Three-lobed spinneret and spinning components

A spinning assembly and spinneret technology, applied in the field of three-blade spinnerets and spinning assemblies, can solve problems such as unsolvable problems, and achieve the effects of high work efficiency, less heat loss, and easy disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

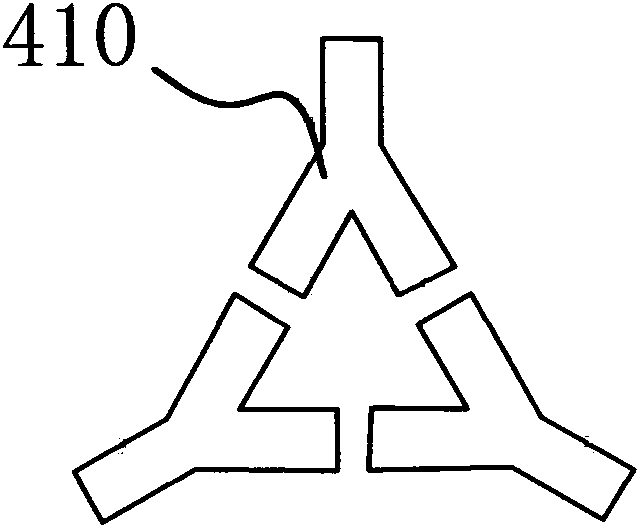

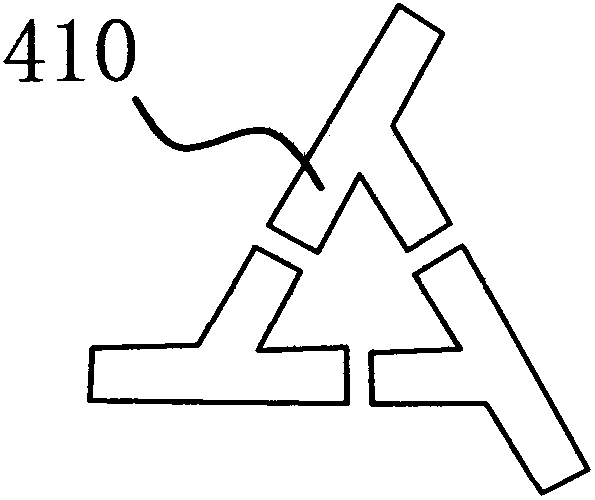

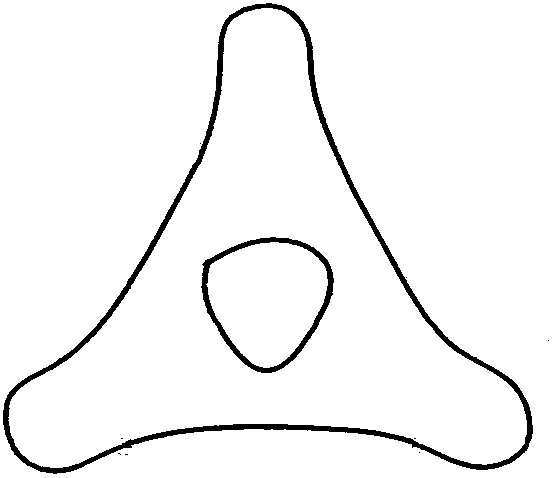

[0019] like figure 1 and 2 As shown, the three-lobed spinneret includes a disc-shaped plate body 40, and a plurality of spinneret holes 41 are provided on the plate body 40, and each spinneret hole 41 includes three injection ports 410 that are enclosed together. The injection port 410 described above is Y-shaped or y-shaped. The fibers produced by the above-mentioned spinneret holes 41 are as follows: image 3 shown.

[0020] like Figure 4 As shown, the three-lobed spinneret spinning assembly is arranged in the spinning box body, including a feed plate 1, a feed port 11 is provided on the side of the feed plate 1, and a feed port 11 is provided at one end of the feed plate 1. The feed port 11 communicates with the feed port 12 . The feed plate 1 is provided with a distribution plate 2 positioned at the discharge port 12, the distribution plate 2 has a number of axially through distribution holes 21 and the distribution plate 2 is fixed on the feed plate 1 through the mi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap