Low and high frequency high sensitivity RFID passive label and batch production method thereof

A high-sensitivity, passive tag technology, applied in the field of RFID, can solve the problems of limited service life and high cost, and achieve the effect of reducing reliability, improving qualification rate and production efficiency without changing passive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

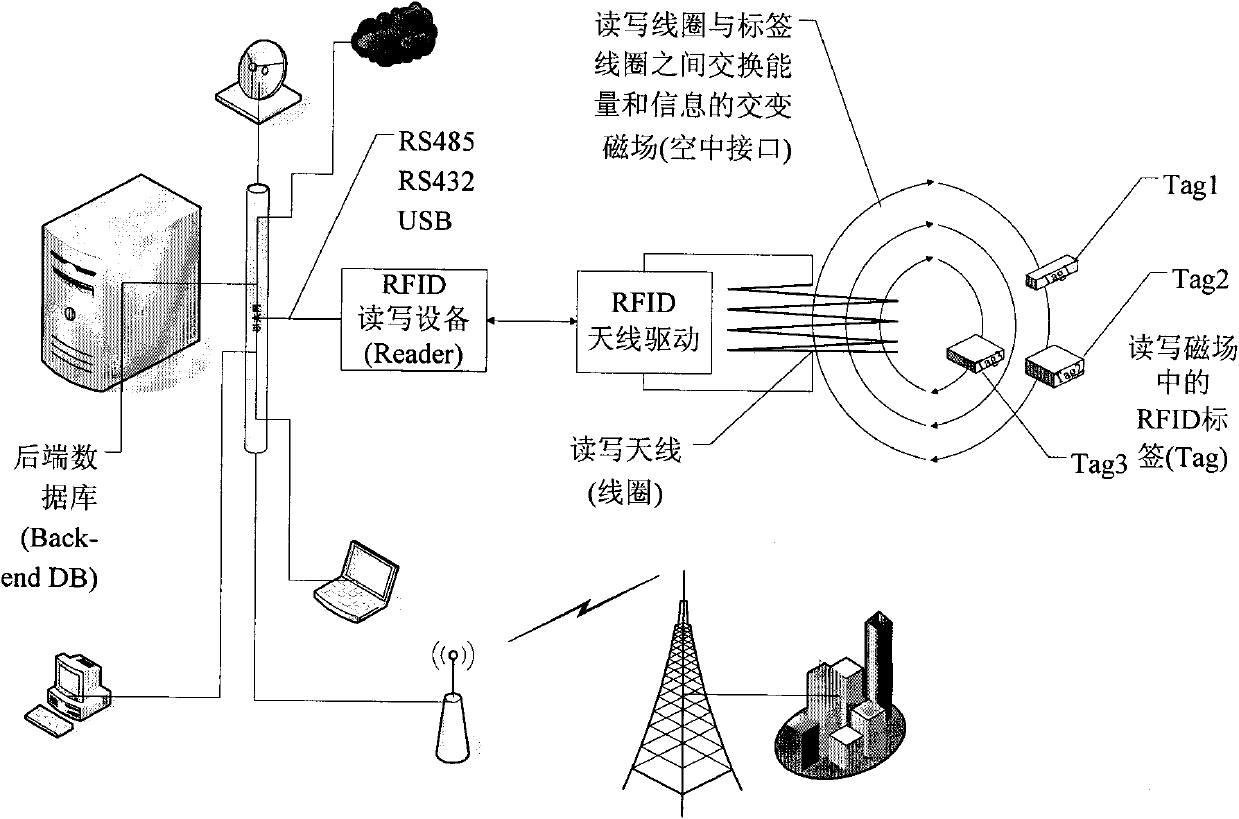

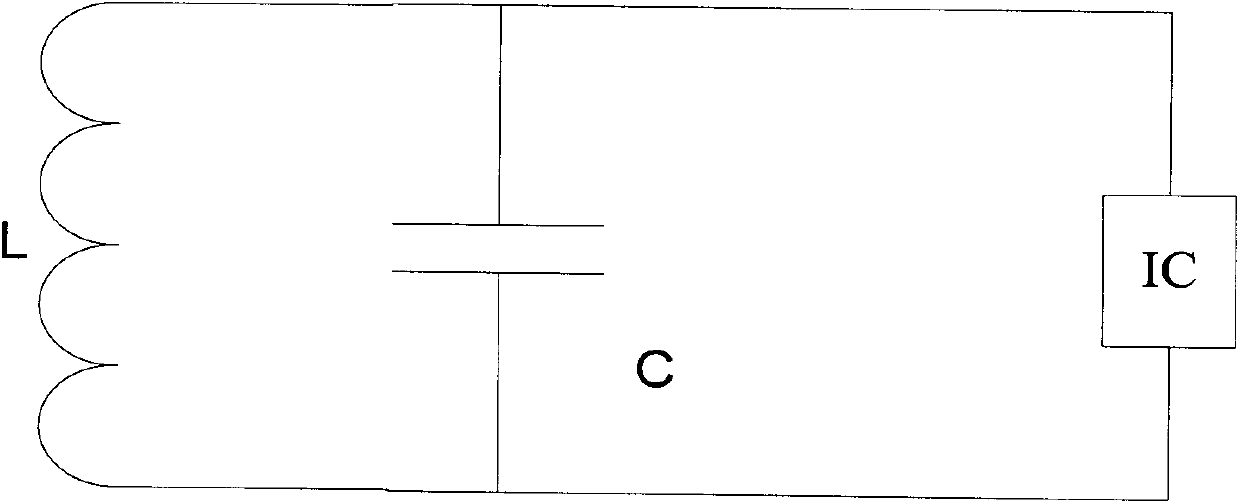

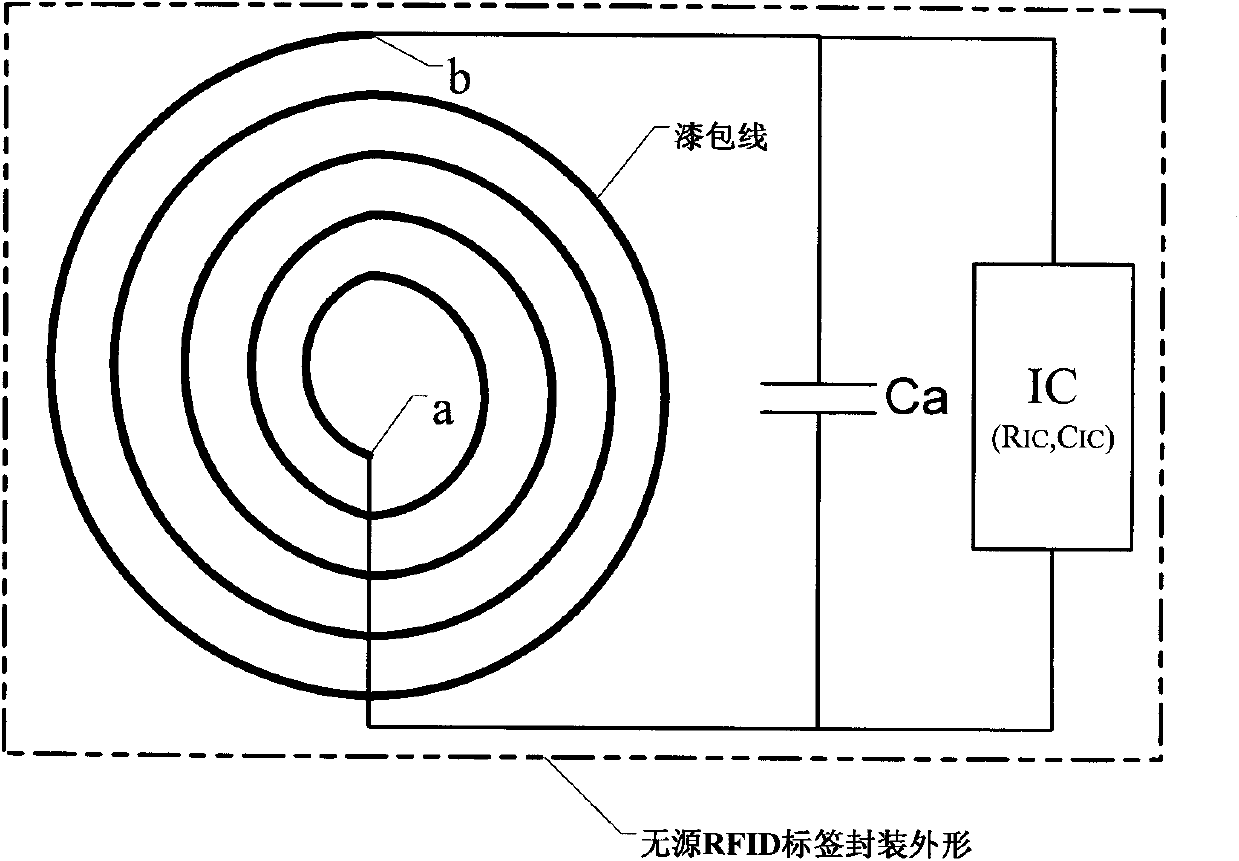

[0030] Below, refer to the attached Figure 1-12 The low-frequency high-sensitivity RFID passive tag of the present invention and its mass production method are described in detail.

[0031] According to the design and shape requirements of the RFID passive tag, determine the inner and outer side length, rounded corners, and thickness of the coil, and make the mold. For example, the standard card requires the length and width of the card to be 85mm and 54mm respectively. Because of the automatic card issuing machine used for card management For this reason, the thickness of the card must also be less than 3mm, and after deducting the package margin, it is the maximum allowable range of the coil. The start end of the coil is marked as "a", the end end is marked as "c", the middle tap is marked as "b", and the coil "ab" is determined according to the electrical performance (L2, Ls, R2, Rs, M) and various comprehensive requirements The number of turns N2, the number of turns of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com