Adjustable plunger pump check valve

A one-way valve, plunger pump technology, applied in the direction of variable capacity pump parts, pump components, parts of the pumping device for elastic fluid, etc. The problem of small amount of material can achieve the effect of prolonging the service life, small amount of return material and large amount of material output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

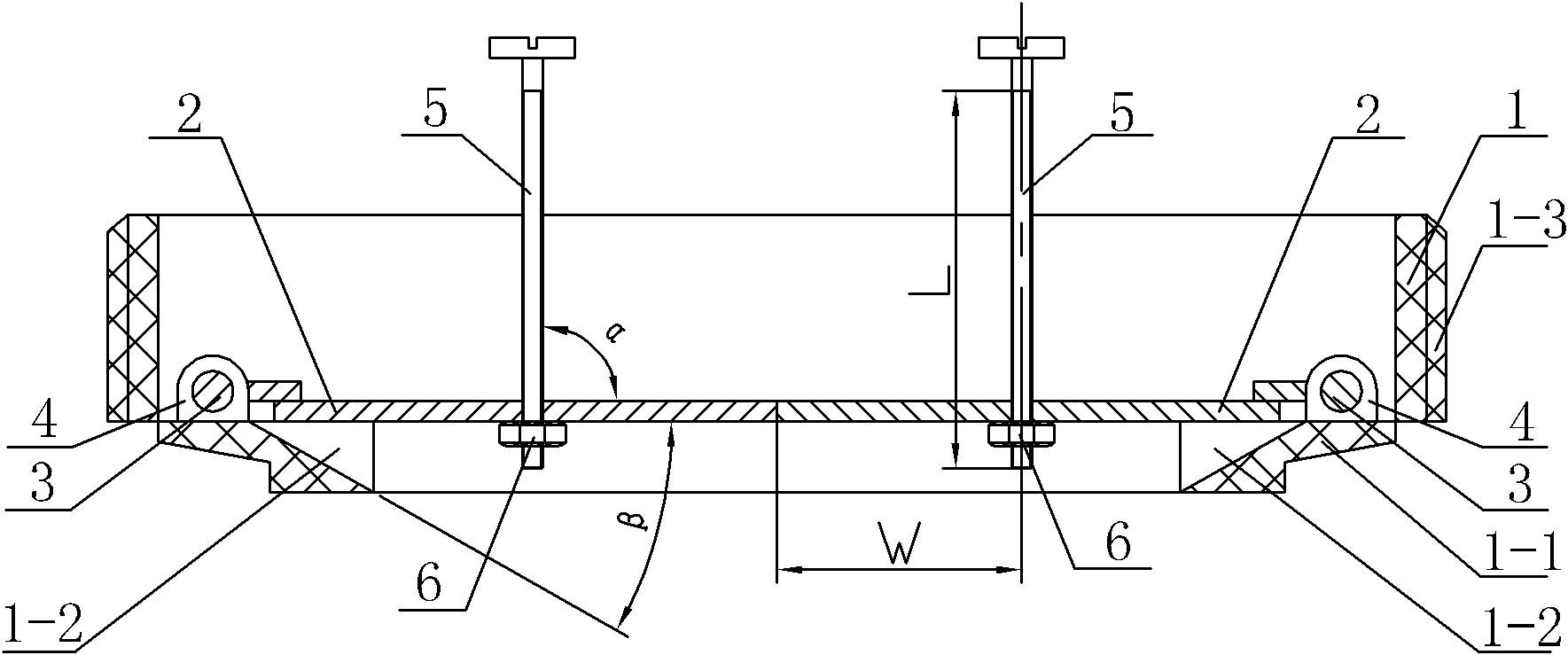

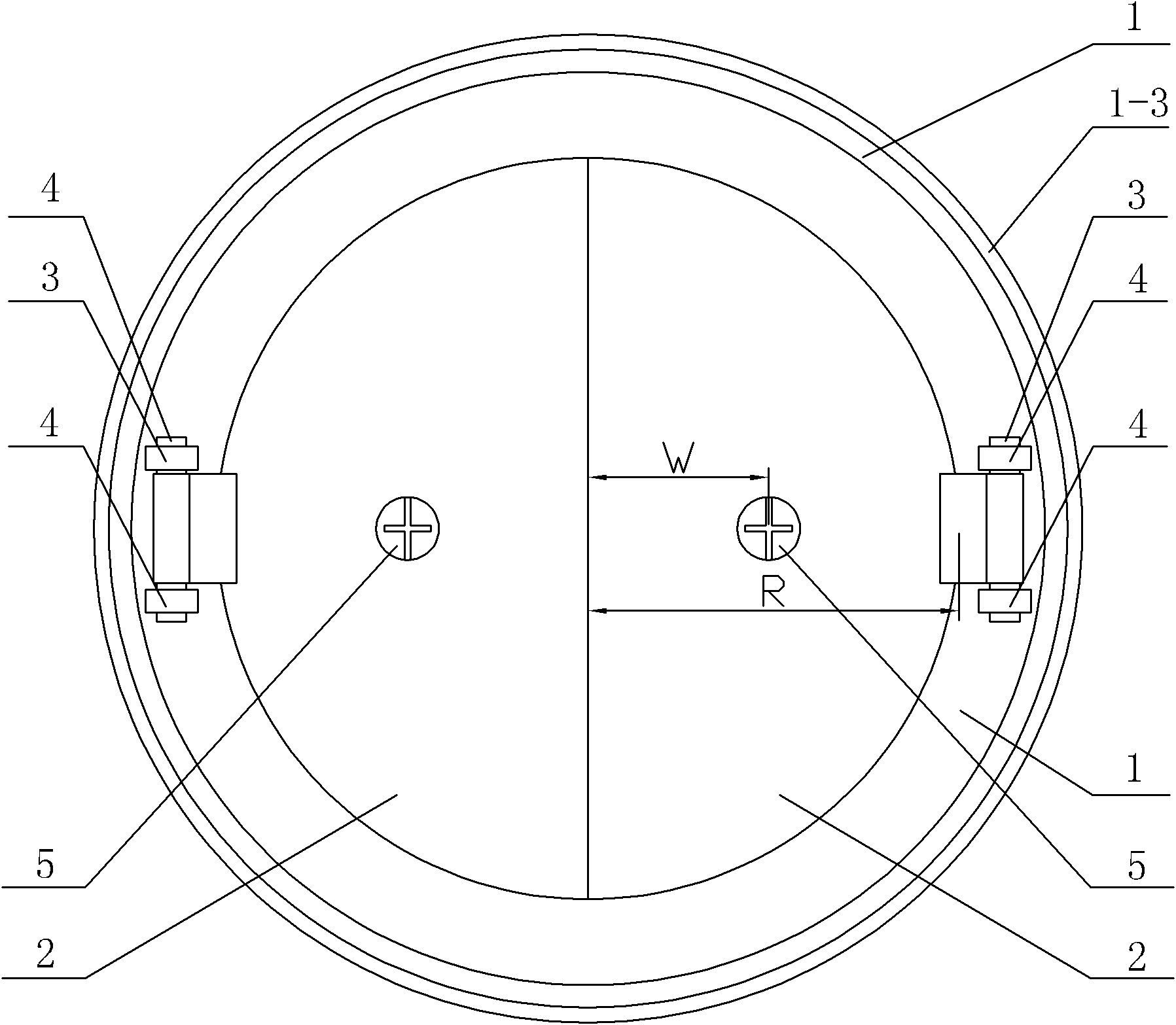

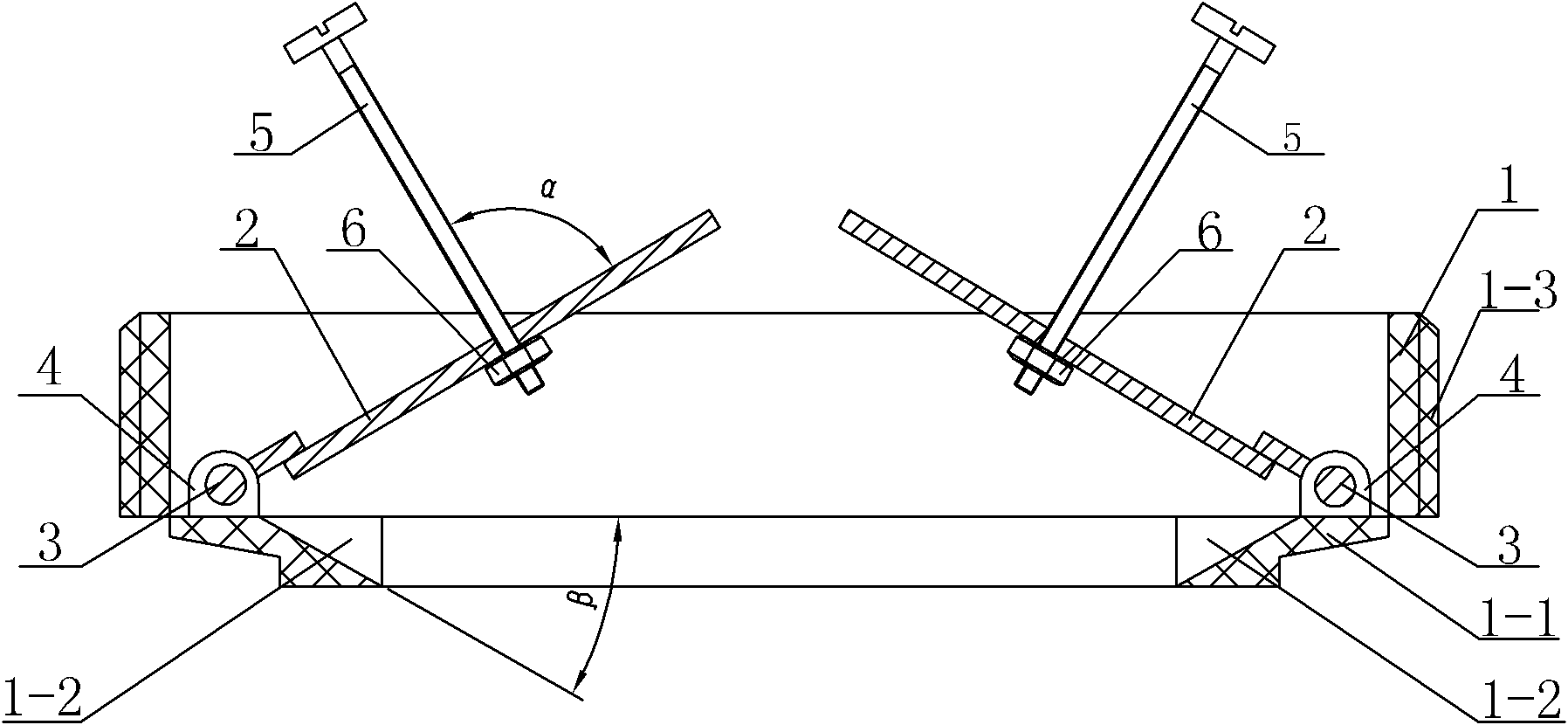

[0007] Specific implementation mode one: as Figure 1-6 As shown, an adjustable plunger pump one-way valve in this embodiment includes a valve body 1, and also includes two semicircular valve covers 2, two rotating shafts 3 and two