Method of matching coke into furnace during blast furnace smelting

A blast furnace smelting and coke technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as the shortage of coking coal resources, rising ironmaking costs, and excess indicators, so as to save resources, reduce ironmaking costs, and prevent coke indicators excess effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

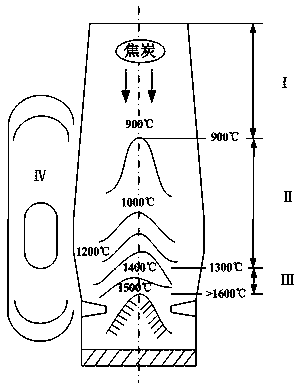

Image

Examples

Embodiment 1

[0014] Embodiment 1: The specific process of the method of matching coke into the furnace during the blast furnace smelting process is as follows.

[0015] Blast furnace effective volume 1000m 3 , other raw fuel quality and operating parameters are normal. There are 4 types of coke used, the indicators are:

[0016] Coke 1: CSR 70%, M 10 5.5%, average particle size 55mm, M 40 90%, Ash 11%, CRI 20%, Sulfur 0.6%;

[0017] Coke 2: CSR 65%, M 10 5.8%, average particle size 50mm, M 40 86%, Ash 12.5%, CRI 25%, Sulfur 0.75%;

[0018] Coke 3: CSR 60%, M 10 7%, average particle size 43mm, M 40 82%, Ash 13%, CRI 28%, Sulfur 0.85%;

[0019] Coke 4: CSR 50%, M 10 8.5%, average particle size 38mm, M 40 70%, Ash 13%, CRI 35%, Sulfur 9%.

[0020] According to 1000m 3 The coke quality requirements of the blast furnace and the actual state of blast furnace smelting, through the weighted average of the four coke indicators, the CSR index reaches 60%, and the blast furnace i...

Embodiment 2

[0021] Embodiment 2: The specific process of the method of matching coke into the furnace during the blast furnace smelting process is as follows.

[0022] Blast furnace effective volume 2000m 3 , other raw fuel quality and operating parameters are normal. There are 4 types of coke used, the indicators are:

[0023] Coke 1: CSR 70%, M 10 5.5%, average particle size 55mm, M 40 90%, Ash 11%, CRI 20%, Sulfur 0.6%;

[0024] Coke 2: CSR 65%, M 10 5.8%, average particle size 50mm, M 40 86%, Ash 12.5%, CRI 25%, Sulfur 0.75%;

[0025] Coke 3: CSR 60%, M 10 7%, average particle size 43mm, M 40 82%, Ash 13%, CRI 28%, Sulfur 0.85%;

[0026] Coke 4: CSR 50%, M 10 8.5%, average particle size 38mm, M 40 70%, Ash 13%, CRI 35%, Sulfur 0.9%.

[0027] According to 2000m 3 The quality requirements of blast furnace coke and the actual state of blast furnace smelting, through the weighted average of the four coke indicators, the CSR index reaches 62%, and the blast furnace ope...

Embodiment 3

[0028] Embodiment 3: The specific process of the method of matching coke into the furnace in the blast furnace smelting process is as follows.

[0029] Blast furnace effective volume 3000m 3 , other raw fuel quality and operating parameters are normal. There are 4 types of coke used, the indicators are:

[0030] Coke 1: CSR 70%, M 10 5.5%, average particle size 55mm, M 40 90%, Ash 11%, CRI 20%, Sulfur 0.6%;

[0031] Coke 2: CSR 65%, M 10 5.8%, average particle size 50mm, M 40 86%, Ash 12.5%, CRI 25%, Sulfur 0.75%;

[0032] Coke 3: CSR 60%, M 10 7%, average particle size 43mm, M 40 82%, Ash 13%, CRI 28%, Sulfur 0.85%;

[0033] Coke 4: CSR 50%, M 10 8.5%, average particle size 38mm, M 40 70%, Ash 13%, CRI 35%, Sulfur 0.9%.

[0034] According to 3000m 3 The quality requirements of blast furnace coke and the actual state of blast furnace smelting, through the weighted average of 4 kinds of coke indexes, make the CSR index reach 63%. 10 index such that M 10 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com