Cracking device

A cracking device and cracking kettle technology, applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., can solve problems such as hidden safety hazards, partial coking, and difficulty in solving the sealing problem of cracking kettles, so as to avoid potential safety hazards and improve sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

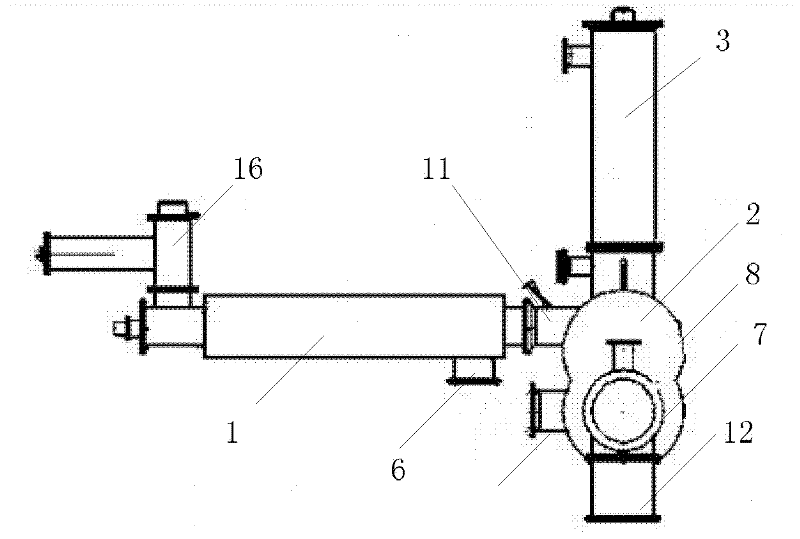

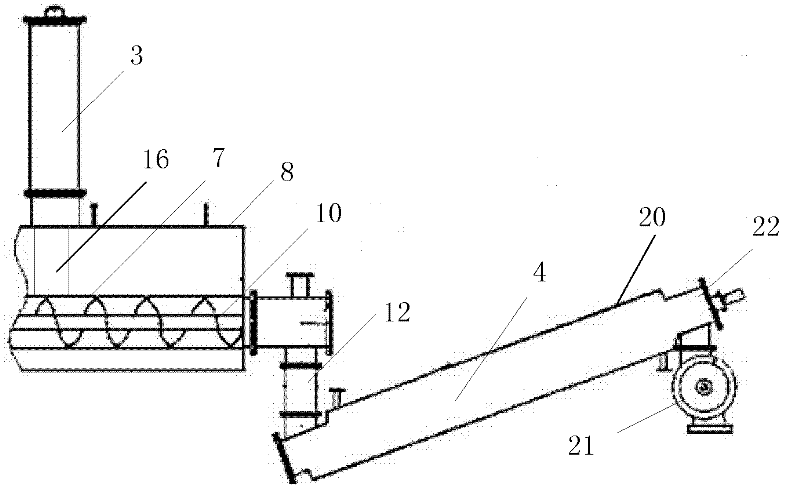

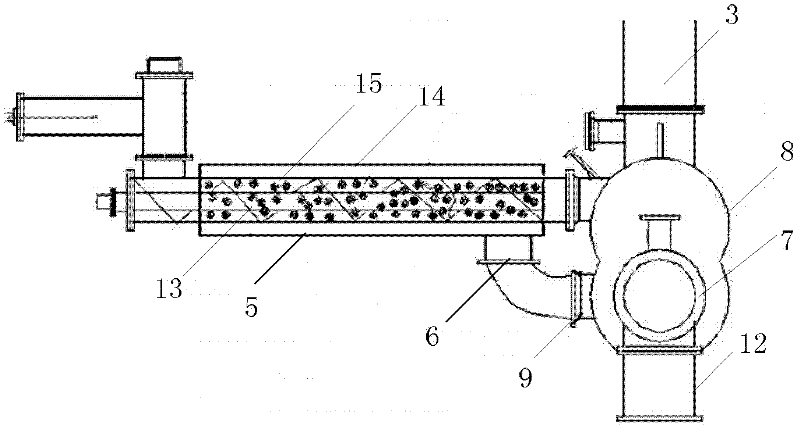

[0026] see also figure 1 with figure 2 , The embodiment of the present invention provides a cracking device, which includes a feed device 1 , a cracking kettle 2 , a reaction tower 3 and a slagging device 4 . see image 3 The feeding device 1 is provided with a preheating channel 5, which can be a preheating jacket, and an opening 6 is set on the preheating jacket, and heat is introduced into the preheating channel 5 through the opening 6 to preheat the feeder. The material in the feeding device 1 can also be preheated by means of an external heating device or the like in the feeding device 1; see also figure 1 with figure 2 The cracking kettle 2 comprises a cracking kettle inner cylinder 7, a cracking kettle outer cylinder 8, a hot blast inlet 9, a hot blast outlet (not shown in the figure), a screw propeller 10, a feed inlet 11 and a slag outlet 12, and the cracking kettle inner cylinder 7 is located in the cracking kettle outer cylinder 8, and forms a jacket with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com