Iron remover

A technology of iron remover and magnet, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc. It can solve the problems of unsatisfactory iron removal effect, large air magnetic resistance, uneven distribution of magnetic induction lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

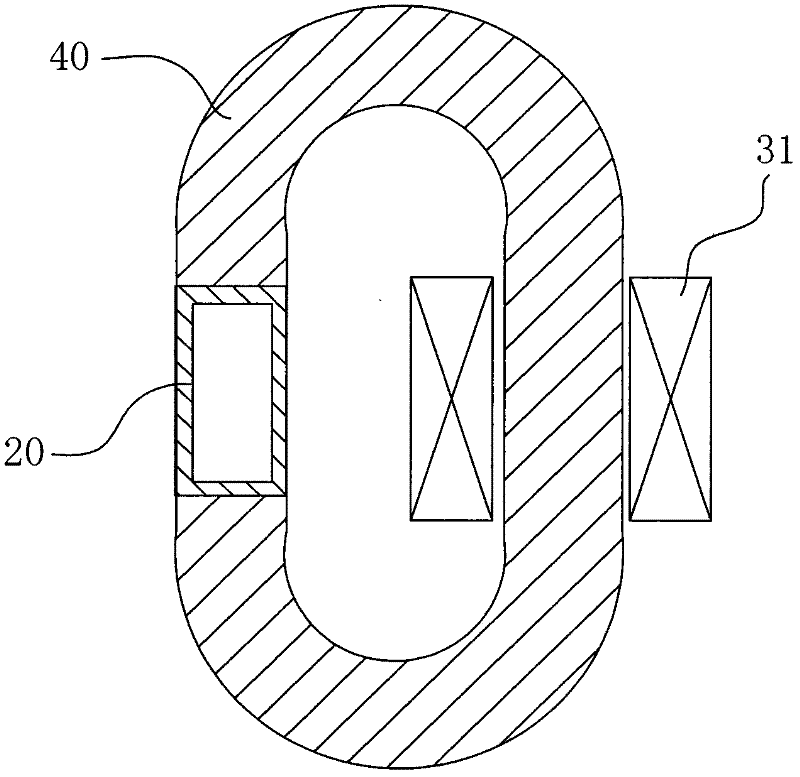

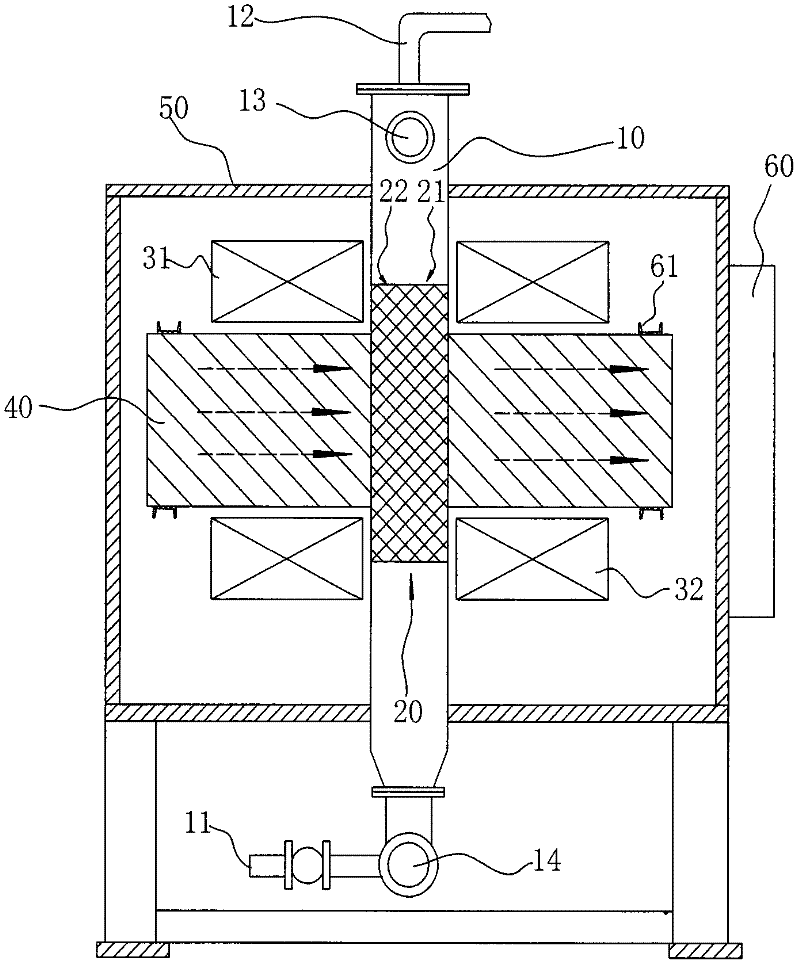

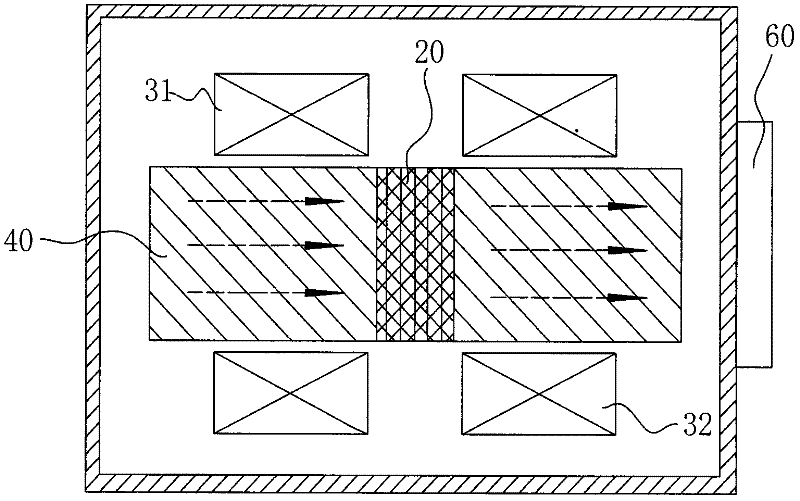

[0009] like figure 1 As shown, an iron remover includes a magnet and a catcher 20 located within the magnetic field of the magnet. The catcher 20 is used to supply the material to circulate and absorb iron filings in the material at the same time, that is, the catcher 20 must first be able to supply the material Circulation, for example, the catcher 20 is a tubular shell; to play the role of being able to absorb and remove iron filings, that is, the material of the catcher 20 should be magnetically conductive, such as iron or steel or pure iron, ferrosilicon, etc. Soft magnetic material; in other words, the catcher 20 is magnetized by the magnetic field of the magnet and has the ability to attract iron. There are many implementations of such a technical solution, which will not be repeated here. The improvement of the present invention is that a low reluctance magnetic conductor 40 is arranged in the magnetic field of the magnet, and the magnetic conductor 40 is arranged alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com