Device for a system components of a high-voltage impulse test system

An inspection system, high-voltage pulse technology, applied in the direction of testing dielectric strength, testing circuits, etc., can solve the problems of time-consuming and inconvenient operation, and achieve the effect of shortening installation time, reducing land occupation requirements, and simple transportability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

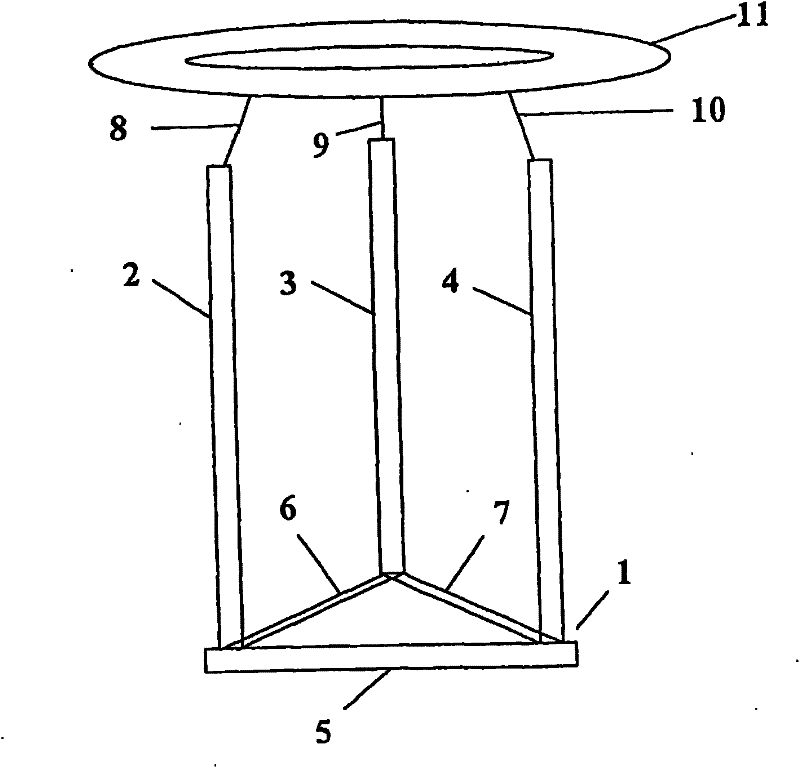

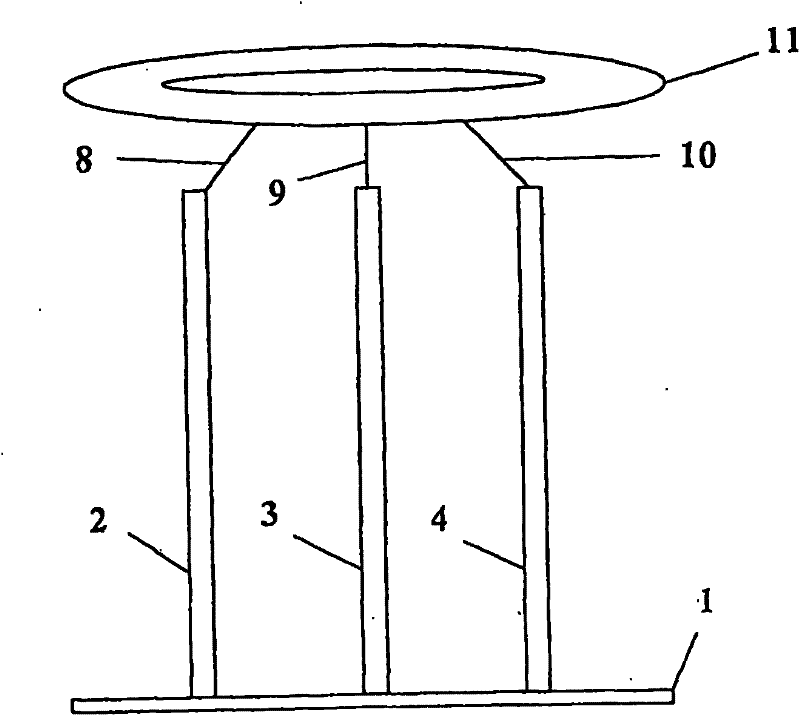

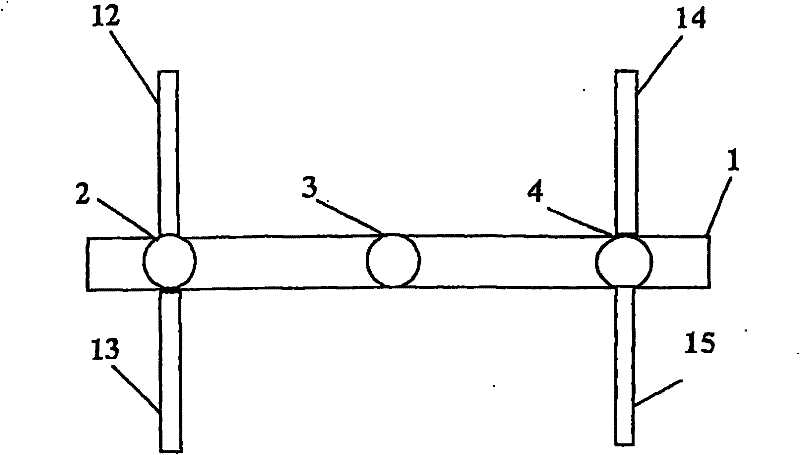

[0021] figure 1 A main frame 1 according to the invention is shown for accommodating auxiliary components such as a cut-off spark gap 2 , a voltage divider 3 or an overshoot compensation component 4 . accessories in figure 1 is only shown schematically for reasons of overview. The main frame 1 is securely upright in this respect and has, for example, a triangular base region consisting of interconnected steel tubes 5 , 6 and 7 . The cut-off spark gap 2, the voltage divider 3 and the overshoot compensating component 4 are arranged on respective corners of the main frame 1 and electrically connected thereto. Furthermore, the upper ends of the respective auxiliary parts are mechanically fixed by means of electrically conductive crossbars 8 , 9 and 10 . Connected to the horizontal frames 8, 9 and 10 are the top electrodes 11, which can be formed as rings, for example. The conductive crossbars 8 , 9 and 10 thus both fulfill the task of mechanically holding the tip electrode 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com