High-strength steel plate for nuclear reactor containment and manufacturing method thereof

A technology of high-strength steel plates and steel plates, applied in the field of high-strength steel plates, can solve problems such as increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0078] Hereinafter, the present invention will be described in more detail through examples.

Embodiment

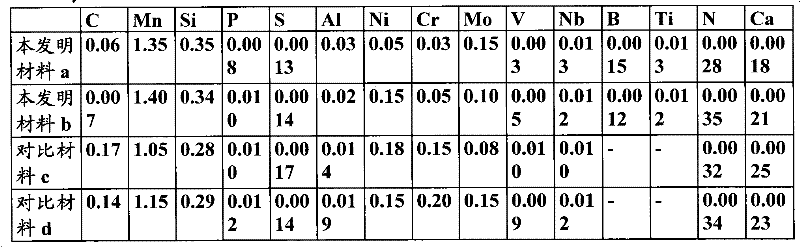

[0080] Steel ingots formed of the inventive material and the comparative material containing the alloying elements shown in Table 1 below were produced.

[0081] Table 1

[0082]

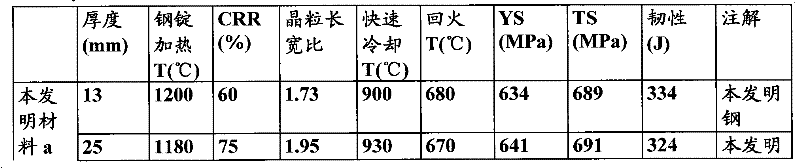

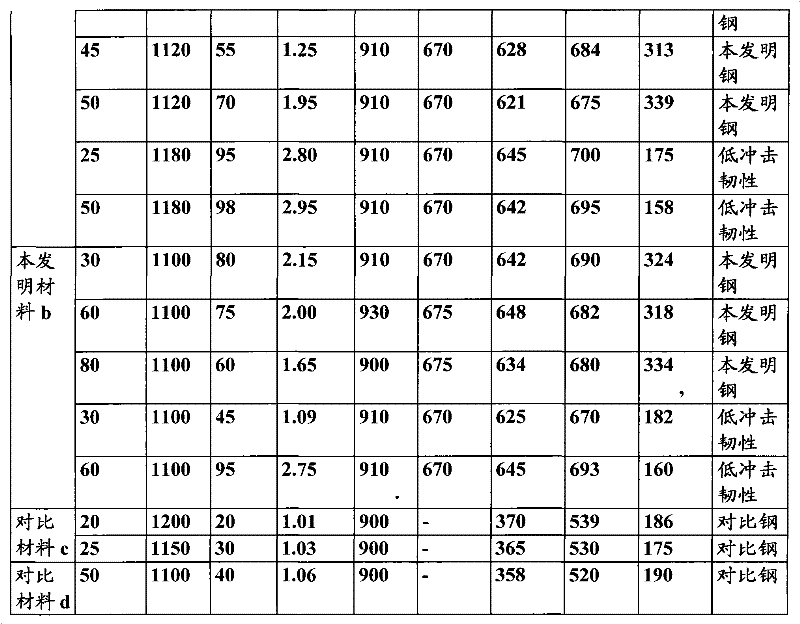

[0083] Each ingot having the composition of the inventive material and the comparative material shown in Table 1 was heated and subjected to controlled rolling for the recrystallized region under the conditions shown in Table 2 below. After performing controlled rolling, heat treatment, etc. under the conditions shown in Table 2, the levels of strength and low-temperature toughness were evaluated. The results are shown in Table 2 below. Here, the low-temperature toughness shown in Table 2 was evaluated based on Charpy impact energy obtained by performing a Charpy impact test on a sample having a V-notch at -50°C.

[0084] Table 2

[0085]

[0086]

[0087] (In Table 2, T: temperature, CRR: cumulative rolling reduction)

[0088] In the above Table 2, the grain aspect ratio refers to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com