Patents

Literature

75 results about "Containment building" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A containment building, in its most common usage, is a reinforced steel or lead structure enclosing a nuclear reactor. It is designed, in any emergency, to contain the escape of radioactive steam or gas to a maximum pressure in the range of 275 to 550 kPa (40 to 80 psi). The containment is the fourth and final barrier to radioactive release (part of a nuclear reactor's defence in depth strategy), the first being the fuel ceramic itself, the second being the metal fuel cladding tubes, the third being the reactor vessel and coolant system.

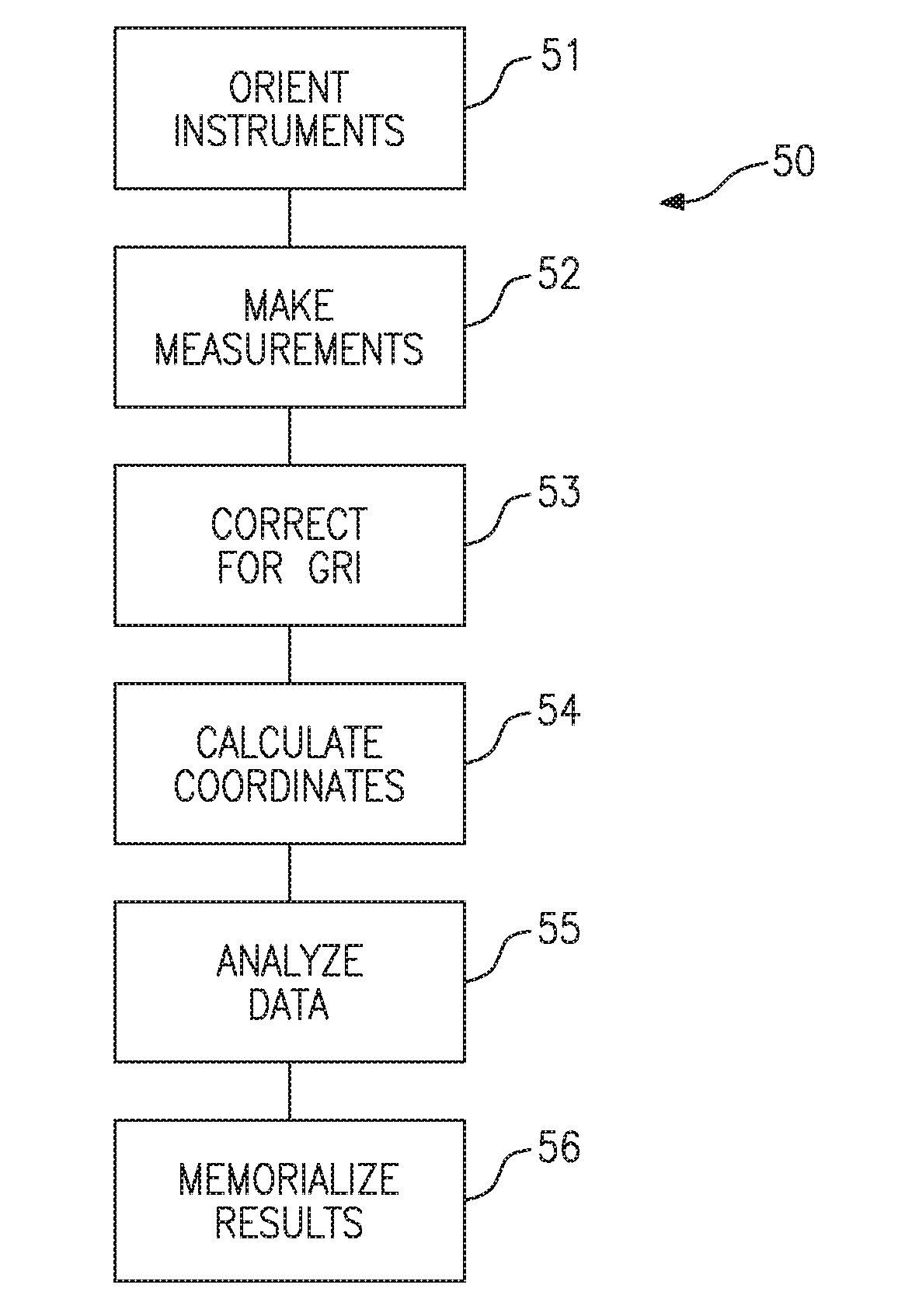

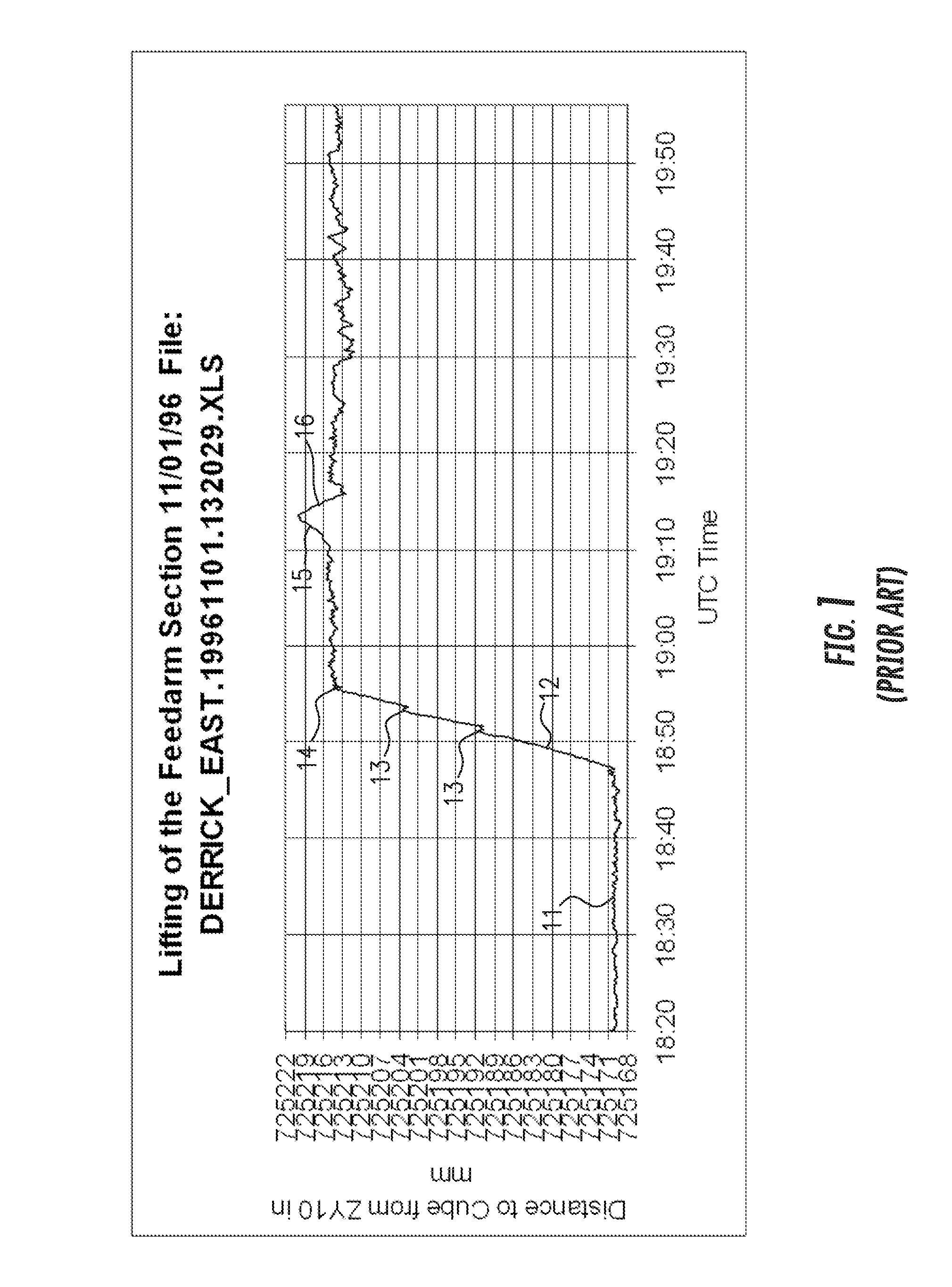

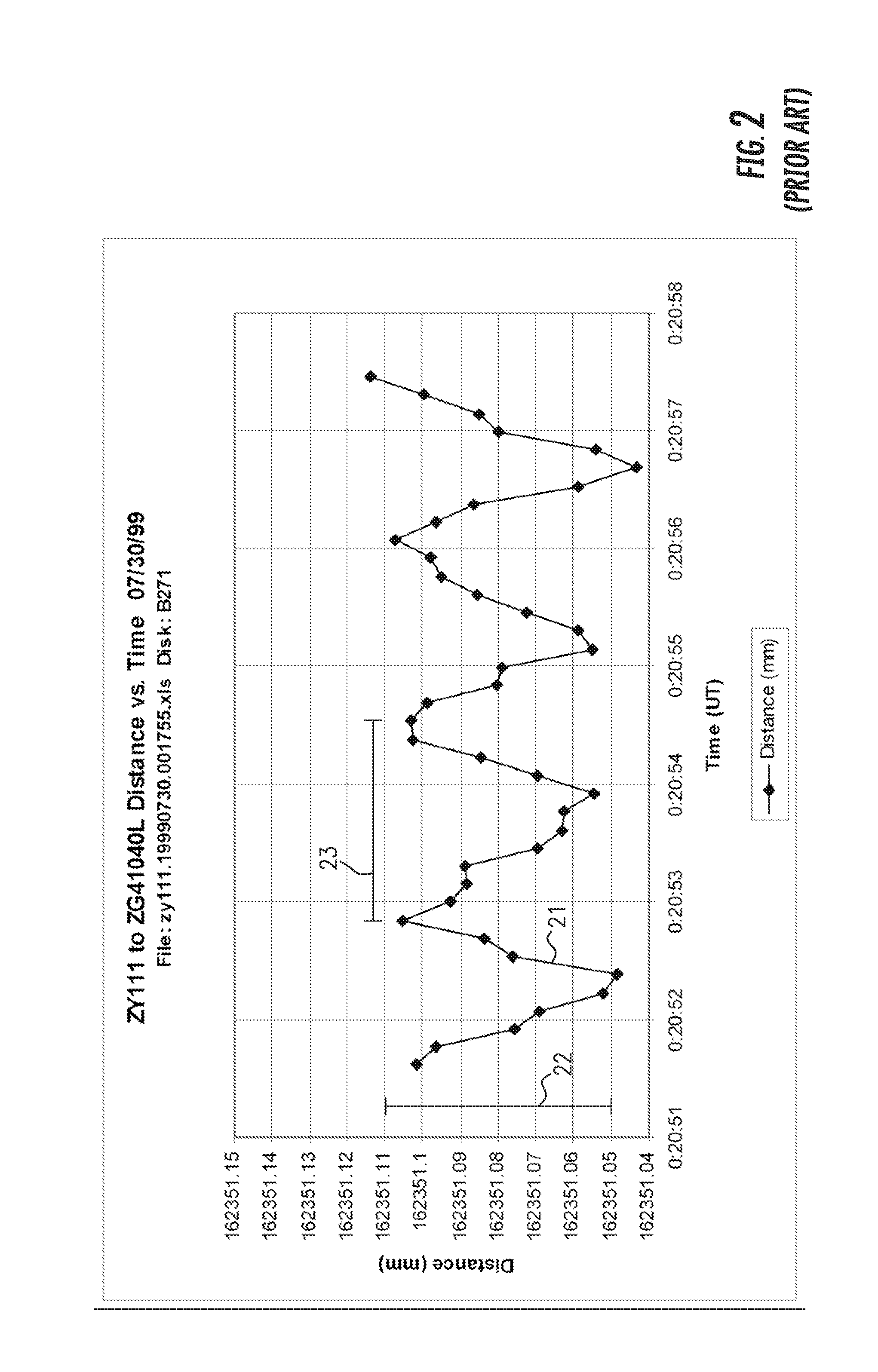

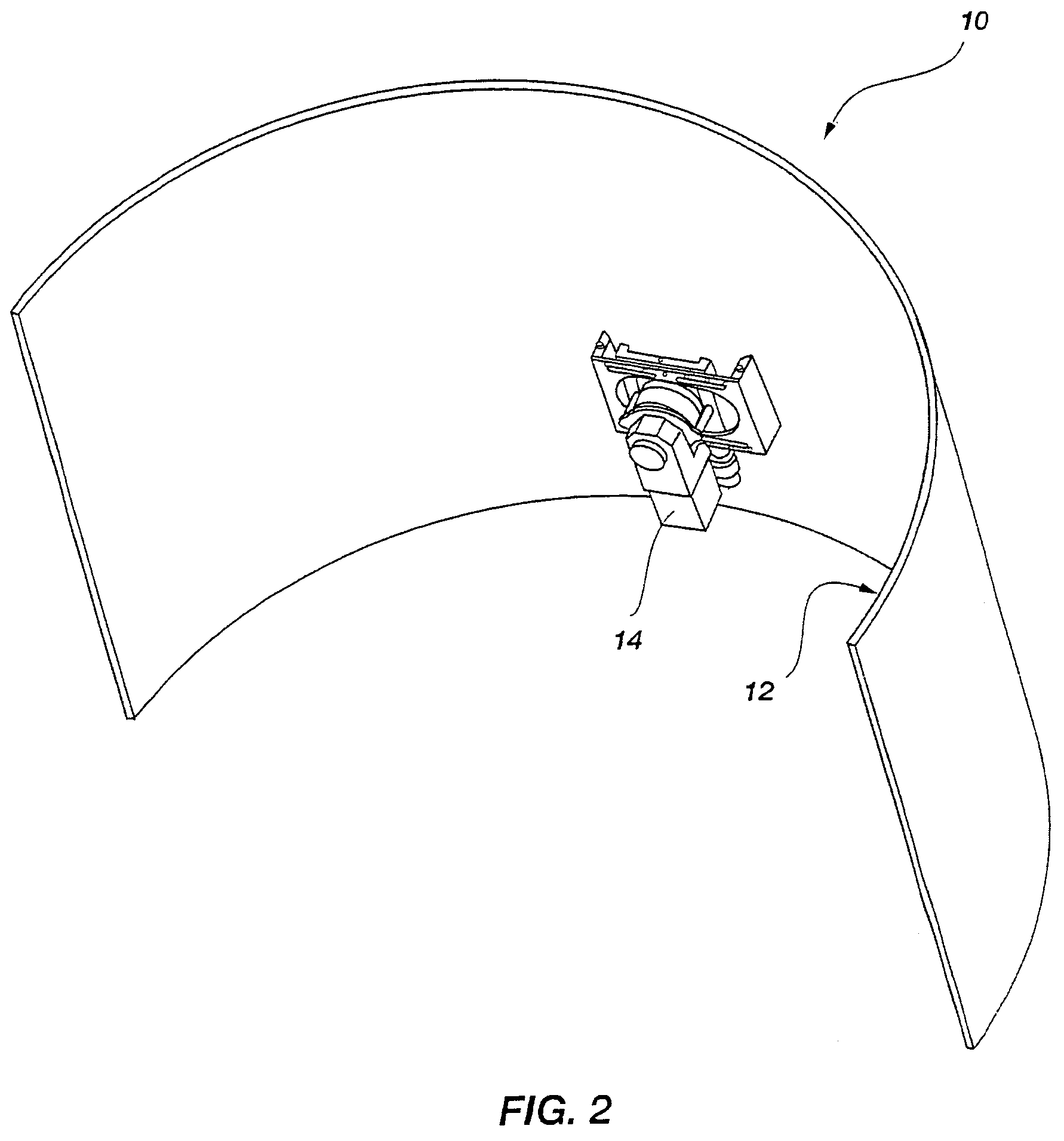

Methods for measuring and modeling the process of prestressing concrete during tensioning/detensioning based on electronic distance measurements

Methods are disclosed for nondestructive testing and measuring the structural health of prestressed concrete structures, such as slabs, columns, girders, bridges, towers, elevated storage tanks, silos, cooling towers, wind power generation towers, liquefied gas storage tanks, nuclear power containment buildings, and the like. Measurements are made as the structure undergoes tensioning and detensioning operations. By measuring actual movements of cardinal points on the structure, in an absolute three-dimensional coordinate system, and comparing the measurements to a model—as tension on a tendon is changed—a margin of safety is assured. High accuracy measurements are made by electronic distance measurement (EDM) instruments over hundreds of meters, which yield coordinates of cardinal points with an uncertainty of the order of one part per million. The methods are proposed as possible alternatives to prior failures of post-tensioned concrete, including the Las Lomas Bridge, the Kapiolani Interchange On-Ramp, Turkey Point Unit 3 Nuclear Power Plant, and Crystal River Unit 3 Nuclear Power Plant. An extensive review of the most closely related prior arts is included.

Owner:SOPHIE LIN TRUSTEE OF THE JOHN MICHAEL PAYNE FAMILY TRUST +1

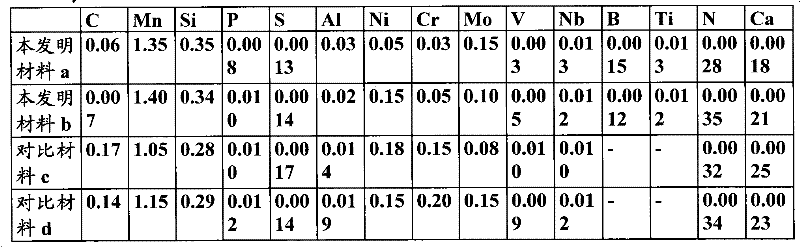

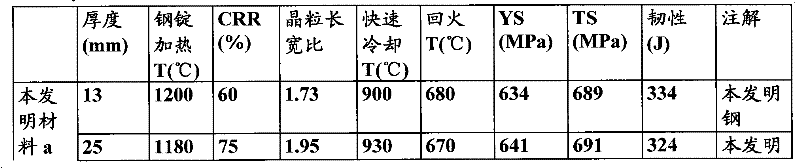

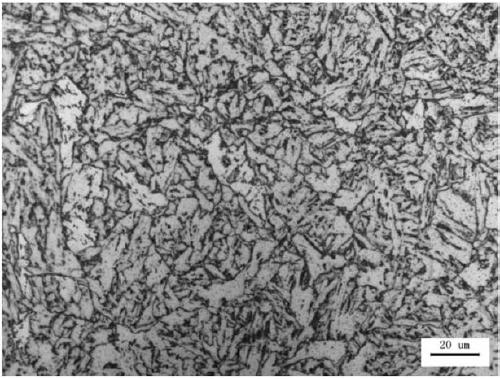

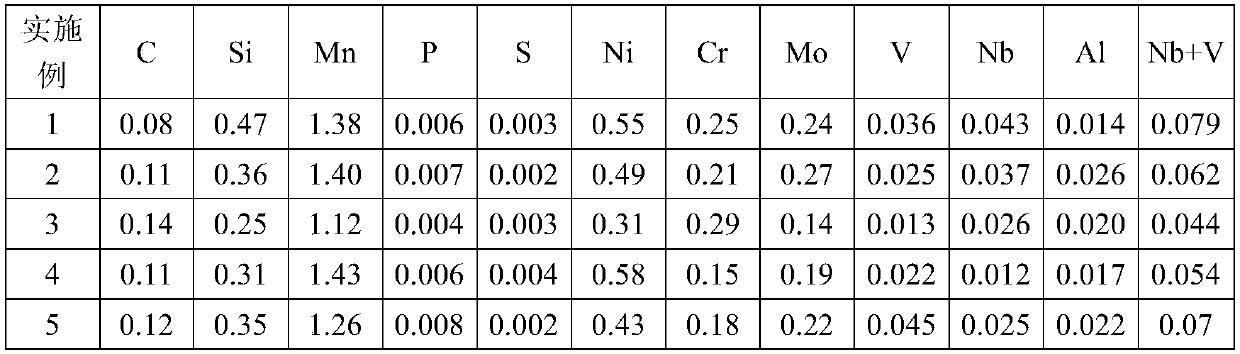

High-strength steel plate for nuclear reactor containment and manufacturing method thereof

InactiveCN102264936AHigh tensile strengthLarge impact toughnessNuclear reactor coreContainment building

