Passive containment cooling system

A passive containment and cooling system technology, applied in cooling devices, nuclear power generation, reactors, etc., can solve the problems of shock resistance and thermal stress shock resistance, many penetrating parts, and limited capacity, so as to promote natural circulation capacity and heat dissipation. Effects of derived performance, fewer penetrations, good seismic performance and thermal stress shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

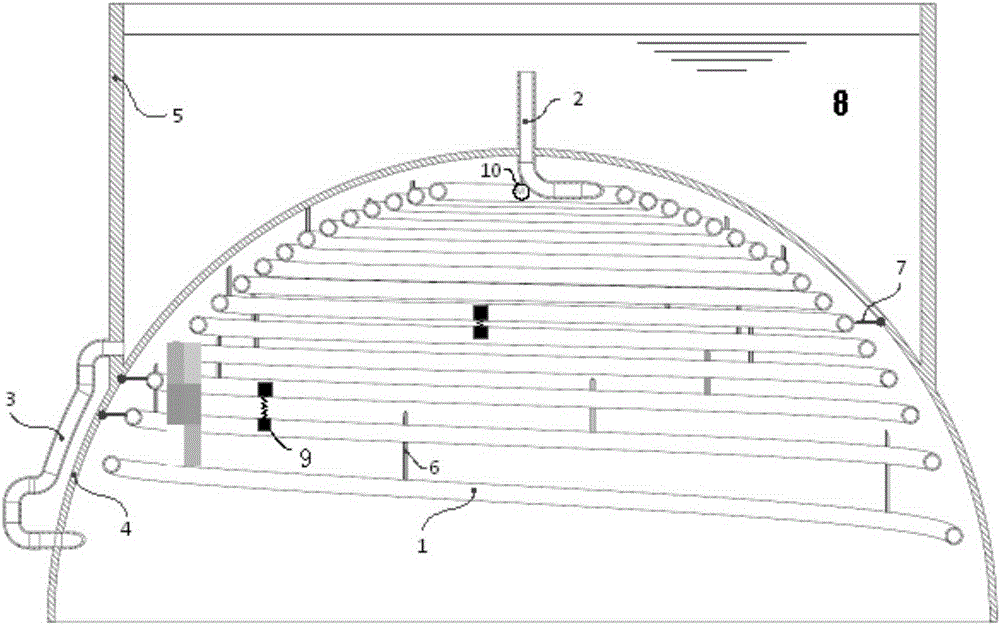

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

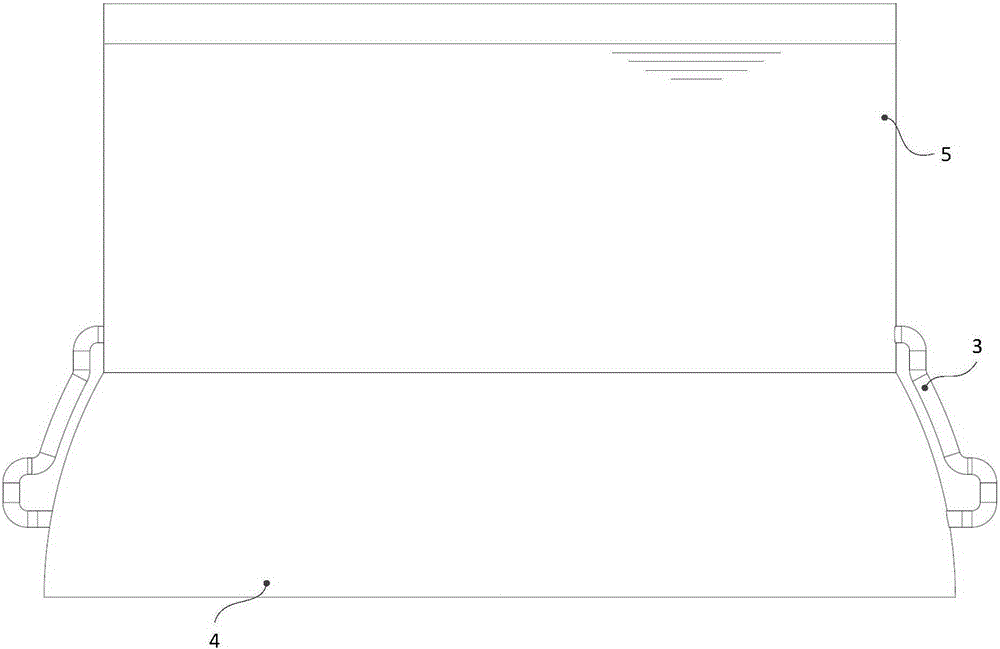

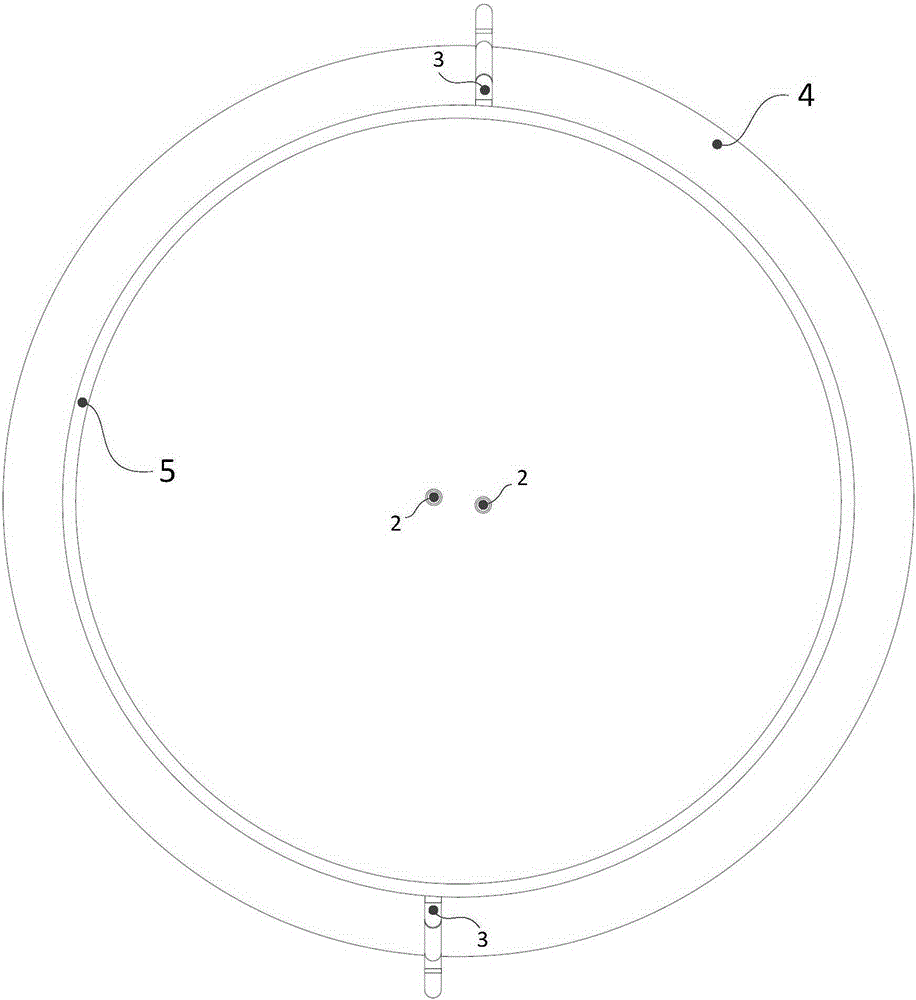

[0023] Such as figure 1 Shown is the passive containment cooling system provided by the present invention. The system includes a top-mounted water tank 5 fixed outside the containment and a spiral coil water cooling wall 1 arranged inside the containment. One end of the spiral coil water cooling wall 1 passes through The natural circulation inlet pipeline 3 is connected to the top water tank 5 , and the other end of the spiral coil water cooling wall is connected to the top water tank 5 through the natural circulation outlet pipeline 2 .

[0024] The spiral coil water wall 1 is arranged in the area of the containment dome 4, and its outer contour surface fits the containment dome 4, and is connected to the containment dome 4 through the longitudinal rigid fixing member 6 and the transverse elastic fixing member 7 respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com