Method by utilizing sulfuric-acid residue to produce iron concentrates

A technology of sulfuric acid slag and iron fine powder, which is applied in the direction of solid separation and flotation, which can solve the problems of high material requirements for production equipment, low grade improvement of sulfuric acid slag, and difficulty in obtaining sorting effects, etc., and achieves low cost and small investment , High recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

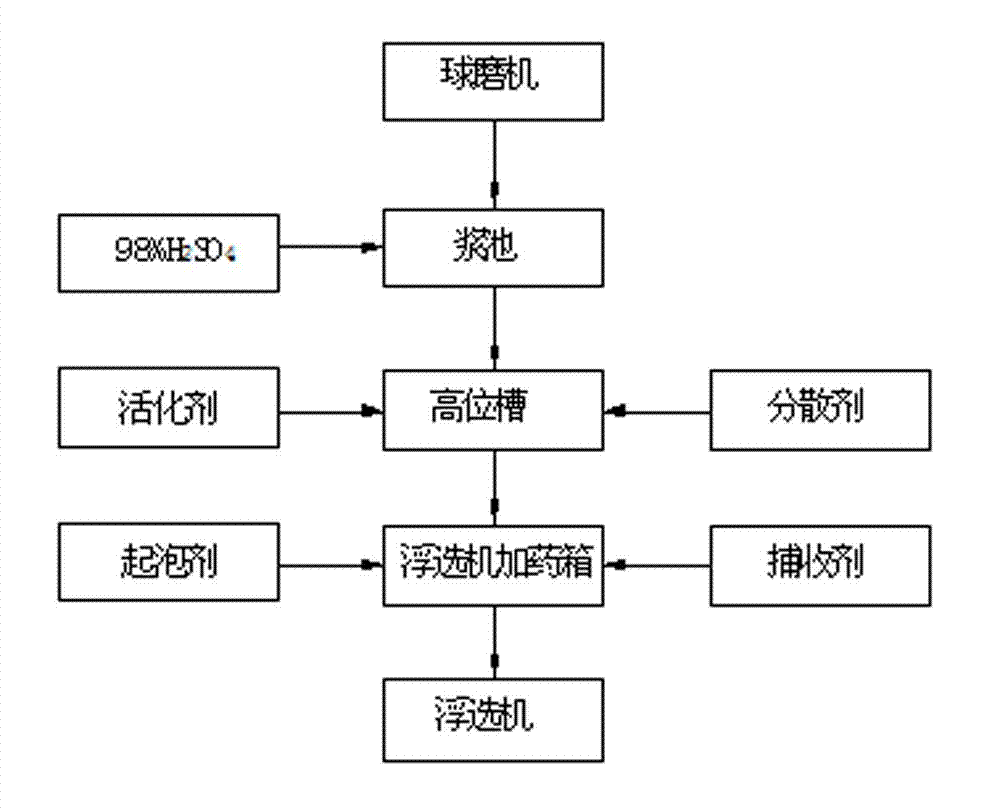

Method used

Image

Examples

Embodiment 1

[0027] Grinding-pickling-activation, dispersion-flotation processes are used to remove harmful elements in sulfuric acid slag. First, 1 ton of sulfuric acid slag is put into wet grinding equipment for grinding treatment. The grinding concentration is 60-75%, and the particle size is ground to 90. % through a 200 mesh sieve; add 98% concentrated sulfuric acid in an amount of 7.0kg / t, and pickle with stirring for 20 minutes; add copper sulfate in an amount of 500g / t as an activator, and add sodium carbonate in an amount of 200g / t as a Dispersant, then add pine oil in an amount of 50g / t as a foaming agent, and finally add butyl xanthate in an amount of 350g / t as a collector, and stir for 2 minutes each time the agent is added; the sulfuric acid slag added with the agent Send it to the flotation machine, the flotation concentration is 20-30%, and the flotation time is 30 minutes. After the harmful elements of arsenic and sulfur are flotation, the iron concentrate powder with an iro...

Embodiment 2

[0029] Grinding-pickling-activation, dispersion-flotation processes are used to remove harmful elements in sulfuric acid slag. First, 1 ton of sulfuric acid slag is put into wet grinding equipment for grinding treatment. The grinding concentration is 60-75%, and the particle size is ground to 90. % pass through a 200 mesh sieve; add 98% concentrated sulfuric acid at 7.5kg / t, and pickle with stirring for 30 minutes; add copper sulfate at 550g / t as an activator, and add starch at 280g / t as a dispersion Add kerosene as a foaming agent in an amount of 50g / t, and finally add dixanthate in an amount of 400g / t as a collector, and stir for 5 minutes each time the agent is added; send the sulfuric acid slag with the agent into Flotation machine, the flotation concentration is 20-30%, and the flotation time is 45 minutes. After flotation to remove harmful elements such as arsenic and sulfur, iron concentrate powder with an iron grade of 61.59% is produced, and the recovery rate is over 8...

Embodiment 3

[0031] Grinding-pickling-activation, dispersion-flotation processes are used to remove harmful elements in sulfuric acid slag. First, 1 ton of sulfuric acid slag is put into wet grinding equipment for grinding treatment. The grinding concentration is 60-75%, and the particle size is ground to 90. % through 200 mesh sieve; add 98% concentrated sulfuric acid at 8.0kg / t, and pickle with stirring for 25 minutes; add copper sulfate at 600g / t as an activator; add sodium humate at 250g / t As a dispersant; then add No. 2 oil in an amount of 90g / t as a foaming agent; finally add amylxanthate in an amount of 450g / t as a collector, and stir for 3 minutes each time the agent is added; The sulfuric acid slag is sent to the flotation machine, the flotation concentration is 20-30%, and the flotation time is 35 minutes. After the harmful elements of arsenic and sulfur are flotation, iron concentrate powder with an iron grade of 61.99% is produced, and the recovery rate is over 80%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com