A cooling system for a combustion engine

A technology of cooling system and internal combustion engine, applied in the direction of engine cooling, mechanical equipment, engine components, etc., can solve the problems of complex assembly, longitudinal gap, inaccurate alignment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

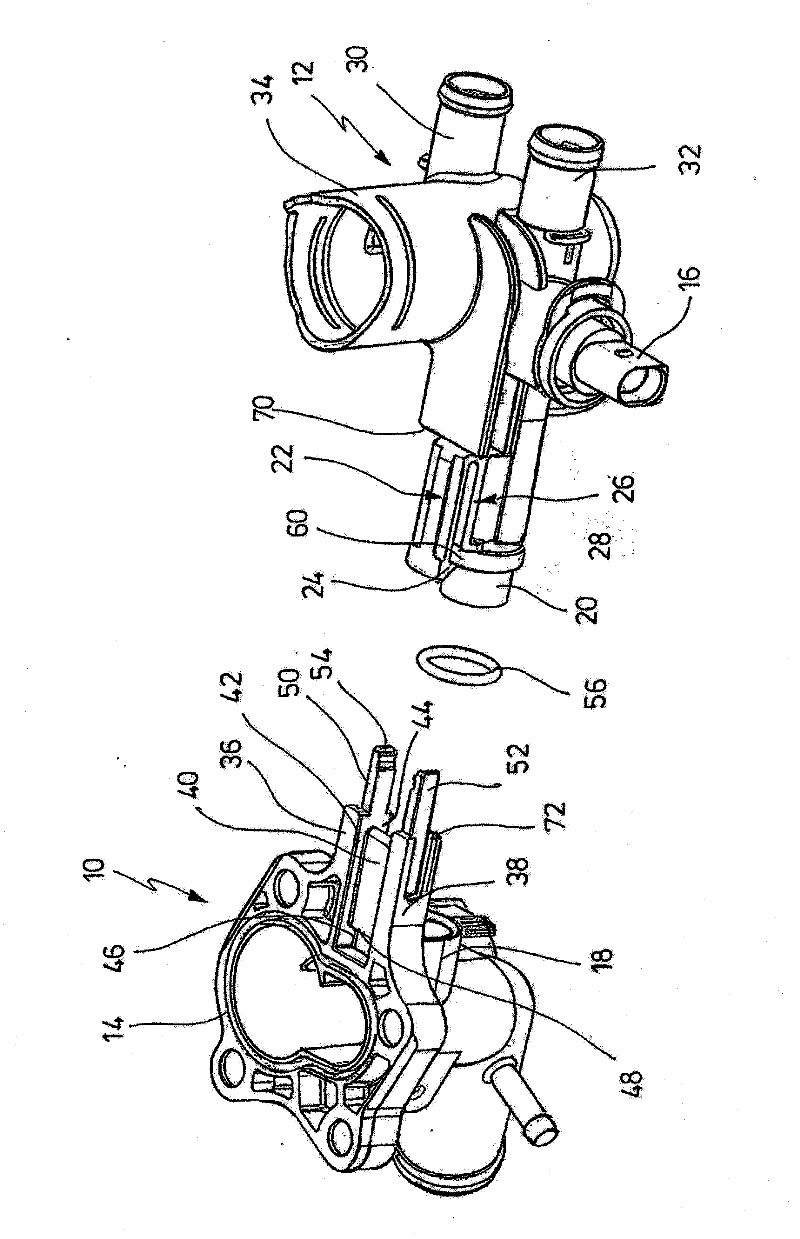

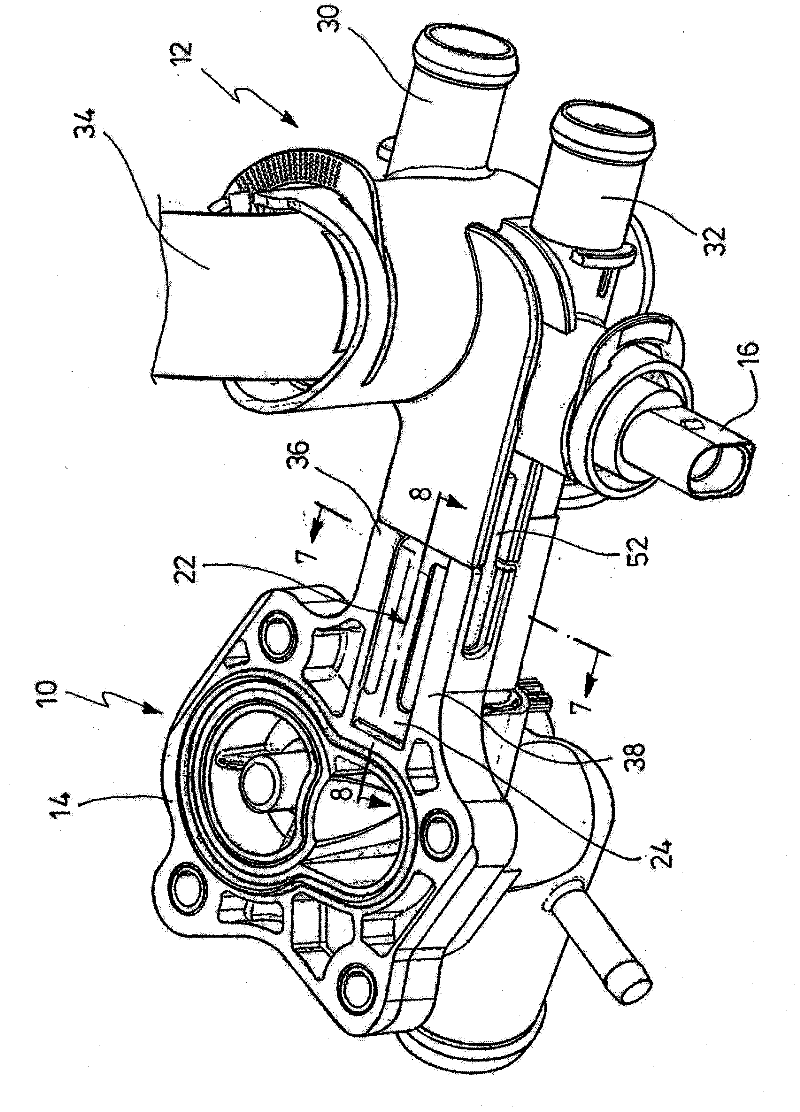

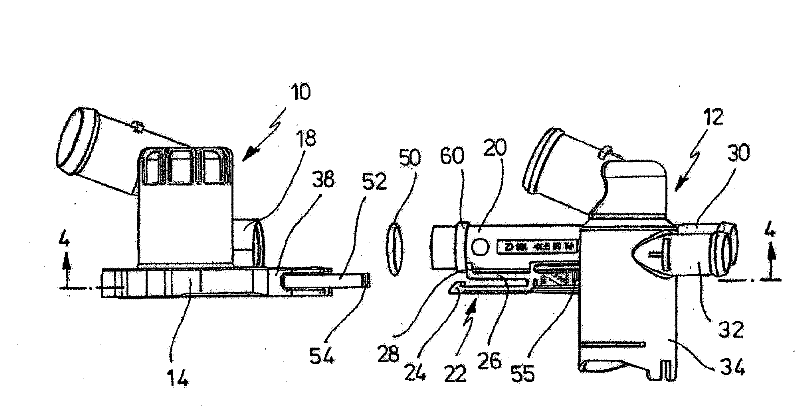

[0019] figure 1 Shown are a first subcomponent 10 and a second subcomponent 12 in a refrigerant circuit (not shown in detail) of a cooling system of an internal combustion engine. As shown, subassembly 10 is a thermostatic valve. The subassembly 10 is secured to the omitted engine section by a flange. The subassembly 10 is tightly secured by flanges 14 to the omitted engine section. As shown, the sub-component 12 is a cooling water regulator equipped with a stub 16 allowing connection to a rotary drive. The two subcomponents 10 and 12 should be connected to each other as a flow connection. This (fluid) connection should be effective when the subassembly 10 is fastened to the internal combustion engine. The subcomponent 10 comprises a pipe section 18 into which a pipe section 20 of the subcomponent 12 can be inserted. The design of the subcomponents will be clarified below. A resilient shank 22 integral with the subassembly 12 extends over, spaced from, and parallel to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com