Method for adjusting an automatic level control of the plane in planing operations in hard coal mining

一种水平控制、刨刀的技术,应用在采矿设备、土方钻采、矿顶支架等方向,能够解决不安全性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

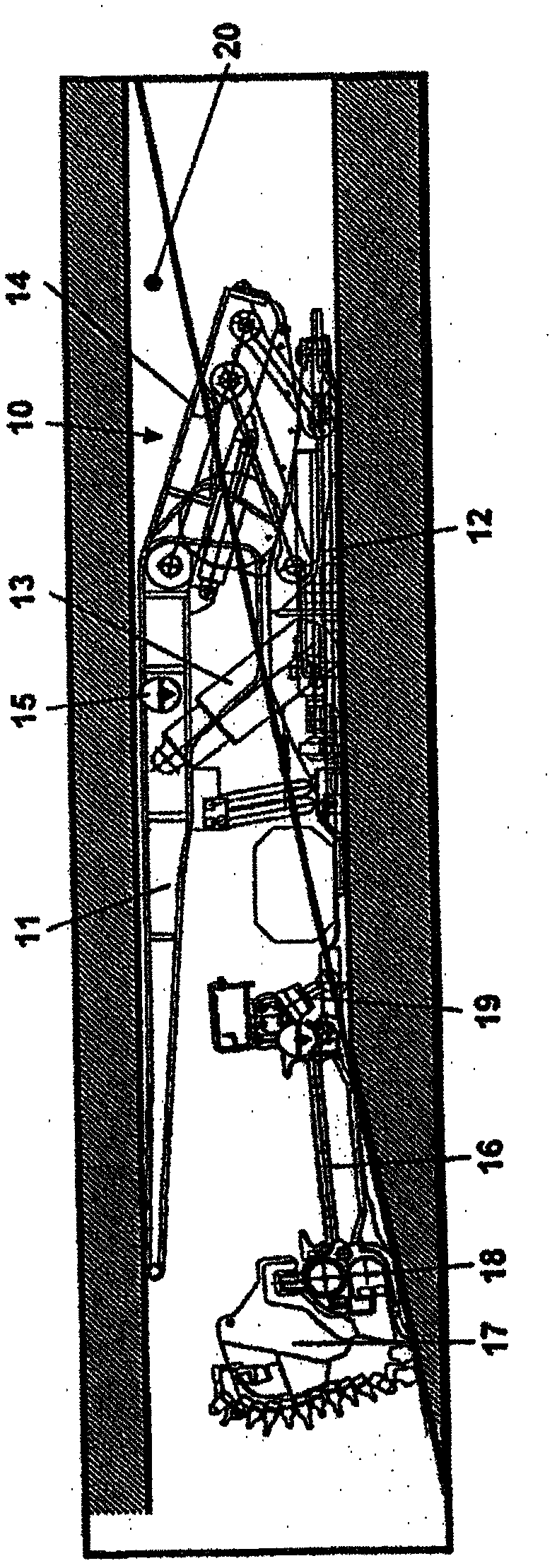

[0044] exist figure 1 The working surface device shown schematically in , firstly has a protective support 10 with a top beam 11 and a bottom plate 12; between the bottom plate 12 and the top beam 11 two struts 13 are placed in a parallel arrangement, in the figure 1 Only one of the pillars can be identified in . When the top beam 11 protruded on the mining machine direction on its front (left) end, a clot shield (Bruchschild) 14 was hinged at the rear (right) end of the top beam 11, and the structure of this protective bracket 10 is known so that no further explanation is required. At least at its top beam 11 an inclination sensor 15 is installed, as not shown in detail, at the protective bracket 10 additional inclination sensors are installed at the base plate 12 and the clot shield 14 and / or carry the clot shield 14 at the carrying rod (Traglenker). The height of the protective support between the roof beam 11 and the base plate 12 can be calculated using the measured va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com