Parameter detection method for optical lens and detecting instrument thereof

A technology of parameter detection and optical lens, applied in optical instrument testing, instruments, measuring devices, etc., can solve the problems of low work efficiency and prone to errors, and achieve the effect of high detection efficiency and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

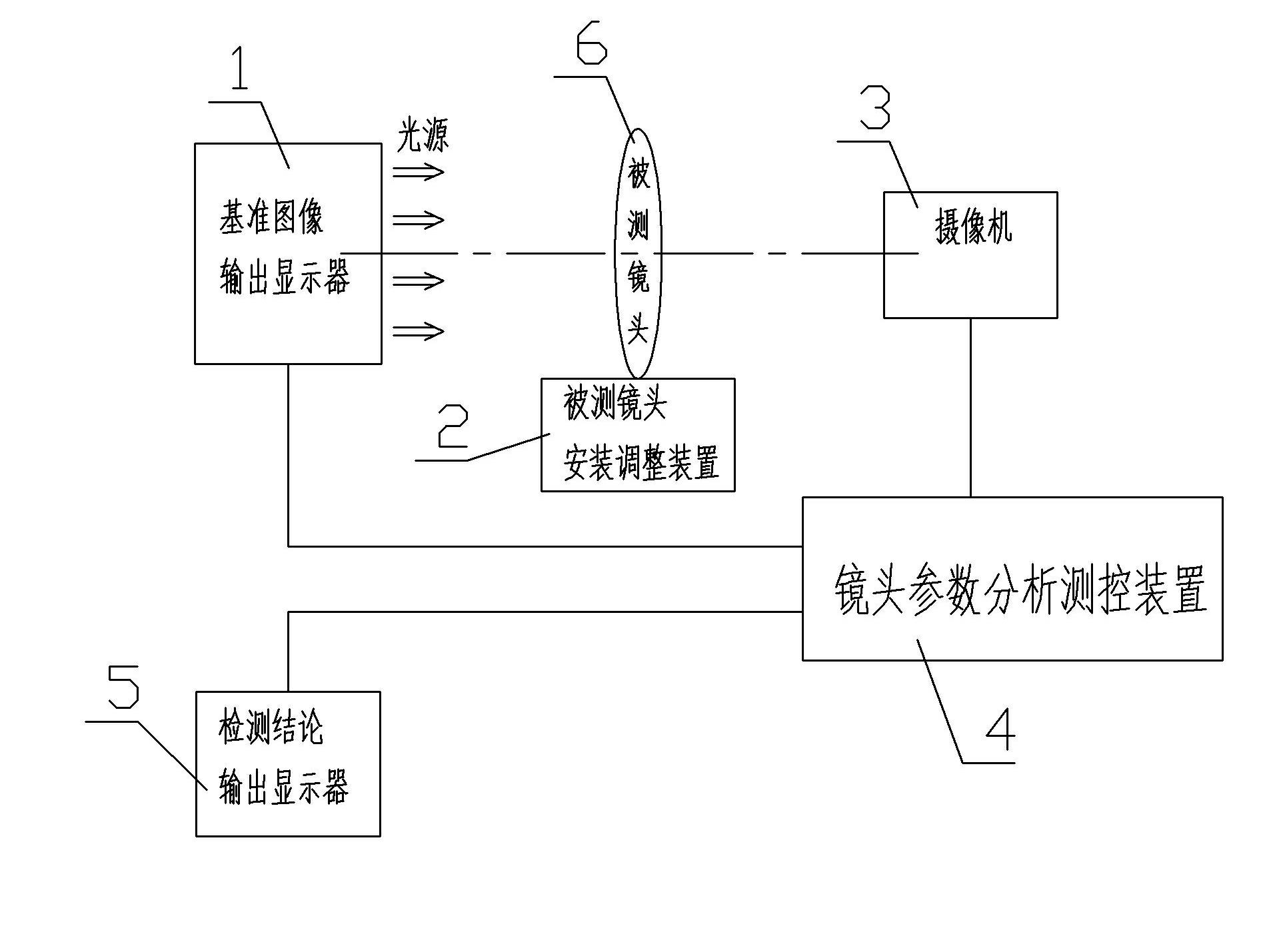

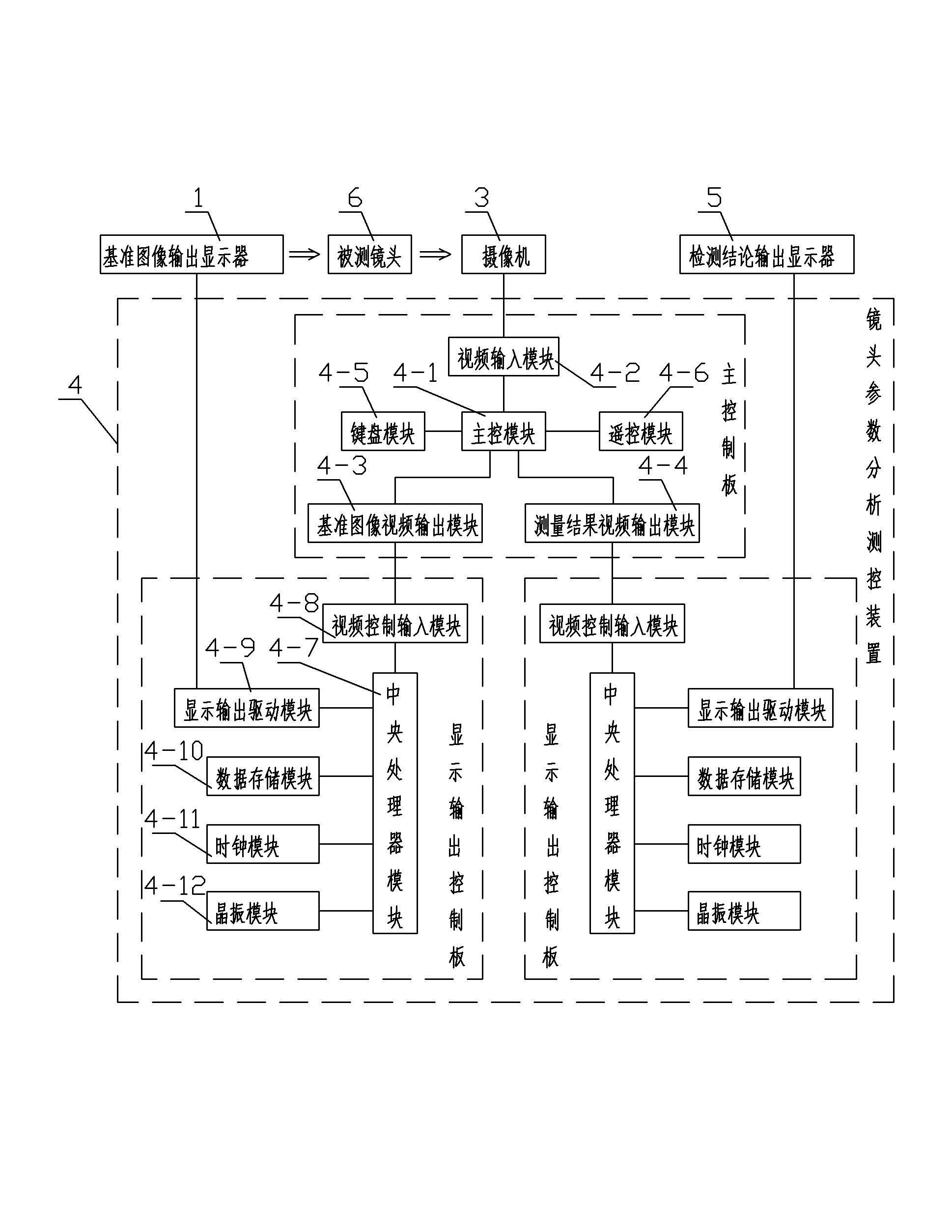

[0021] One, specific embodiment one: the specific embodiment one of the present invention provides a kind of optical lens parameter detection method, it is characterized in that: it is that the measured lens 6 is placed between the benchmark image output display 1 and the camera 3, through the measured The lens installation adjustment device 2 adjusts the measured lens 6 to an appropriate light source projection position; the set reference image is output by the lens parameter analysis measurement and control device 4 to the reference image output display 1 as a reference light source display, and is shot by the camera 3 through the measured lens 6 The video image projected onto the camera 3 is transmitted to the lens parameter analysis and control device 4, and the lens parameter analysis and control device 4 compares the image parameters of the video image with the image parameters of the reference image, and judges whether the tested lens 6 is qualified by comparison and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com