Sleeve combined type embedded part for rebar dense part of high-temperature gas-cooled reactor containment building

A high-temperature gas-cooled reactor and containment technology, which is applied to building components, building reinforcements, structural elements, etc., can solve problems such as difficult installation and placement, and achieve the effect of avoiding mutual influence and improving installation quality and construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

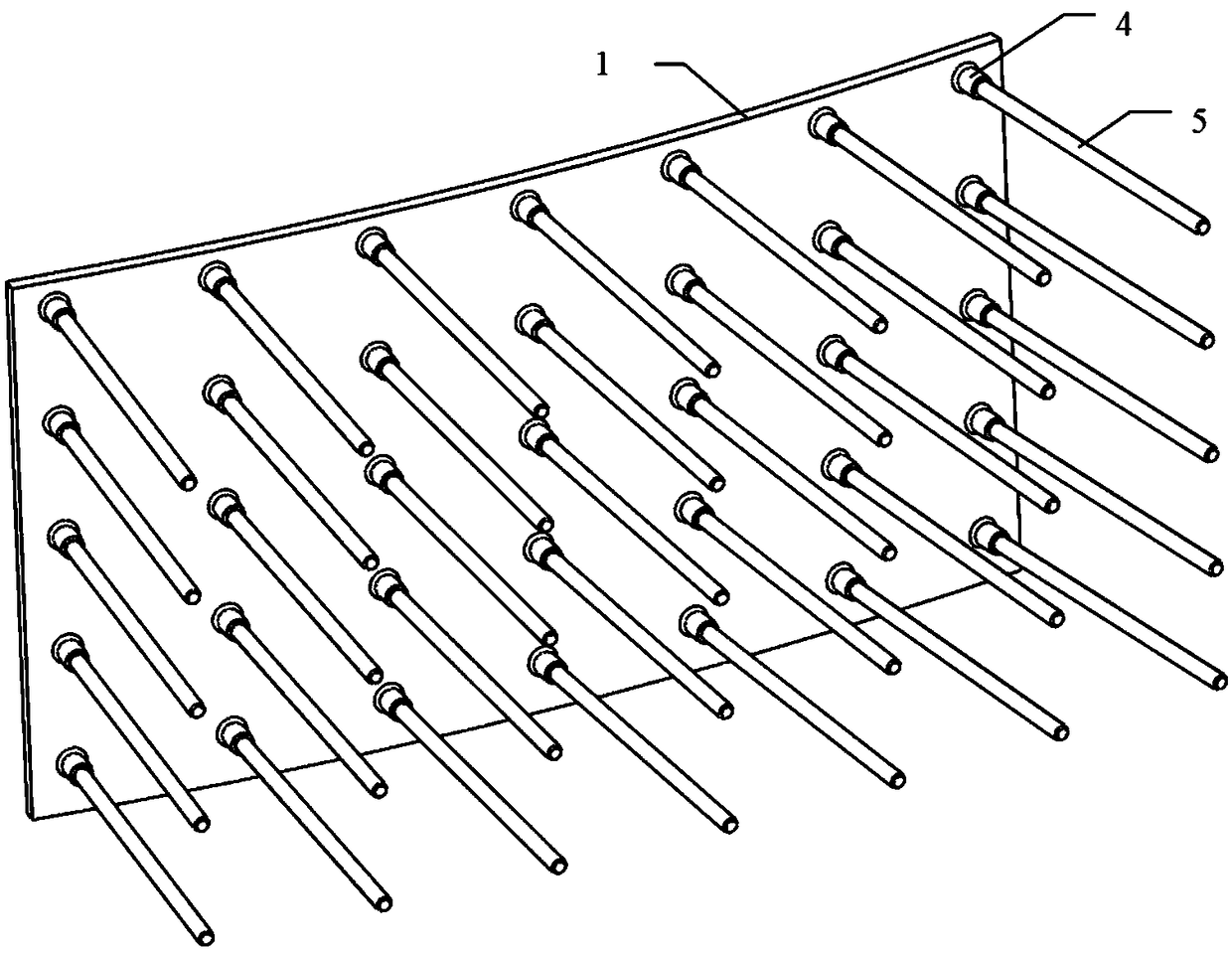

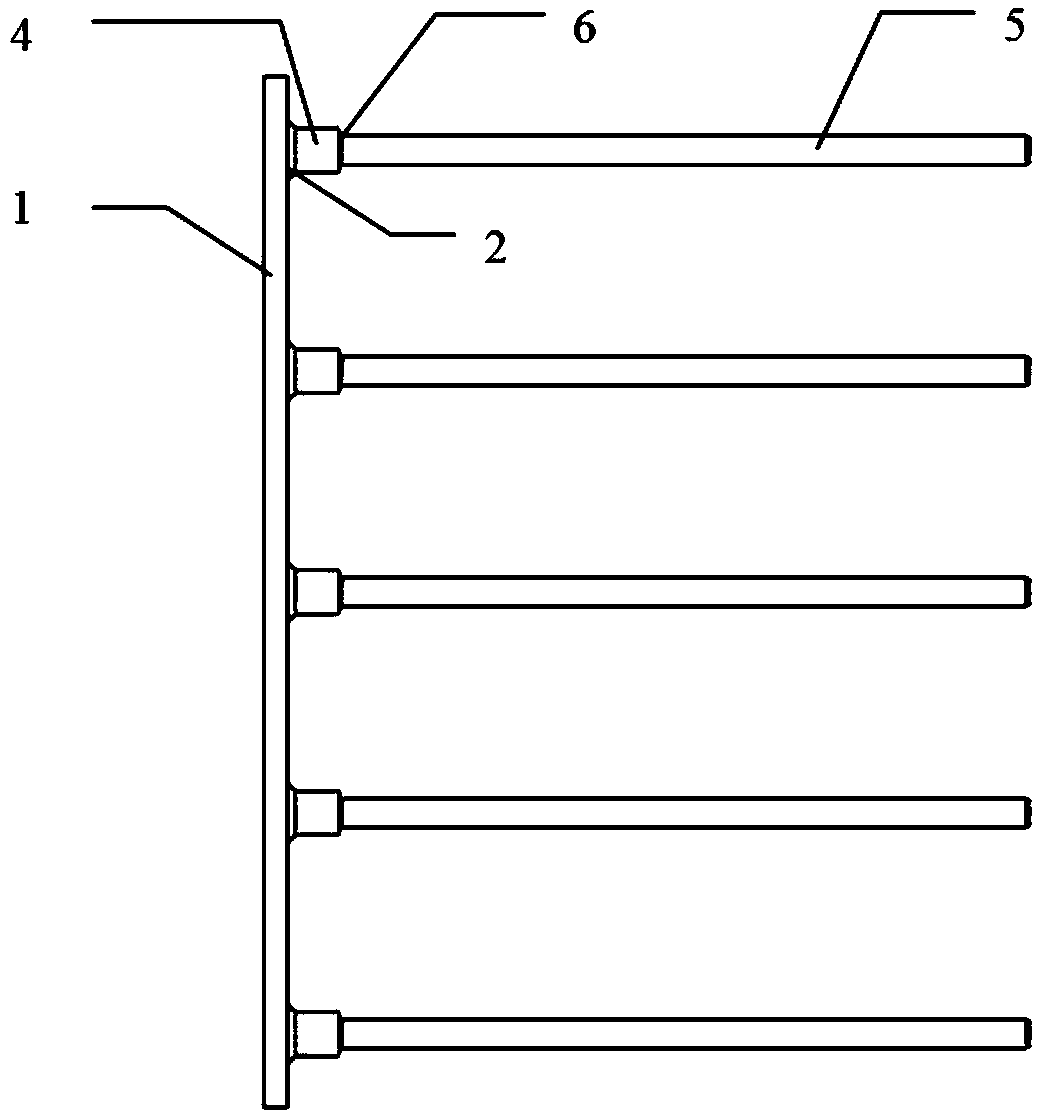

[0013] The sleeve-combined pre-embedded part proposed by the present invention is used for the high-temperature gas-cooled reactor containment where steel bars are densely packed. Its structure is as follows: figure 2 As shown, it includes an anchor plate 1, a screwable anchor bar 5 and a threaded connection sleeve 4, the threaded connection sleeve is processed with internal threads, and one end of the threaded connection sleeve is directly connected to the inner surface of the anchor plate by welding 2; the screwable anchor bar One end of 5 is processed with external thread, which can be screwed. One end with external thread of anchor bar 5 is screwed into its internal thread from one end of threaded connection sleeve 4 and tightened to form threaded connection 6, such as image 3 shown.

