Novel hot-air internal circulation tempering furnace

A hot air internal circulation and tempering furnace technology, which is applied to furnaces, vertical furnaces, furnace types, etc., can solve problems such as insufficient internal circulation of temperature, reduced economic benefits, and waste of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

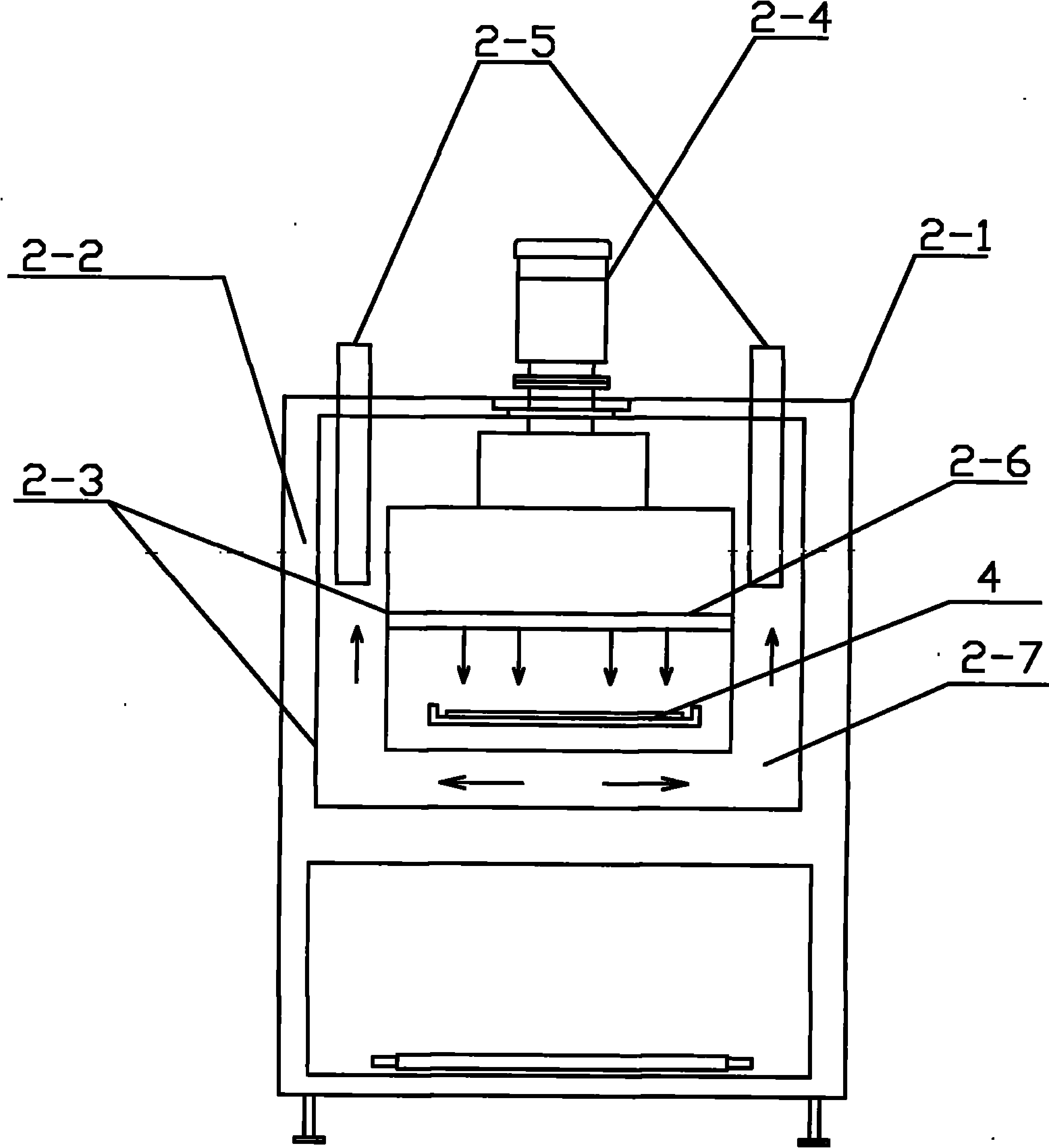

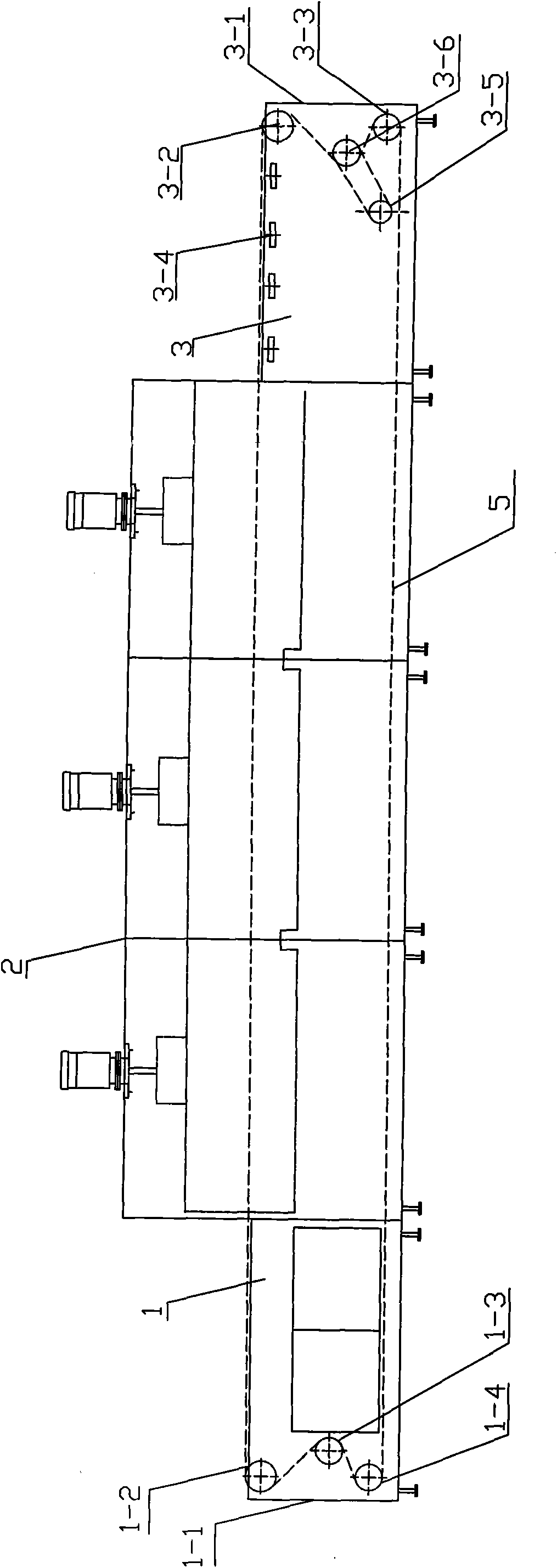

[0021] Such as figure 1 with figure 2 A new type of hot air internal circulation tempering furnace is shown, including a feeding platform 1, a furnace body 2, a discharging platform 3 and a conveyor belt 5 located inside the tempering furnace. The feeding platform 1 and the discharging platform 3 are respectively located at both ends of the furnace body 2 , the furnace body 2 includes a furnace shell 2-1, the inside of the furnace shell 2-1 is provided with a furnace gall 2-3, the furnace gall 2-3 is divided into two layers, the middle is an air guide channel 2-7, and the air guide channel 2-7 is provided with a heating element 2-5, a fan 2-4 is arranged above the furnace 2-3, the air outlet of the fan 2-4 is located inside the furnace 2-3, and the air inlet of the fan 2-4 Connected with the air guide channel 2-7, the air guide channel 2-7 communicates with the inside of the furnace tube 2-3 at the bottom of the furnace tube 2-3; the inside of the furnace tube 2-3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com