Passive containment vessel spraying device

A passive containment and spray device technology, applied in cooling devices, nuclear power generation, reactors, etc., can solve problems such as high engineering cost and maintenance cost, unfavorable anti-seismic shielding plant, and inability to eliminate the effect of water flow grooves, etc., to achieve improved Safety and economy, low cost and maintenance cost, and the effect of eliminating the effect of water flow grooves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

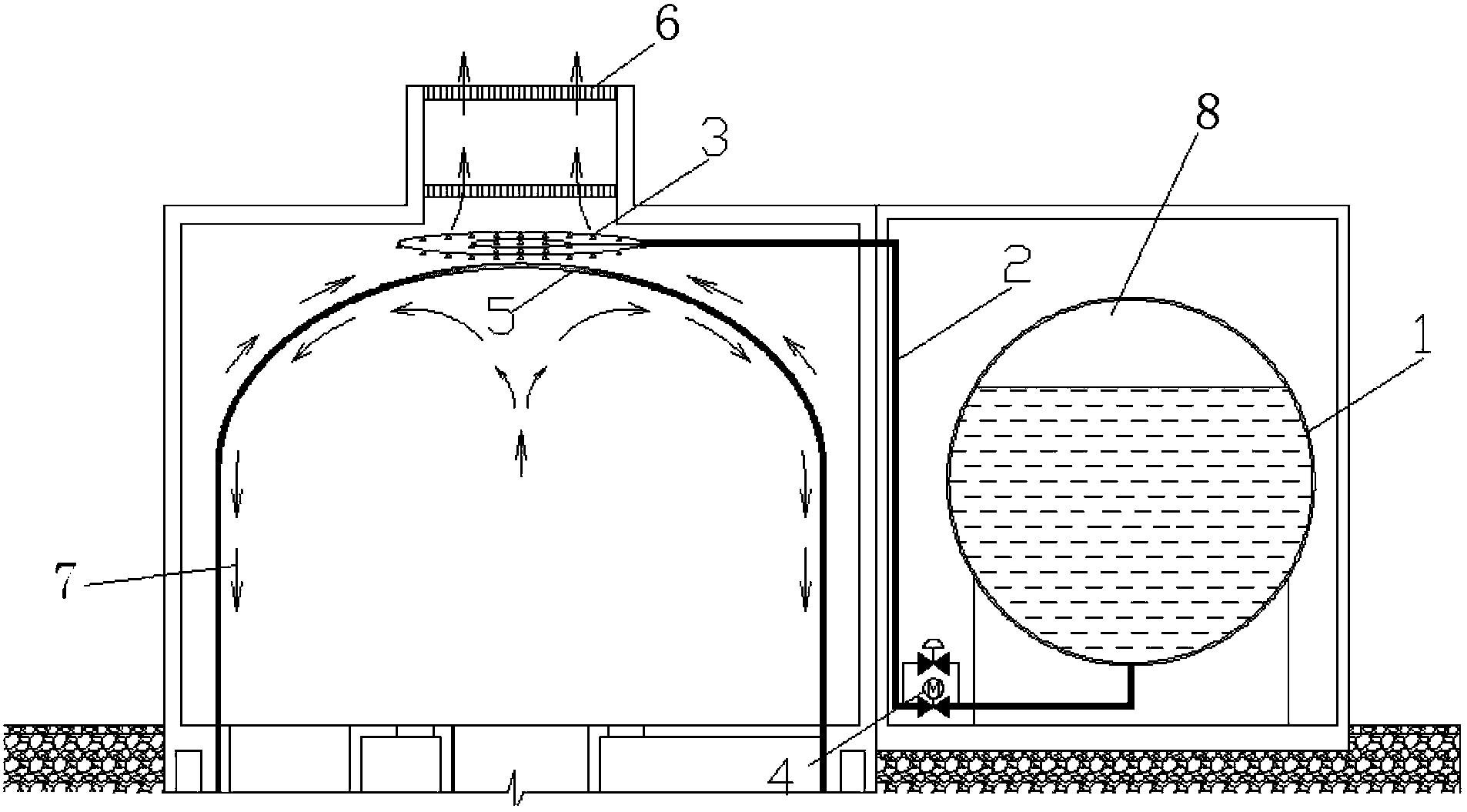

[0014] Such as figure 1 As shown, a passive containment spraying device includes a steel spherical safety spray box 1 filled with water and compressed air 8, and the safety spray box 1 is connected to the annular spray collection through a water pipeline 2 The pipe 3 and the annular spray header 3 are arranged above the containment dome 5, and a normally closed valve group 4 is installed between the water delivery pipeline 2 and the annular spray header 3, wherein the normally closed valve group 4 includes parallel One electric ball valve and one manual valve.

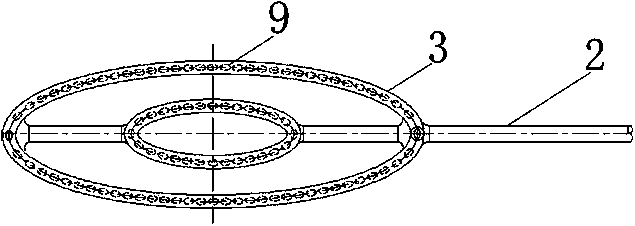

[0015] Such as figure 2 As shown, the annular spraying header 3 includes 2 rings of ring-shaped shower pipes, each ring of ring-shaped shower pipes is connected to the water delivery pipeline 2, and a plurality of overflow holes 9 are opened on the ring-shaped shower pipes.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com