Lock-on switch system for hand drill and hand drill having the same

A technology for locking switches and switches, which is applied in the direction of electric switches, manufacturing tools, striking tools, etc., can solve the problems of low locking reliability, large cumulative tolerance, and inaccurately limited locking size, etc., so as to reduce development time and Processing cost, effect of reducing tolerance chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

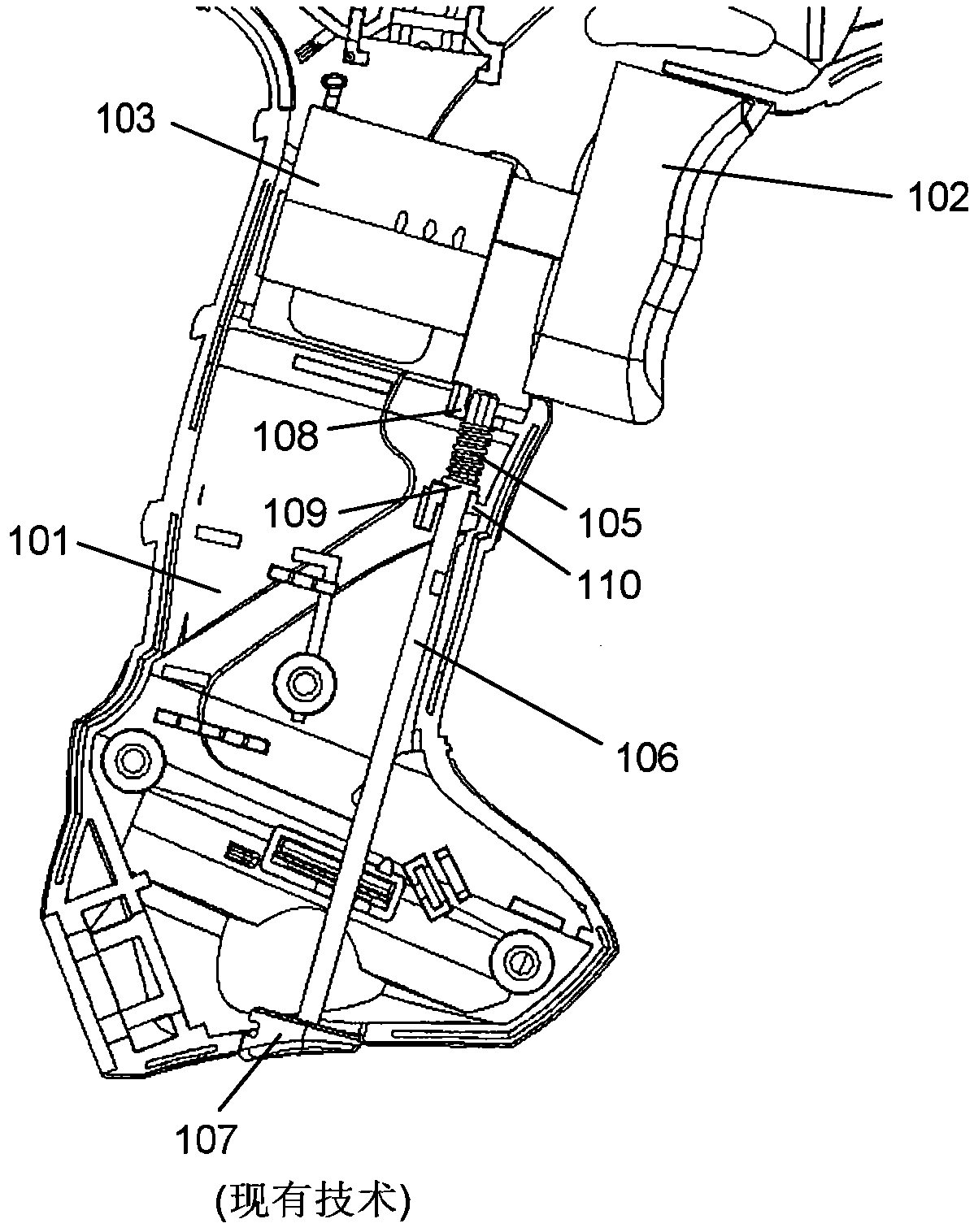

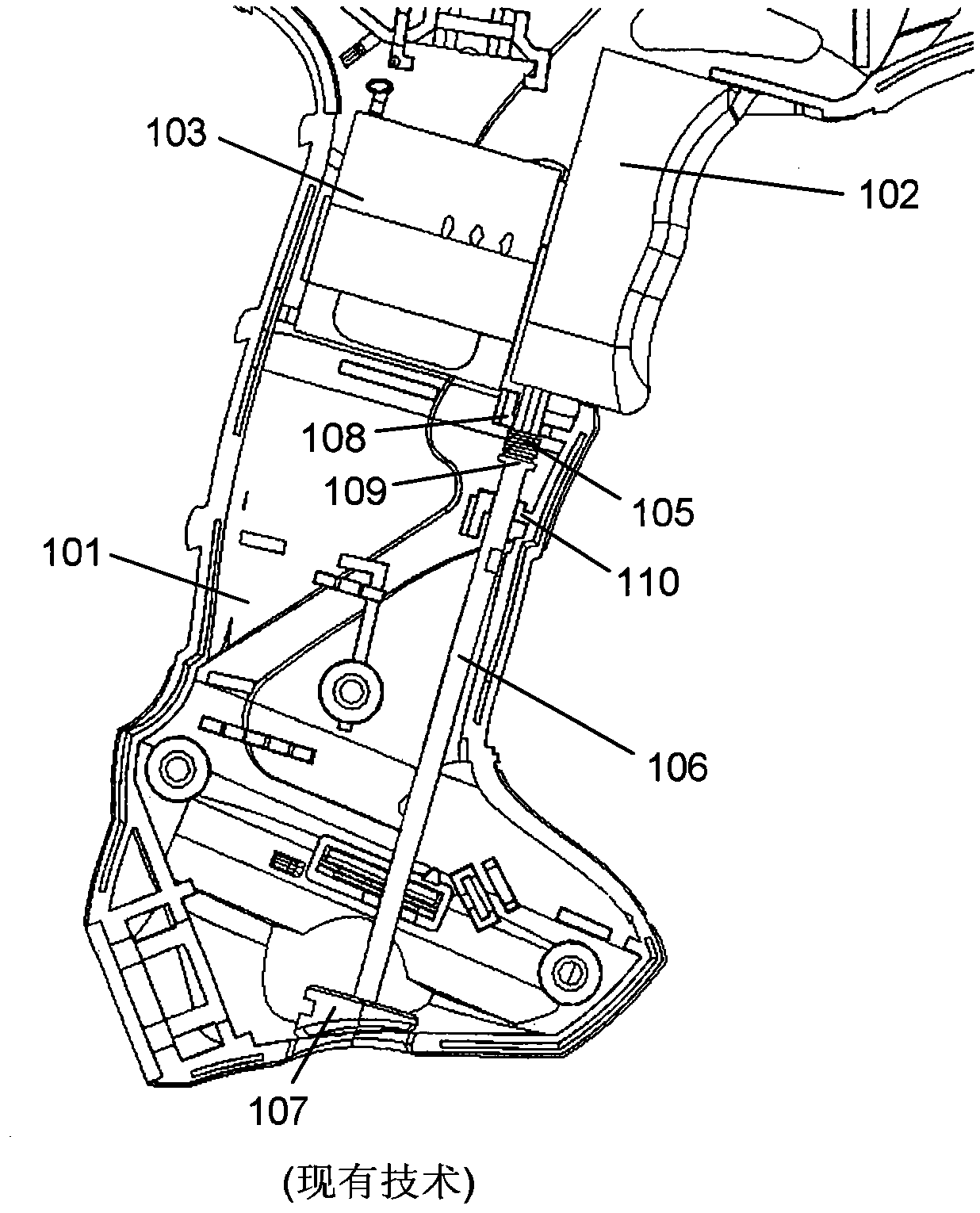

