Preparation process of low-grade laterite nickel ore oxidized pellet

A technology of lateritic nickel ore and oxidized pellets, which is applied in the field of preparation of low-grade laterite nickel ore oxidized pellets, can solve the problems of blast furnace antegrade and high yield, short construction period, small investment, etc., and achieve low compressive strength , promote liquid phase bonding, improve the effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

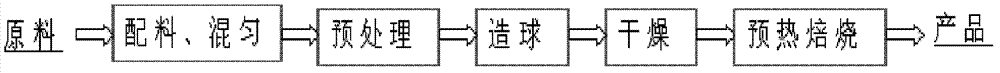

[0016] see figure 1 , dry the low-grade laterite nickel ore until the water content is 12%, and crush it to -3mm with a roller crusher; 45% laterite nickel ore, 34.3% iron concentrate, 15% chromite, 5.7% calcium Under the conditions of raw material ratio, when the water content of the mixture is 10%, the pressure is 0.67N / mm 2 After the high-pressure roller mill pretreatment, pelletize on the disc pelletizer, the pelletizing water is 12.2%, pelletizing time is 12min, the particle size of the pellets is controlled at 12mm; the drop strength of the pellets is 13.3 times / 0.5m, the additive formula: limestone : quartz sand: borax=58%: 27%: 15%, the particle size is less than 0.074mm and the content reaches more than 85%; under the conditions of pellet preheating temperature 1100°C, preheating time 13min, roasting temperature 1220°C, roasting time 13min, the preparation The finished product pellets have a compressive strength of 1915N / piece.

Embodiment 2

[0018] see figure 1 , dry the low-grade laterite nickel ore until the water content is 13%, and crush it to -3mm with a double-roller crusher; Under the conditions of raw material ratio, when the water content of the mixture is 10%, the pressure is 0.77N / mm 2 After pretreatment by high-pressure roller mill, pelletize on a disc pelletizer, the pelletizing moisture is 12.5%, the pelletizing time is 14min, and the particle size of the green pellets is controlled at 14mm; the drop strength of the green pellets is >20 times / 0.5m. Additive formula: limestone: quartz sand: borax = 62%: 23%: 15%, the particle size is less than 0.074mm and the content reaches more than 85%; the preheating temperature of the pellets is 1000, the preheating time is 15min, the roasting temperature is 1280, and the roasting time is 15min. Under these conditions, the finished pellets were prepared with a compressive strength of 2326N / piece.

Embodiment 3

[0020] see figure 1 , dry the low-grade laterite nickel ore until the water content is 11%, and crush it to -3mm with a roller crusher; 45% laterite nickel ore, 35% iron concentrate, 15% chromite, 5.0% calcium additive Under the conditions of raw material ratio, when the water content of the mixture is 10%, the pressure is 0.57N / mm 2 After pretreatment by high-pressure roller mill, pelletize on a disc pelletizer, pelletizing water is 12.3%, pelletizing time is 10min, particle size of green pellets is controlled at 15mm; green pellet drop strength is 13.3 times / 0.5m, additive formula: limestone : quartz sand: borax=60%: 27%: 13%, the particle size is less than 0.074mm and the content reaches more than 85%; under the conditions of pellet preheating temperature 1050, preheating time 12min, roasting temperature 1240, roasting time 12min, the preparation The finished product pellets have a compressive strength of 1900N / piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com