Owner:POHANG IRON & STEEL CO LTD

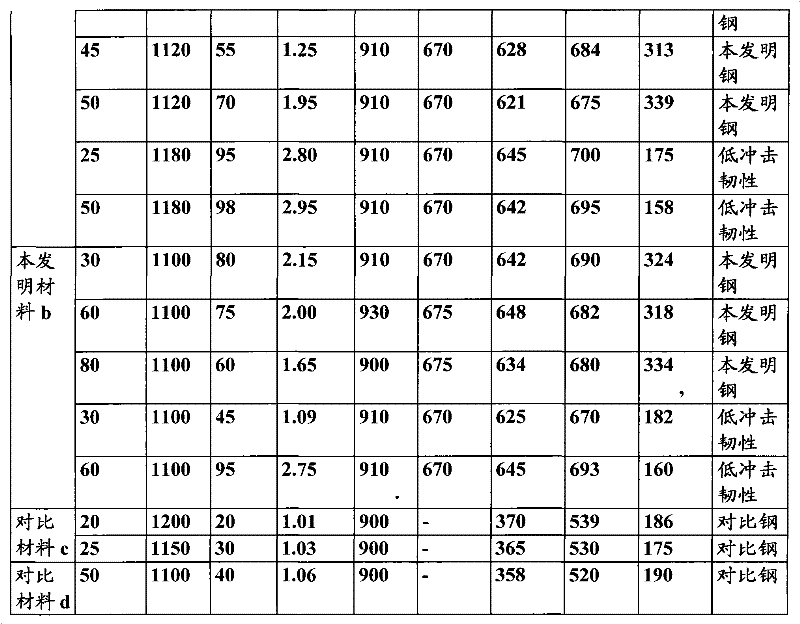

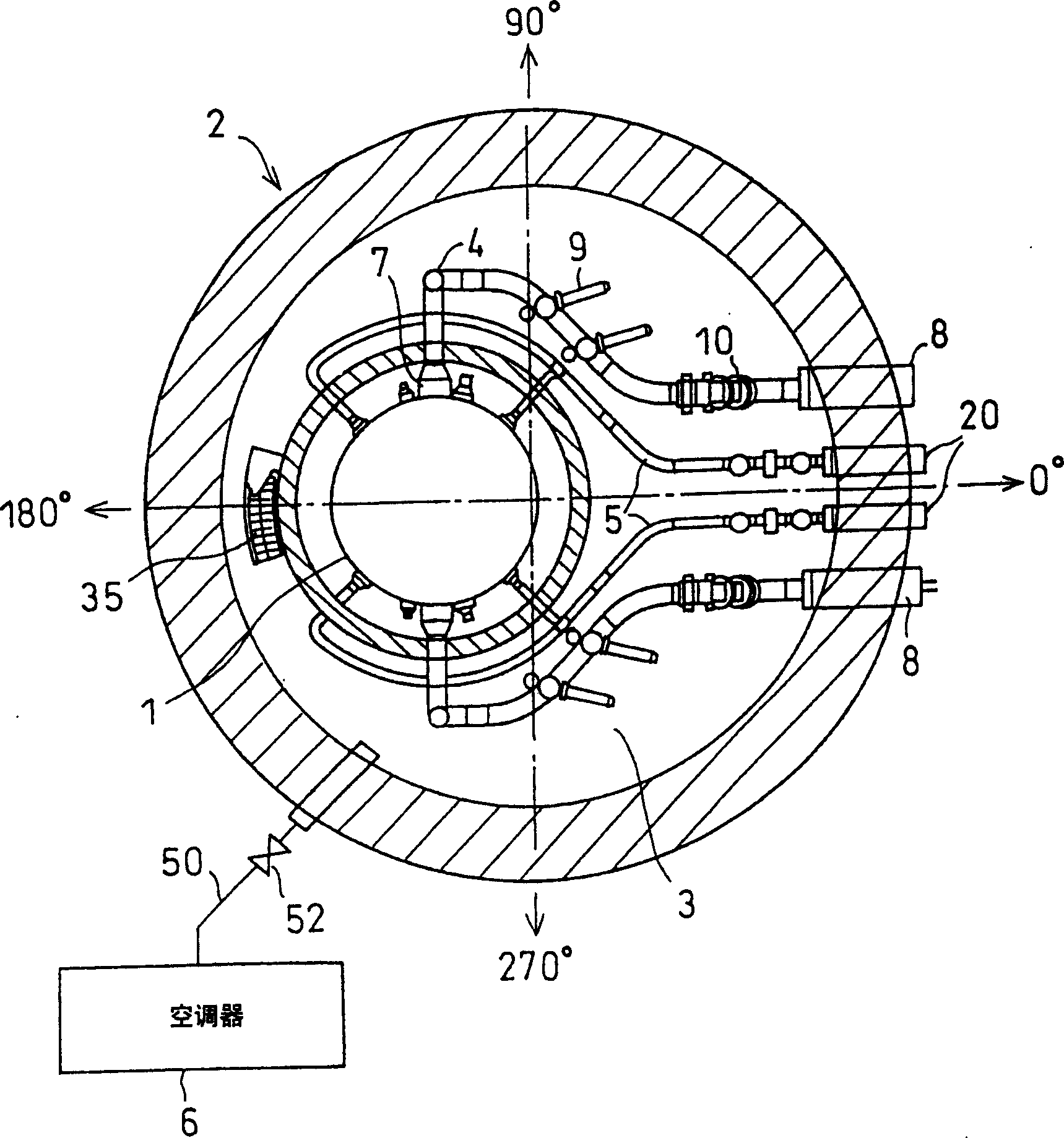

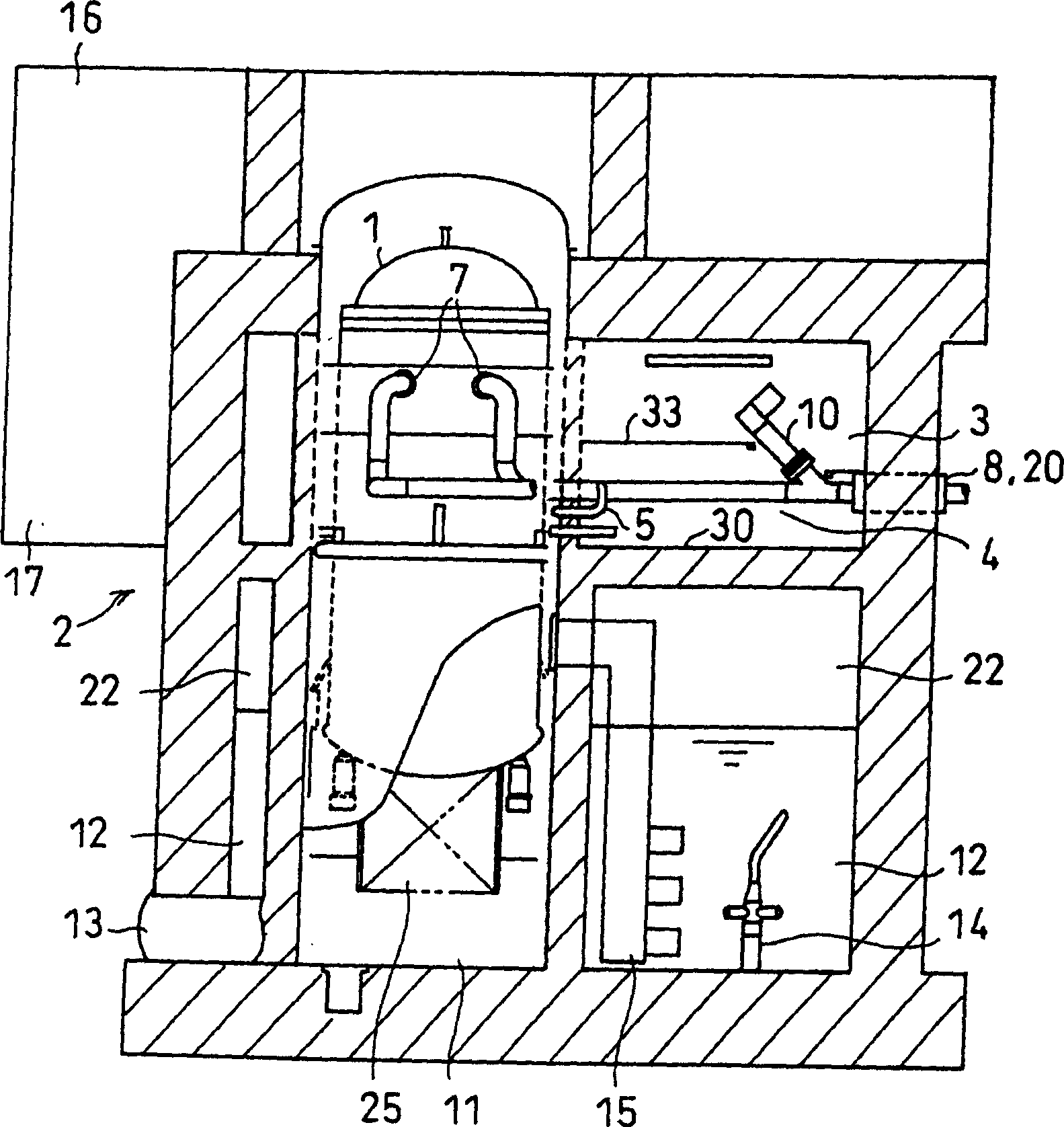

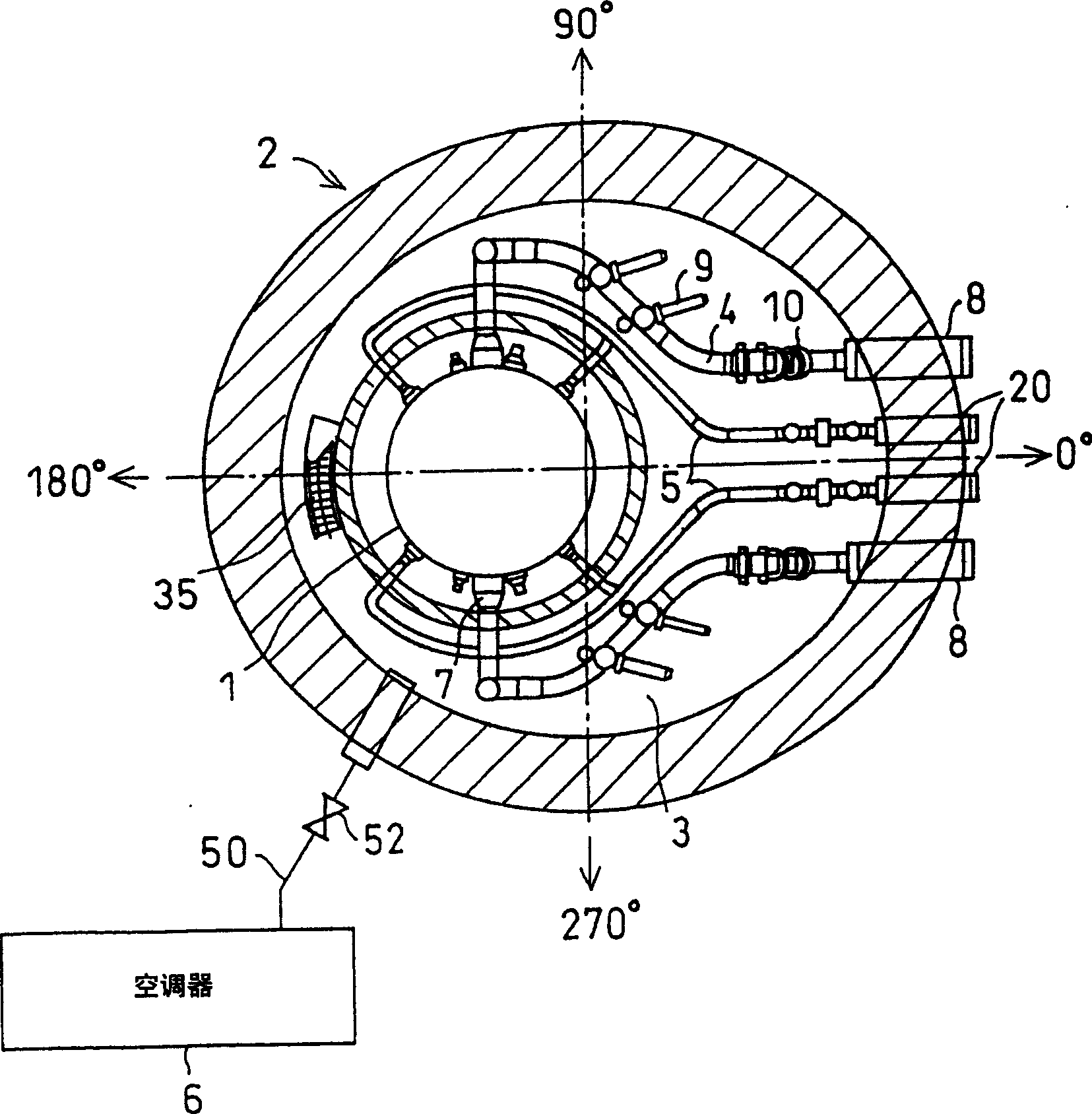

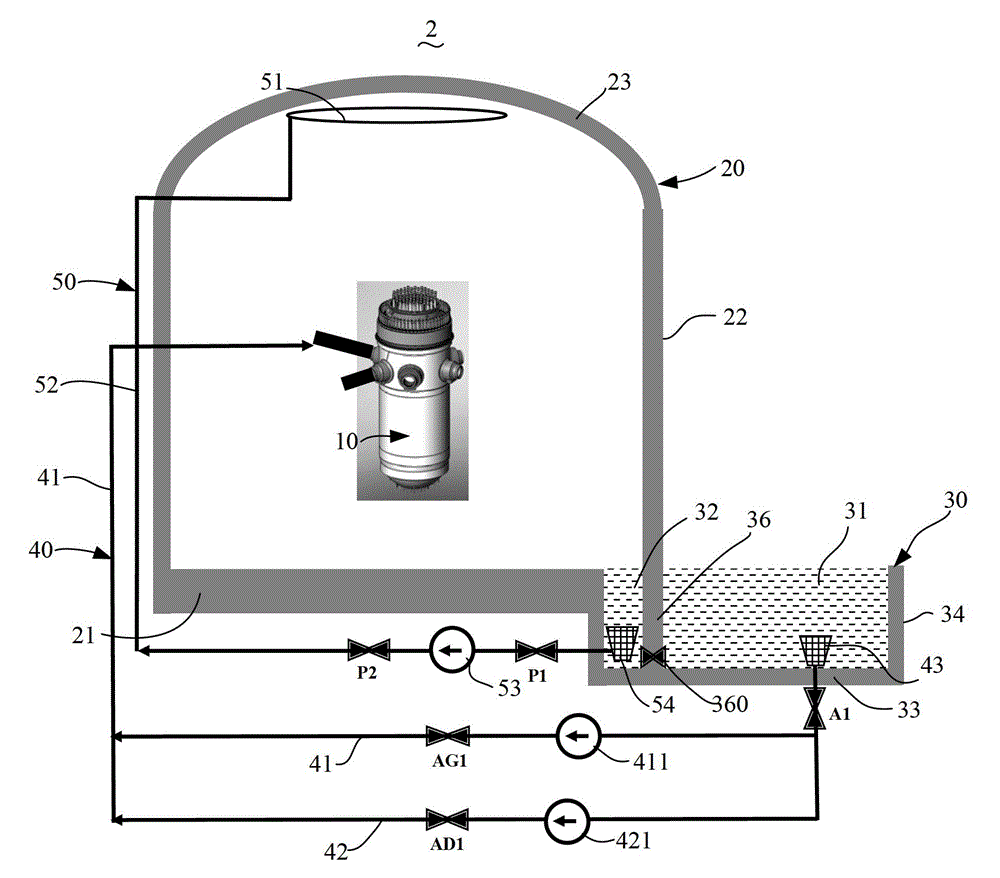

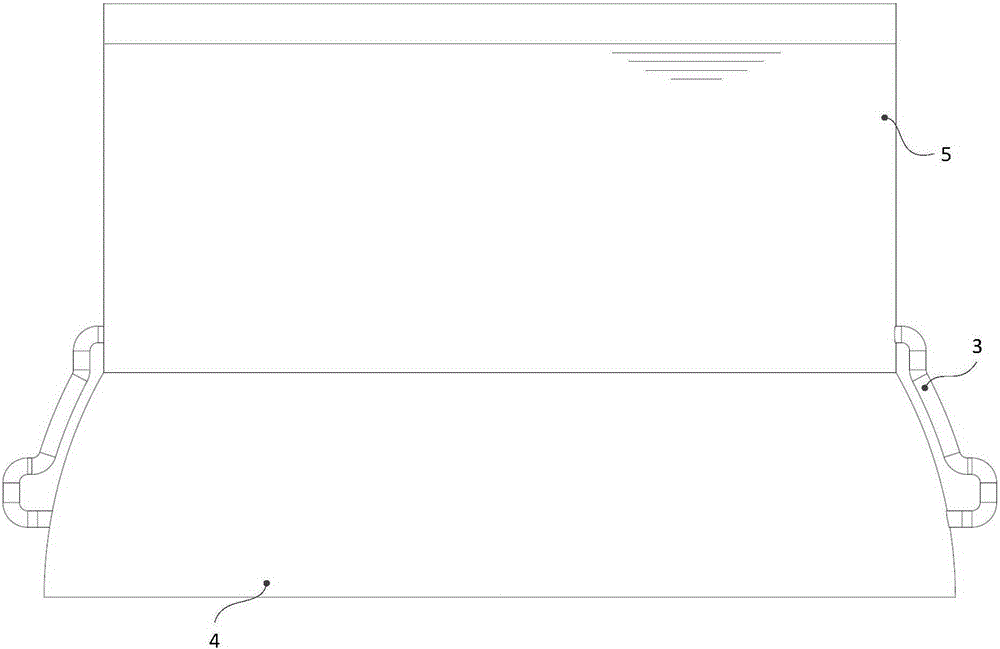

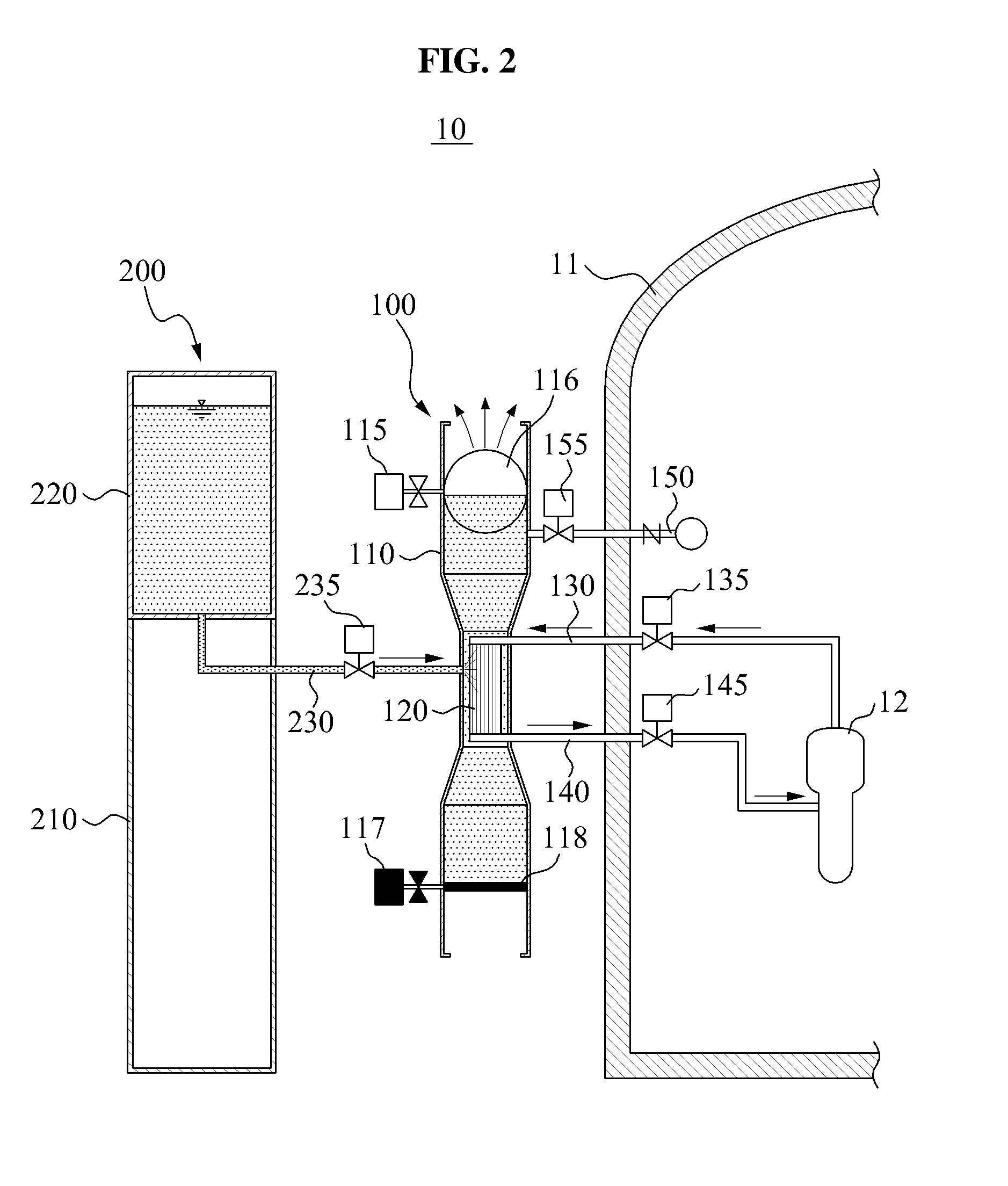

Passive containment vessel spraying device

InactiveCN103489490ASpray evenlyImprove securityNuclear energy generationCooling arrangementNuclear reactorActive component

The invention belongs to a device for spraying and cooling of the outer surface of a containment vessel in a passive mode, and particularly relates to the nuclear reactor containment vessel spraying and cooling device. The passive containment vessel spraying device comprises a safe spraying box, the safe spraying box is connected with an annular spraying header through a water transmission pipeline, the annular spraying header is arranged above a containment vessel dome, and a normally closed valve assembly is arranged between the water transmission pipeline and the annular spray header. The passive containment vessel spraying device has the advantages that the passive containment vessel spraying device is different from an active containment vessel interior spraying system of a conventional nuclear power plant and adopts an external spraying mode, does not need a safety-level emergency power supply and active components, and can realize short-term and long-term cooling of the containment vessel during superposition of a reactor loss-of-coolant accident or a main steam pipeline fracture accident with a station blackout accident and other superposition of multiple extreme accidents.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Nuclear reactor safety casing

A reactor containment vessel of a boiling water reactor configured to contain a reactor pressure vessel. The reactor pressure vessel is connected to at least one main steam pipe which penetrates the reactor containment vessel at a main-steam-line penetration point. The main-steam-line penetration point is disposed on a first side of the reactor containment vessel. Distance between outer surface of the reactor pressure vessel and inner surface of the reactor containment vessel on the first side is longer than the distance on a second side which is opposite to the first side.