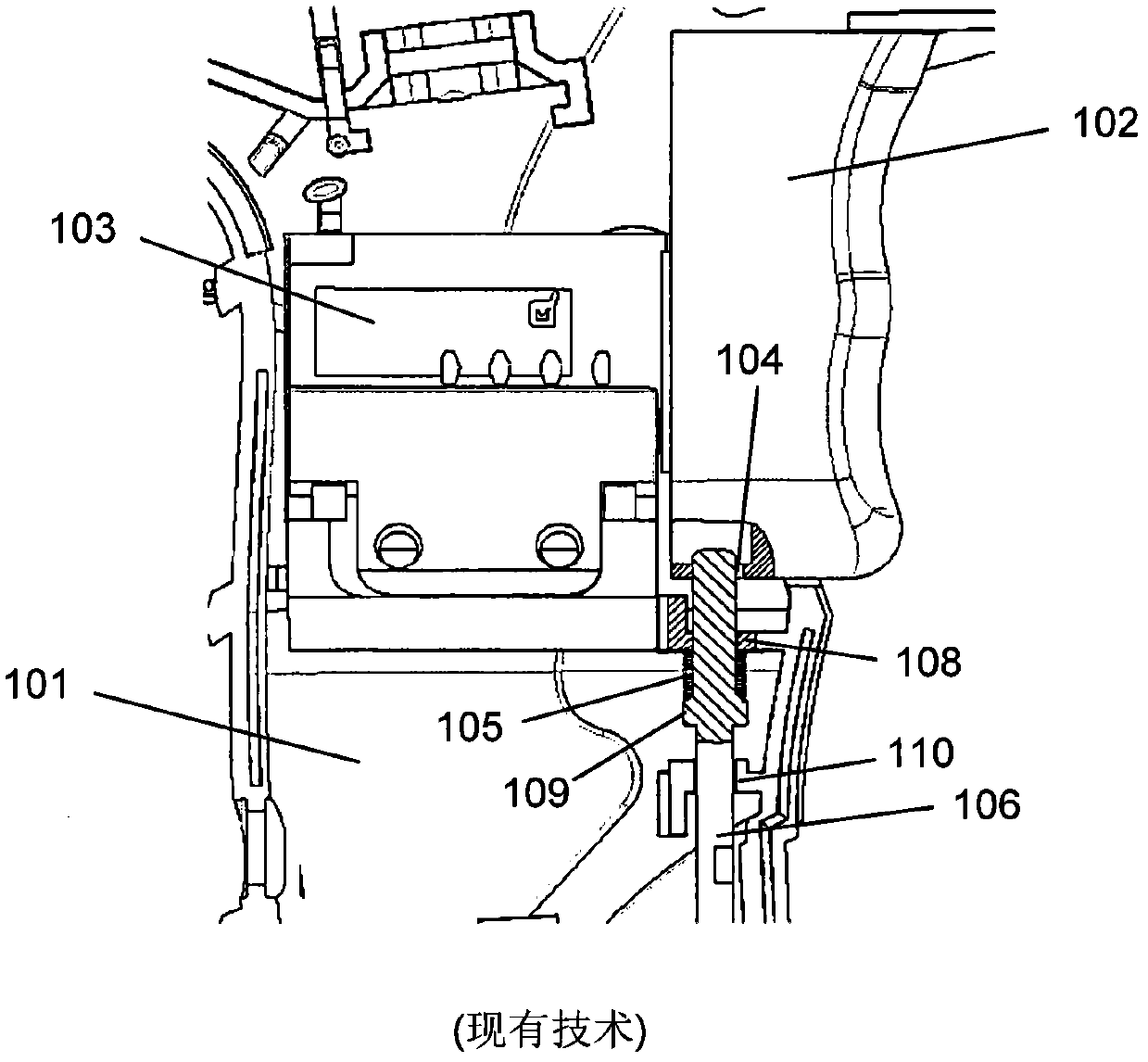

[0028] Now, preferred embodiments of a lock switch system for a hand drill and a hand drill having such a lock switch system of the present invention will be described with reference to the accompanying drawings.

[0029] Figure 4 and 5 A switch system for a hand drill according to an embodiment of the invention is shown. The switch system includes a switch (not shown) provided in a switch housing 3 for controlling the operation of the hand drill. A switch is arranged in the upper part of the handle of the hand drill and can be actuated by the user via a trigger 2 arranged in front of the switch and movable horizontally between a starting position and a pushed-in position. That is, the trigger can be pushed toward the switch to the pushed position, thereby actuating the switch. The trigger 2 can be locked in the pushed position by a locking mechanism when the pushing force applied to the trigger is released. The trigger 2 can also be unlocked from the pushed-in position a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com