Wheel position control method for boarding bridge butt-joint cabin door

A boarding bridge and cabin door technology, applied in two-dimensional position/channel control, vehicle position/route/height control, program control, etc., to achieve the effect of improving accuracy and reducing the impact of measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

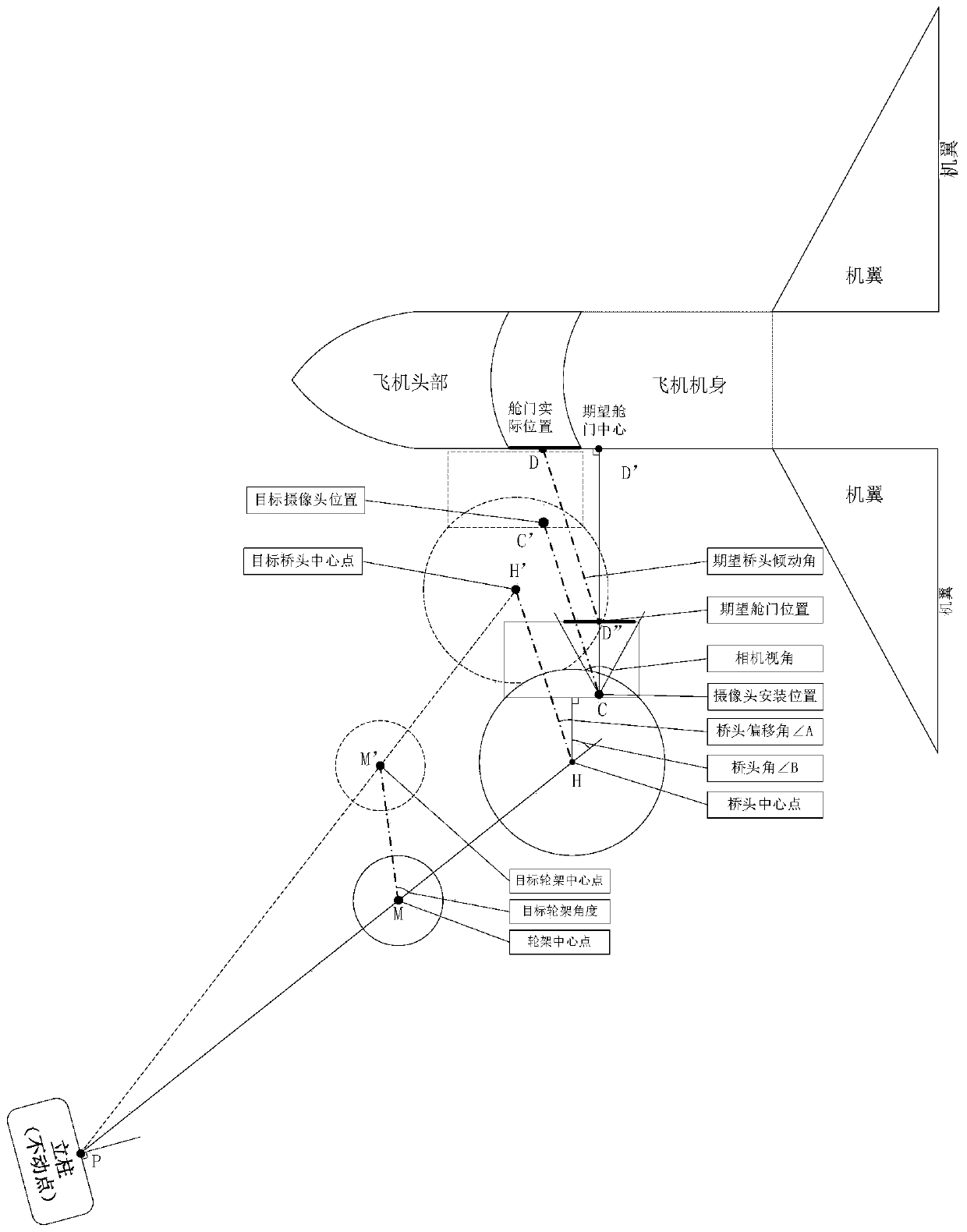

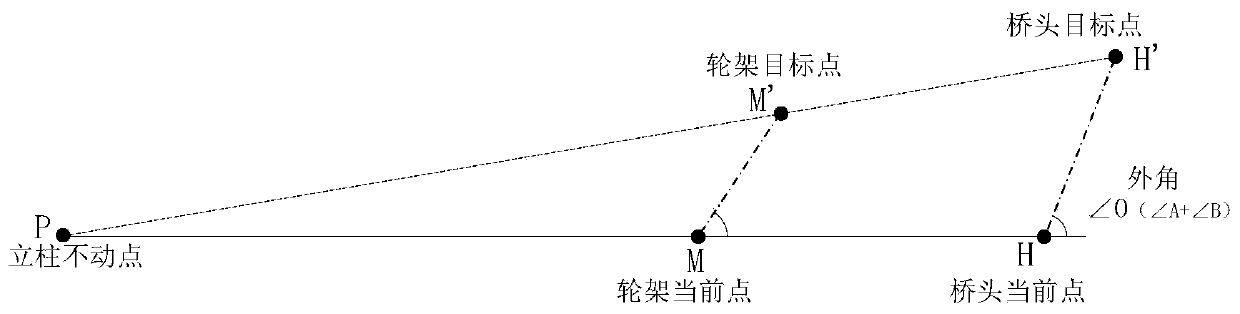

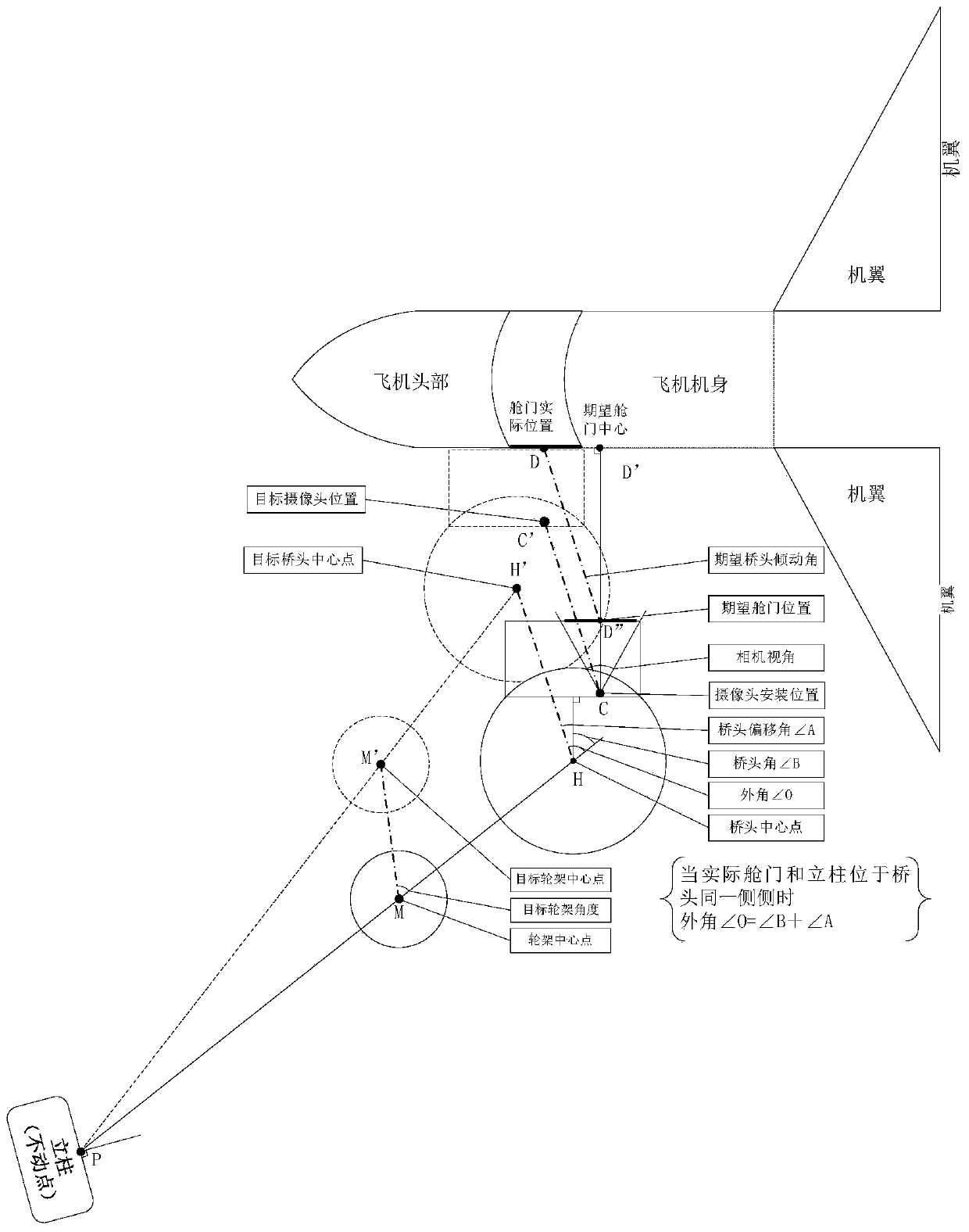

[0026] The present invention is described in detail below in conjunction with accompanying drawing

[0027] The invention analyzes the optimal angle when the boarding bridge docks with the cabin door in the horizontal direction. The control in the vertical direction is relatively simple, and the height of the boarding bridge in the vertical direction is the same as that of the cabin door by default in the present invention. The control method of the present invention needs to be combined with relevant sensors to obtain part of the data. For the convenience of description, it is set as a prerequisite, including:

[0028] 1. It is necessary to ensure that the bridge head of the boarding bridge is at the same height as the aircraft door and that the bridge head is level with the fuselage of the aircraft, that is, the outer edge of the bridge head of the boarding bridge is parallel to the aircraft fuselage. The premise can be achieved by installing ultrasonic sensors on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com