Steel for gate of extra-thick nuclear reactor containment, and manufacturing method thereof

A nuclear reactor and manufacturing method technology, applied in the field of material processing, can solve the problems that the strength of the steel plate cannot meet the steel requirements for containment gates, and the compression ratio requirements, etc., and achieve novel and unique production technology, uniform and stable low-temperature toughness, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

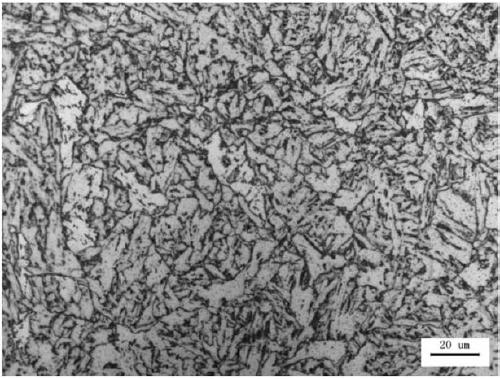

Image

Examples

Embodiment Construction

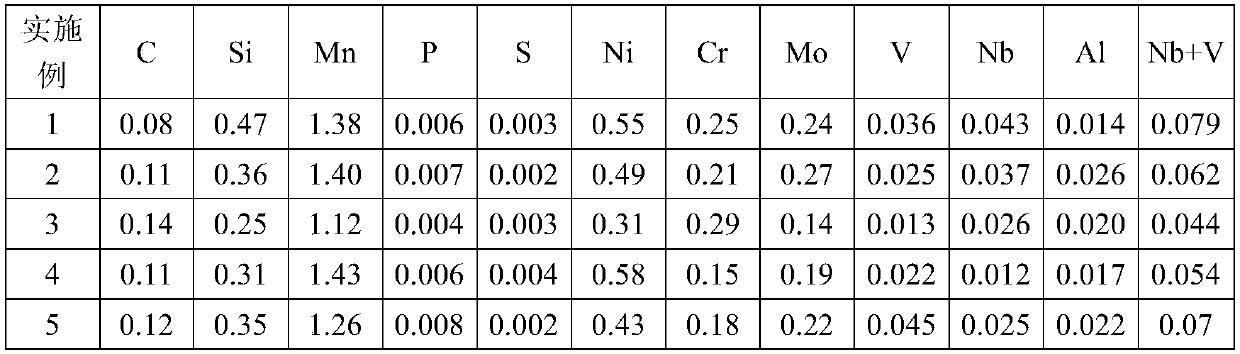

[0035] Below by embodiment the present invention will be further described.

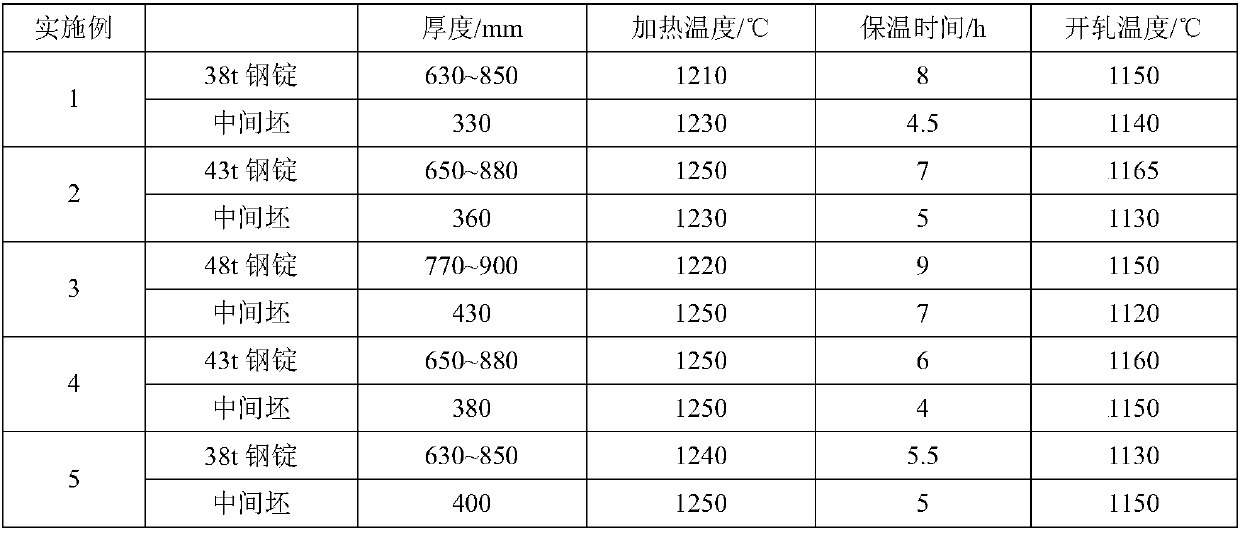

[0036] In the embodiment of the present invention, according to the composition ratio of the technical solution, billeting of the steel ingot—rolling of the intermediate billet—heat treatment is carried out.

[0037] Steel ingot billeting: heat the steel ingot to 1200°C-1250°C for 5h-9h and then carry out billet rolling. The rolling temperature is ≥1100°C. After the intermediate billet is rolled to a thickness of 330mm-450mm, it will be stacked and slowly cooled. Time ≥ 48h.

[0038] Intermediate billet rolling: after unstacking, the intermediate billet is heated at 1200°C-1250°C, held for 4h-7h, and the rolling start temperature is ≥1100°C. After rolling, the steel plates are stacked and slowly cooled, and the slow cooling time is ≥24h.

[0039] