A material automatic identification storage system and its material storage method

A warehousing system and automatic identification technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of inconvenient implementation, labor-intensive, error-prone, etc., and achieve simple identification and setting methods , The effect of improving storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

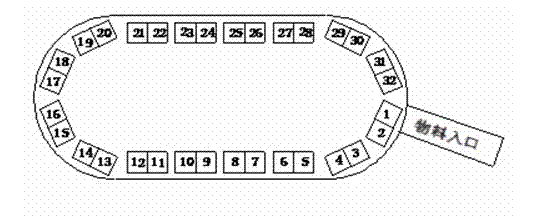

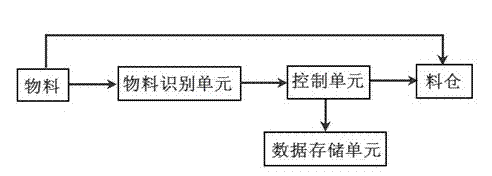

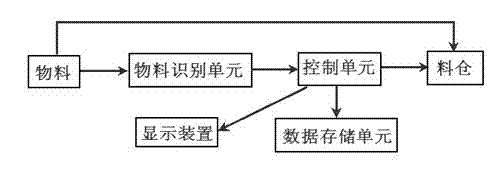

[0040] A specific embodiment of the material automatic identification storage system of the present invention is given below. The material automatic identification storage system of the present invention includes a track, where the track is arranged in a ring, such as figure 1 As shown, it can also be set as a square or other shapes according to the specific environment and space. There is a material inlet on the track, and the material inlet can be connected to a conveying device for conveying materials such as a conveyor belt, and the material with an information identification code can be transported Up to this point, in this embodiment, the barcode is selected as the identification code of the material, and other types of scanning codes (such as infrared scanning codes, IC information codes, etc.) can also be selected. The material identification unit is arranged at the material entrance, where the material identification unit includes a barcode scanner, which reads and sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com