[0014] Below in conjunction with accompanying drawing, introduce content of the present invention in detail:

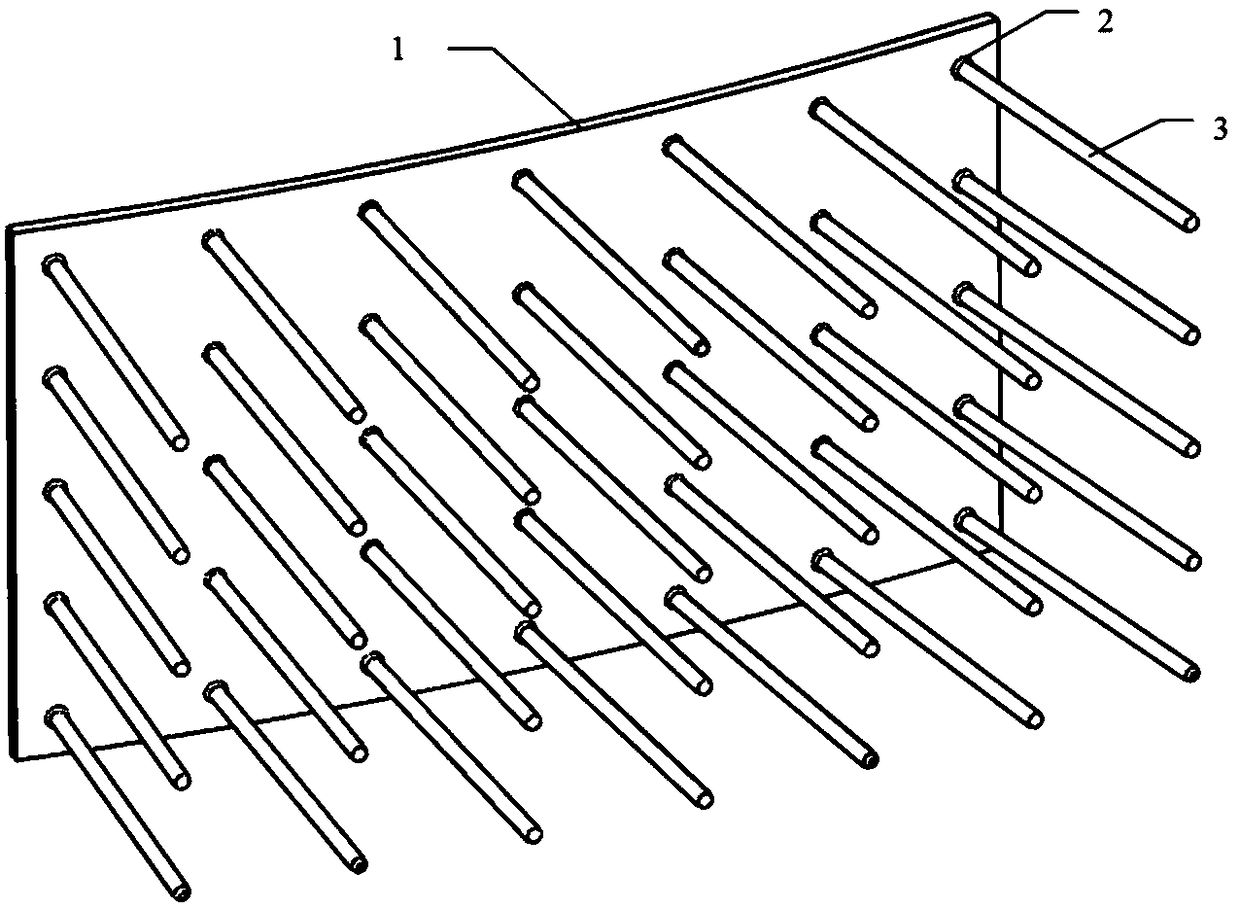

[0015] The present invention proposes a sleeve-combined pre-embedded part fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com