Owner:KK TOSHIBA

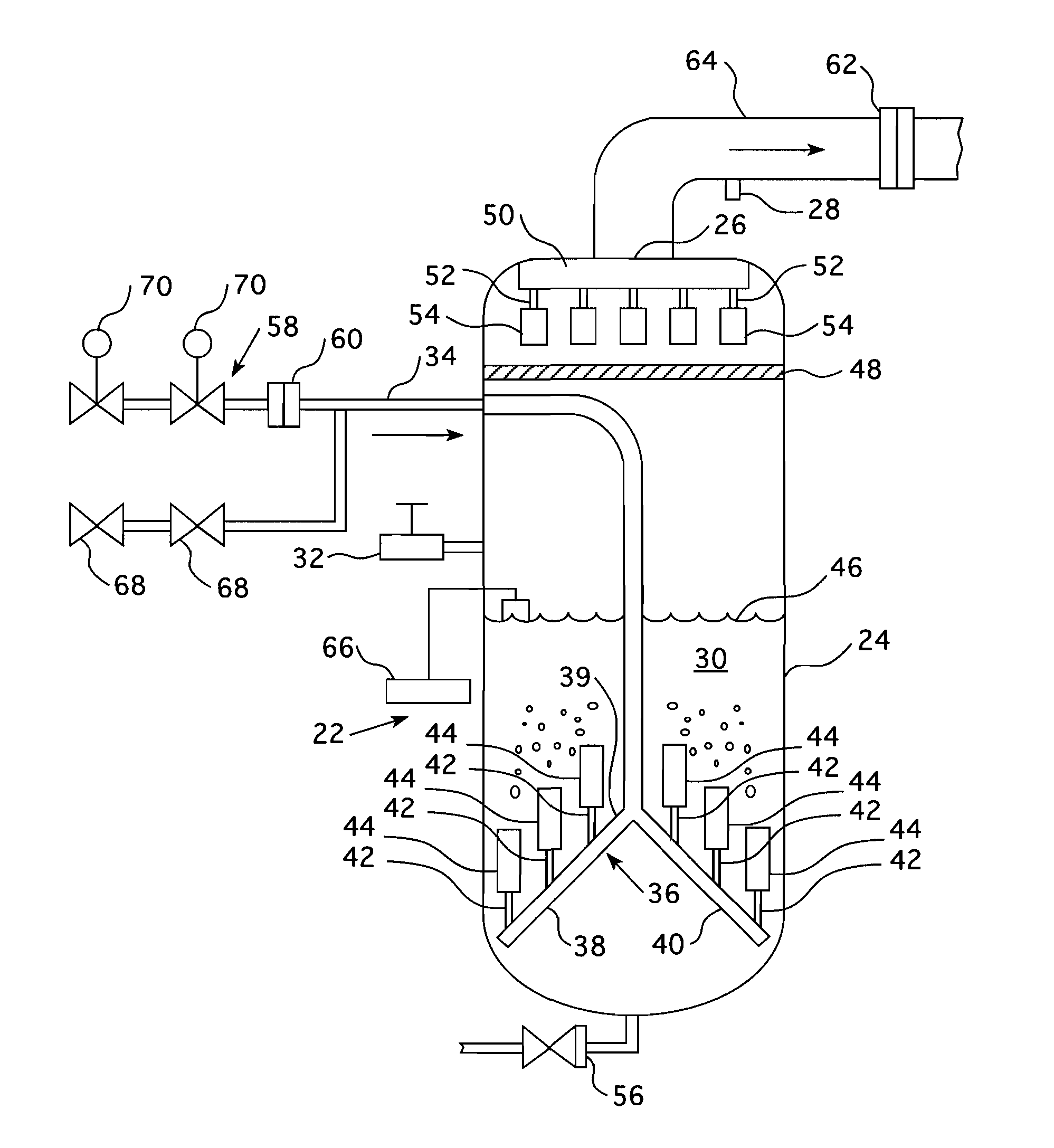

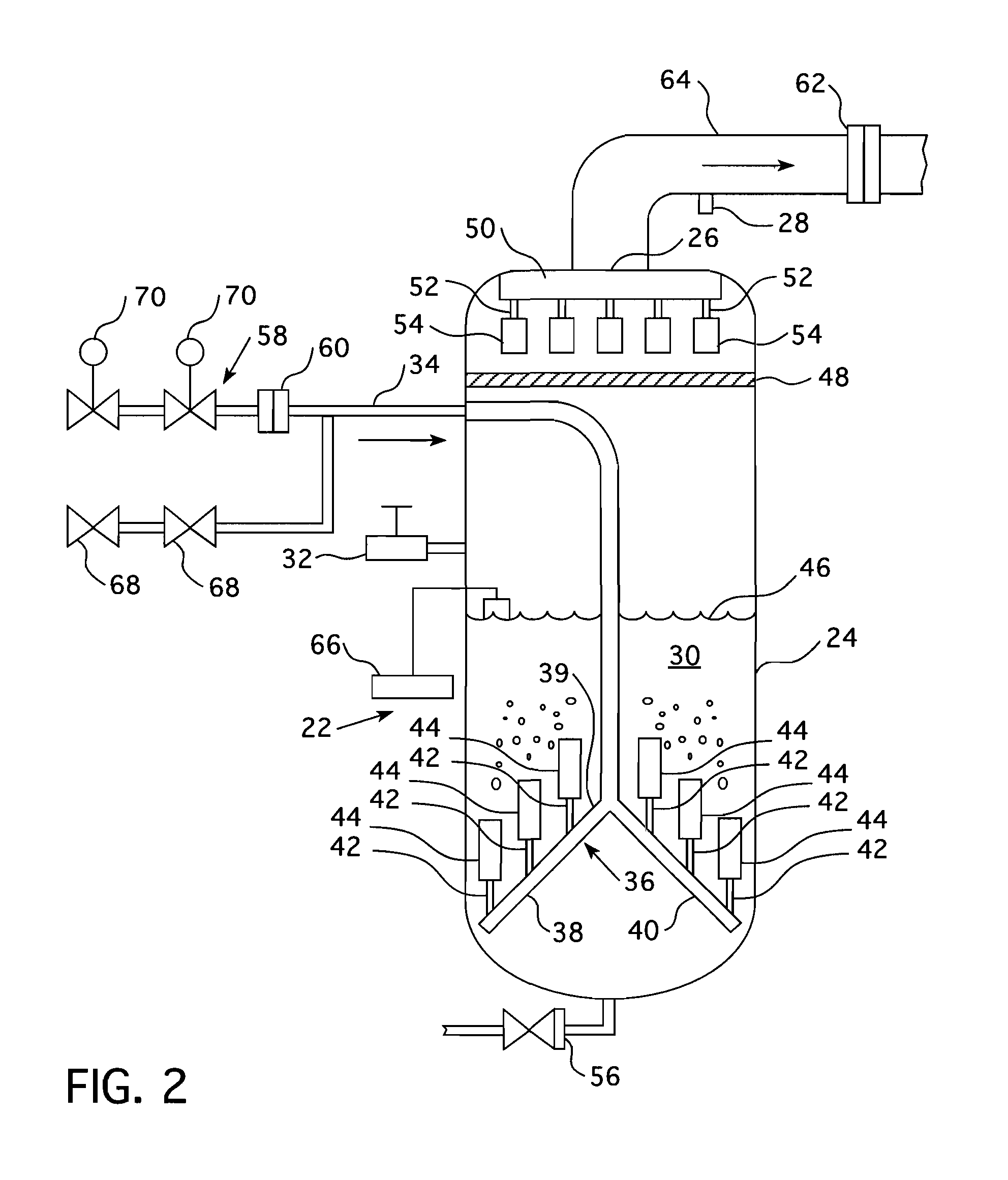

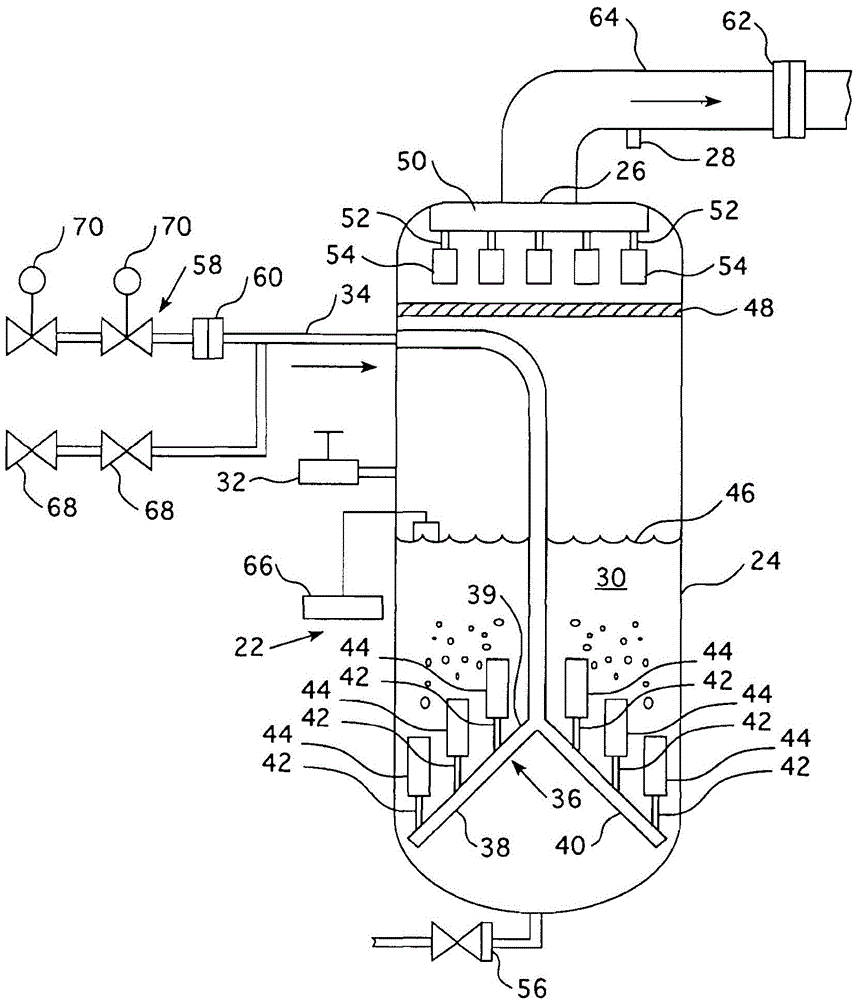

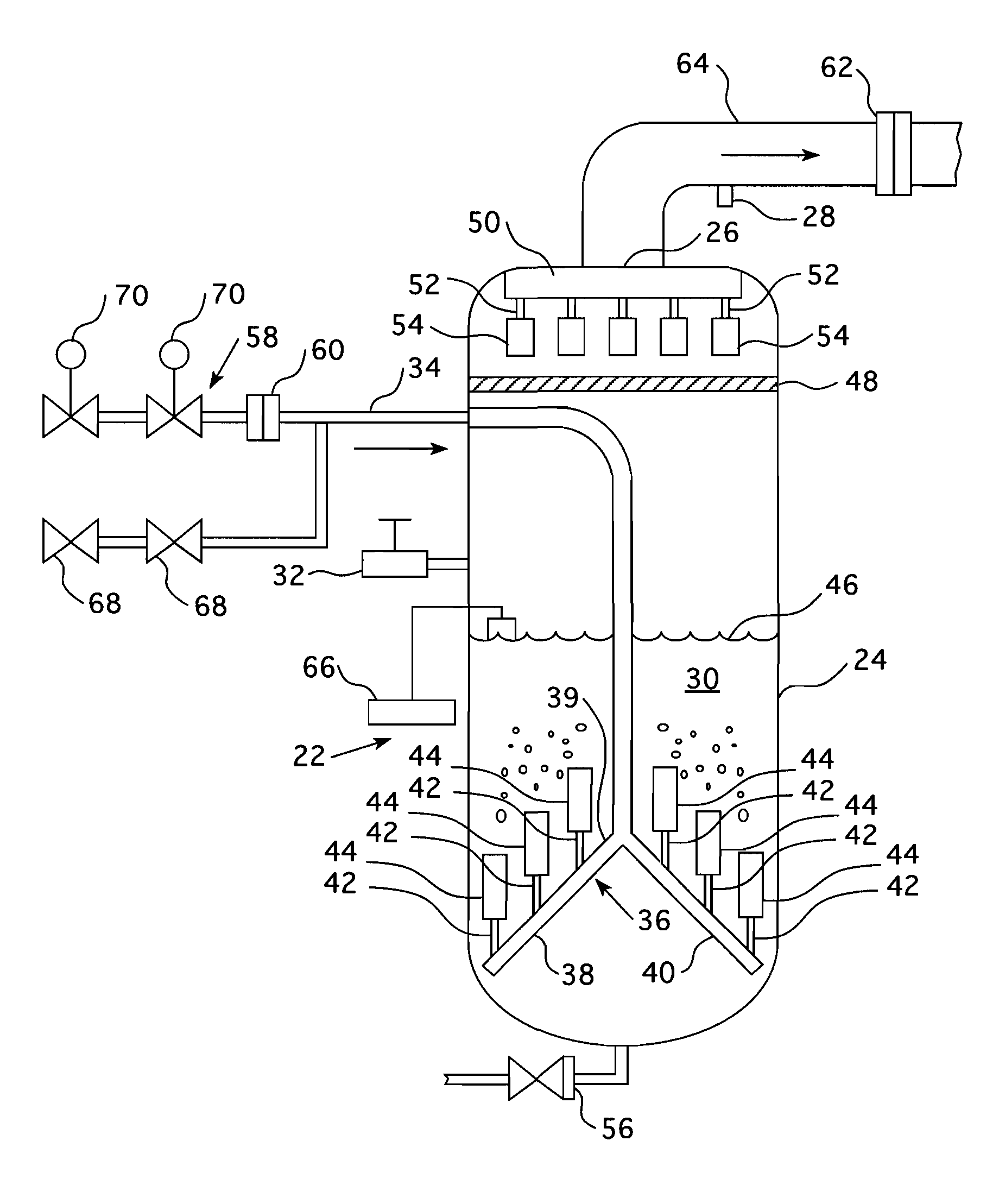

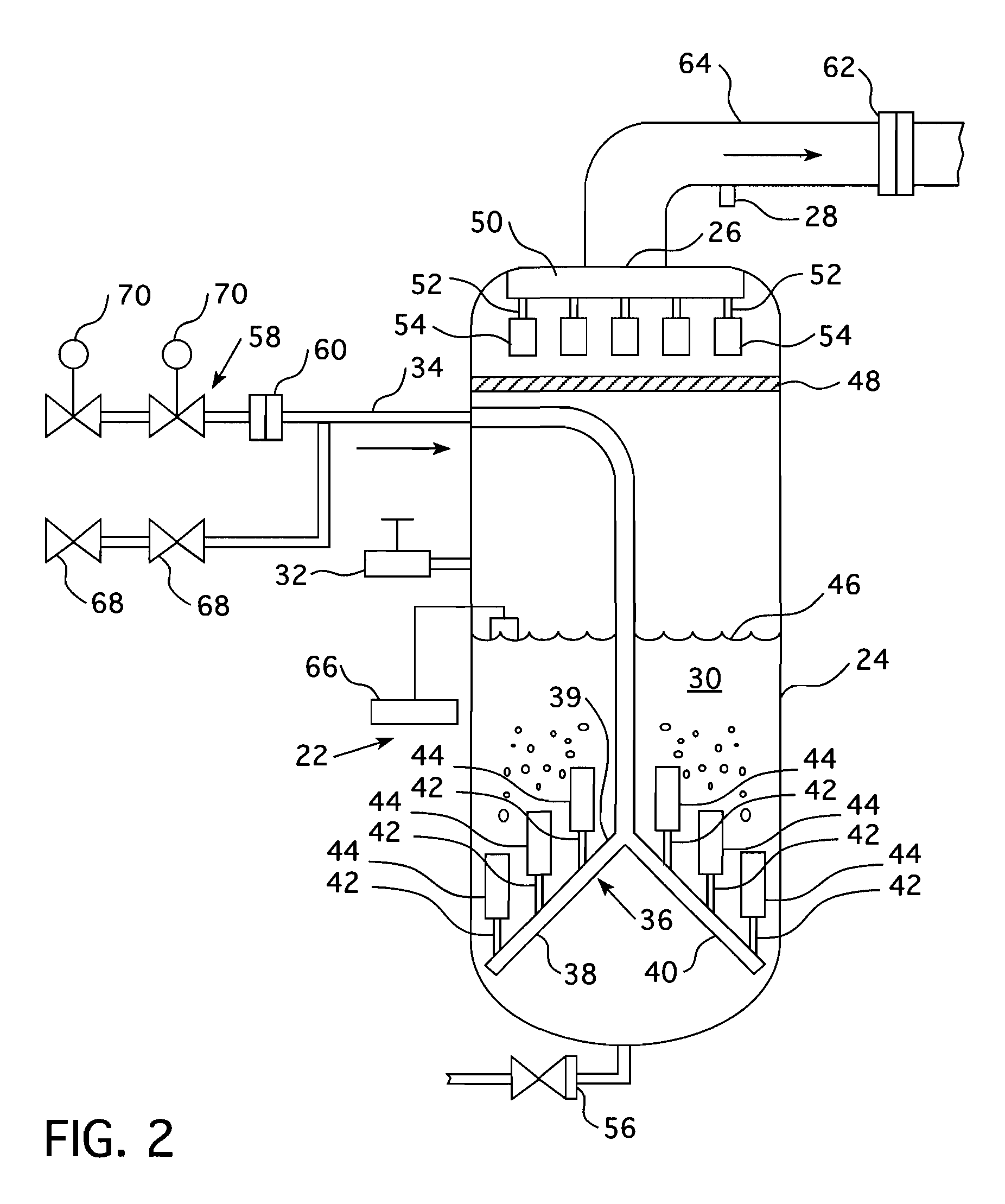

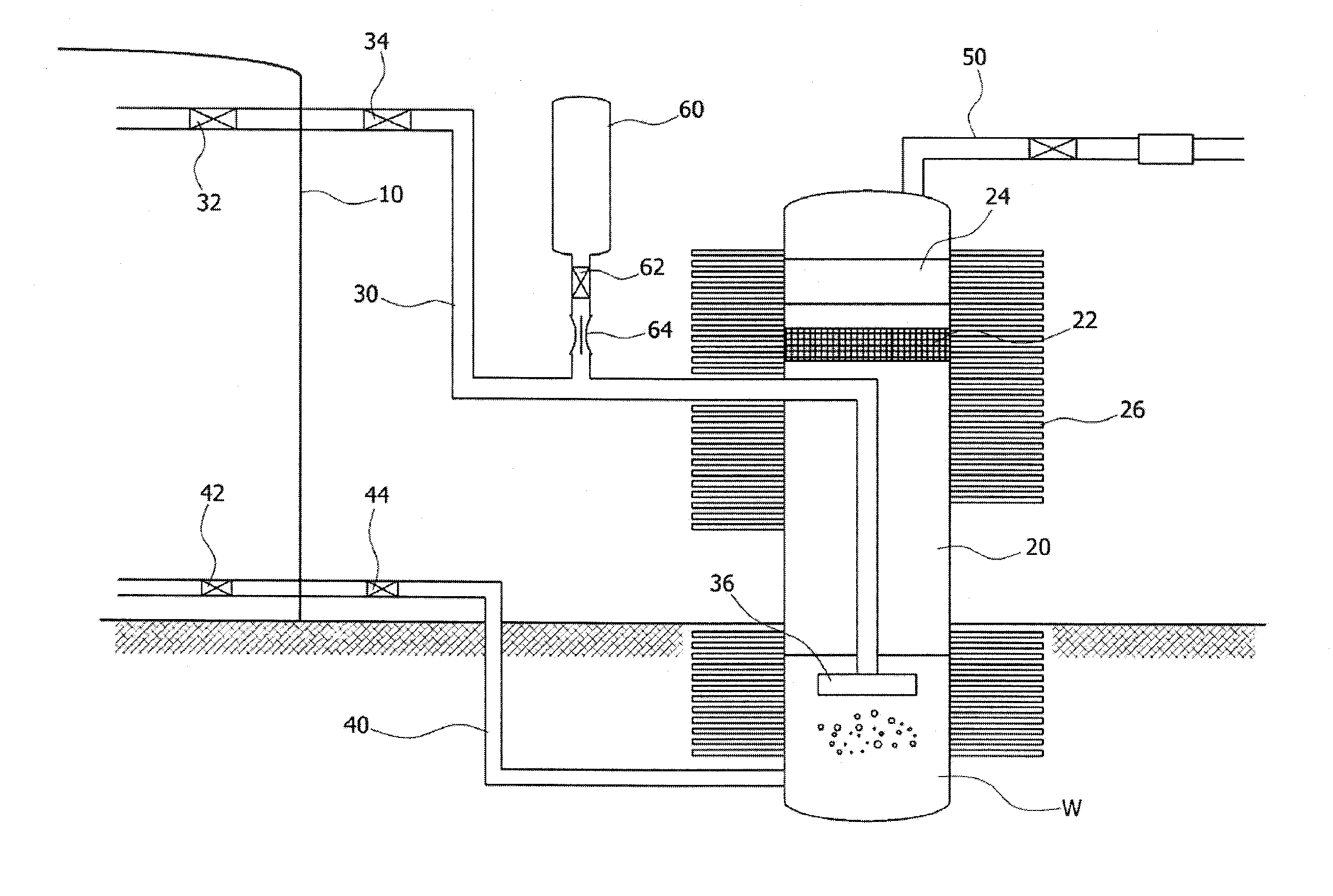

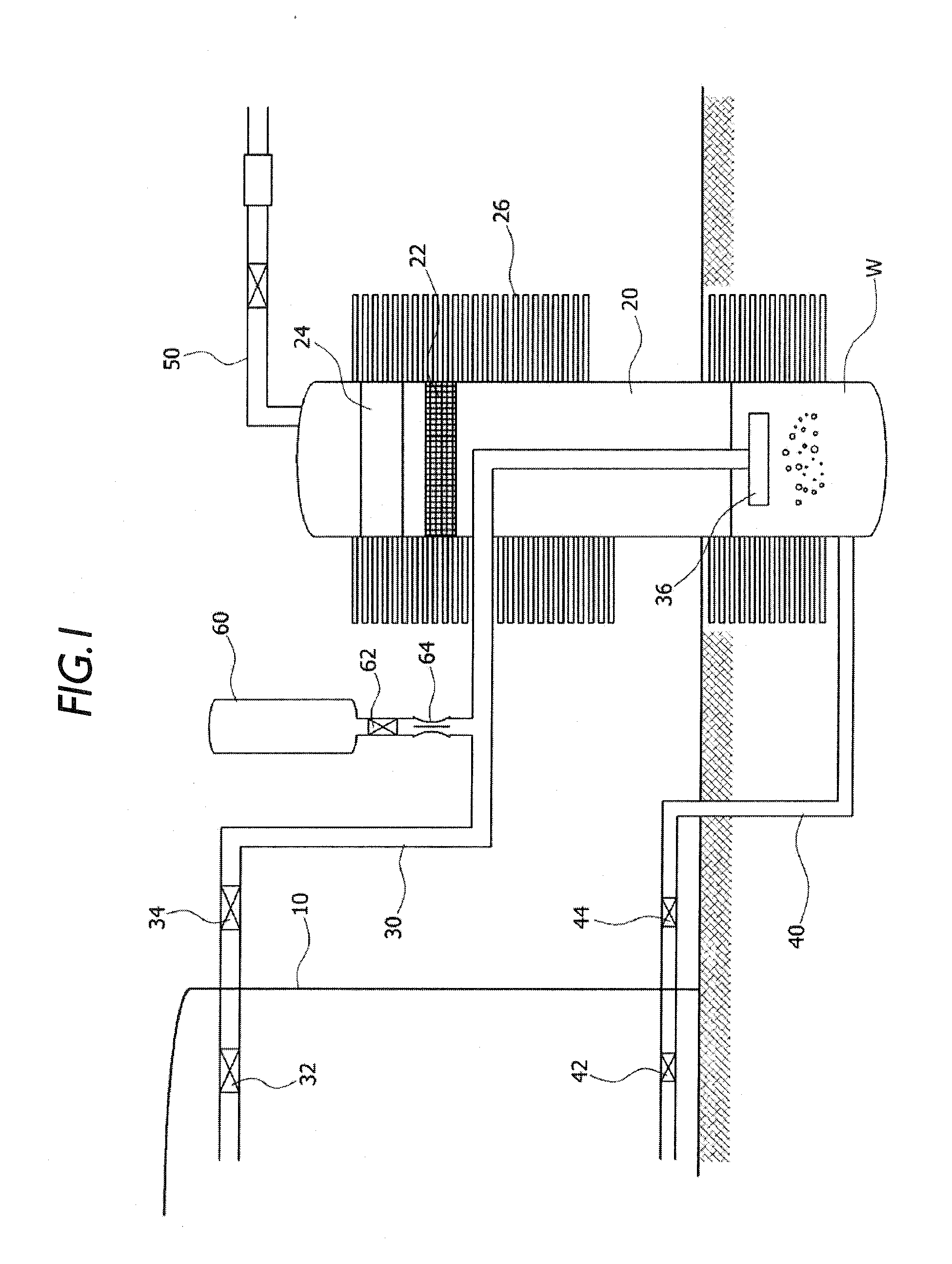

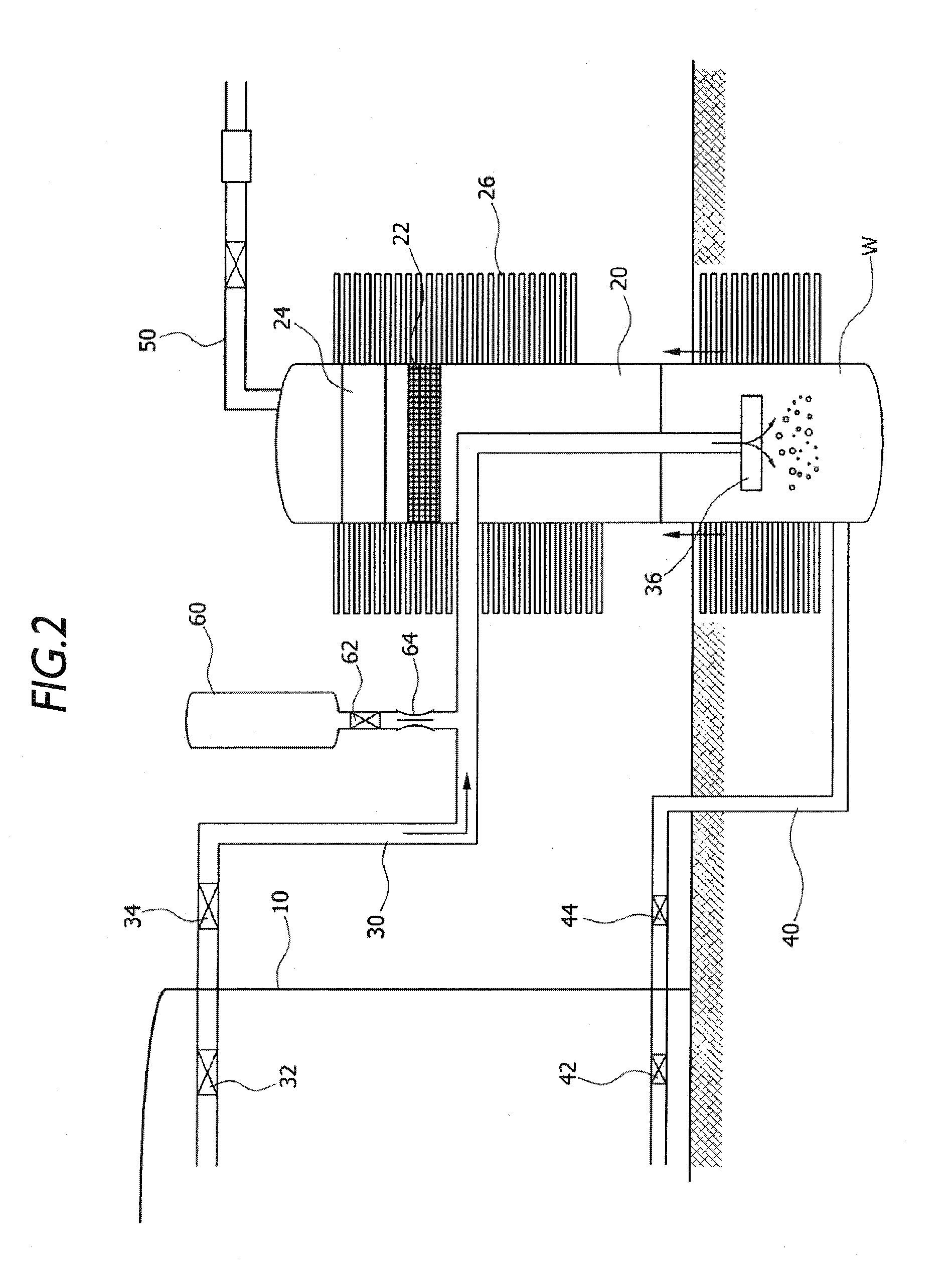

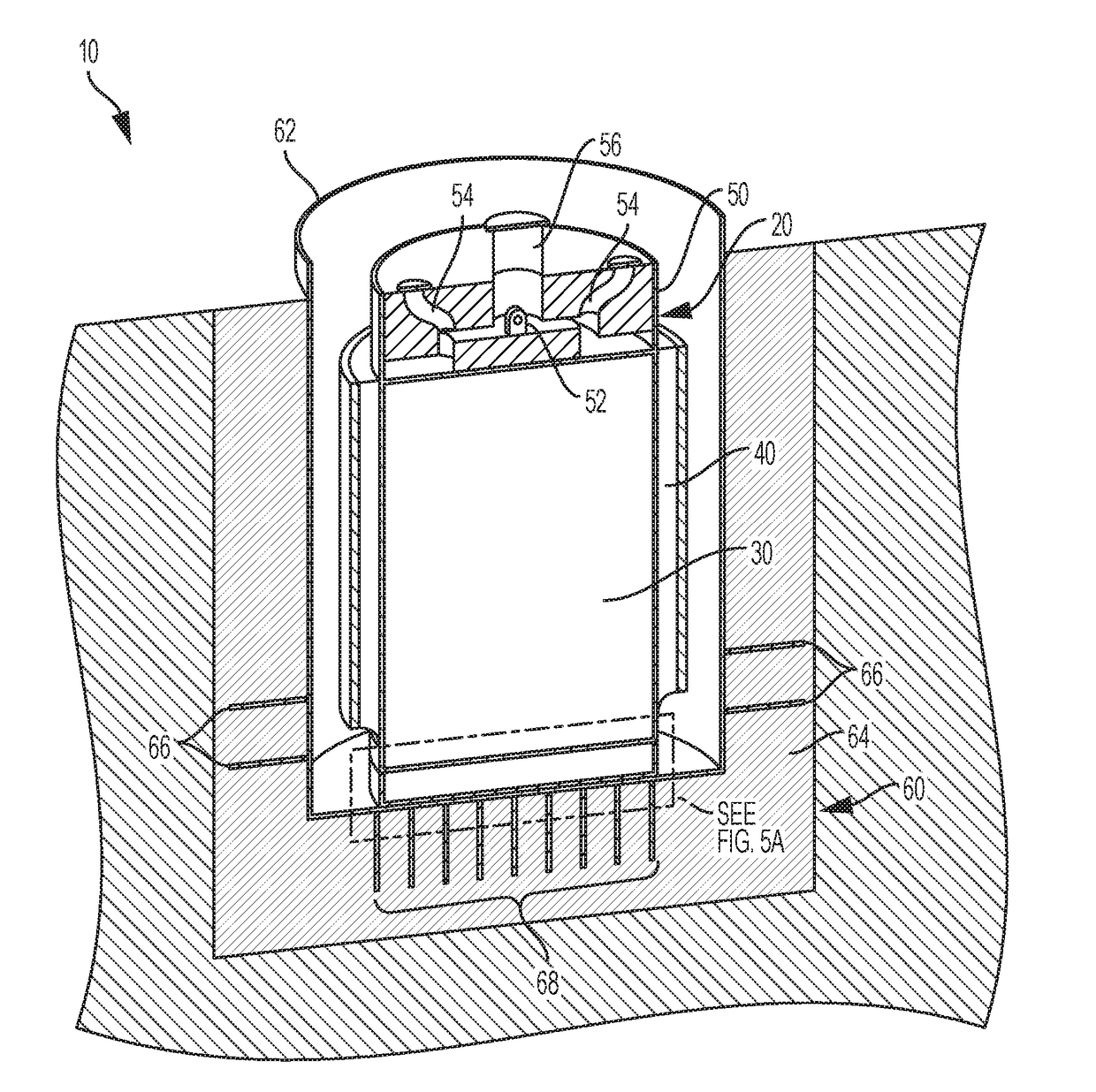

Filter for a nuclear reactor containment ventilation system

ActiveUS20140010340A1Nuclear energy generationEmergency protection arrangementsNuclear reactorHigh density

A wet filter for a nuclear reactor primary containment vent that employs an inclined manifold having a plurality of outlets that communicate through a first set of metal fiber filters submerged in a pool of water enclosed within a pressure vessel. A demister suspended above the pool of water to remove any entrained moisture in the filtered effluent before being passed through a second stage of higher density, dry, metal fiber filters connected to a second manifold that communicates with an outlet on the pressure vessel that is connected to an exhaust passage to the atmosphere.

Owner:WESTINGHOUSE ELECTRIC CORP

Crack repair using friction stir welding on materials including metal matrix composites, ferrous alloys, non-ferrous alloys, and superalloys

InactiveUS7225968B2Avoid loopholesWelding/cutting auxillary devicesAuxillary welding devicesCrazingEngineering

A system and method of using friction stir welding and friction stir processing to perform crack repair or preventative maintenance of various materials and structures, wherein the structures include pipeline, ships, and nuclear reactor containment vessels, wherein the friction stir welding and processing can be performed on various materials including metal matrix composites, ferrous alloys, non-ferrous alloys, and superalloys, and wherein the friction stir welding and processing can be performed remotely and in harsh environments such as underwater or in the presence of radiation.

Owner:BABB JONATHAN A +1

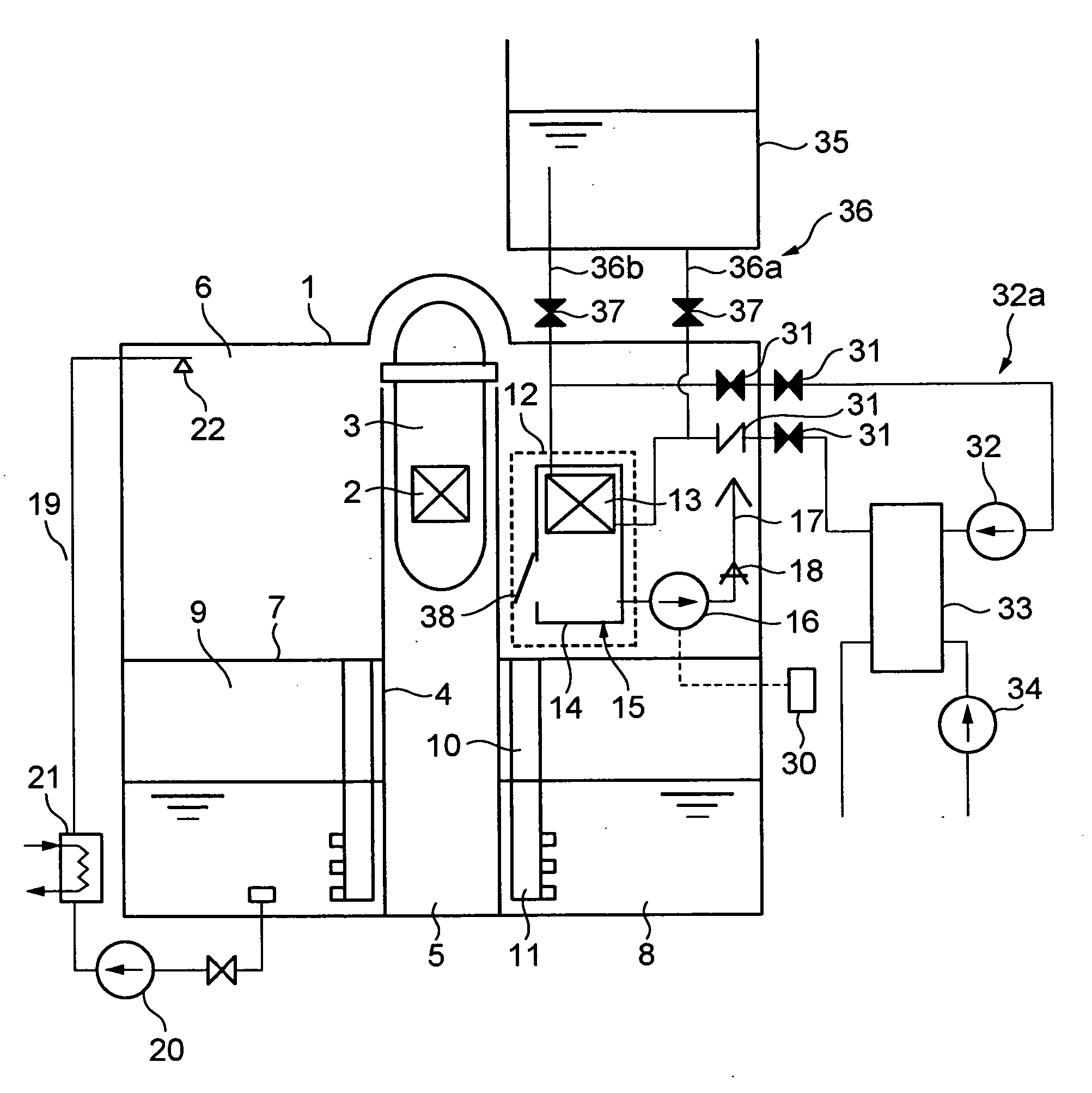

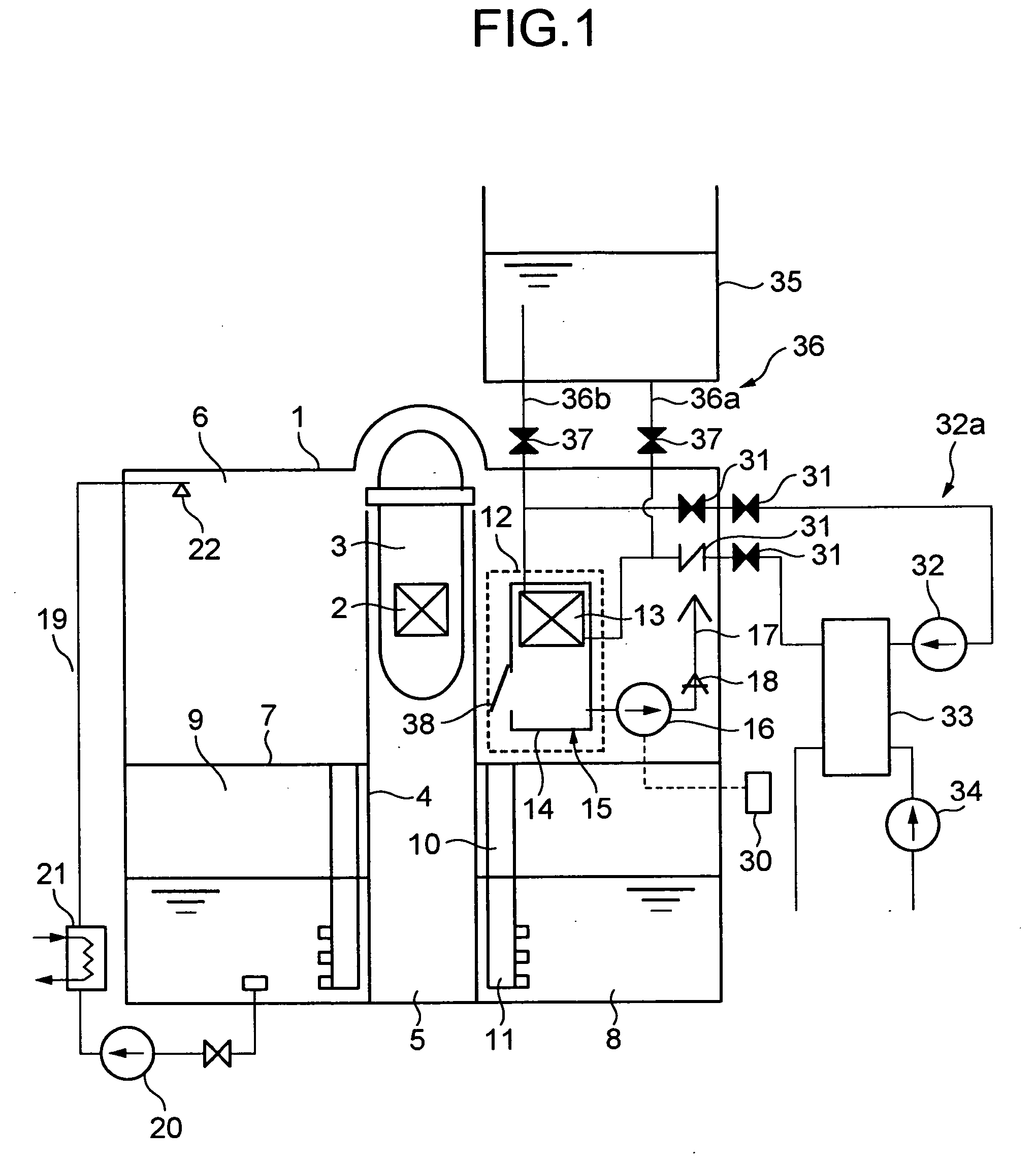

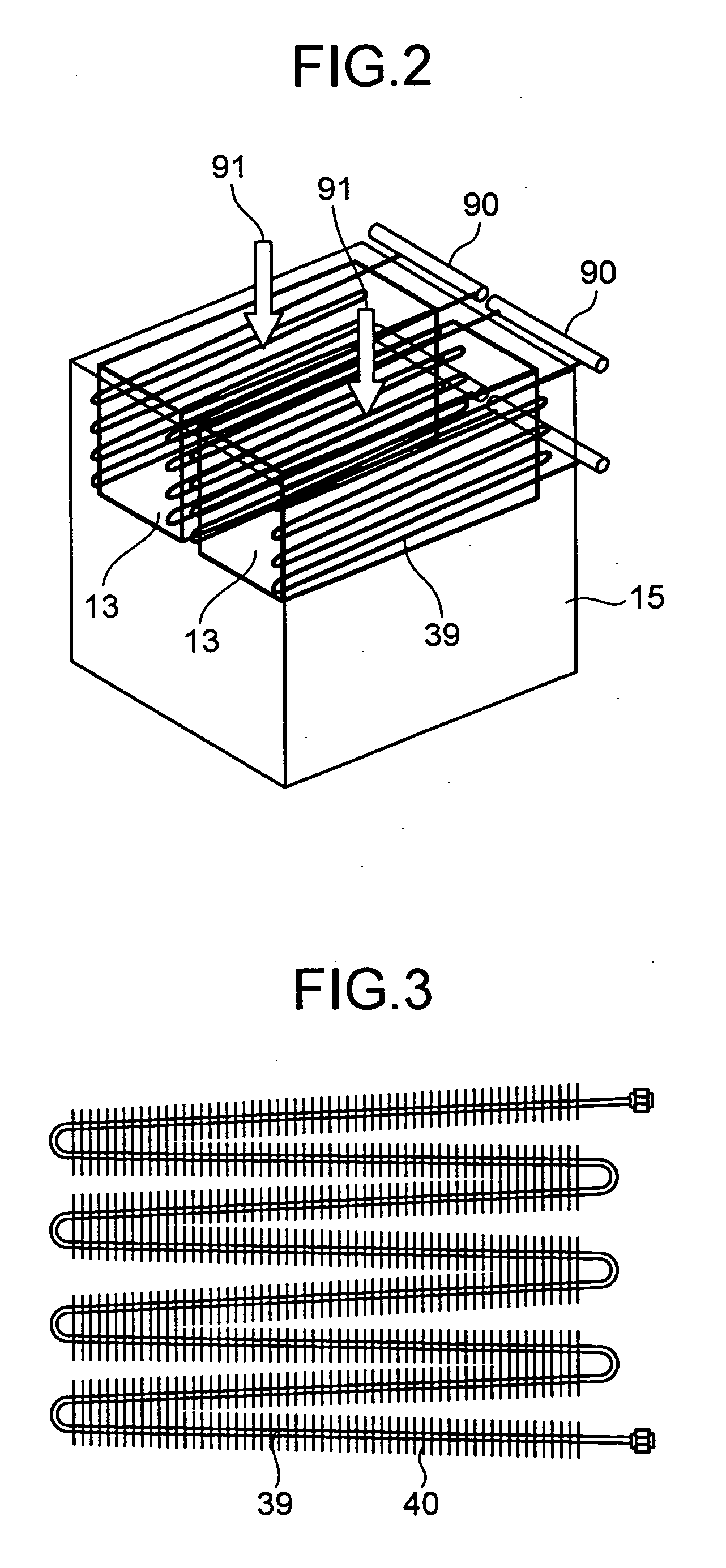

Reactor containment vessel cooling equipment

InactiveUS20070076835A1Reduce steam pressureNuclear energy generationEmergency protection arrangementsNuclear reactorWater circulation

A nuclear reactor containment vessel cooling equipment has: a dry well cooler casing in a containment vessel, having an opening at its top and a shutter at its lower part; a heat transfer tube arranged at an upper part in the dry well cooler casing; a forced cooling water circulation system for feeding cooling water from outside of the containment vessel into the heat transfer tube by a pump; a blower for mobilizing gas around the heat transfer tube; an external pool container arranged outside the containment vessel and above the heat transfer tube and containing cooling water; and a gravity-driven cooling system to supply cooling water in the external pool container into the heat transfer tube, utilizing gravity.

