Brake cylinder device and unit brake

A brake cylinder, commonly used brake technology, applied in the direction of brakes, brake types, brake components, etc., can solve problems such as increased reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

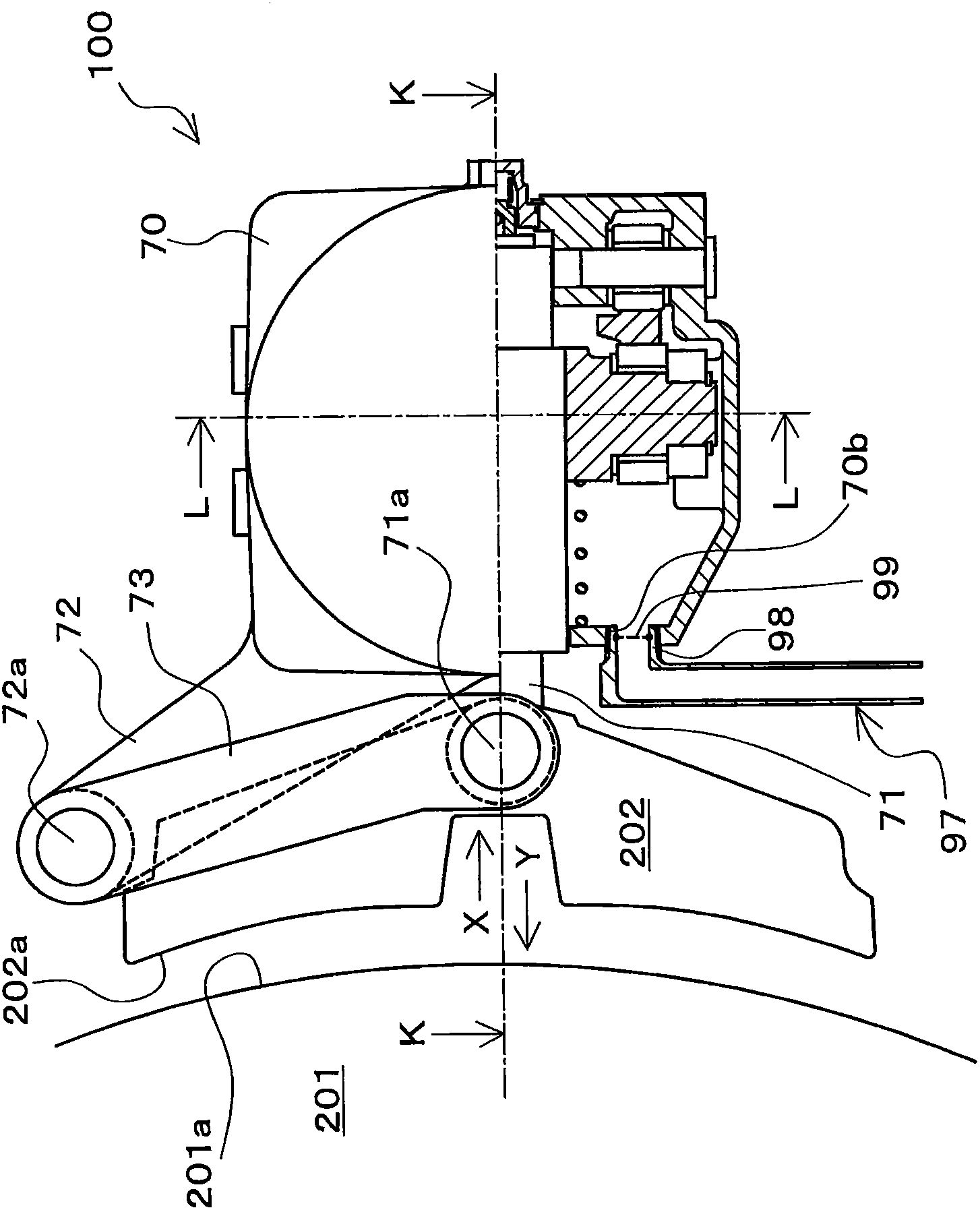

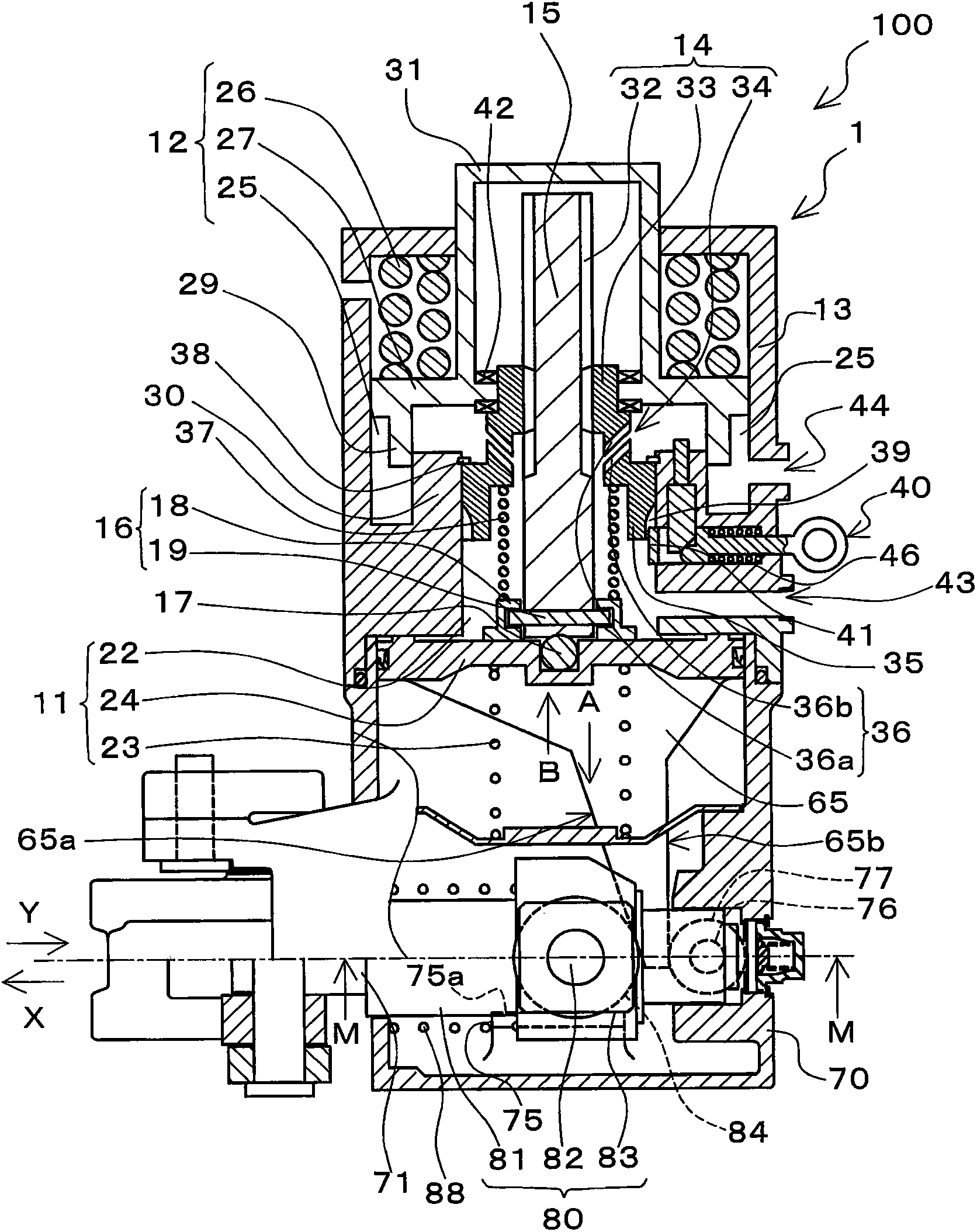

[0061] A brake cylinder device and a unit brake according to a first embodiment of the present invention will be described. figure 1 It is a partial cross-sectional view viewed from the axial direction of a wheel 201 when the unit brake 100 of the first embodiment is mounted on a vehicle. figure 2 is along figure 1 A partial cross-sectional view at the position observed in the direction of the K-K line.

[0062] figure 1 and figure 2 The illustrated unit brake 100 includes the brake cylinder device 1 of the first embodiment and a box-shaped brake body 70 for mounting the brake cylinder device 1 and covering a part of a drive mechanism of the brake. Furthermore, the unit brake 100 is configured to brake the brake shoe 202 held relatively movable with respect to the brake main body 70 by actuating at least one of the service brake mechanism 11 and the spring brake mechanism 12 described later. The surface 202a abuts against the tread surface 201a of the wheel 201 of the ve...

