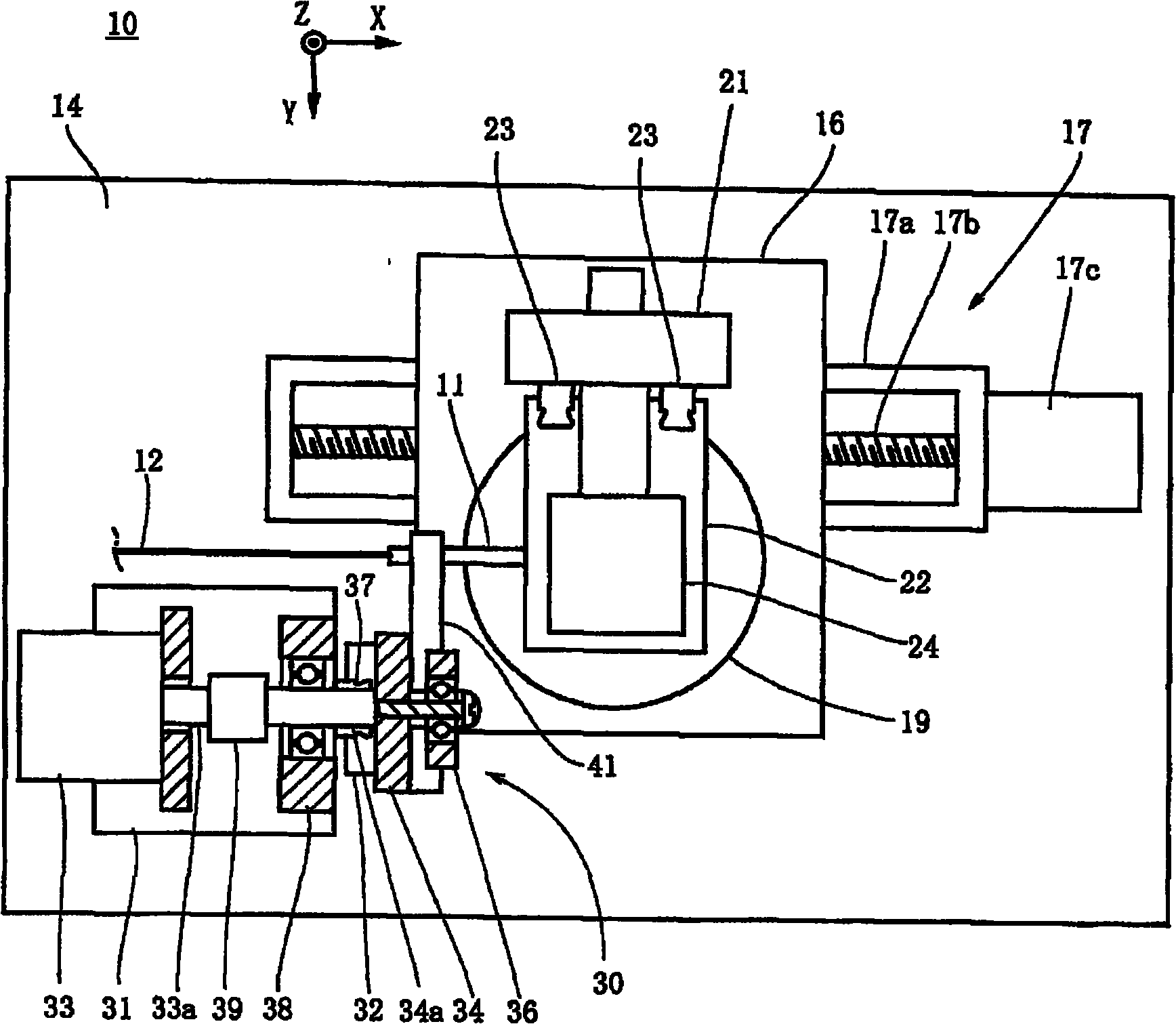

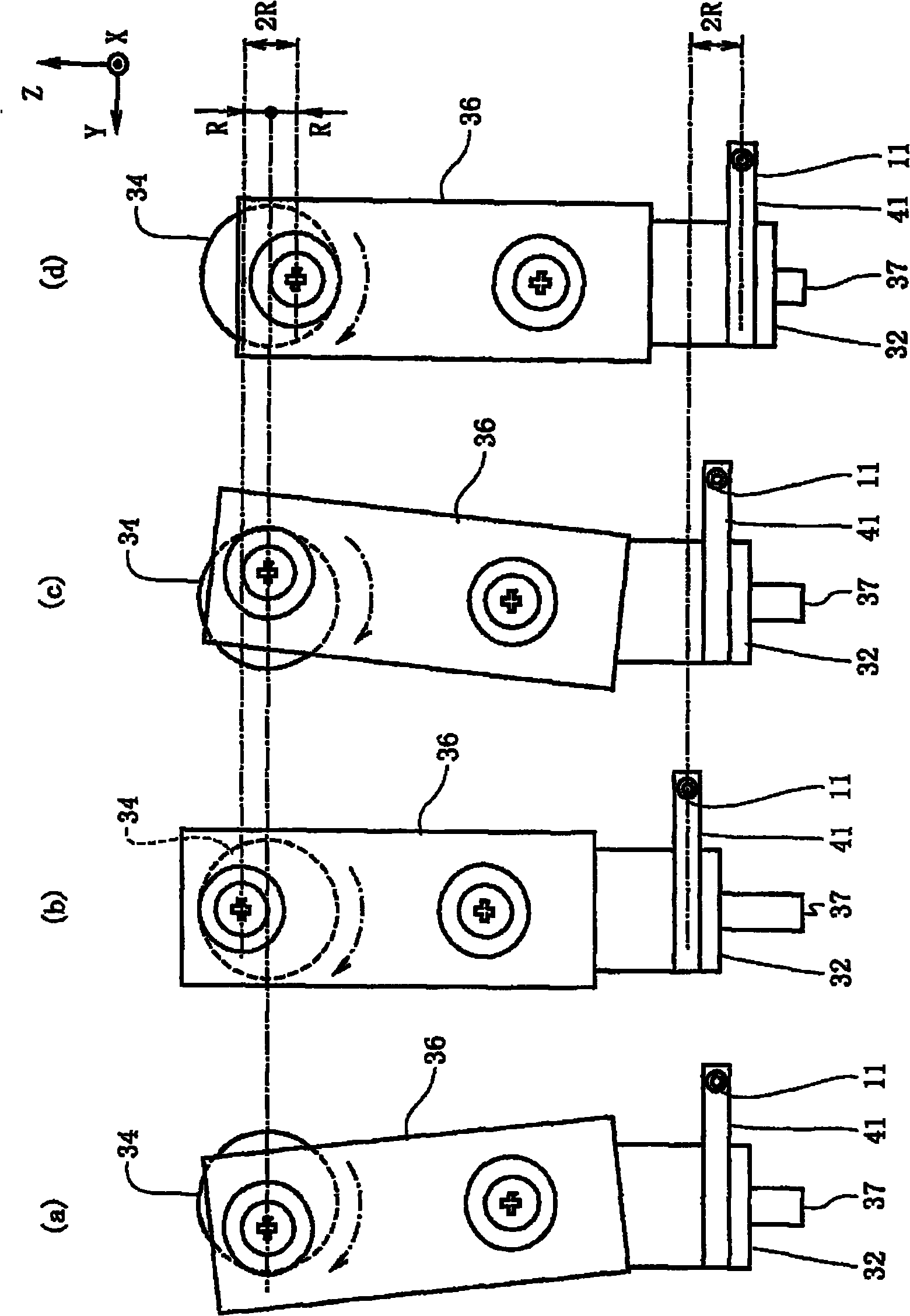

[0031] exist figure 1 and figure 2 The wire winding device 10 of the present invention is shown in . In each figure, three axes X, Y, and Z that are perpendicular to each other are set, and the X axis is defined as an axis extending in a substantially horizontal front-rear direction, the Y axis is defined as an axis extending in a substantially horizontal horizontal direction, and the Z axis is defined as an axis extending approximately horizontally. The structure of the winding device 10 will be described as an axis extending in the vertical direction. This winding device 10 is a device that winds the wire 12 drawn out from the nozzle 11 around the magnetic pole 13 b of the stator core 13 . and if Figure 7 As shown, the stator core 13 of this embodiment uses an external gear-type stator core, and includes: an annular ring portion 13a and a plurality of mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com