Owner:KK TOSHIBA

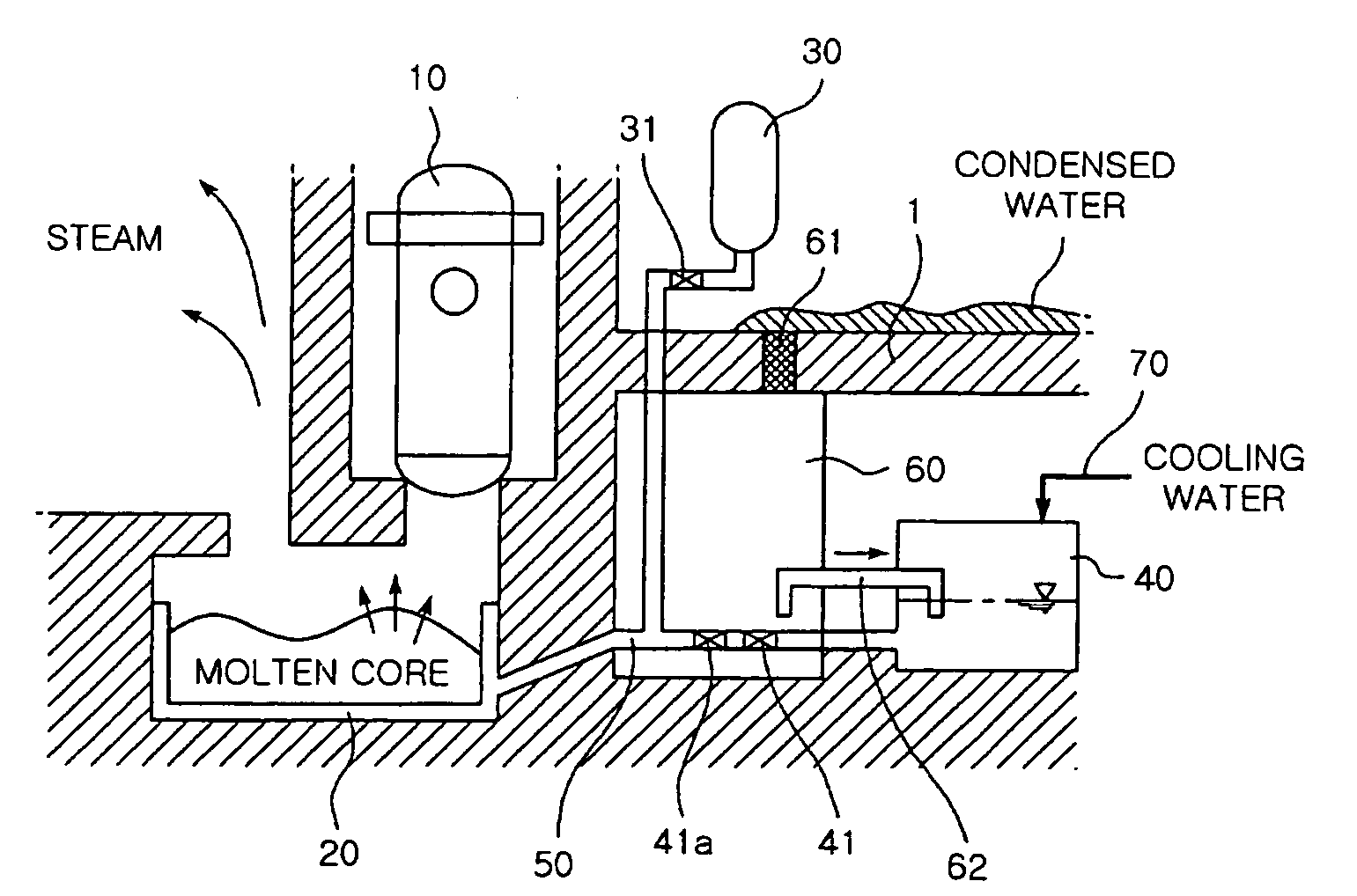

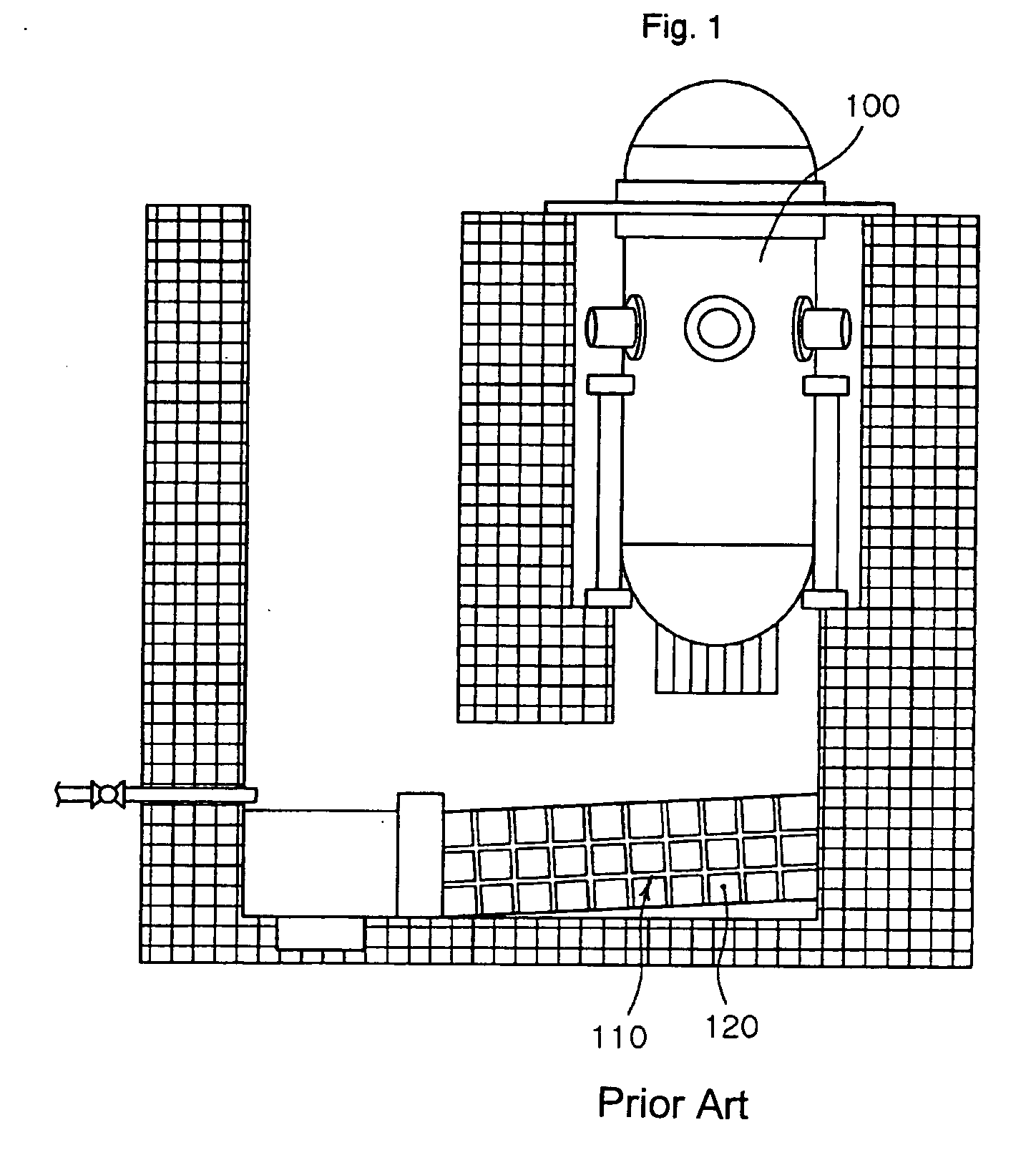

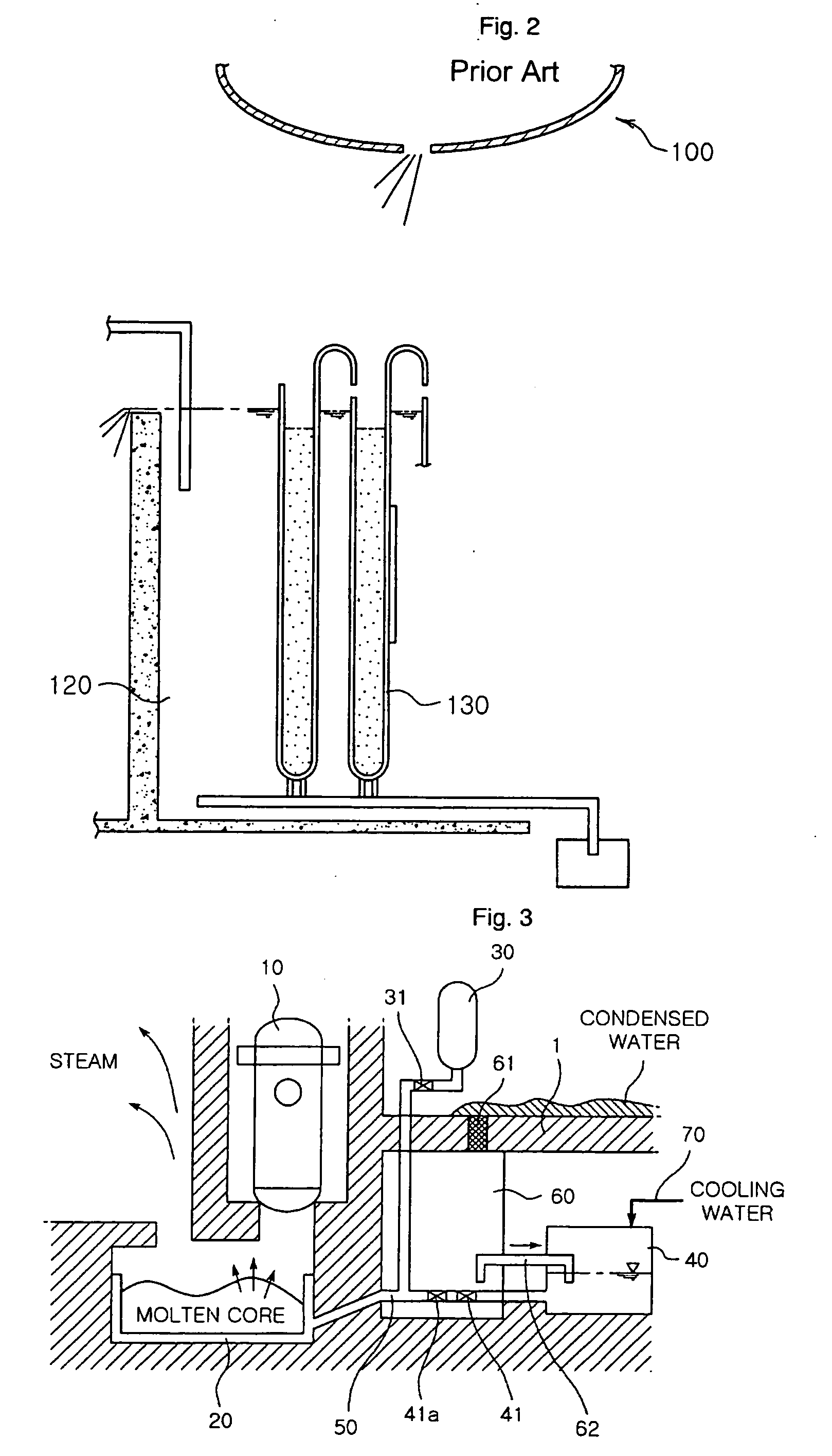

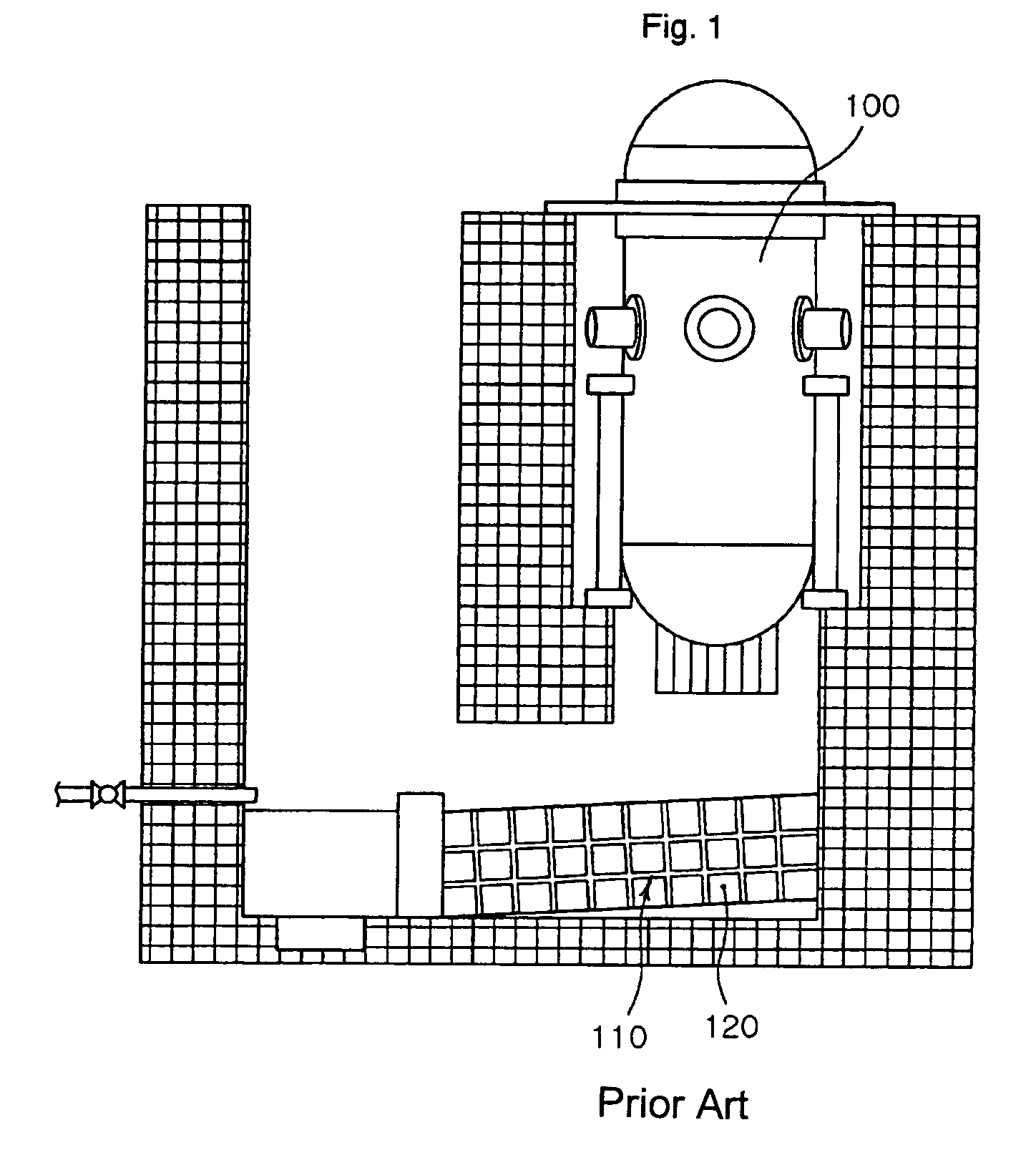

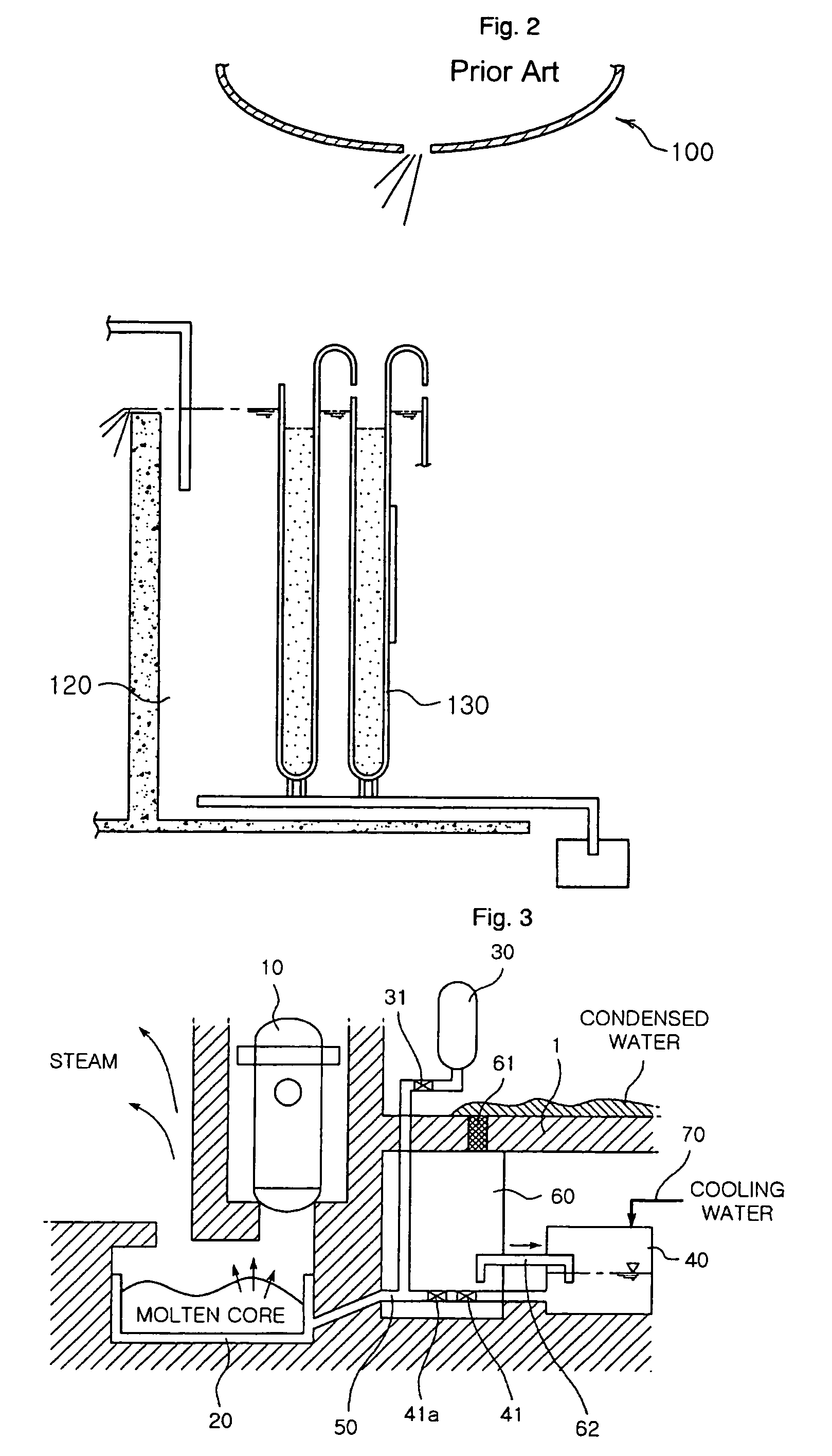

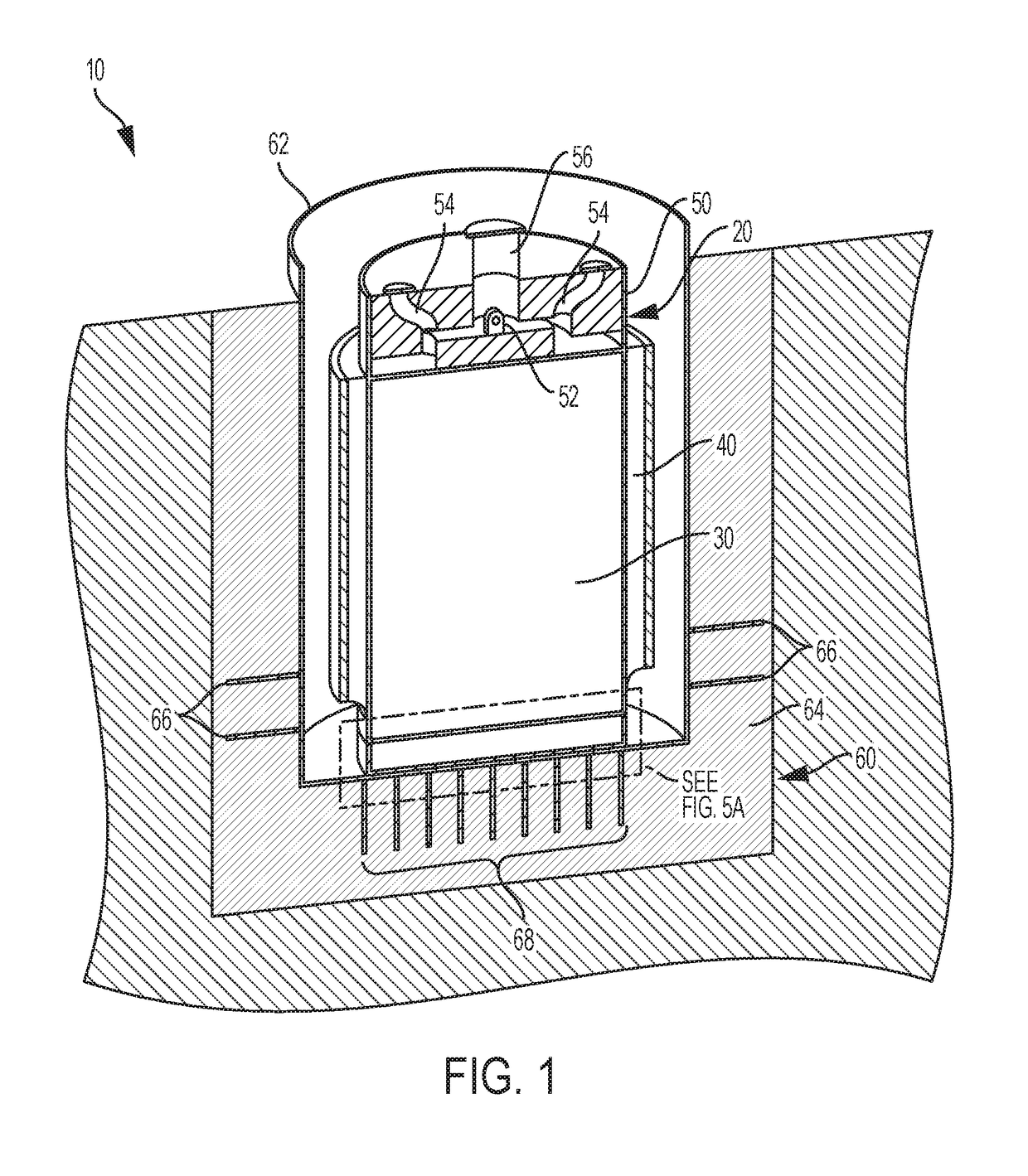

Passive cooling and arresting device for molten core material

ActiveUS20090116607A1Reduce the possibilityEffectively remove decay heatNuclear energy generationNuclear engineering problemsNuclear plantWater storage tank

An apparatus for passively cooling and retaining molten core material discharged from a damaged reactor vessel during a severe accident in the nuclear plant including: a molten core material retention tank to retain molten core material; a compressed gas tank storing high-pressure inert gas; a cooling water storage tank being installed higher than the molten core material retention tank; and a mixing means. The molten core material retention tank includes an outer retention vessel having at least one coolant hole, a porous protection vessel formed at an inside of the outer retention vessel, and a gravel layer formed between the outer retention vessel and the porous protection vessel. The apparatus can be installed in a reactor cavity without changing the compartment structure of a containment building, and makes it possible to prevent a steam explosion during the cooling process for the ultrahigh-temperature molten core material and to secure the reliability of the cooling process.

Owner:KOREA ATOMIC ENERGY RES INST +1

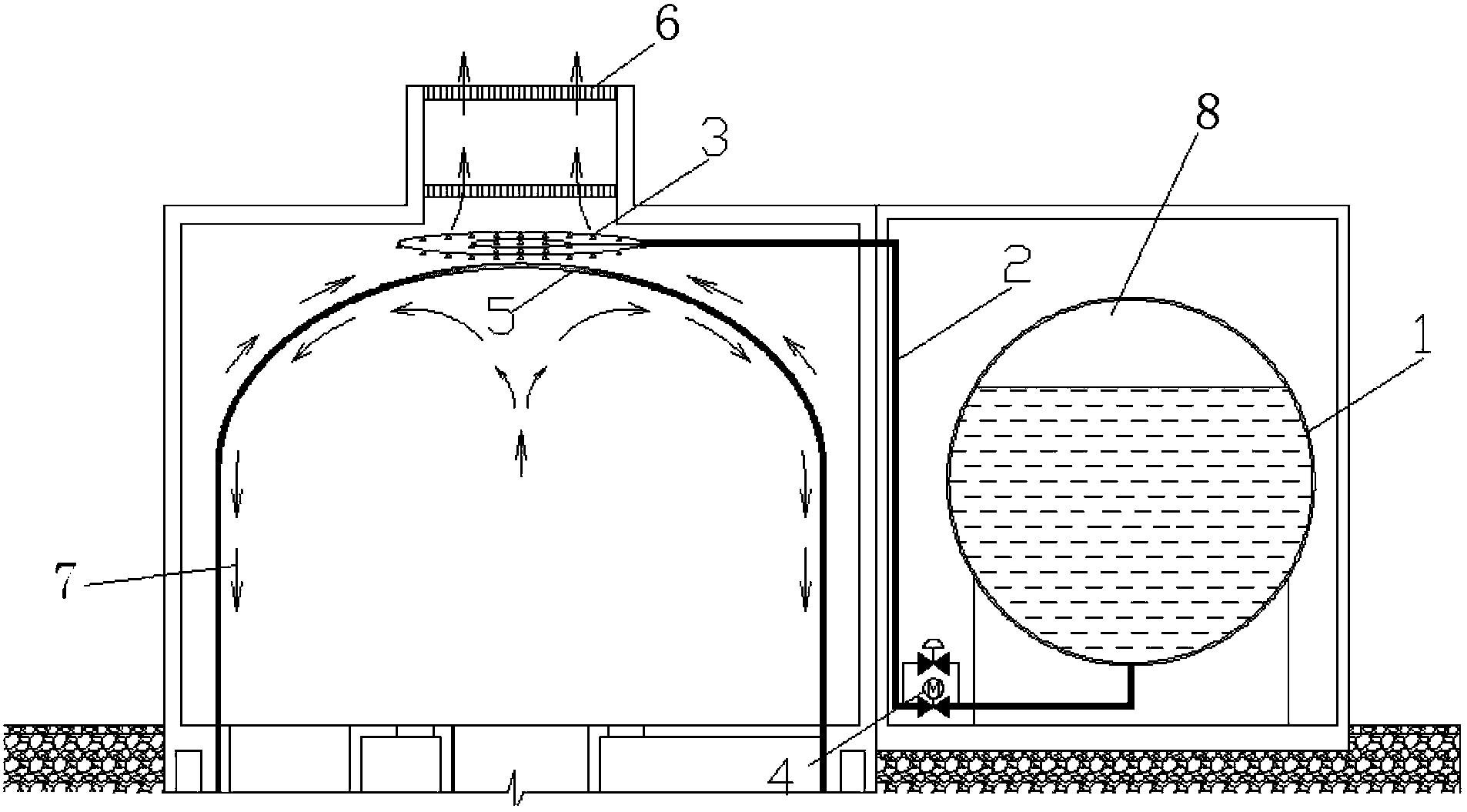

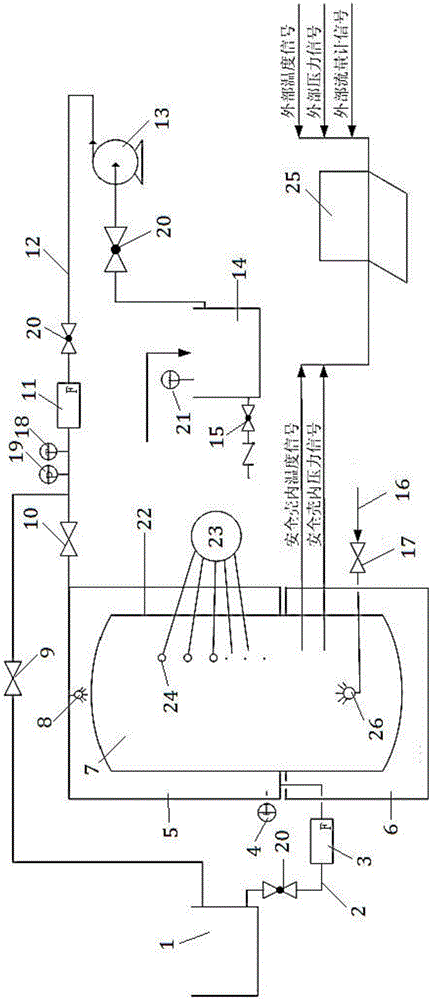

Nuclear reactor containment cooling simulation system and method based on external spraying

ActiveCN105788682ASimple designOptimize layoutPower plant safety arrangementNuclear energy generationNuclear reactor coreThermal spraying

The invention relates to a nuclear reactor containment cooling simulation system and method based on external spraying. The system comprises containment, experiment gas nozzle, a raw water high-level water tank, a variable-frequency spraying water pump, a spraying nozzle and a liquid storage tank, wherein the raw water high-level water tank, the variable-frequency spraying water pump, the spraying nozzle and the liquid storage tank are sequentially connected, the spraying nozzle is located right above the containment, and the experiment gas nozzle is located in the containment; a data collecting device and a mass spectrometer are arranged outside the containment, an inlet flowmeter, an inlet thermocouple, an inlet pressure sensor and an experiment gate valve are sequentially serially connected between the variable-frequency spraying water pump and the spraying nozzle; an outlet thermocouple and an outlet flowmeter are sequentially serially connected between the spraying nozzle and the liquid storage tank. Water is injected through the opening and closing of a water injection gate valve and the experiment gate valve, the spraying nozzle sprays water, and the features and rules of the internal thermal-hydraulic phenomena of the containment after the outside of the containment is sprayed according to obtained data. The nuclear reactor containment cooling simulation system is reasonable in design and widely applicable and provides technical and data support for the engineering construction and design transformation of advanced nuclear reactors of China.

