Radiating device

A heat dissipation device and heat conduction plate technology, which is applied to indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve the problems of cumbersome manufacturing process of heat dissipation devices, unfavorable rapid mass production, etc., and achieve saving in manufacturing processes , Reduce the effect of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

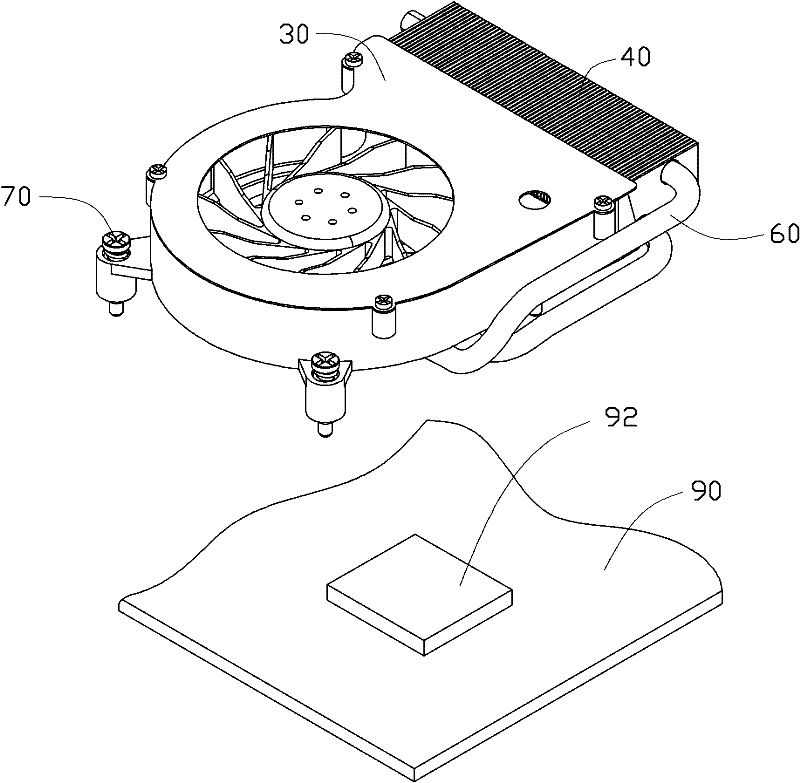

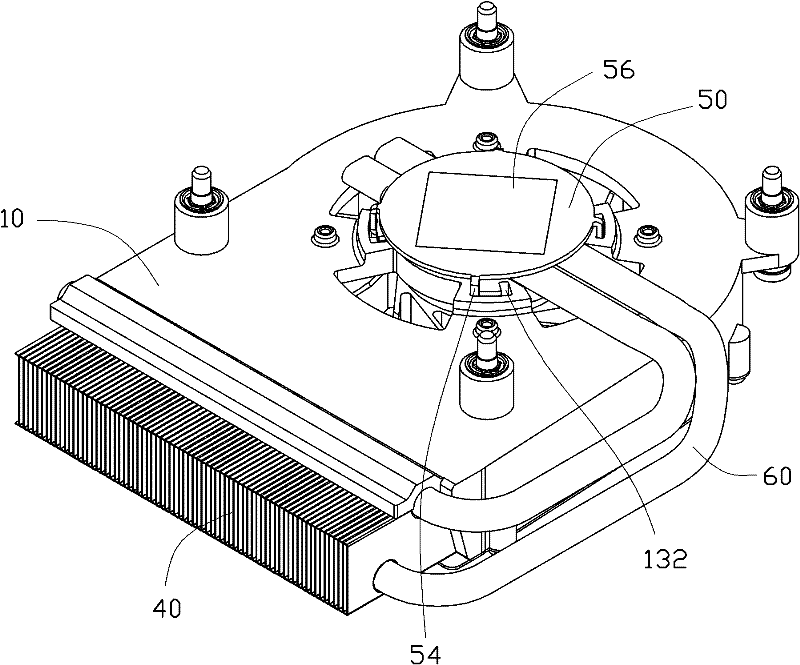

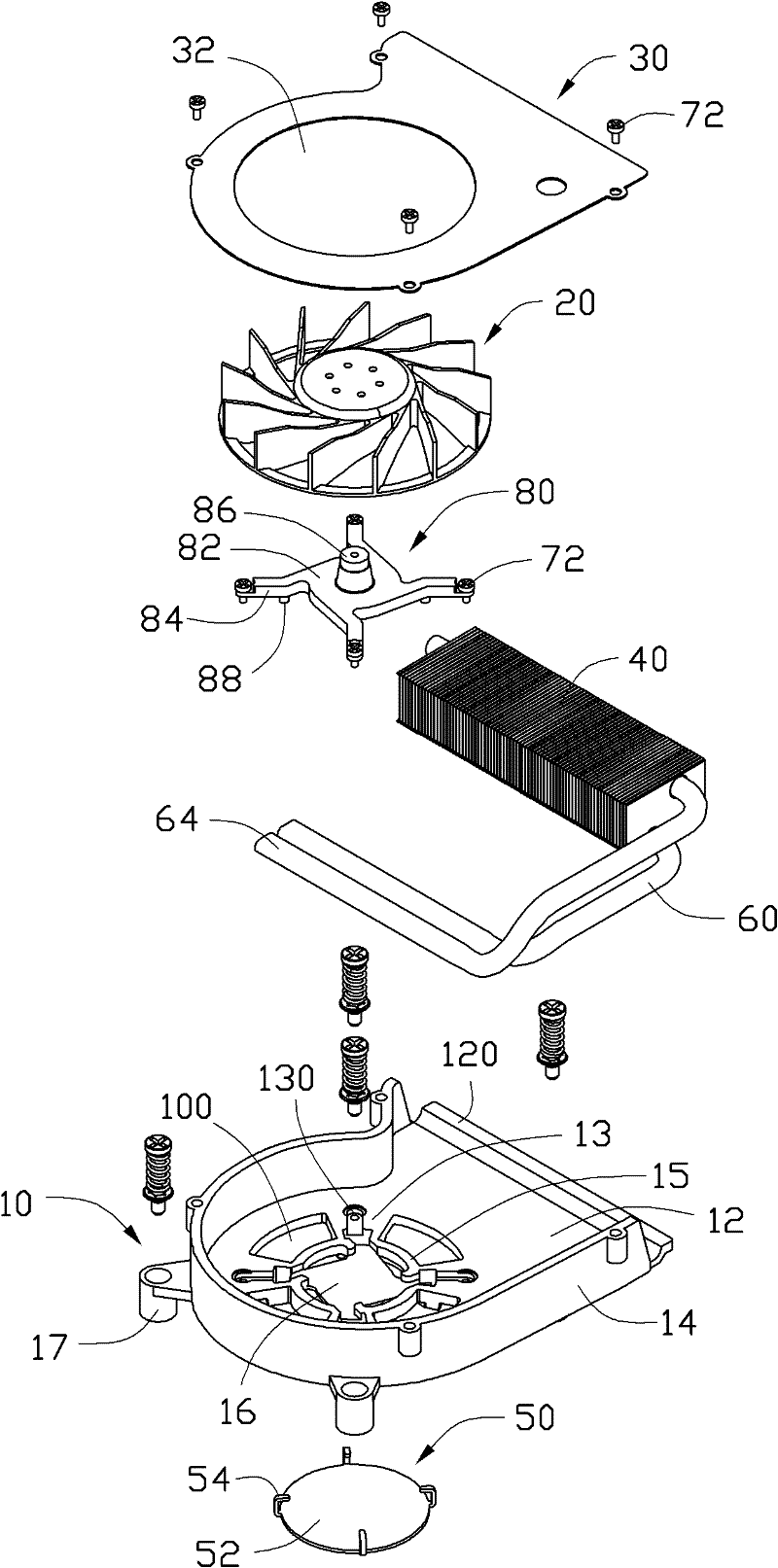

[0016] see Figure 1-3 , which shows the heat dissipation device of the present invention. The heat dissipation device includes a base 10, a fan 20 accommodated in the base 10, a cover plate 30 covering the base 10, a fin set 40 fixed on the base 10, a fin set 40 fixed on the base 10 The base plate 50 at the bottom and two heat pipes 60 connecting the fin set 40 and the base plate 50 .

[0017] Please also refer to Figure 4 , the base 10 includes a base 12 and a sidewall 14 vertically extending upward from the periphery of the base 12 . The base 12 is formed by connecting a circular part and a rectangular part. The base 12 defines a circular opening 100 in the middle area of the circular portion, and a rectangular plate 16 concave relative to the base 12 is provided in the middle of the opening 100 . A ring wall 18 is formed around the plate body 16 , the plate body 16 is connected to the inner side of the ring wall 18 through its four corners, and the outer side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com