Automatic detection system and method for hollowing in steel lining of nuclear reactor containment

A nuclear reactor and containment steel technology, which is applied in nuclear reactor monitoring, reactors, nuclear engineering, etc., can solve the problems of containment safety accidents, detection loopholes, time-consuming and expensive expenses, etc., to improve detection efficiency, avoid missed detection errors, reduce The effect of testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiment of the system of the present invention is:

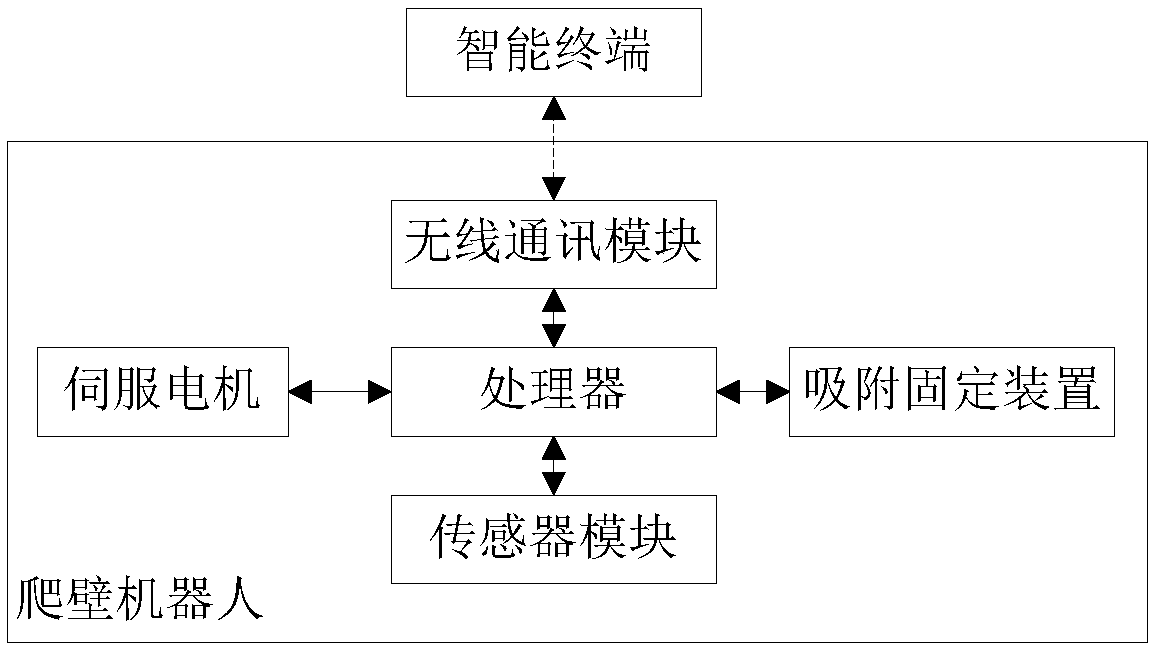

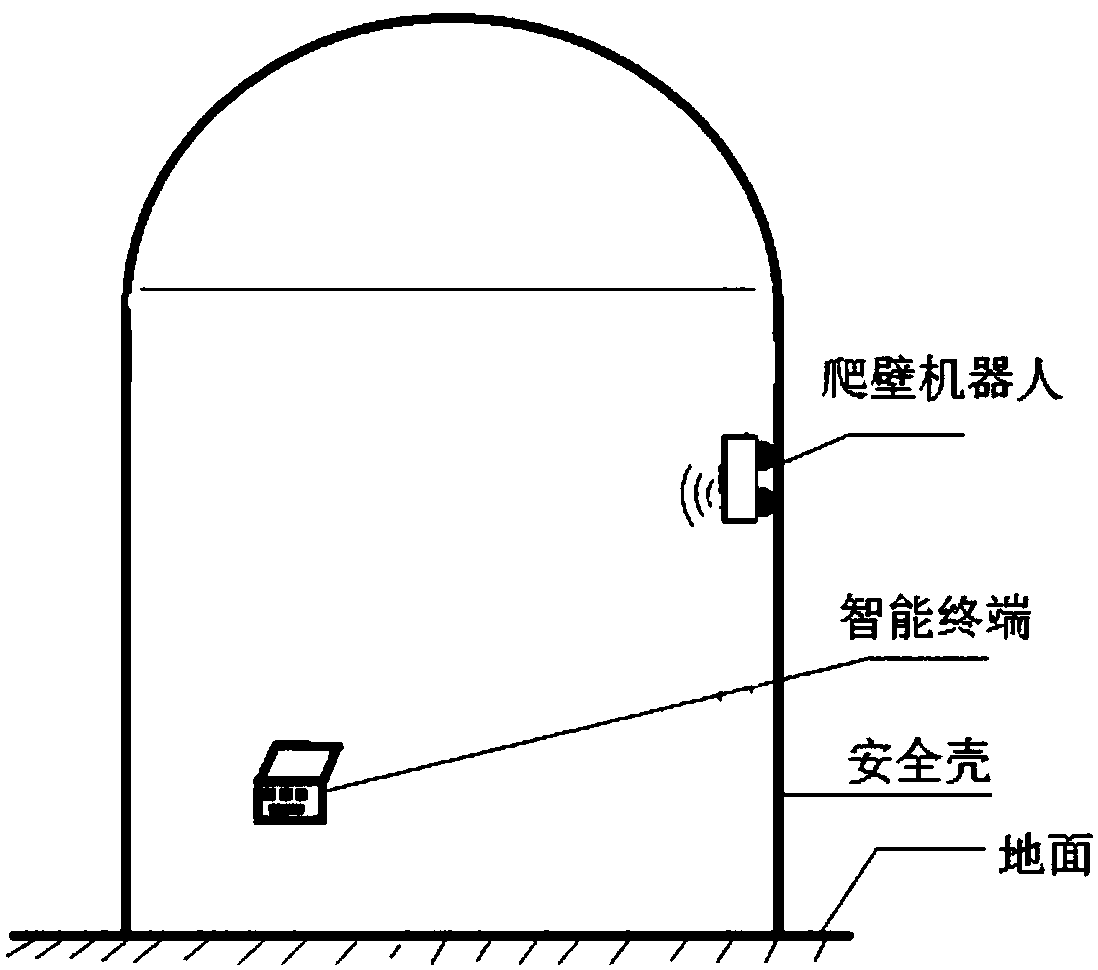

[0040] refer to figure 1 , nuclear reactor containment steel liner hollowing automatic detection system, comprising a wall-climbing robot and an intelligent terminal, the wall-climbing robot is connected to the intelligent terminal, and the wall-climbing robot is provided with a knocking device and a sound collection module;

[0041] The wall-climbing robot is used for crawling in all directions on the inner wall of the nuclear reactor containment, and uses a sound collection module to collect real-time knocked sound information after hitting the inner wall with a knocking device, and transmits the sound information to an intelligent terminal;

[0042] The smart terminal is used to control the wall-climbing robot to move on the inner wall of the containment vessel of the nuclear reactor, and after receiving the sound information, detect whether the steel lining and the inner wall are hollowed according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com