Owner:SHANGHAI JIAO TONG UNIV

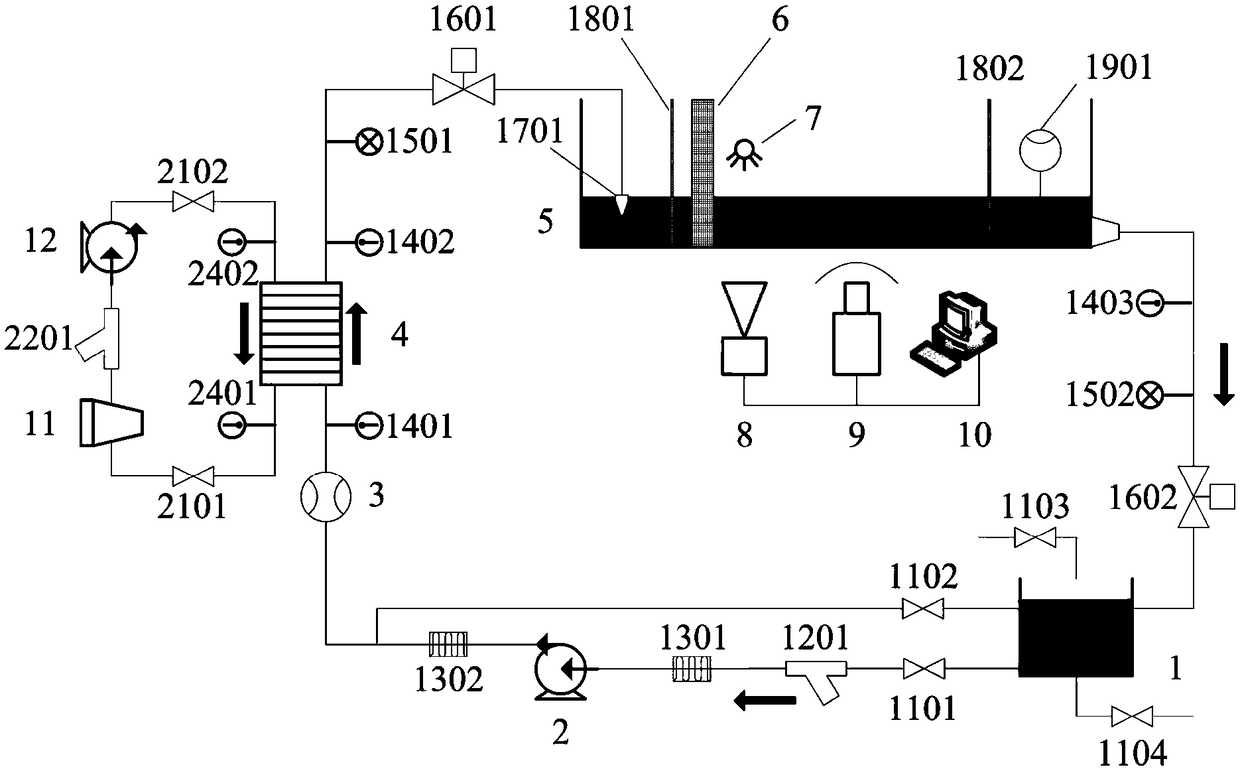

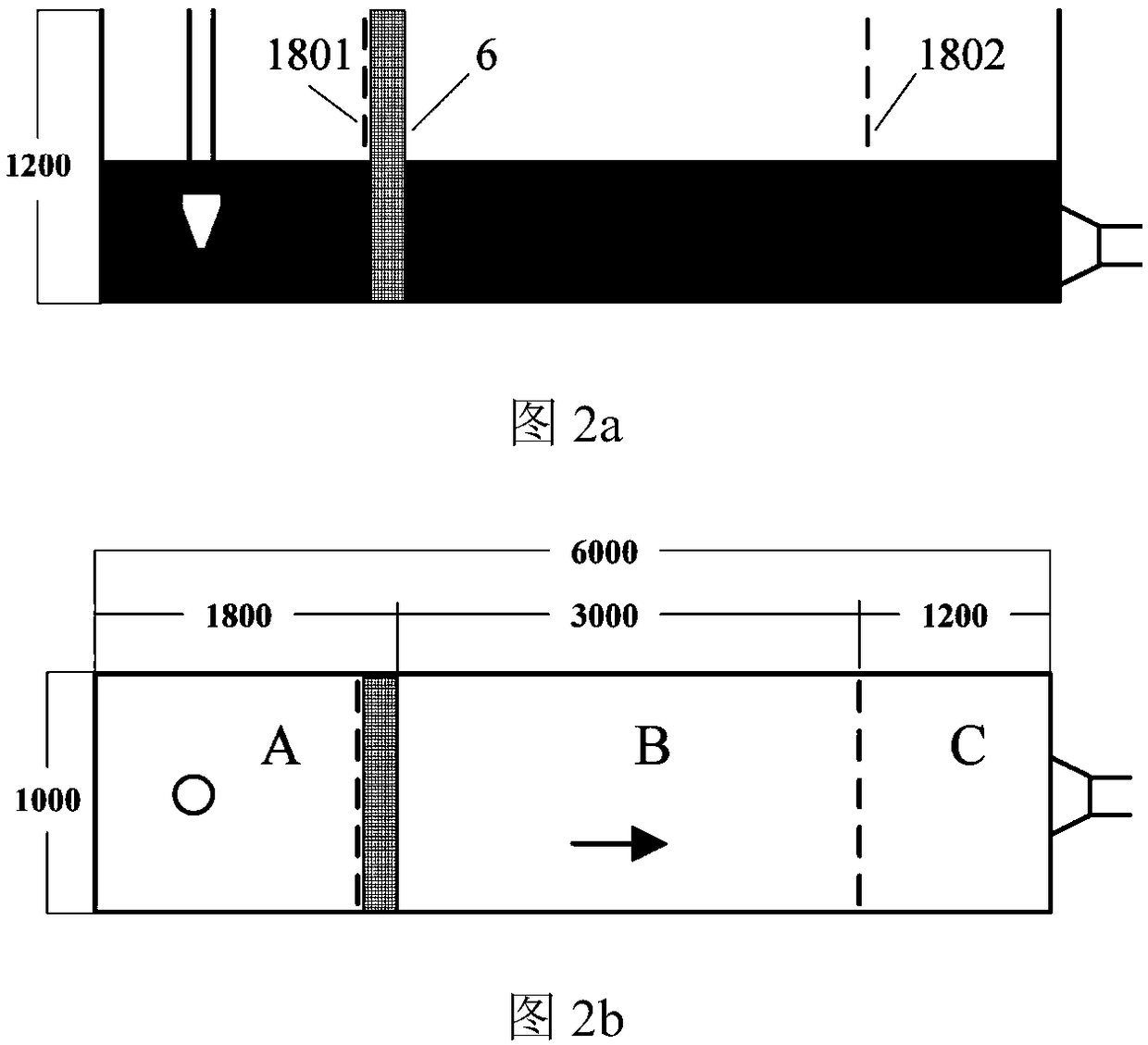

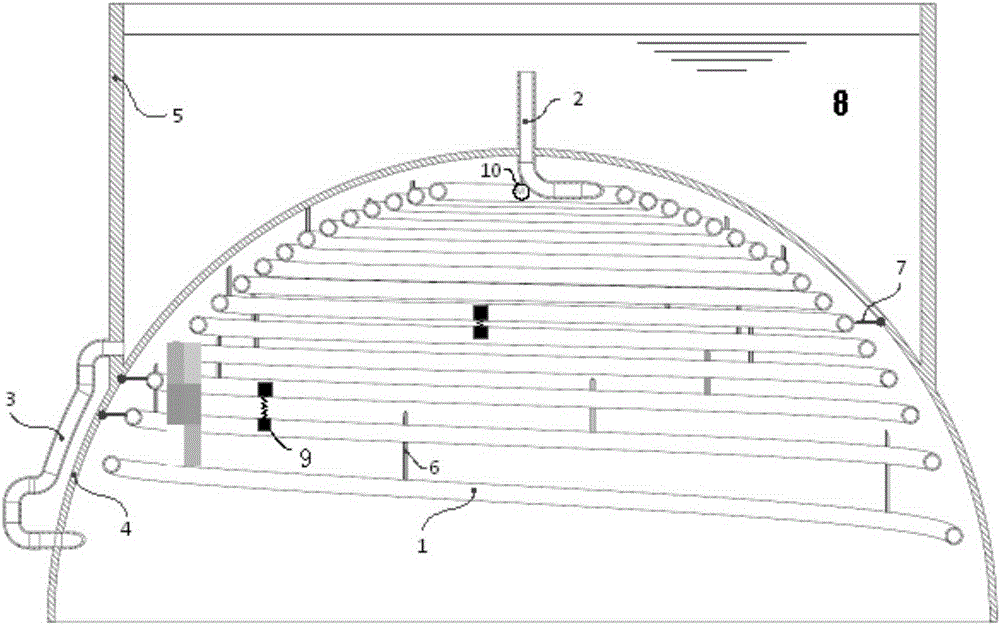

Migration transfer characteristic test system of fragments of reactor containment and test method thereof

ActiveCN109243638AGet sportyMeet the test strength requirementsNuclear energy generationNuclear monitoringCooling towerTest segment

The invention relates to a migration transfer characteristic test system of fragments of a reactor containment and a test method thereof. The system comprises a test segment module composed of a waterchannel, a rectifying grid, a filter screen and related equipment, a flow rate adjusting module composed of a water tank, a main water pump, an electric valve and related pipelines and instruments, acooling module composed of a cooling water pump, a heat exchanger, a cooling tower and related pipelines and instruments, a thermotechnical hydraulic parameter measuring module composed of a flowmeter, a temperature sensor, a pressure sensor and a liquidometer, an image collecting module composed of a high-speed camera, a local area network computer and related image processing software, a flow field information collection module composed of PIV equipment, a local area network computer and related flow field processing software and a remote control module composed of a programmable logic controller, a water pump, an electric valve and related equipment. The system simulates a ground water flow velocity field of the containment accurately after loss of coolant accident and acquires characteristic parameters of different fragments migrating in water.

Owner:XI AN JIAOTONG UNIV

Filter for a nuclear reactor containment ventilation system

ActiveCN104412328ANuclear energy generationEmergency protection arrangementsHigh densityNuclear reactor

A wet filter for a nuclear reactor primary containment vent that employs an inclined manifold having a plurality of outlets that communicate through a first set of metal fiber filters submerged in a pool of water enclosed within a pressure vessel. A demister suspended above the pool of water to remove any entrained moisture in the filtered effluent before being passed through a second stage of higher density, dry, metal fiber filters connected to a second manifold that communicates with an outlet on the pressure vessel that is connected to an exhaust passage to the atmosphere.

Owner:WESTINGHOUSE ELECTRIC CORP

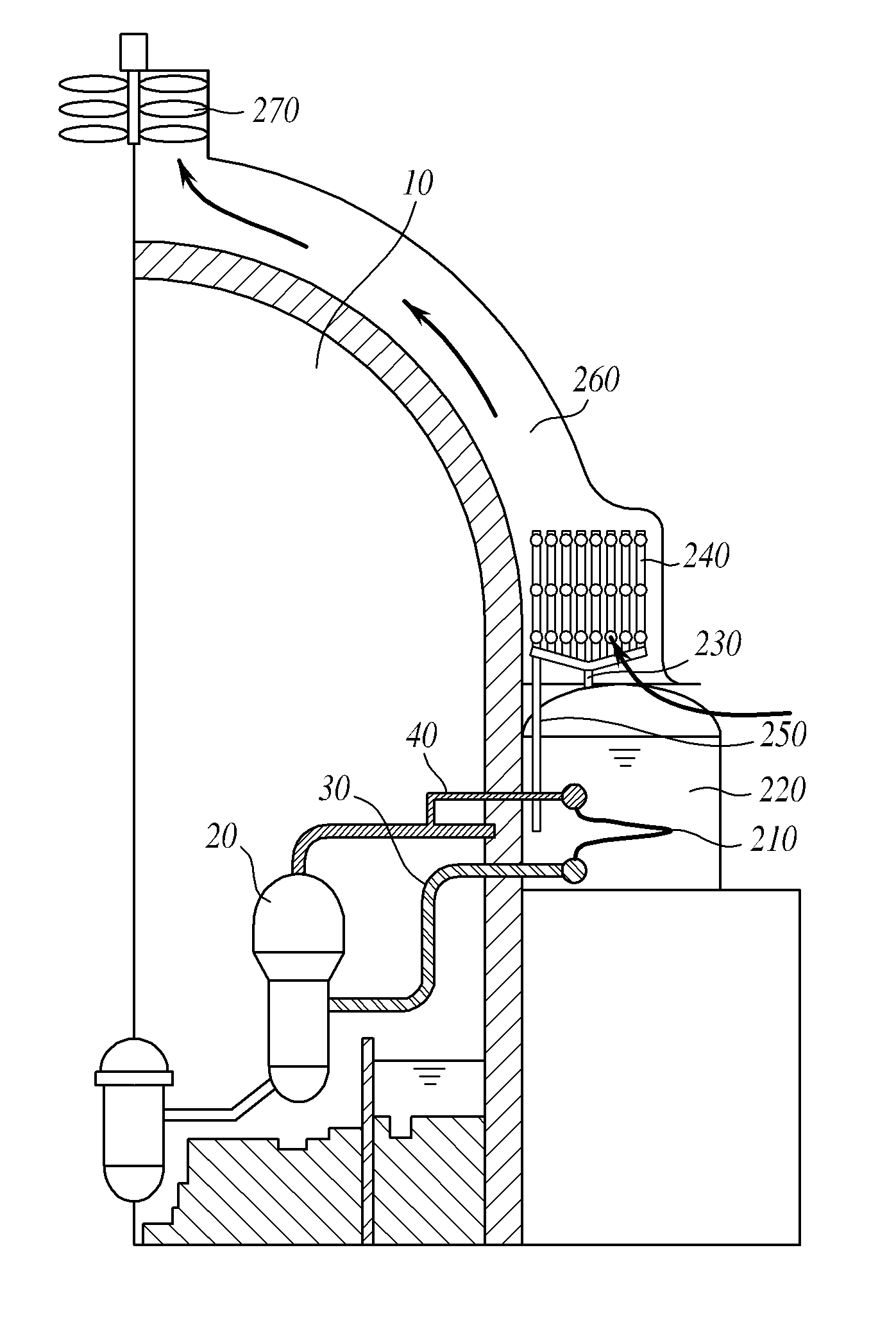

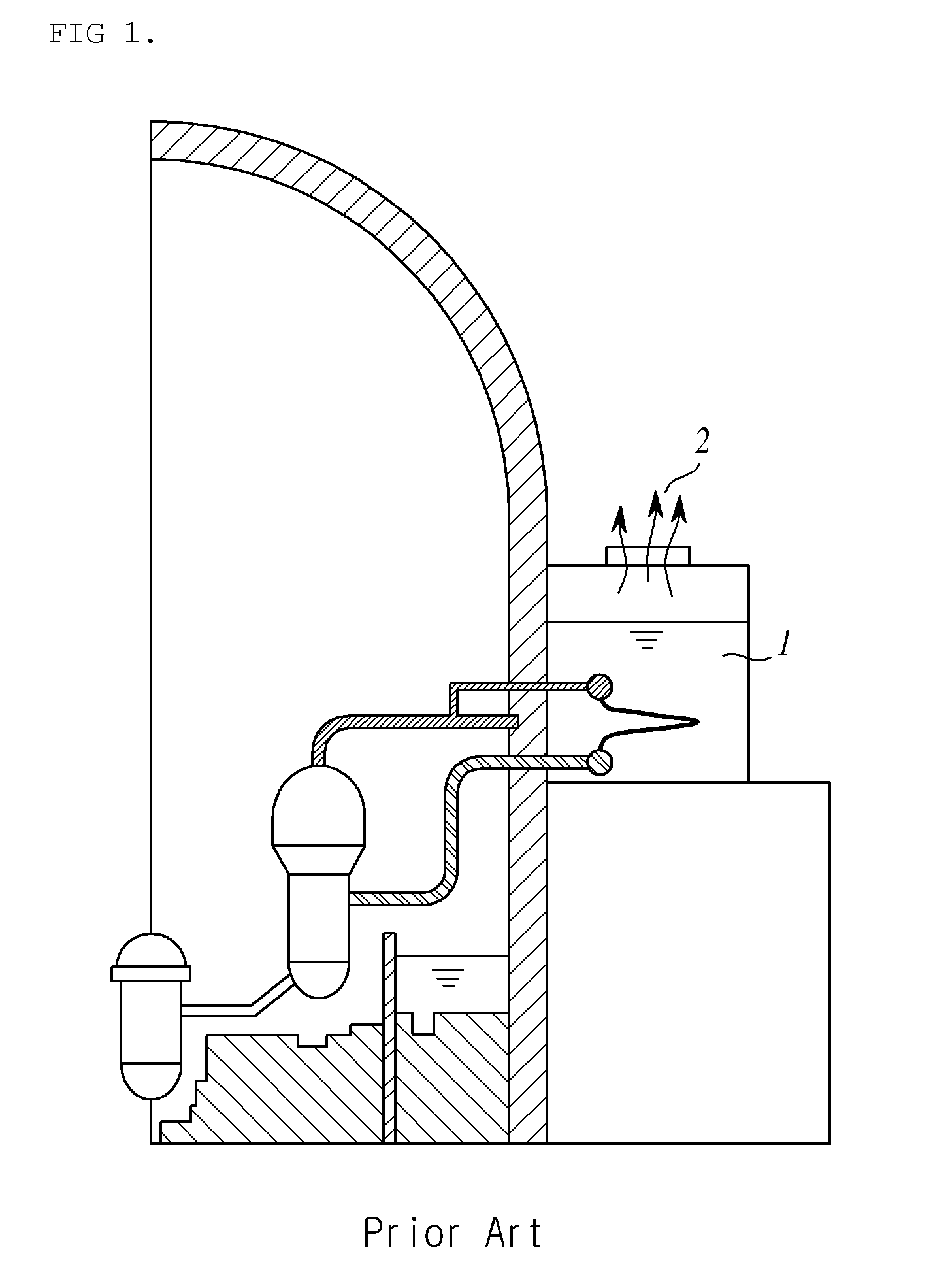

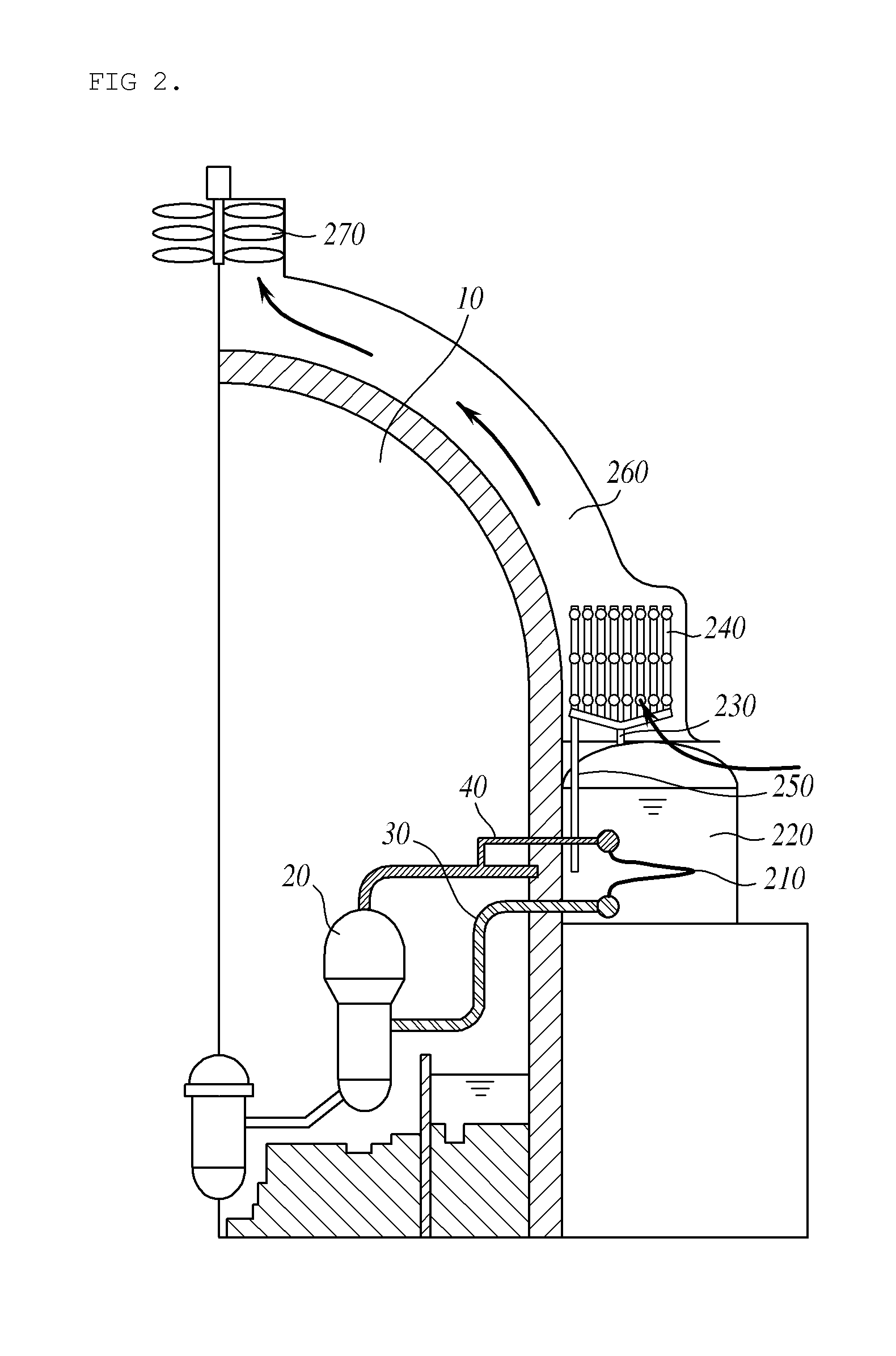

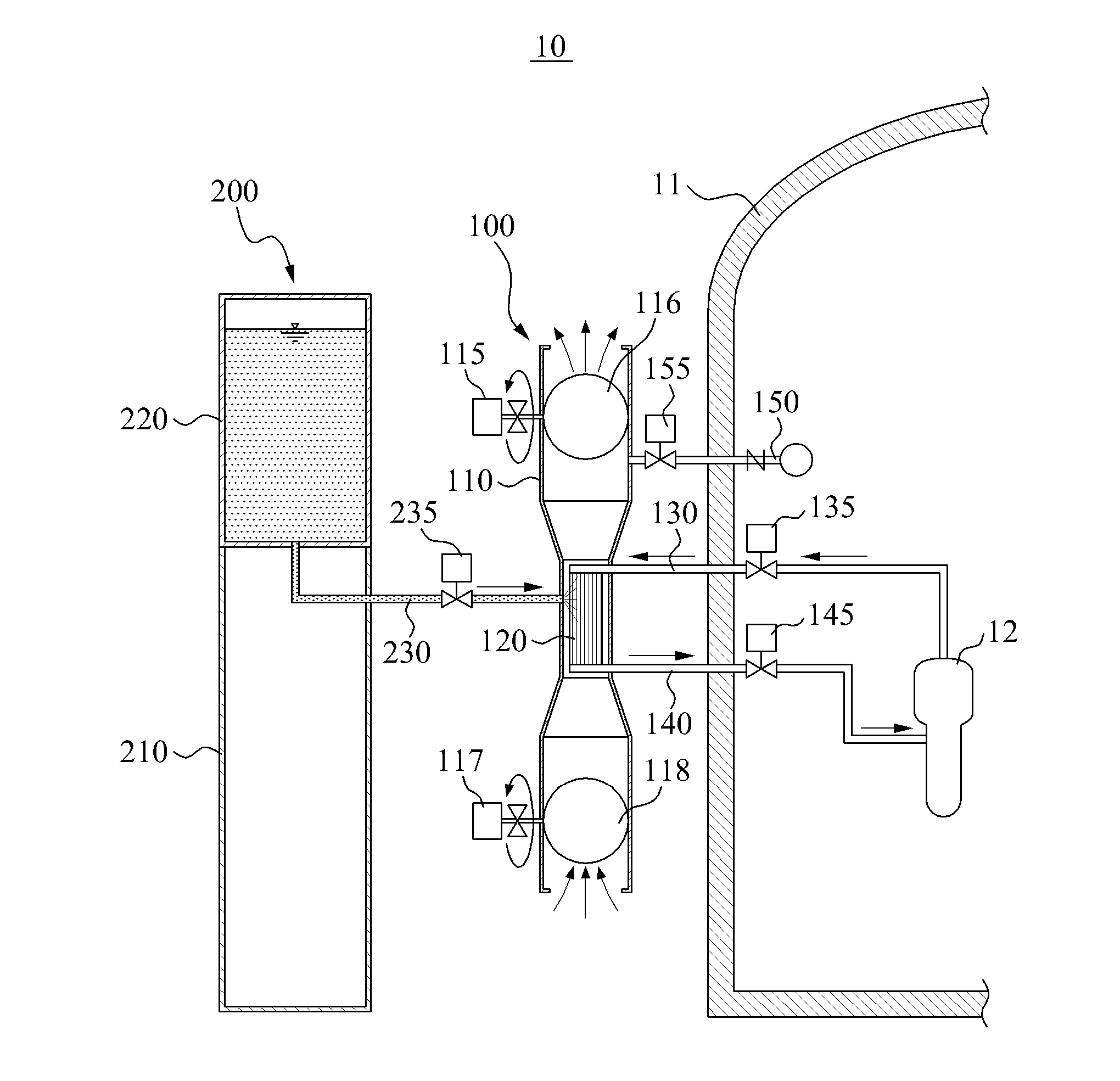

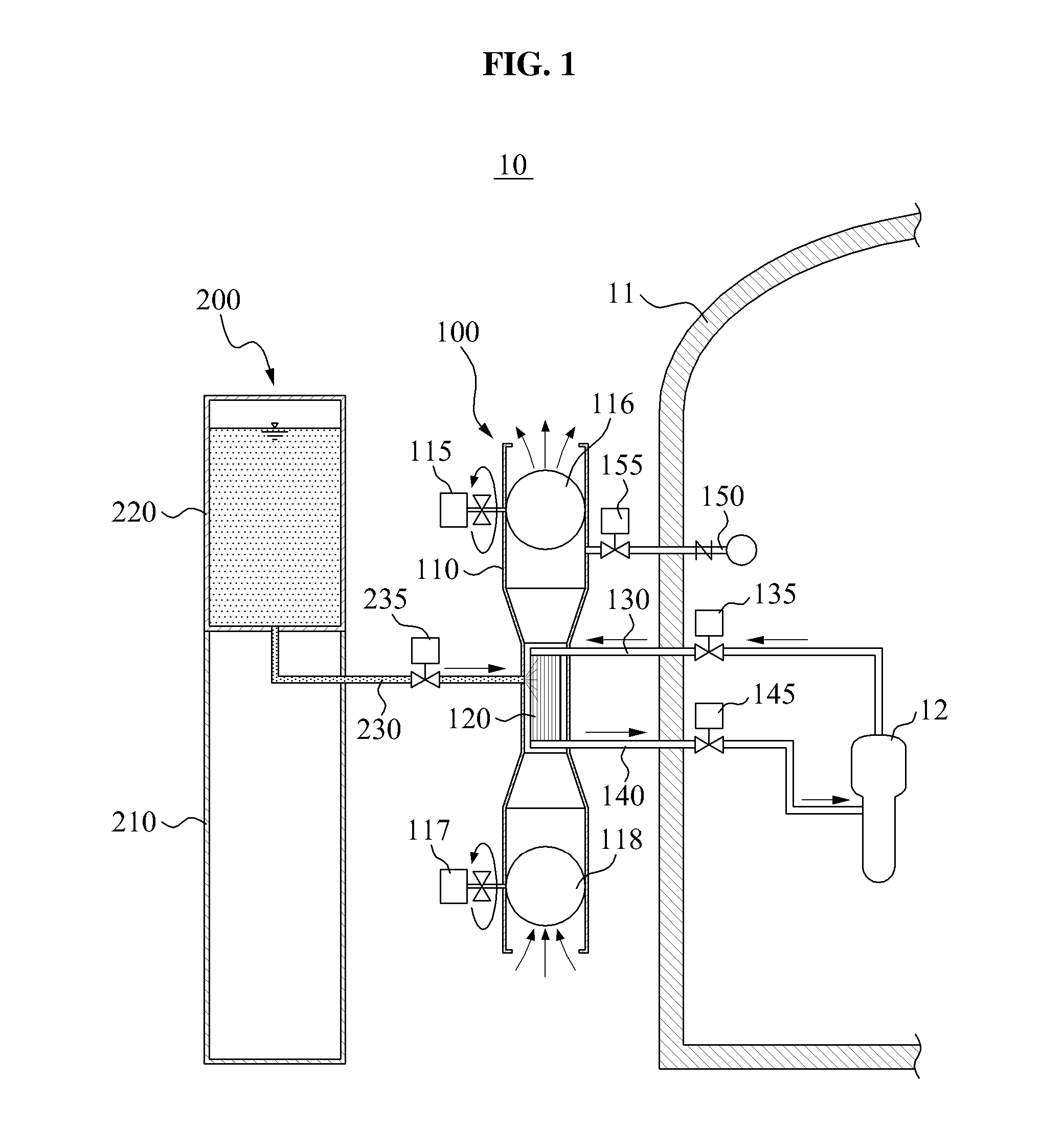

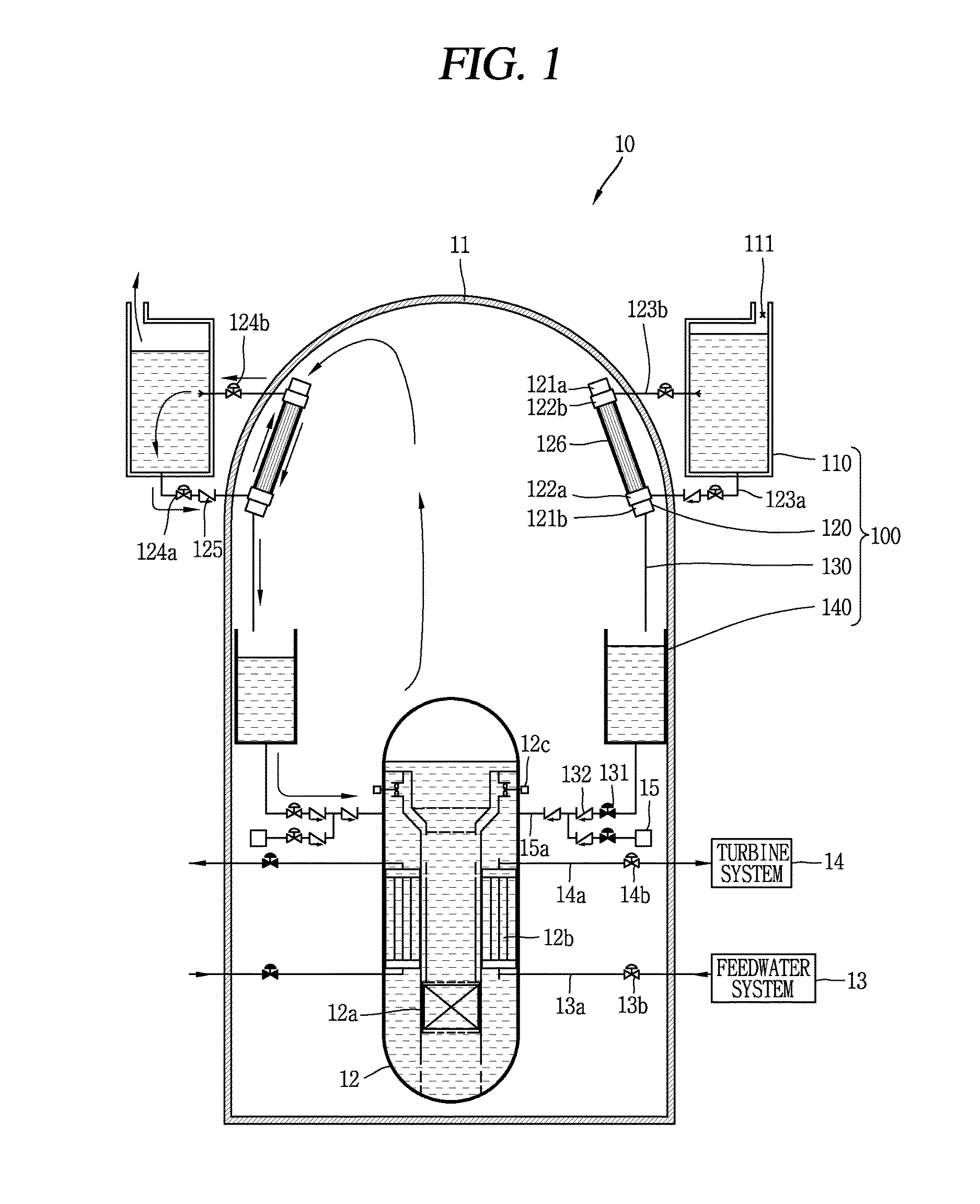

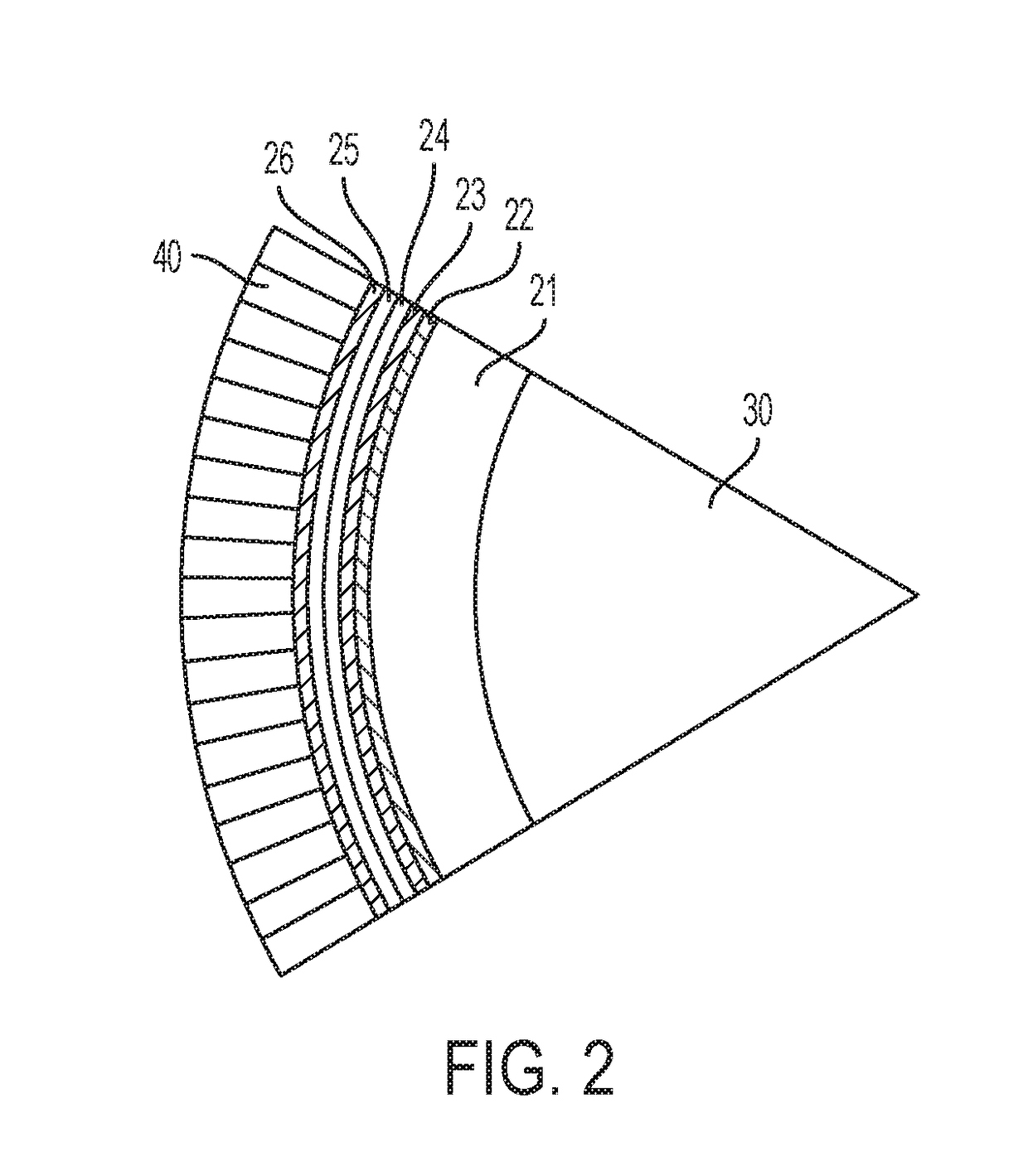

Water-air combined passive feed water cooling apparatus and system

ActiveUS20150243383A1Extend the exhaust timeImprove emission efficiencyPower plant safety arrangementNuclear energy generationEngineeringContainment building

Disclosed herein is a water-air combined passive feed water cooling apparatus including a water cooling heat exchanger connected to the inside of a containment building to cool down heat of a steam generator using a water cooling method, a cooling tank including the water cooling heat exchanger therein and storing cooling water condensing main steam generated by the steam generator, an evaporative steam pipe connected to the cooling tank, the evaporative steam pipe, into which steam of the cooling water generated by the water cooling heat exchanger in the cooling tank flows, an air cooling heat exchanger connected to the evaporative steam pipe and cooling down and liquefying the steam flowing into the evaporative steam pipe, and a condensed water collecting pipe for refilling the cooling tank with the steam liquefied by the air cooling heat exchanger.

