A low carbon steel hollow tube rotor structure for permanent magnet motor

A technology of permanent magnet motor and rotor structure, which is applied in the shape/style/structure of the magnetic circuit and the rotating parts of the magnetic circuit, etc., can solve the problems of large moment of inertia, complicated punching process for punching silicon steel rotor, and difficult to control flexibly, etc. achieve a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

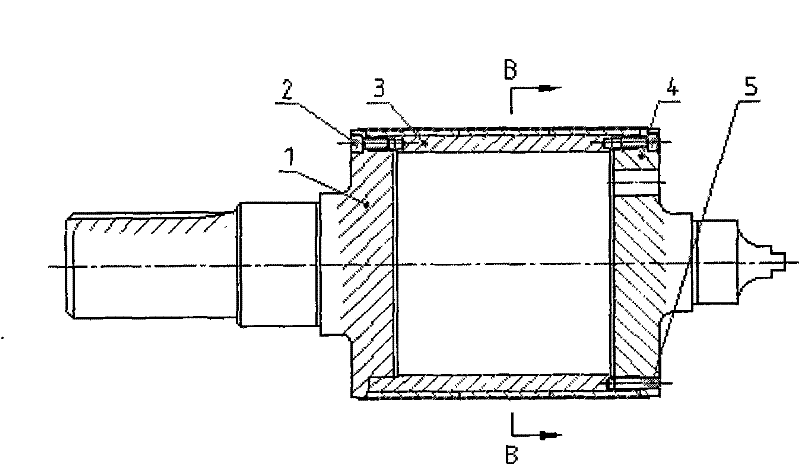

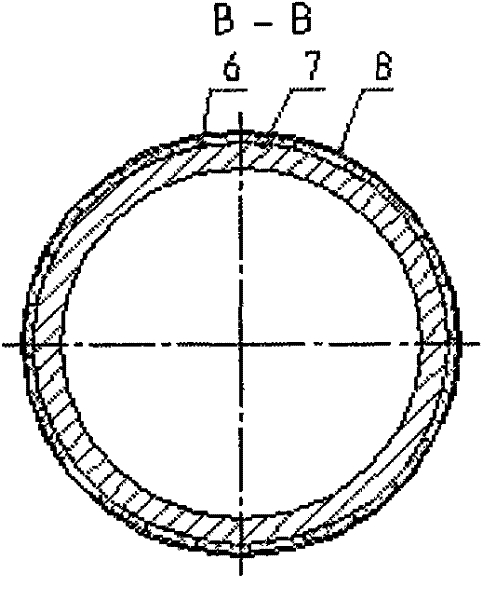

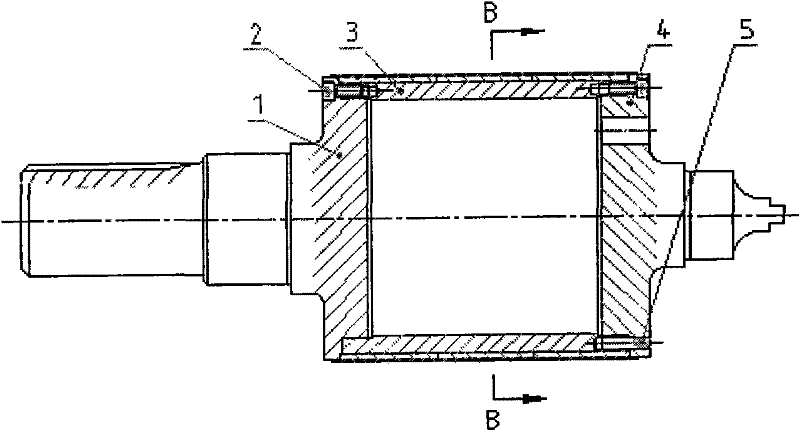

[0012] Such as figure 1 , figure 2 The shown invention relates to a low-carbon steel hollow circular tube rotor structure for a permanent magnet motor. It is provided with a rotor sleeve 3, and the two ends are installed with the shaft extension end shaft 1 and the non-shaft extension end shaft 4, which are connected by seams, and are fastened together with the rotor sleeve 3 by 12 hexagon socket head screws 2 respectively, and are connected with the rotor sleeve 3 by a cone. The pin 5 is positioned, and the outer circle of the rotor sleeve 3 is pasted with the arc-shaped magnetic steel 6 with anaerobic adhesive 7, and the inner surface of the arc is N, S, N, S... (or S, N, S, N... ) are arranged on the circumference and glued on the outer circle of the rotor sleeve 3 . Wrap carbon fiber cloth 8 outside, put glue in the oven after brushing, and dry and solidify below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com