Eave connecting part, building framework structure and mounting method

A frame structure and connector technology, applied in the field of eaves connectors, can solve the problems of inability to realize fasteners, damage to ecology, and weak connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

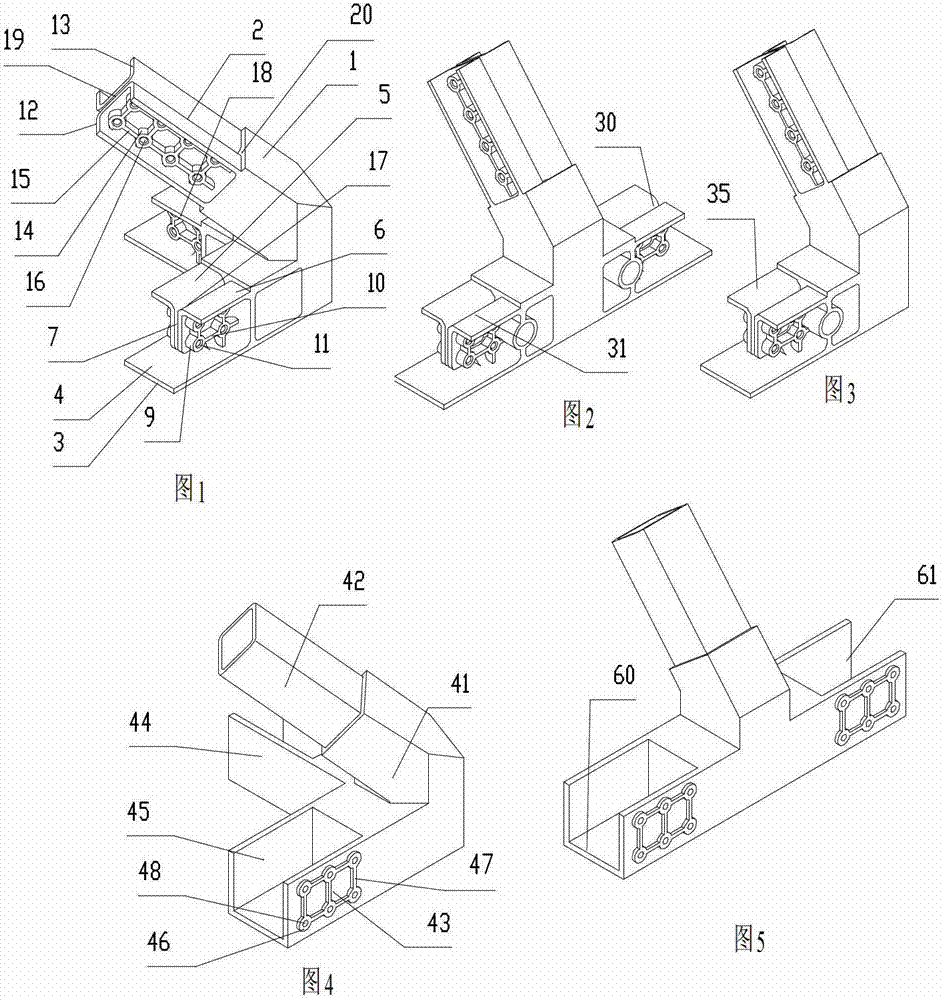

[0081] Such as figure 1 As shown, an eaves connector of a building frame structure includes an integrally formed eaves connector body 1, a beam plug joint 2 that is inserted into the end of a connecting beam that matches with it and protrudes obliquely upwards from the eaves connector body 1, two The ends of the side beams parallel to the horizontal plane, the side beam support joints 17 and the side beam support joints 18 perpendicular to each other are supported.

[0082]The side beam support joint 17 and the side beam support joint 18 all include side protrusions 3 extending vertically from the side of the eaves connector body 1, and the top surface 4 of the side protrusions 3 is the horizontal plane of the support side beam directly supporting the side beam; The top surface 4 of the side convex part 3 extends vertically upwards and then bends outwards. There are two symmetrical, horizontally juxtaposed limiting convex parts 5 and 6, and between the limiting convex parts 5 ...

Embodiment 2

[0086] Such as figure 2 As shown, the difference from Embodiment 1 is that the two side beam support joints 30, 31 are located on the same straight line.

Embodiment 3

[0088] Such as image 3 As shown, the difference from Embodiment 1 is that there is only one side beam support joint 35 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com