Owner:KOREA ATOMIC ENERGY RES INST

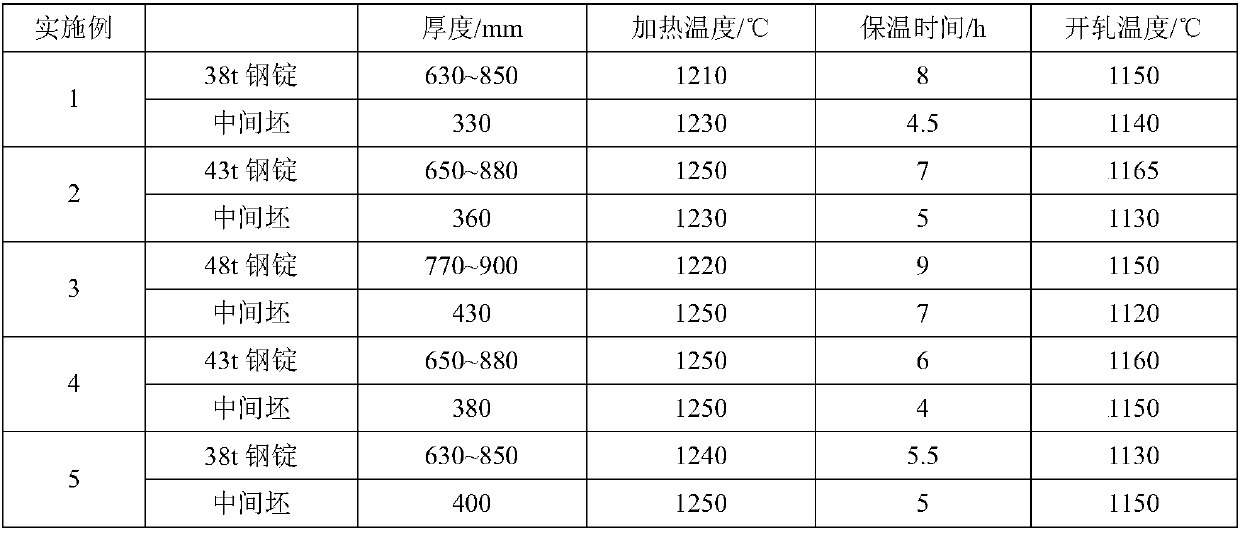

Steel for gate of extra-thick nuclear reactor containment, and manufacturing method thereof

ActiveCN109694984AHigh strengthUniform and stable low temperature toughnessNuclear reactor coreNuclear reactor

The invention provides steel for a gate of extra-thick nuclear reactor containment, and a manufacturing method thereof. The components of a steel plate include, by weight percentage, 0.08-0.15% of C,0.25-0.50% of Si, 0.90-1.50% of Mn, P <= 0.01%, S which is less than or equal to 0.005%, 0.30-0.60% of Ni, 0.10-0.30% of Cr, 0.10-0.30% of Mo, 0.01-0.05% of V, 0.01-0.05% of Nb, 0.01-0.03% of Al, andNb and V which are less than or equal to 0.08%, with the balance being Fe and inevitable impurities. The manufacturing method includes steel ingot cogging, intermediate billet rolling and heat treatment. The steel plate can be guaranteed to have high intensity while having uniform and stable low-temperature toughness, and the steel plate can still have good comprehensive properties after simulatedwelding and heat treatment.

Owner:ANGANG STEEL CO LTD

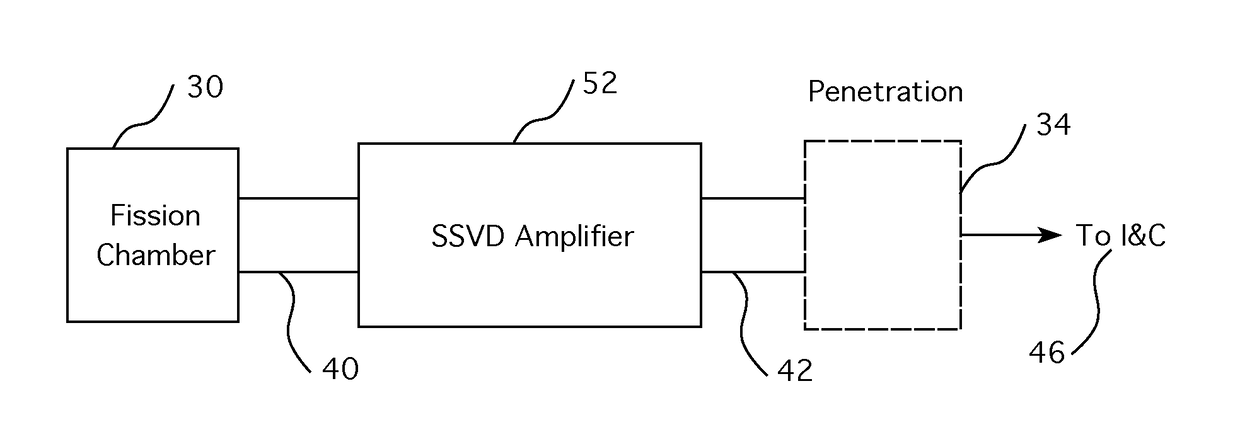

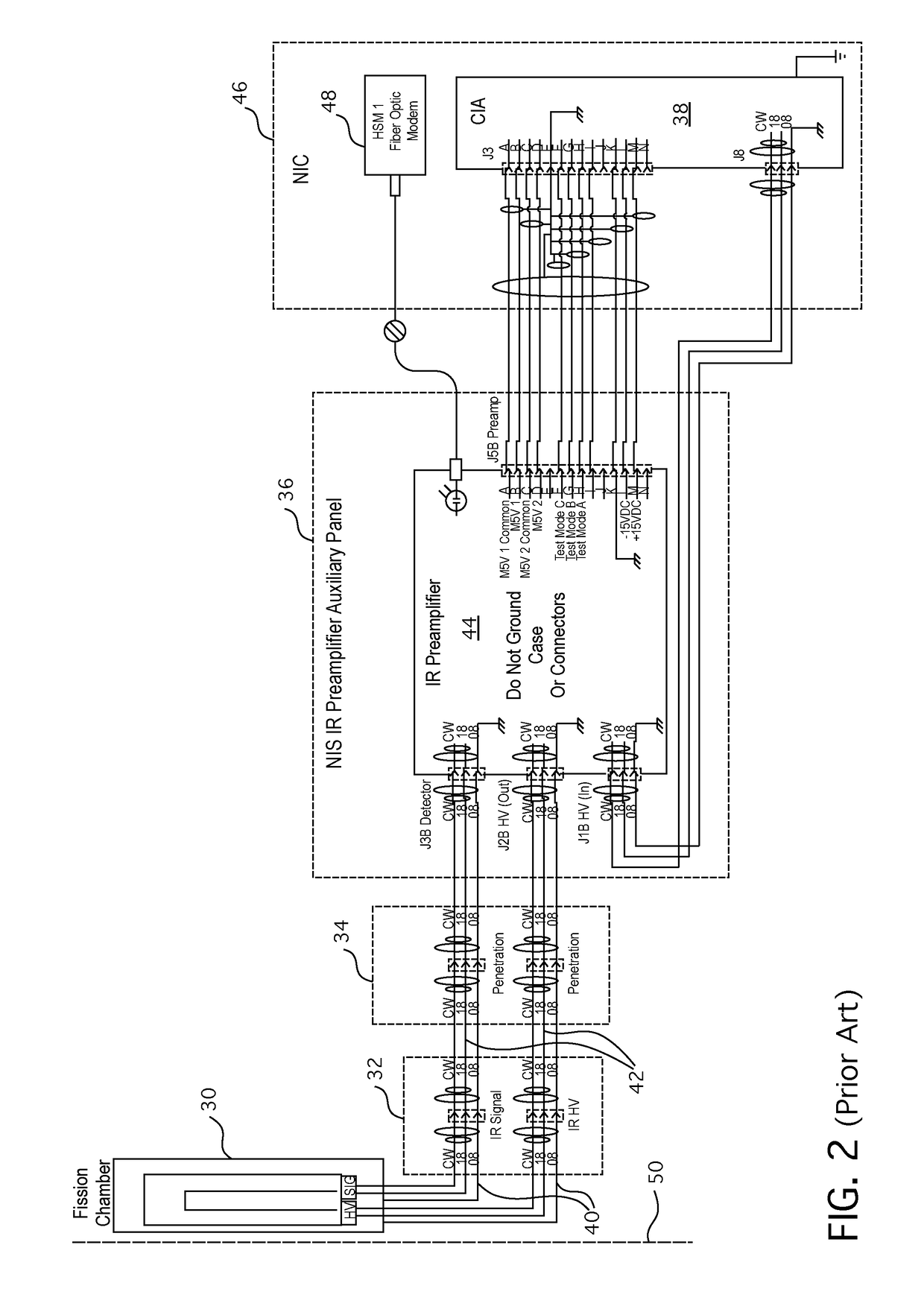

In-Containment Ex-Core Detector System

ActiveUS20170206989A1Increase power outputEnhanced output signalNuclear energy generationNuclear monitoringNuclear plantAudio power amplifier

Apparatus for amplifying low level signals within a nuclear plant's containment building, derived from the ex-core nuclear instrumentation system. The system employs vacuum micro-electronic devices in place of conventional pre-amplifier assemblies to position the pre-amplifier assemblies closer to and within the vicinity of the ex-core detector outputs.

Owner:WESTINGHOUSE ELECTRIC CORP

Low replacement material water-tank emergency coolant system outside nuclear reactor containment vessel

The invention relates to a low replacement material water-tank emergency coolant system outside a nuclear reactor containment vessel, which is used for providing cooling fluid for a pressure vessel and / or a containment vessel of a nuclear reactor, the emergency coolant system comprises a material replacement water-tank used for storing the cooling fluid, the material replacement water-tank comprises a first part positioned outside the containment vessel, the first part is communicated to the bottom of the containment vessel, and the cooling fluid collected at the bottom of the containment vessel is capable of flowing in the first part. The low replacement material water-tank emergency coolant system can realize continuous operation of emergent cooling without switching.

Owner:中广核(北京)仿真技术有限公司 +1

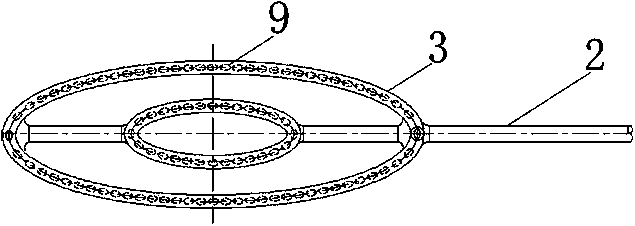

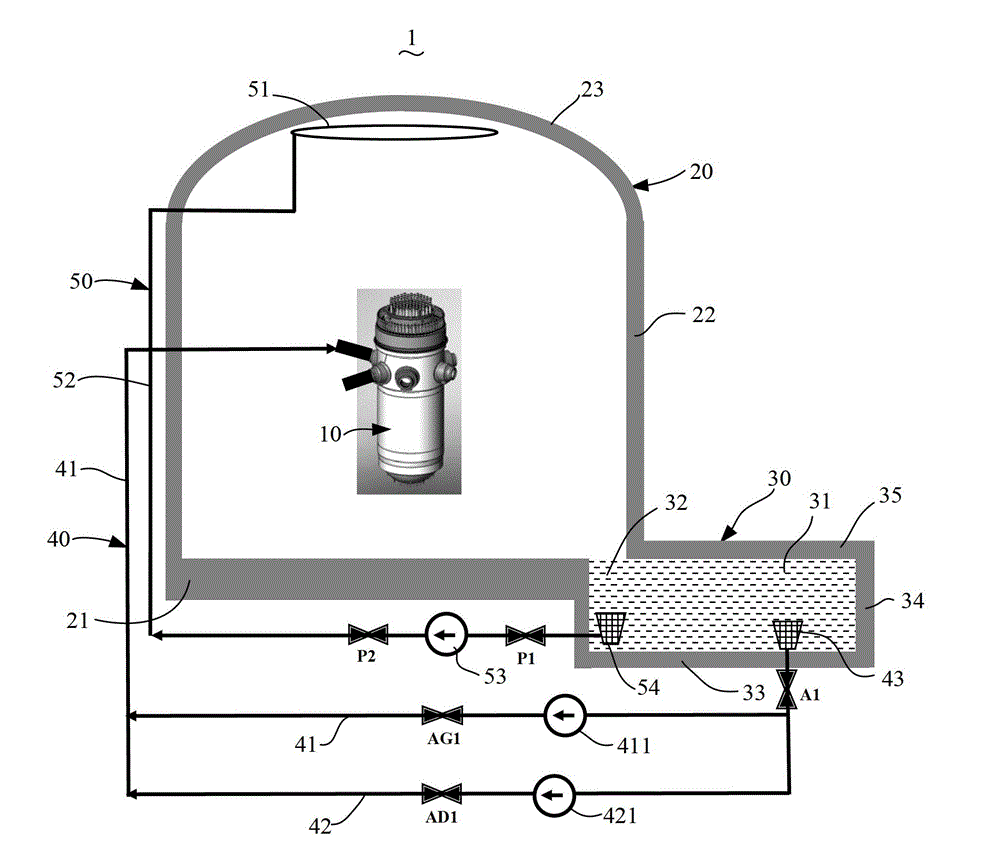

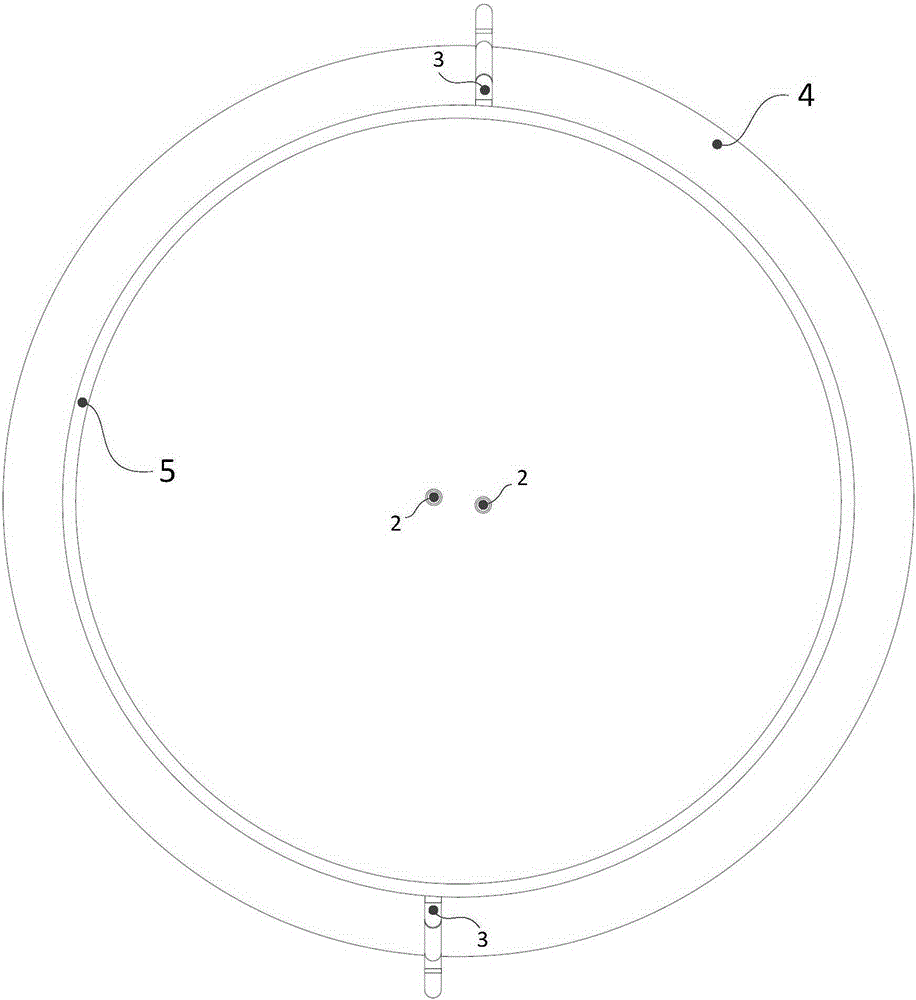

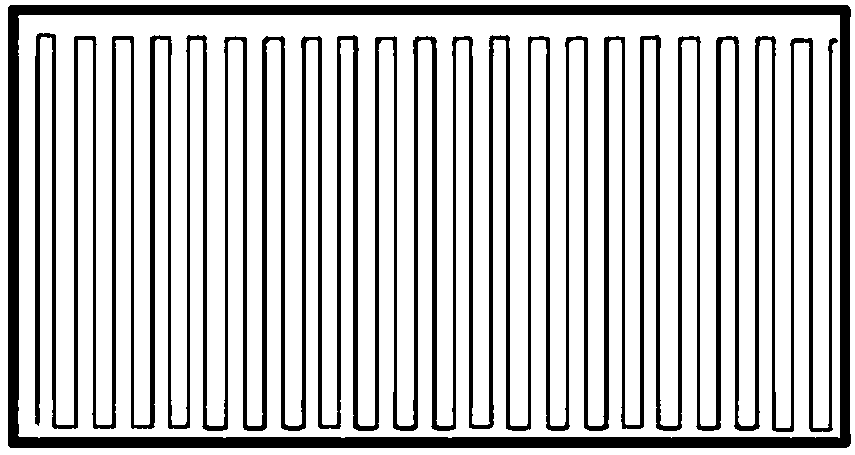

Passive containment cooling system

ActiveCN105355239AIncrease the heat exchange areaImprove seismic performanceNuclear energy generationCooling arrangementNuclear reactor coreInherent safety

The invention relates to a passive containment cooling system, which includes a top water tank (5) disposed outside a containment and a spiral coil water cooled wall (1) arranged in the containment, one end of the spiral coil water cooled wall (1) is connected to the top water tank (5) through a natural circulation inlet pipeline (3), the other end of the spiral coil water cooled wall (1) is in connection with the top water tank (5) through a natural circulation outlet pipeline (2), the spiral coil water cooled wall (1) is disposed in a containment dome (4) area and includes one or more spiral coils. The containment cooling system provided by the invention has the advantages of few containment penetration pieces, large heat exchange area, high heat exchange efficiency and good seismic performance, and also has a simple structure, thus providing higher inherent safety for nuclear reactor containments.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Method for treatment of hazardous paint residue

ActiveUS8796501B2Low toxicityReduce solubilitySemiconductor/solid-state device manufacturingCoatingsContainment buildingNuclear chemistry

The invention provides an optimal method for stabilization of heavy metal bearing paint residue subject to acid and water leaching tests or leach conditions by addition of environment safe, worker safe, multi-media compatible, non-separating, non-embedding, stabilizing agent and optional complexing agent(s) to the blast media, thus allowing for pre-blending of stabilizer and blast media and field production of a uniform and steady state stabilizer within media for stabilization outside or within an OSHA containment building or collection device, such that leaching of heavy metals such as lead are inhibited to desired levels. The resultant stabilized paint residue and spent blast media mixture is suitable for on-site reuse, off-site reuse, or disposal as RCRA non-hazardous waste.

Owner:FORRESTER KEITH E

Water-spray residual heat removal system for nuclear power plant

ActiveUS20130202075A1Residual heat level is reNuclear energy generationEmergency protection arrangementsNuclear plantNuclear power

A residual heat removal system for a nuclear power plant. The residual heat removal system for a nuclear power plant may include an air duct provided on an outside of a reactor containment building, a heat exchanger disposed on an inside of the air duct, a first pipe to transfer, to the heat exchanger, steam generated in a steam generator disposed on an inside of the reactor containment building, and second pipe to transfer, to the steam generator, water condensation that is cooled and condensed in the heat exchanger, wherein the heat exchanger is air-cooled using outside air flowing inside of the air duct.

Owner:KOREA ATOMIC ENERGY RES INST

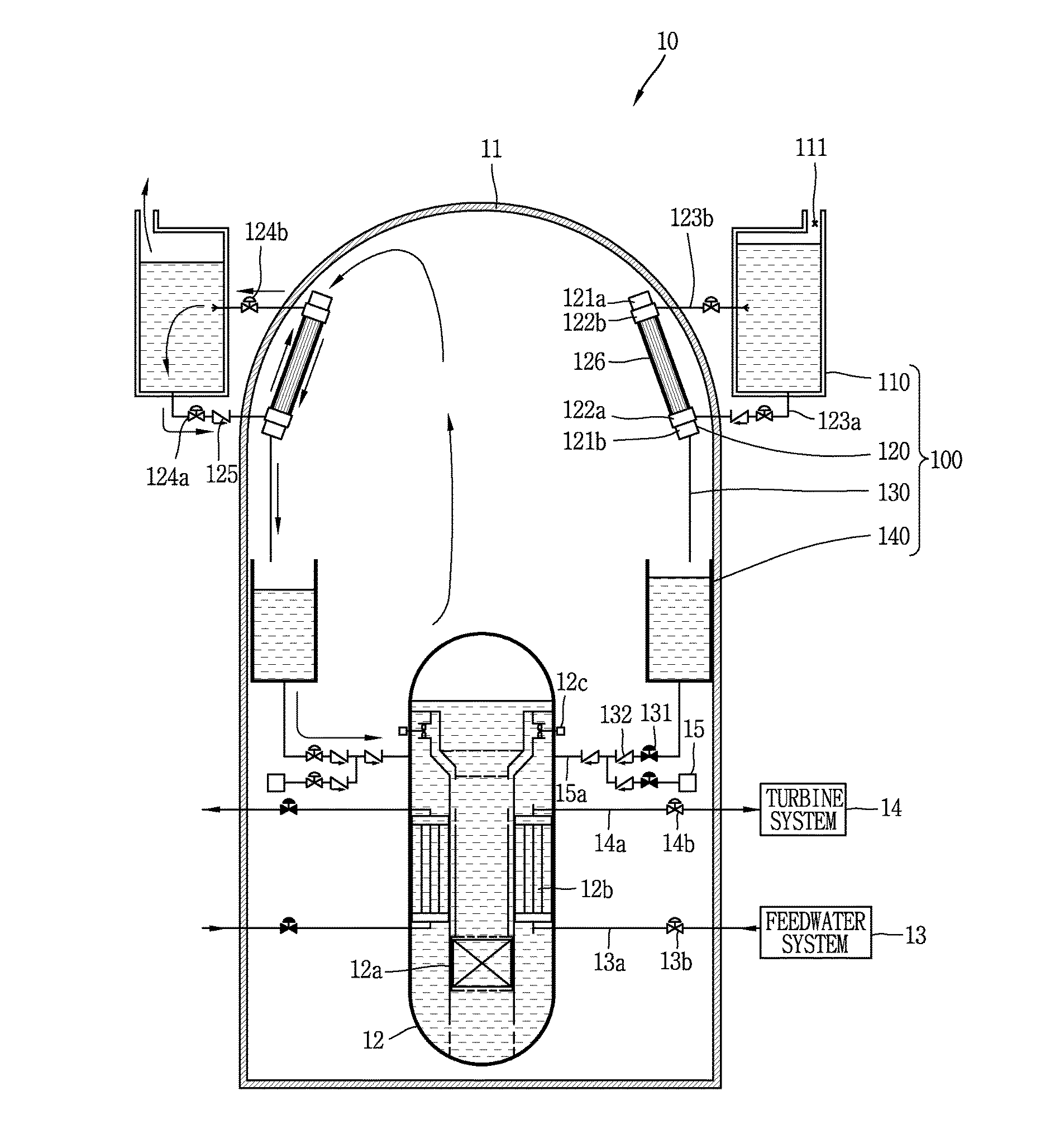

Passive cooling system of containment building and nuclear power plant comprising same

ActiveUS20170004892A1Easy maintenanceSmall sizeNuclear energy generationEmergency protection arrangementsPlate heat exchangerNuclear engineering

The present invention discloses a passive cooling system of a containment building, to which a plate-type heat exchanger is applied. A passive cooling system of a containment building comprises: a containment building; a plate-type heat exchanger provided to at least one of the inside and the outside of the containment building and comprising channels respectively provided to the both sides of a plate so as to be arranged dividedly from each other such that the plate-type heat exchanger carries out mutual heat exchange between the internal atmosphere of the containment building and a heat exchange fluid while maintaining a pressure boundary; and a pipe connected to the plate-type heat exchanger by penetrating the containment building so as to form the path of the internal atmosphere of the containment building or the heat exchange fluid.

Owner:KOREA ATOMIC ENERGY RES INST

Method for stabilization of paint residue

InactiveUS20060116545A1Reduce solubilitySolid waste disposalTransportation and packagingEnvironmental engineeringContainment building

This invention provides a method for stabilization of paint residue subject to acid and water leaching tests or leach conditions by addition of stabilizing agents within an OSHA containment building or collection device such that leaching of lead is inhibited to desired levels. The resultant waste after stabilization is deemed suitable for on-site reuse, off-site reuse or disposal as RCRA non-hazardous waste.

