Solar vacuumizing hydraulic electrogenerating system, and operation method thereof

An operation method and vacuum pumping technology, applied in the field of solar energy, can solve the problems of high manufacturing cost, large floor area, and high requirements for lighting conditions, and achieve the effect of simple equipment, meeting user needs, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

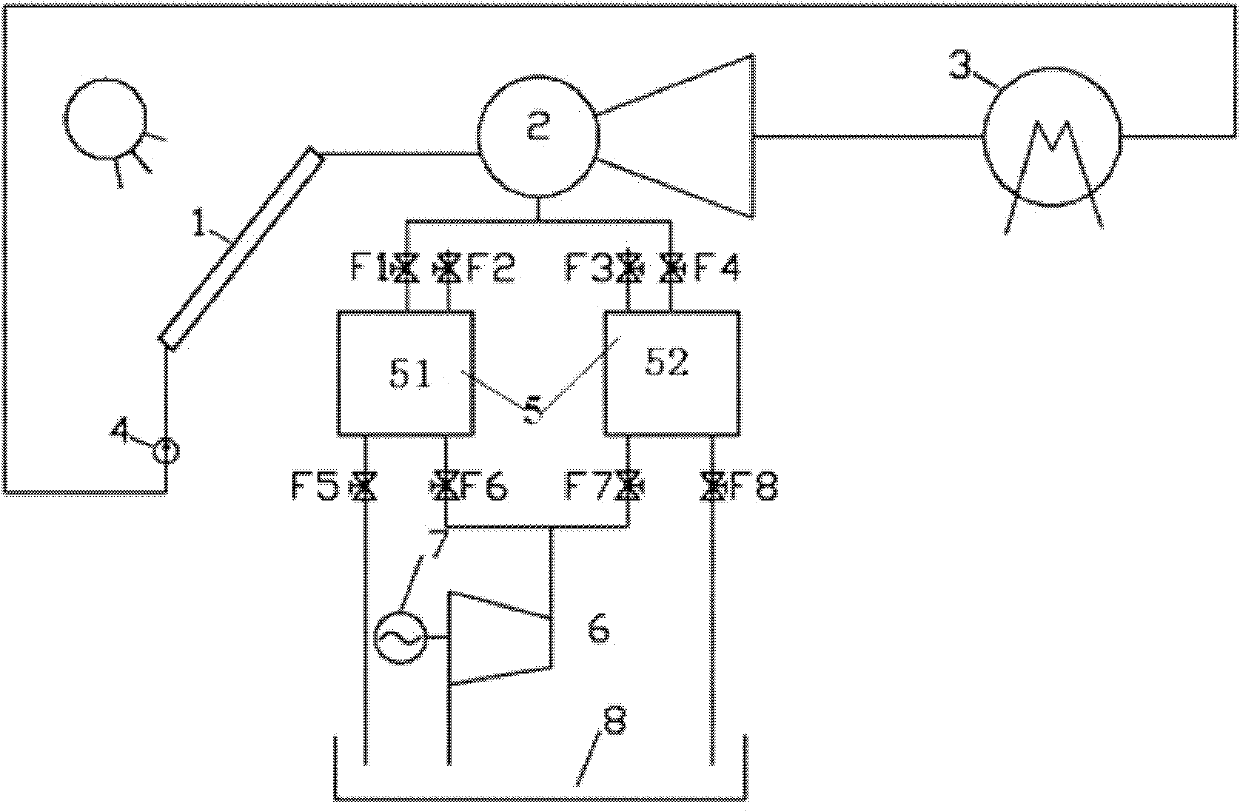

[0021] see figure 1 As shown, a kind of solar vacuum pumping hydropower generation system of the present invention comprises the solar steam jet vacuum pumping sub-system and the pumped storage energy hydropower generation sub-system using water as working medium; The solar steam jet vacuum pump sub-system includes solar heat collector 1, A steam ejector 2, a condenser 3, a circulating water pump 4, and a water storage tank 5, wherein the water storage tank 5 is a shared device of the solar steam jet vacuum pumping subsystem and the pumped storage hydroelectric power generation subsystem. The water storage tank 5 includes a first water storage tank 51 and a second water storage tank 52 . The arrangement height of the water storage tank 5 is adapted to the vacuum degree that the steam ejector 2 can achieve, and can suck liquid water to a certain height.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com