no. 2 Embodiment approach

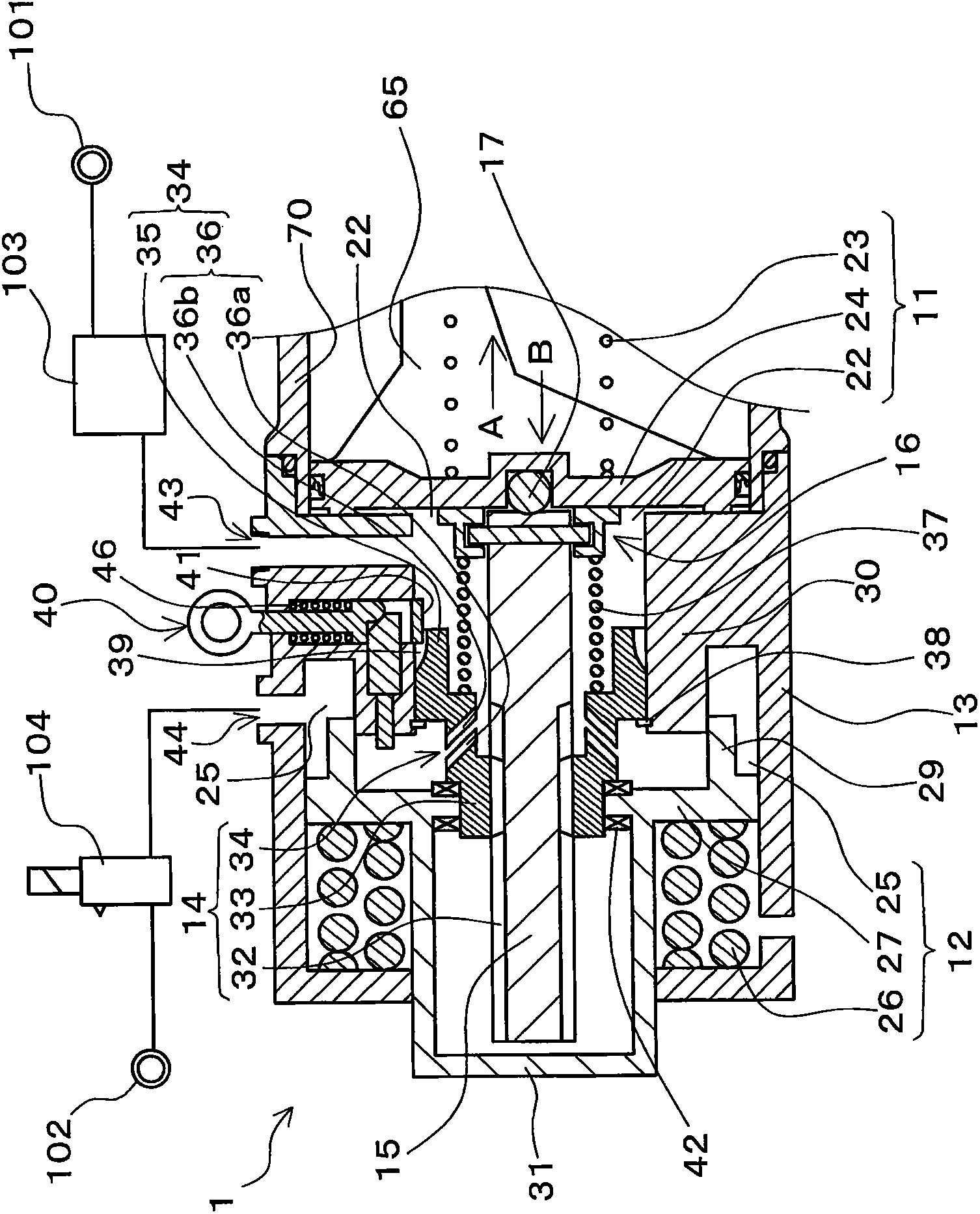

[0116] A unit brake 110 according to a second embodiment of the present invention will be described. Figure 12 It is a partial sectional view of the unit brake 110 of the second embodiment. Figure 12 The illustrated unit brake 110 includes: the brake cylinder device 2 according to the second embodiment; and a brake main body 70 formed in a box shape to cover a part of a drive mechanism of the brake to which the brake cylinder device 2 is attached. The unit brake 110 with figure 1 The unit brake 100 of the first embodiment shown has the same configuration, and by actuating at least one of the service brake mechanism 11 and the spring brake mechanism 12, the brake shoe held so as to be relatively movable relative to the brake main body 70 The braking surface abuts against the tread of the wheel of the vehicle, thereby braking the rotation of the wheel by friction (see figure 1 ). However, the unit brake 110 differs from the unit brake 100 of the first embodiment in part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com