sets of bushings 4, the valve body 1 is provided with a boss 1-1 on the inner wall, and a group of bushings 4 are symmetrically arranged on both ends of the upper surface of the boss 1-1, and a rotating shaft 3 is inserted correspondingly in each group of bushings 4, and each rotating shaft 3 corresponds to the arc edge of a semicircular valve cover 2, and the two valve covers 2 are circular after closing. Each semicircular valve cover 2 is inserted with an adjusting bolt 5, and each adjusting bolt 5 The length L of the screw rod is R≤L≤3R, and R is the radius of the semicircular valve cover 2. This embodiment prolongs the service life of the valve cover and reduces the production cost. In this embodiment, the opening angle of the semicircular valv...

specific Embodiment approach 2

[0008] Specific implementation mode two: as figure 1 and 3 As shown, the lower end of the adjusting bolt 5 of the one-way valve of the adjustable plunger pump described in this embodiment is provided with several counterweight nuts 6 . In this embodiment, the opening speed of the semicircular valve cover 2 and the flow rate of the material can be adjusted by adjusting the number of counterweight nuts 6 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as figure 1 and 3 As shown, the included angle α between each adjusting bolt 5 of the one-way valve of the adjustable plunger pump described in this embodiment and the plane where the upper surface of the semicircular valve cover 2 is located is 90°. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com