Owner:FORRESTER KEITH EDWARD

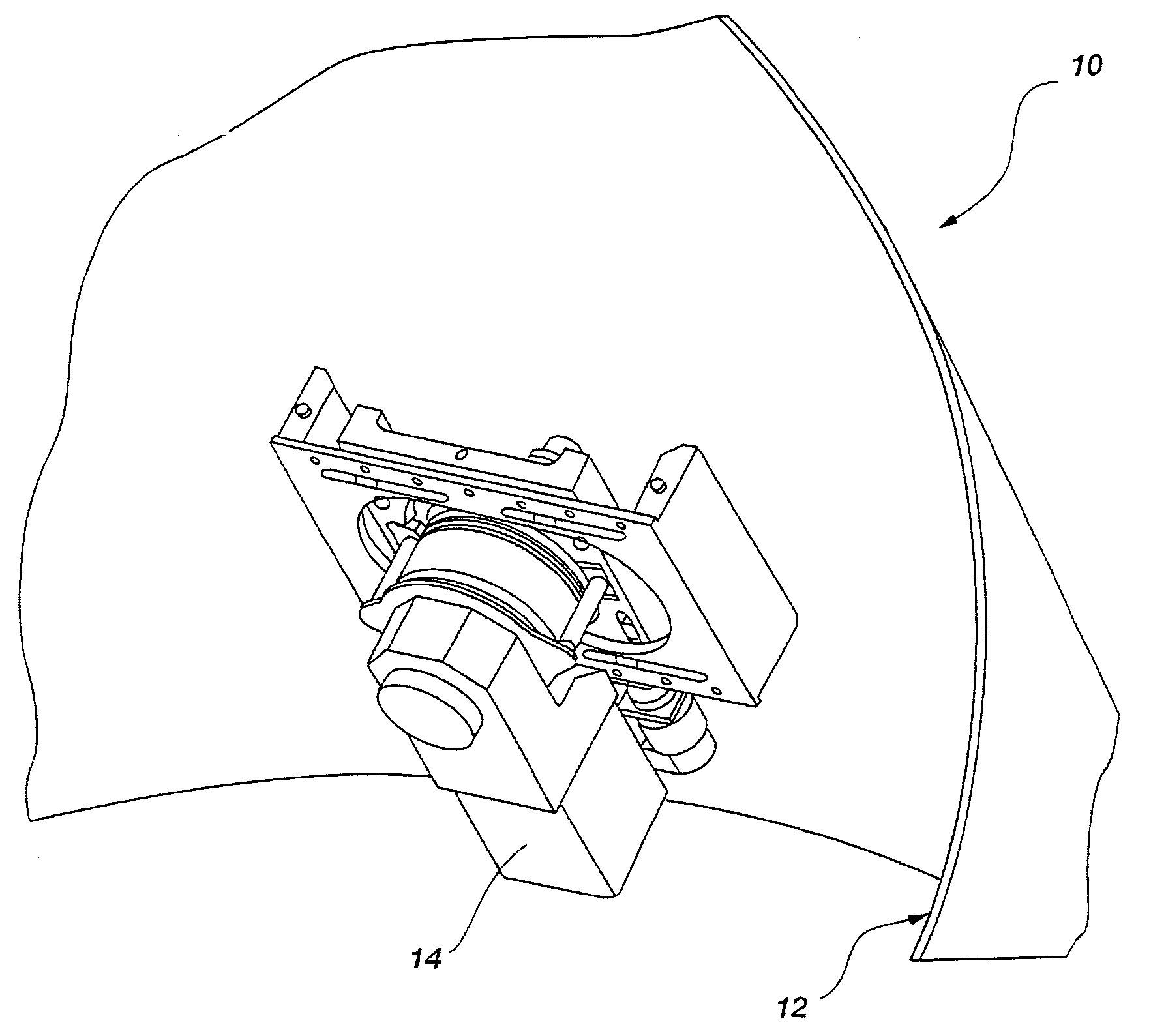

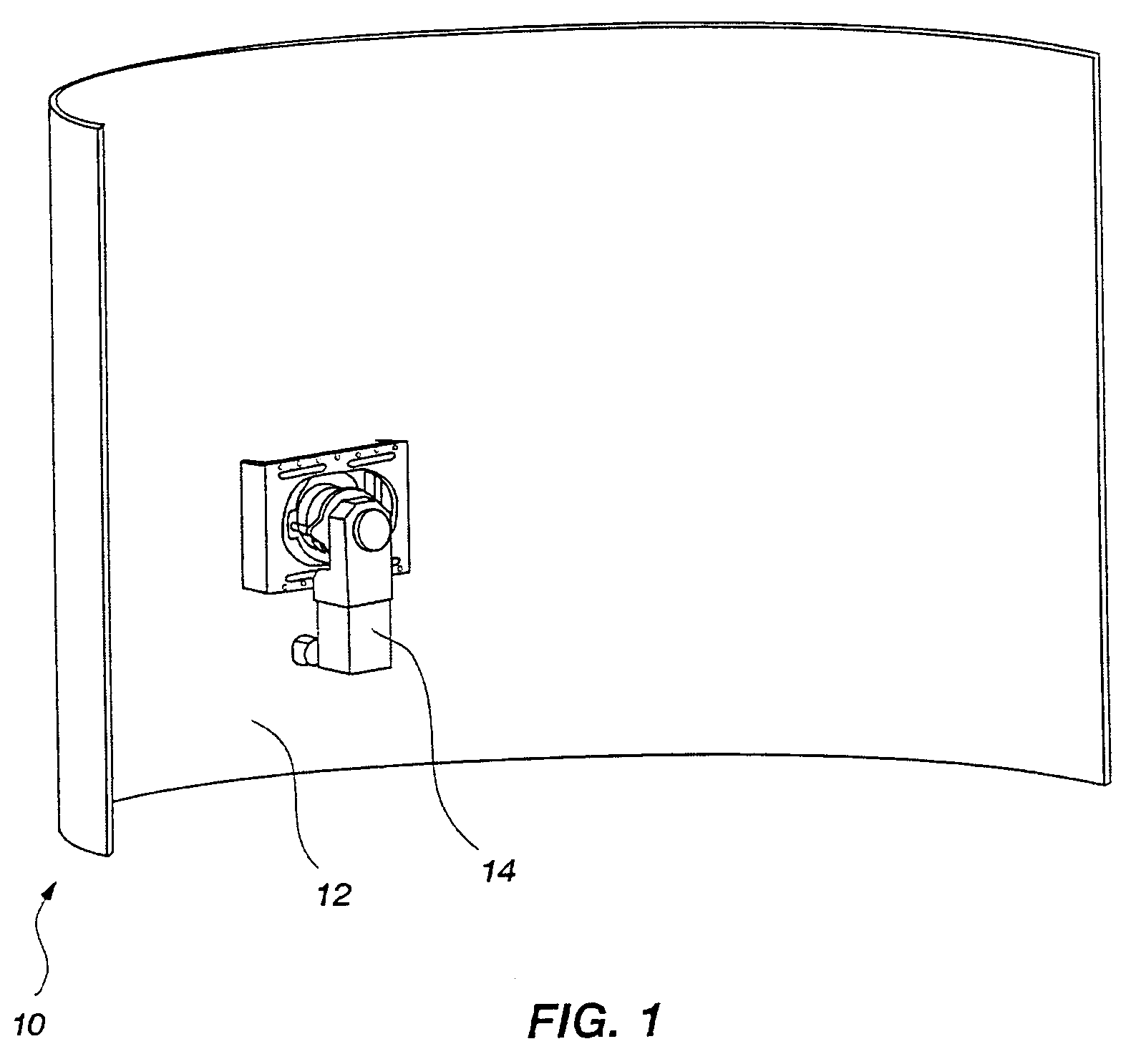

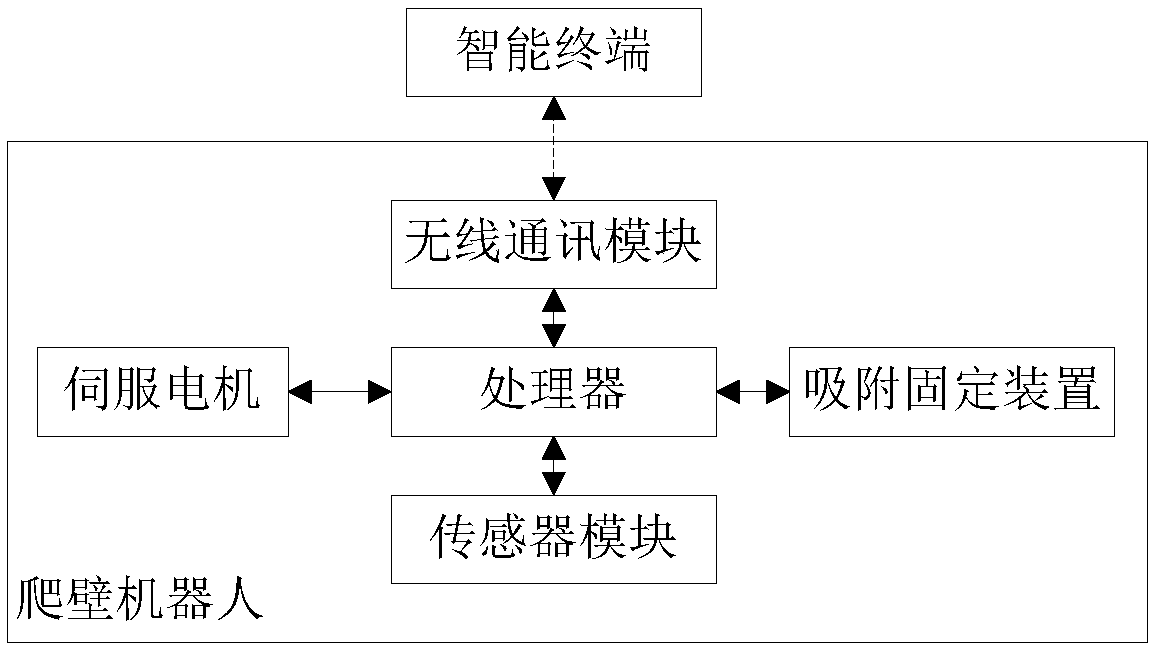

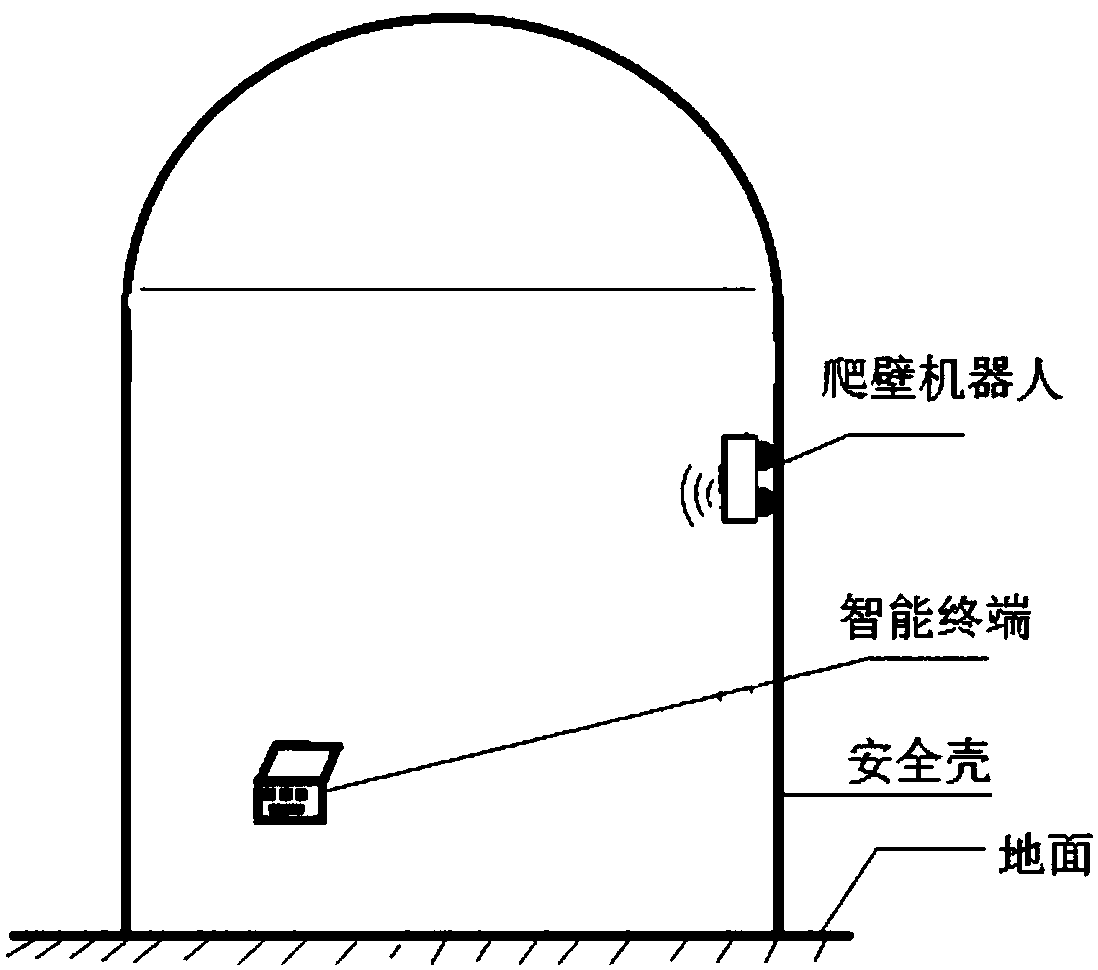

Automatic detection system and method for hollowing in steel lining of nuclear reactor containment

ActiveCN108447572AImprove detection efficiencyQuality improvementNuclear energy generationNuclear monitoringNuclear reactor coreNuclear reactor

The invention discloses automatic detection system and method for hollowing in a steel lining of a nuclear reactor containment. The system includes a wall-climbing robot and an intelligent terminal, which are connected to each other. A knocking apparatus and a sound collection module are arranged on the wall-climbing robot. The wall-climbing robot climbs all over on the inner wall of the nuclear reactor containment and knocks the inner wall by means of the knocking apparatus, wherein the knocking sound information is collected by the sound collection module in real time and is sent to the intelligent terminal; the intelligent terminal then controls the wall-climbing robot to move on the inner wall of the nuclear reactor containment and receives the sound information and detects whether hollowing exists or not between the steel lining and the inner wall according to the sound information. The system and method can automatically detect the swelling in the steel lining of the nuclear reactor containment and are reduced in detection cost and improved in detection efficiency and quality, and are extensively applied to the field of auto-detection computing.

Owner:深圳市智能机器人研究院

Method for treatment of hazardous paint residue with non-separating, non-embedding, non-toxic, compatable, dry stabilizer and blast media pre-blend

ActiveUS20130098269A1Low toxicityReduce solubilitySemiconductor/solid-state device manufacturingCoatingsContainment buildingNuclear chemistry

The invention provides an optimal method for stabilization of heavy metal bearing paint residue subject to acid and water leaching tests or leach conditions by addition of environment safe, worker safe, multi-media compatible, non-separating, non-embedding, stabilizing agent and optional complexing agent(s) to the blast media, thus allowing for pre-blending of stabilizer and blast media and field production of a uniform and steady state stabilizer within media for stabilization outside or within an OSHA containment building or collection device, such that leaching of heavy metals such as lead are inhibited to desired levels. The resultant stabilized paint residue and spent blast media mixture is suitable for on-site reuse, off-site reuse, or disposal as RCRA non-hazardous waste.

Owner:FORRESTER KEITH E

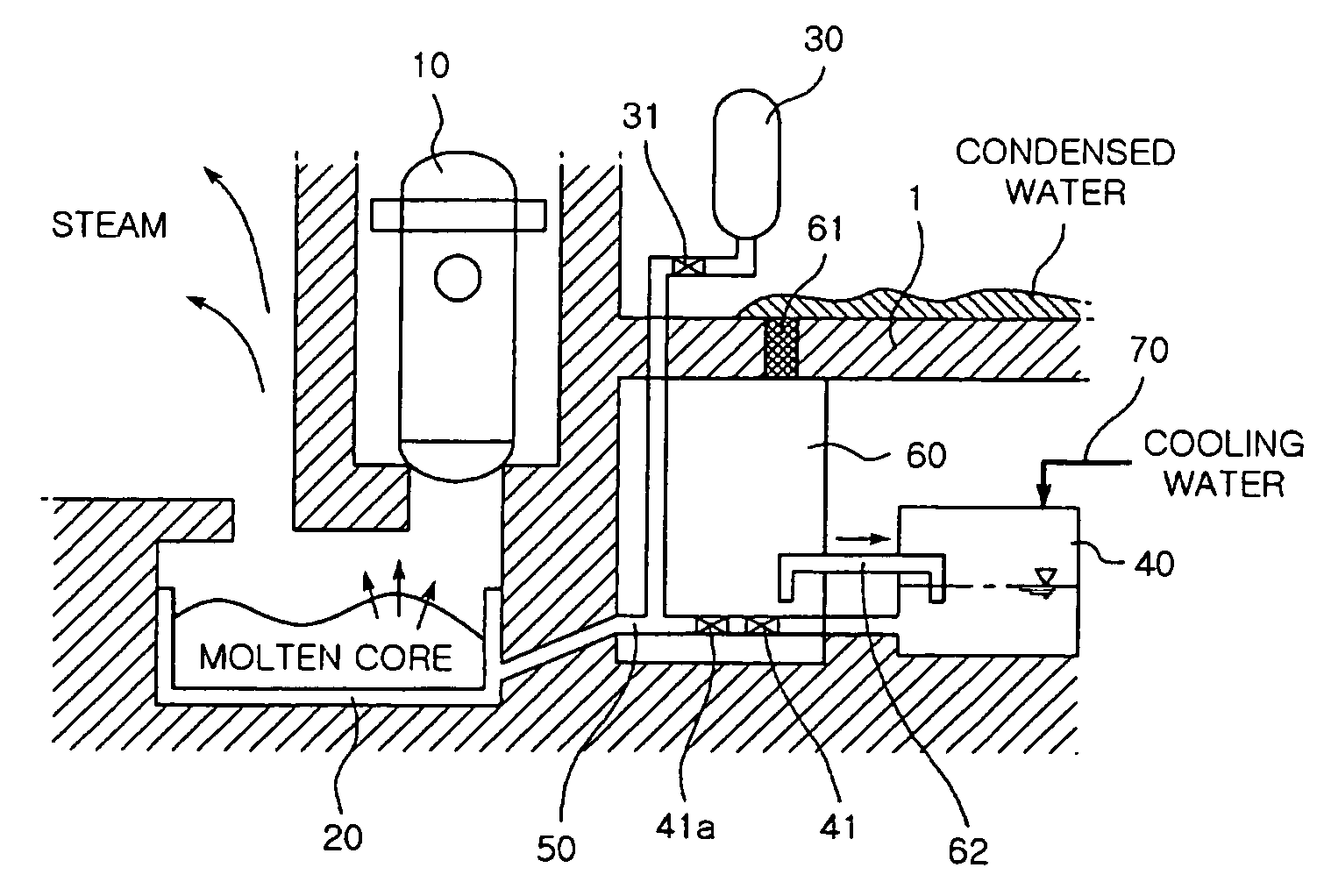

Passive cooling and arresting device for molten core material

ActiveUS7949084B2Reduce the possibilityEffectively remove decay heatNuclear energy generationNuclear engineering problemsNuclear plantWater storage tank

An apparatus for passively cooling and retaining molten core material discharged from a damaged reactor vessel during a severe accident in the nuclear plant including: a molten core material retention tank to retain molten core material; a compressed gas tank storing high-pressure inert gas; a cooling water storage tank being installed higher than the molten core material retention tank; and a mixing means. The molten core material retention tank includes an outer retention vessel having at least one coolant hole, a porous protection vessel formed at an inside of the outer retention vessel, and a gravel layer formed between the outer retention vessel and the porous protection vessel. The apparatus can be installed in a reactor cavity without changing the compartment structure of a containment building, and makes it possible to prevent a steam explosion during the cooling process for the ultrahigh-temperature molten core material and to secure the reliability of the cooling process.

Owner:KOREA ATOMIC ENERGY RES INST +1

Filter for a nuclear reactor containment ventilation system

A wet filter for a nuclear reactor primary containment vent that employs an inclined manifold having a plurality of outlets that communicate through a first set of metal fiber filters submerged in a pool of water enclosed within a pressure vessel. A demister suspended above the pool of water to remove any entrained moisture in the filtered effluent before being passed through a second stage of higher density, dry, metal fiber filters connected to a second manifold that communicates with an outlet on the pressure vessel that is connected to an exhaust passage to the atmosphere.

Owner:WESTINGHOUSE ELECTRIC CORP

Cooling system of nuclear reactor containment structure

ActiveUS20140376679A1Nuclear energy generationEmergency protection arrangementsNuclear reactor coreNuclear reactor

A nuclear power plant includes a nuclear reactor containment structure housing a nuclear reactor, a pressure vessel containing condensed water therein and having a receiving space located lower than a bottom of the containment structure, a release pipe connecting the containment structure to the pressure vessel such that water vapor and fission products generated in the containment structure in the event of an accident is capable of flowing into the pressure vessel, and a recovery pipe connecting the pressure vessel to the containment structure such that the condensed water received in the pressure vessel is capable of flowing into the containment structure. When a level of the condensed water received in the pressure vessel is higher than a water level in the containment structure, the condensed water flows from the pressure vessel toward the containment structure by a water head difference.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

Evaluation method for maintenance opportunity of nuclear reactor containment internal coating layer

The invention relates to an evaluation method for a maintenance opportunity of a nuclear reactor containment internal coating layer. The evaluation method successively comprises the following steps: (a) determining the area S of a nuclear reactor containment break affected zone, and calculating the mass M[1] of latent coating layer fragments; (b) carrying out visual inspection on four coating layer systems of a nuclear reactor containment outside the break affected zone; (c) followed by testing tested points, and recording test results; (d) determining LOCA simulation test unqualified ratios of the four coating layer systems; (e) combining with a formula 2, respectively calculating the total mass M[2] of the latent fragments outside the break affected zone; (f) determining the mass M[3] of a qualified coating layer falling off during a reactor machine set normal operation; (g) determining X[CCD] and the maximum value M[max] of all the coating layer fragments produced from loss of coolant accidents; and (h) according to a formula (3), calculating the approximation rate gamma. The evaluated total amount of the coating layer fragments is quantized and is compared with the amount of critical coating layer fragments, so as to confirm whether a nuclear reaction is required to be stopped for maintenance of the coating layer in the containment.

Owner:SUZHOU NUCLEAR POWER RES INST +1

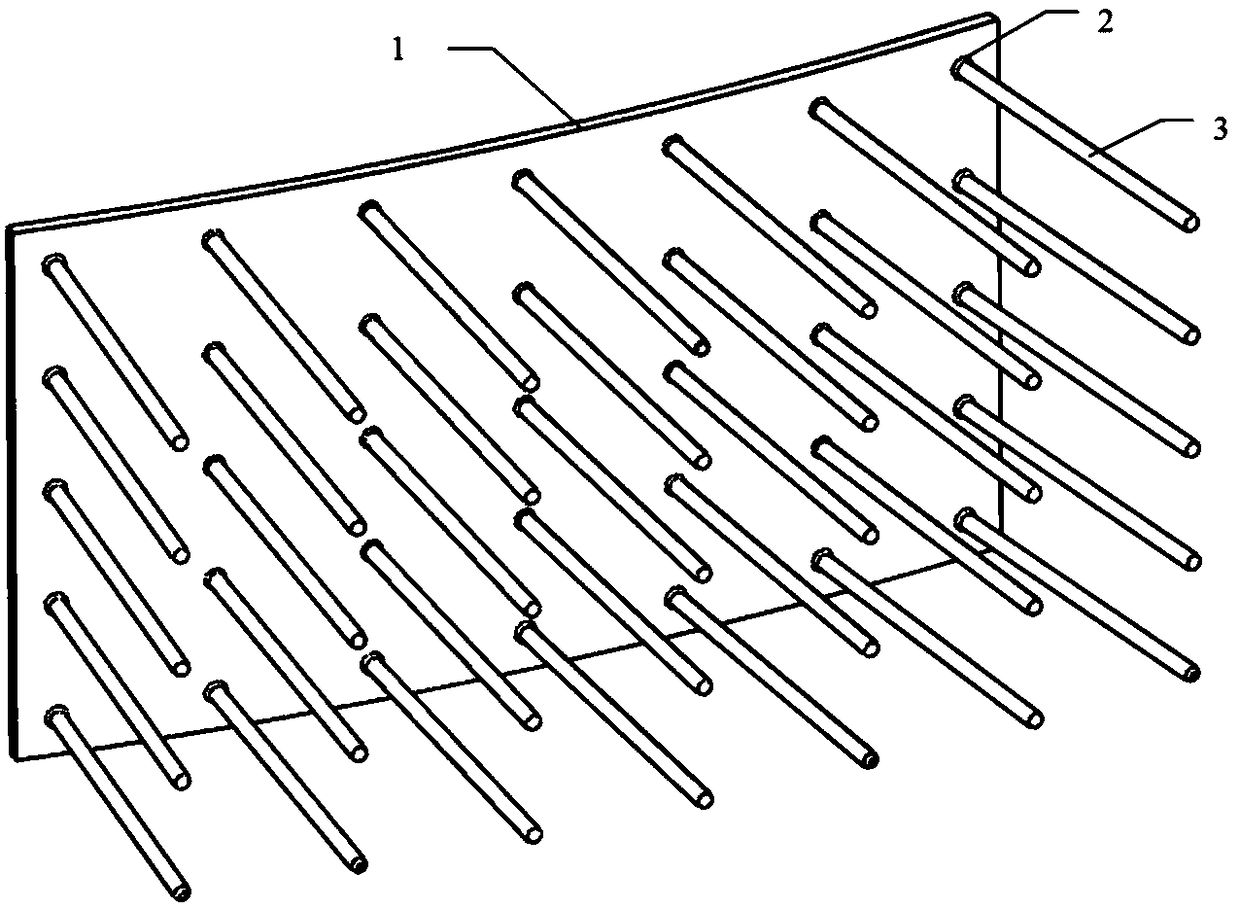

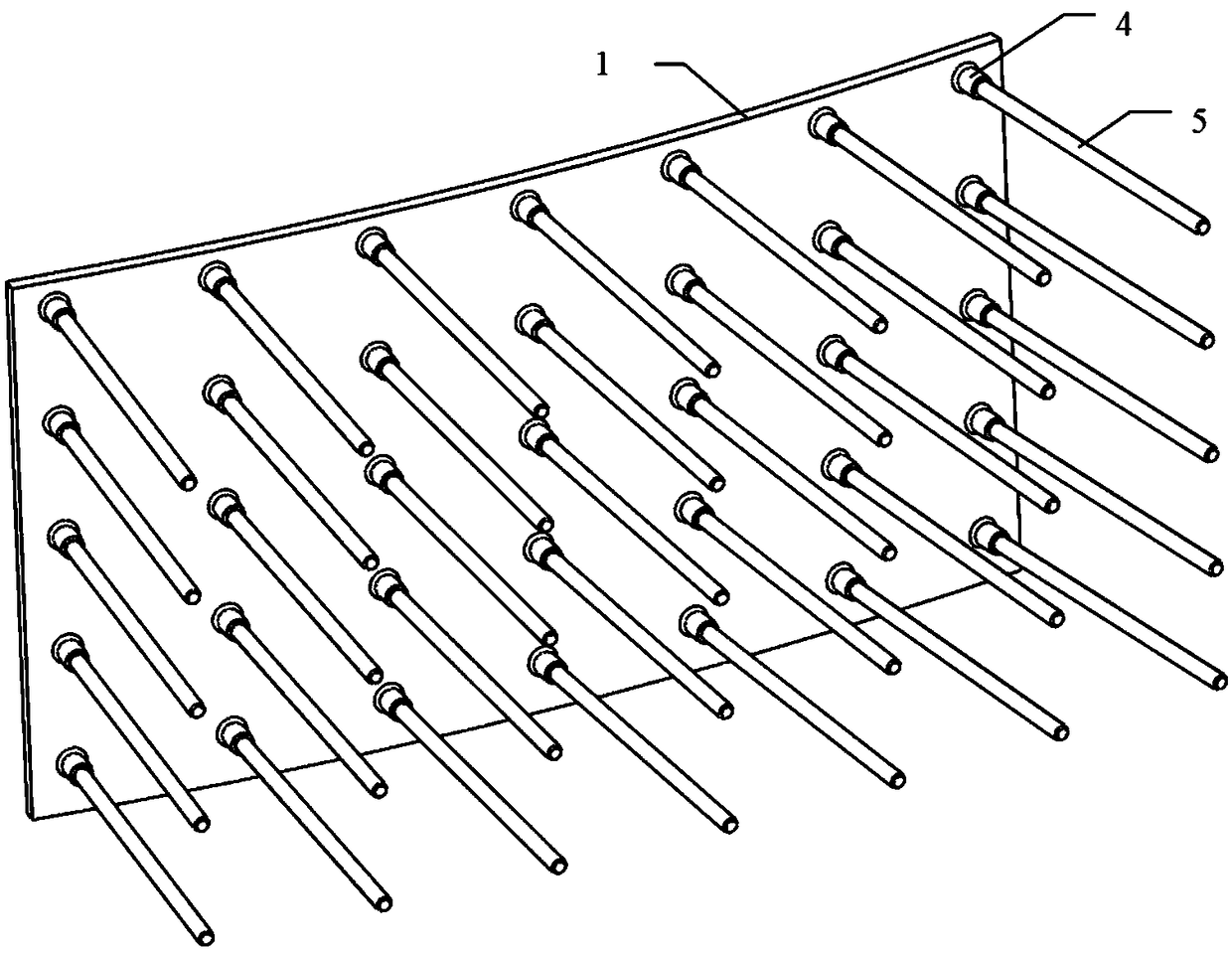

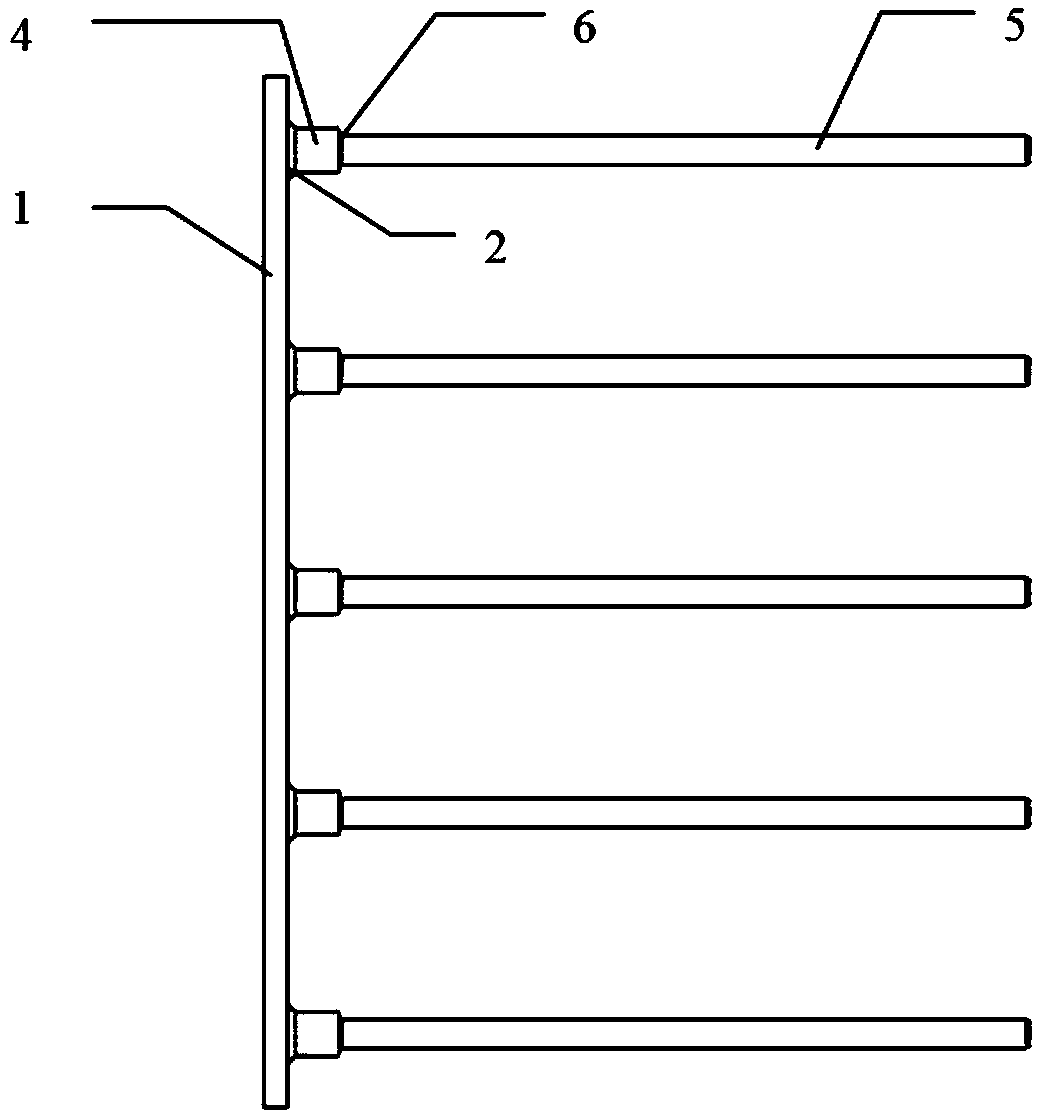

Sleeve combined type embedded part for rebar dense part of high-temperature gas-cooled reactor containment building

InactiveCN109469212AImprove quality and efficiencyImprove construction efficiencyBuilding reinforcementsNuclear reactorControl engineering

The invention relates to a sleeve combined type embedded part for a rebar dense part of a high-temperature gas-cooled reactor containment building, and belongs to the technical field of nuclear powerengineering construction. The sleeve combined type embedded part comprises an anchor plate, a twistable anchor rib and a threaded connection sleeve. An internal thread is machined in the threaded connection sleeve. One end of the threaded connection sleeve is directly connected to the inner surface of the anchor plate through welding. An external thread is machined in one end of the twistable anchor rib. The end, with the external thread, of the twistable anchor rib is screwed into the internal thread of one end of the threaded connection sleeve and screwed down to form threaded connection. Bymeans of the sleeve combined type embedded part, the problem that conventional anchor plate-anchor rib welded type embedded parts especially some large embedded parts of a rebar dense part of a containment building are difficult to install in place is successfully solved, the installation quality and construction efficiency of the embedded part are greatly improved, the construction cycle of thecontainment building is shortened, and the sleeve combined type embedded part has application and popularization value for designing and installing of embedded parts of rebar dense parts in other nuclear reactor types and other engineering fields.

Owner:CHINERGY CO LTD

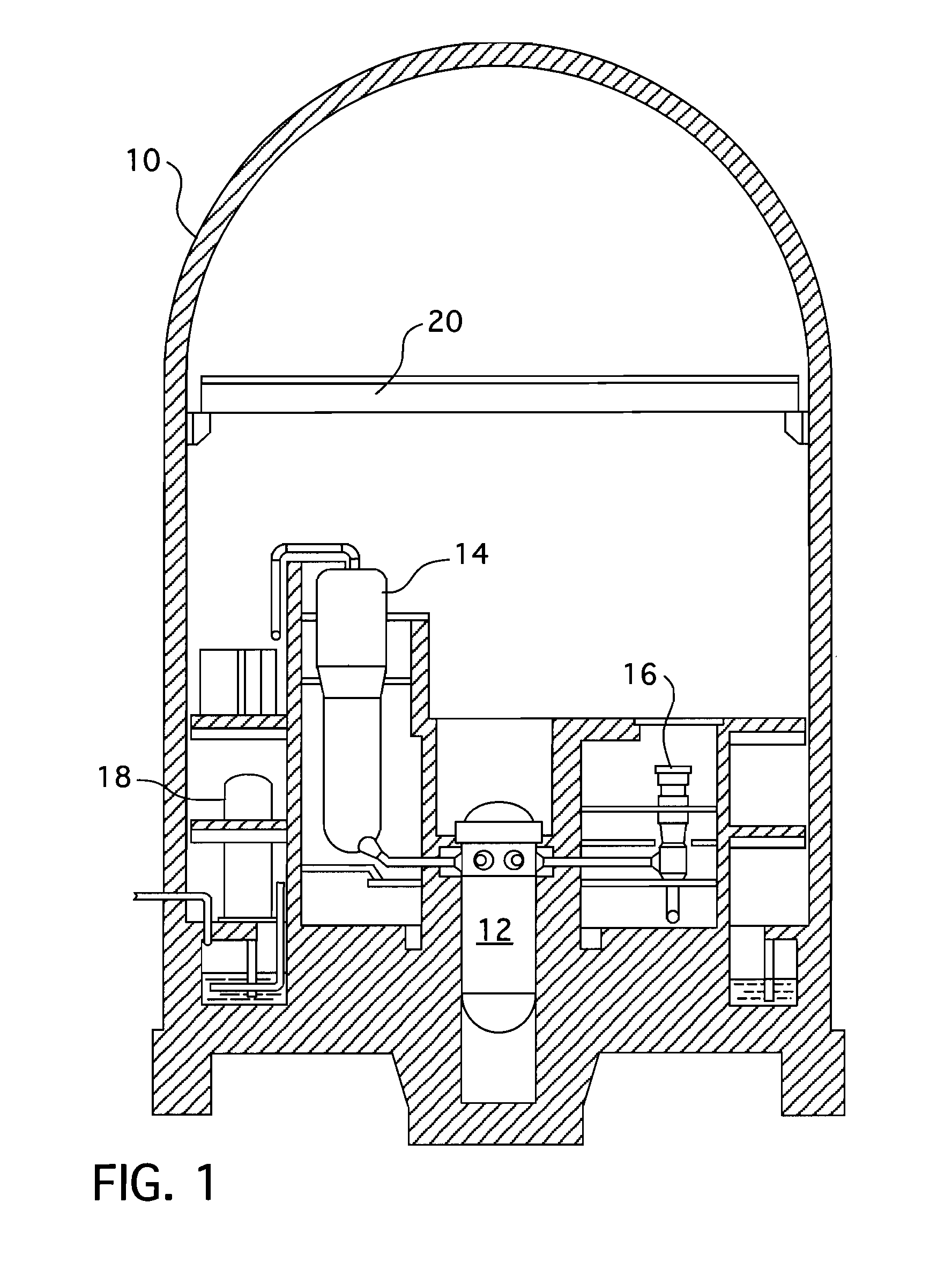

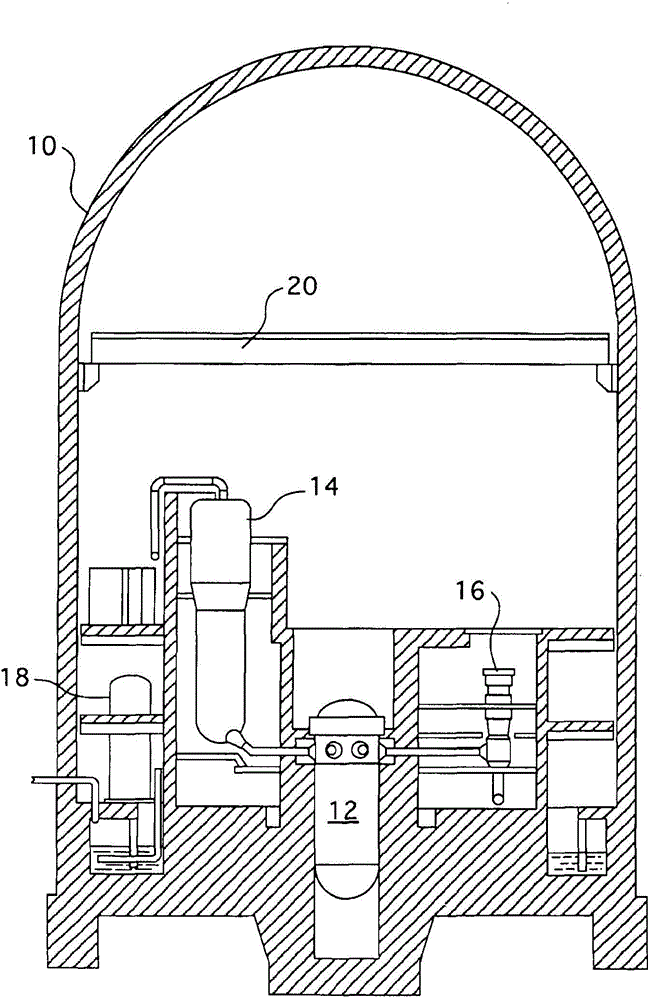

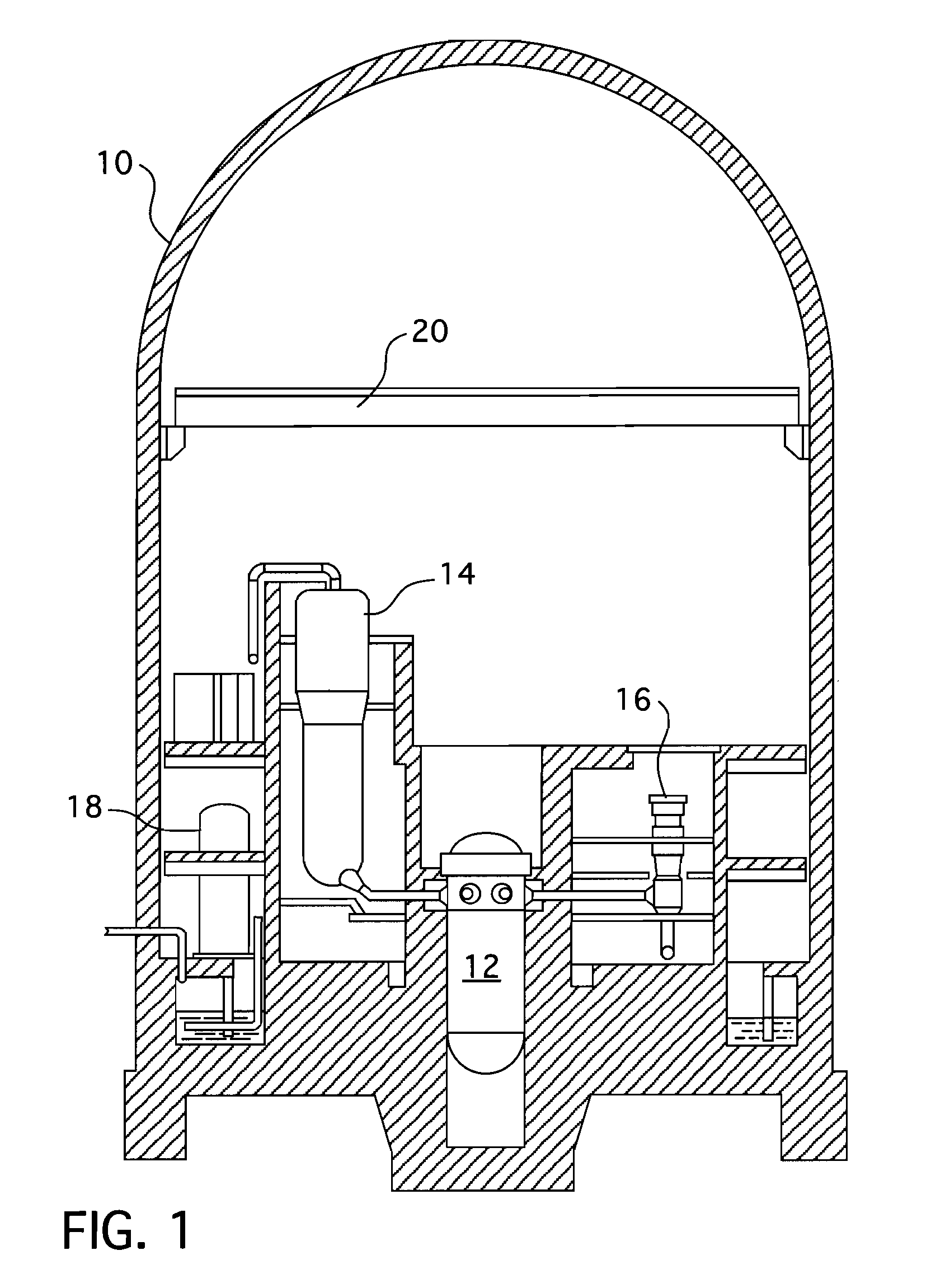

Small nuclear reactor containment system

ActiveUS20180330836A1More heat dissipationEffective coolingPower plant safety arrangementIntegral reactorsContainment buildingReactor safety

A nuclear reactor containment system including a nuclear reactor and a container enclosing the nuclear reactor. The container includes a number of heat removal systems each having an active state and an inactive state, wherein the heat removal systems dissipate heat from the container more efficiently in the active state than in the inactive state, and wherein the heat removal systems are structured to switch from the inactive state to the active state based on a temperature of the container.

Owner:WESTINGHOUSE ELECTRIC CORP

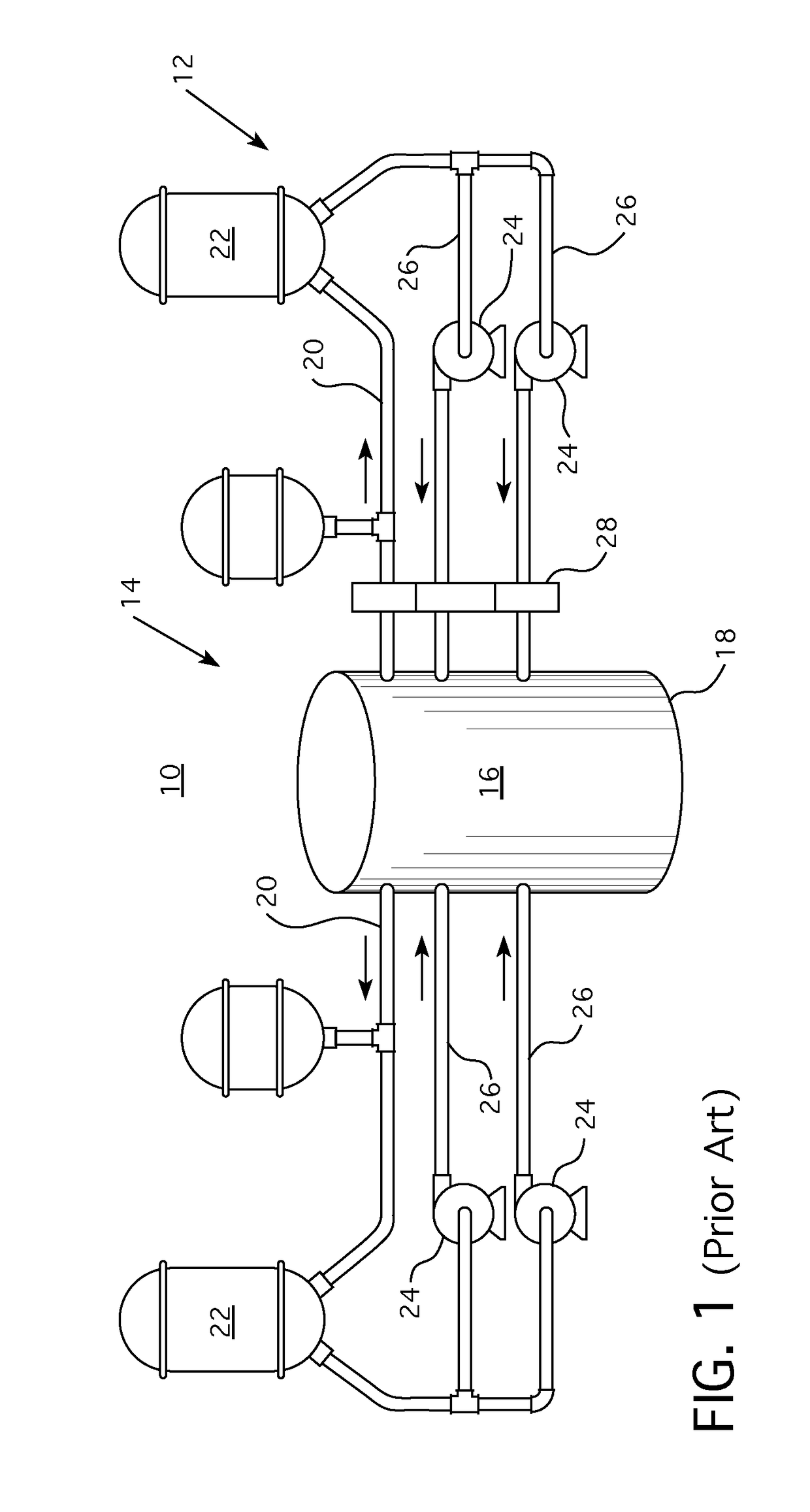

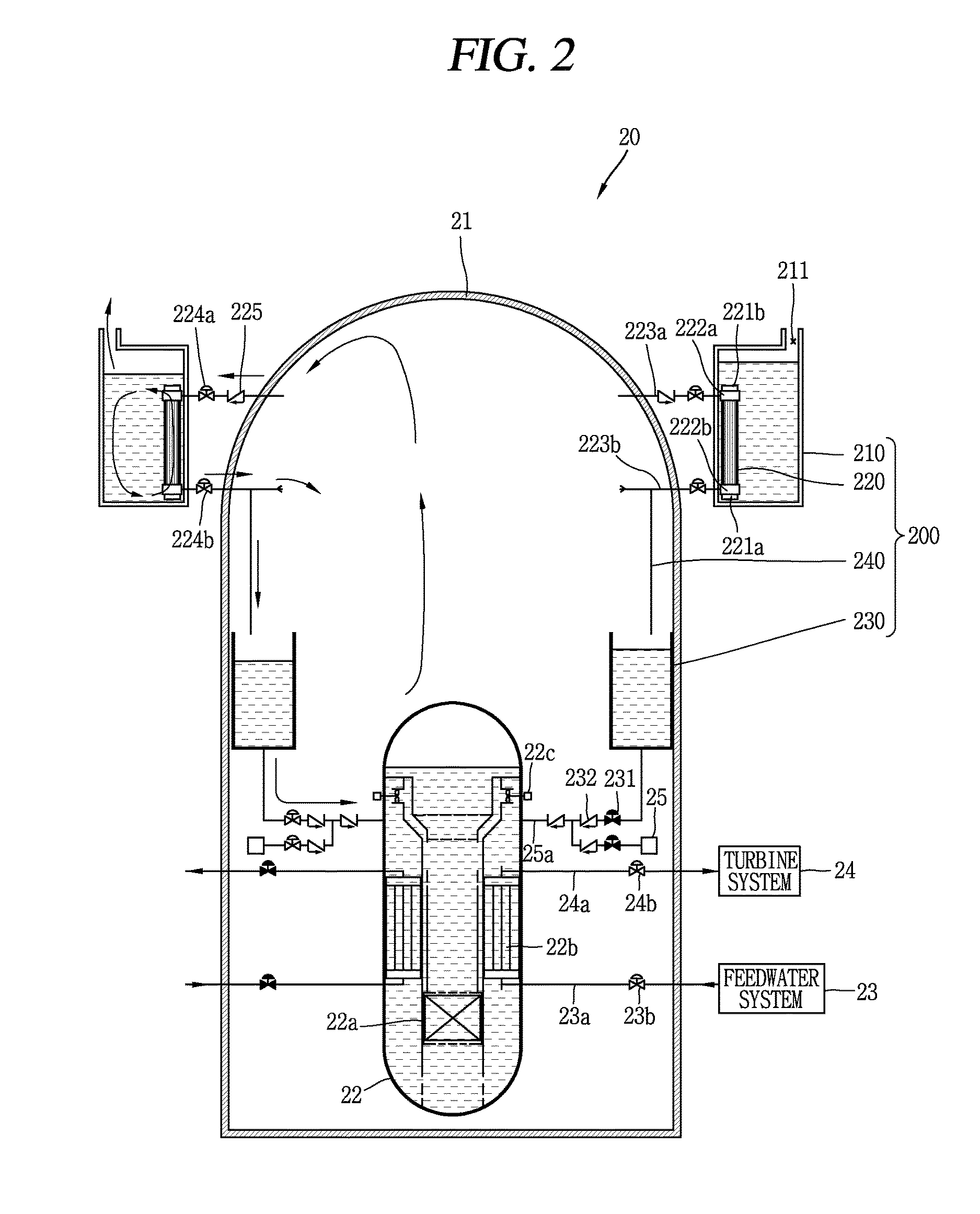

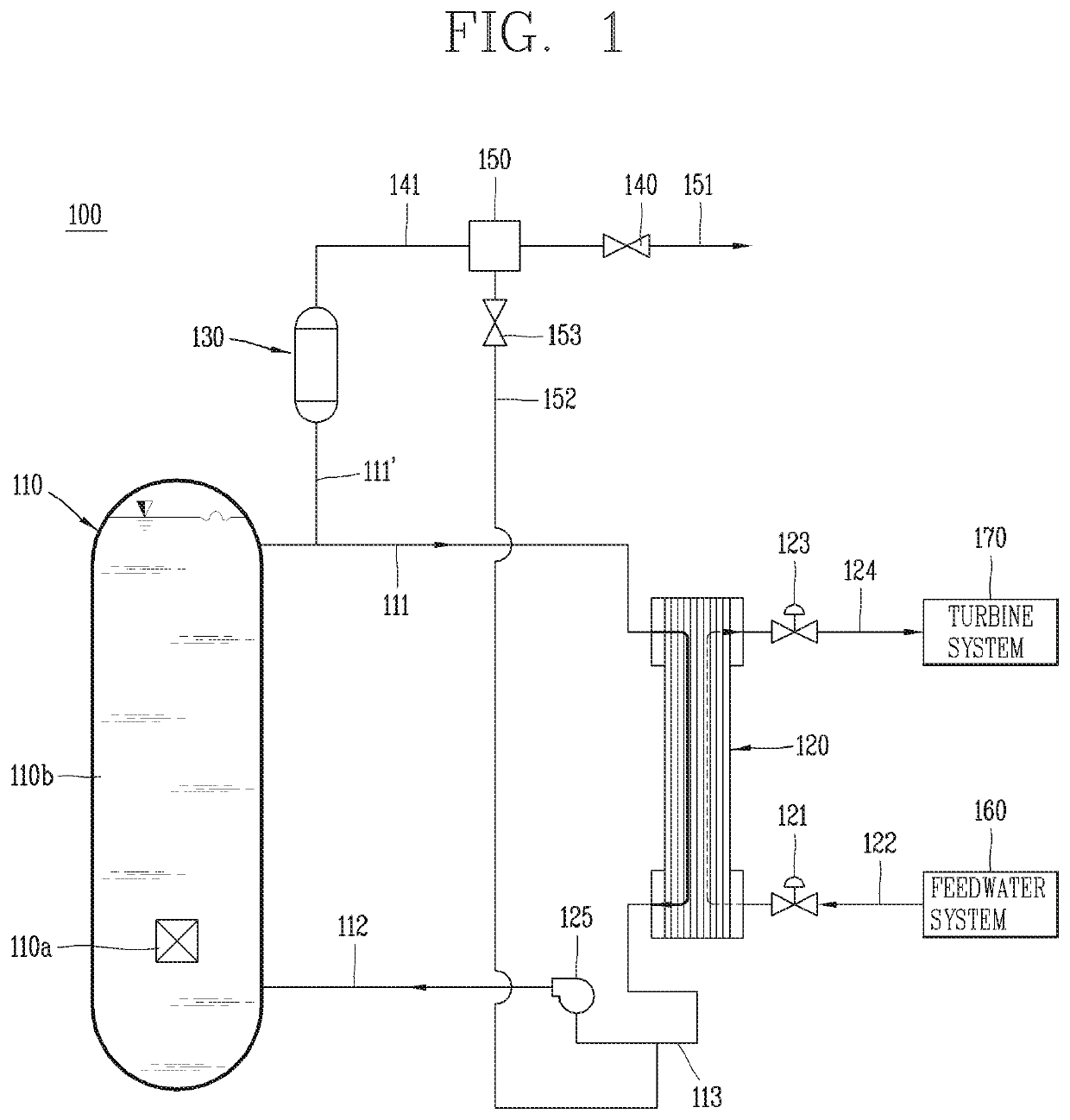

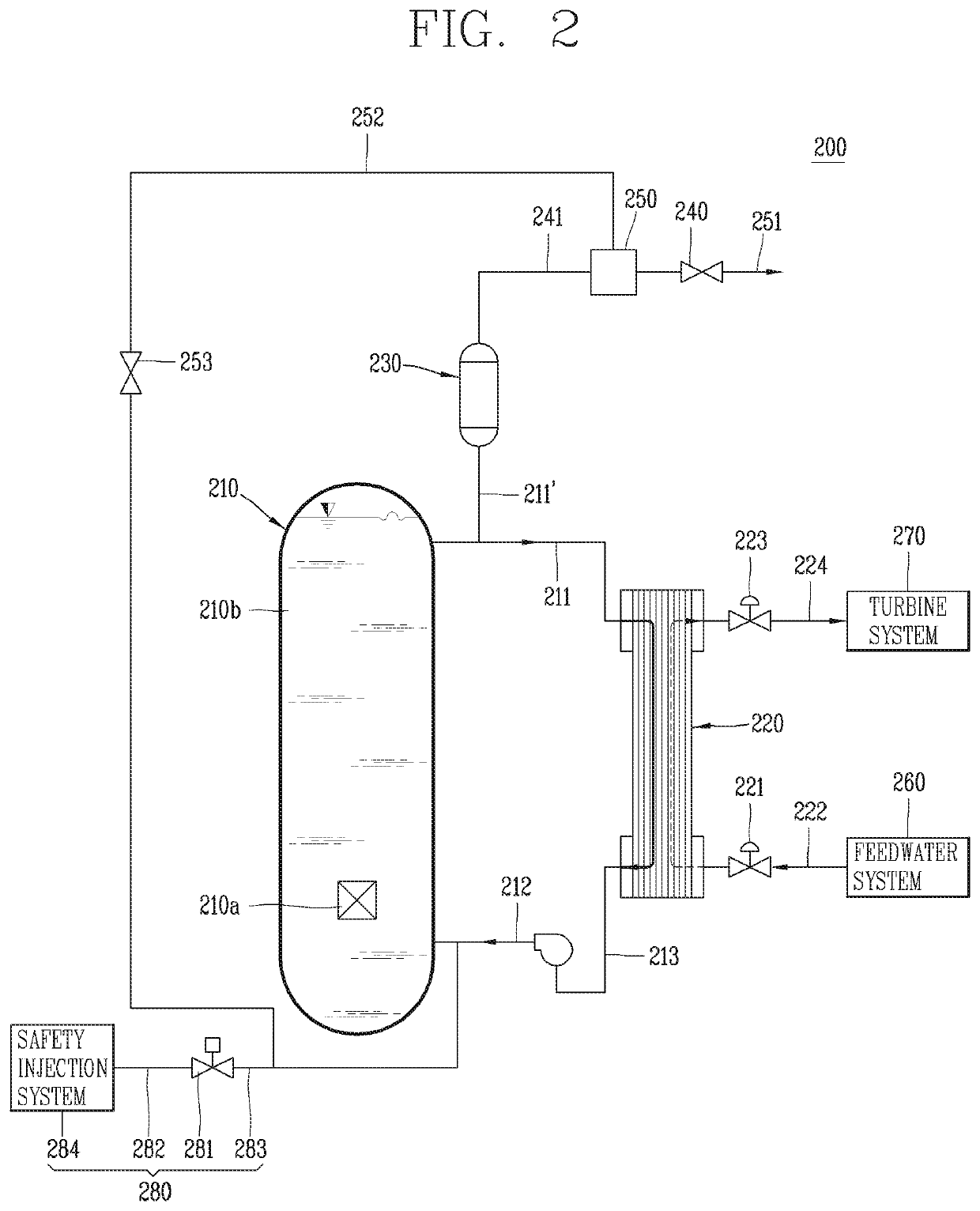

Coolant recirculation system of nuclear power plant

InactiveUS20200234835A1Easy dischargeSteam generation using mechanical energyNuclear energy generationNuclear engineeringGas phase

A coolant recirculation system of a nuclear power plant is provided that may include: a reactor vessel configured to accommodate a reactor core and a reactor coolant therein; a steam generator configured to transfer a gas, converted from a liquid phase to a gaseous phase by exchanging heat with the reactor coolant, to a turbine system; a pressurizer configured to control pressure of the reactor coolant in the reactor vessel; a primary system pressure reducing valve located above the pressurizer and configured to open at a predetermined pressure to discharge the reactor coolant into a containment building for rapid depressurization; and a moisture separator connected to the primary system pressure reducing valve to separate moisture. The moisture separator may separate the reactor coolant into a gaseous phase and a liquid phase. Then, the liquid phase reactor coolant may be returned to the reactor vessel to be recirculated.

Owner:KOREA ATOMIC ENERGY RES INST

Electrical penetration piece of liquid-sealed nuclear reactor containment

PendingCN109859864AReduce volumeSmall footprintNuclear energy generationContainmentNuclear reactorContainment building

The invention relates to a nuclear reactor containment assembly, and particularly relates to an electrical penetration piece of the liquid-sealed nuclear reactor containment. The electrical penetration piece comprises a sleeve; a plunger is arranged at the opening part of the sleeve, and the plunger is in sealing connection with the sleeve; conductive columns are arranged in the sleeve, and a gapis formed between the conductive columns and the inner wall of the sleeve; two ends of each conductive column respectively penetrate through the plunger and the bottom of the sleeve to extend outsides; and the conductive columns are in sealing connection with the plunger and the bottom of the sleeve. The electrical penetration piece is characterized in that the sleeve is filled with an insulatingliquid, the side wall of the sleeve is provided with a liquid level opening, a liquid level meter is arranged in the liquid level opening, and the outer wall of the liquid level meter is in sealing connection with the inner wall of the liquid level opening. The sealing effect of the electrical penetration piece is good, potential safety hazards are avoided, the use range is wide, the size is small, and the occupied space is small.

Owner:WUXI HAIHE EQUIP TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com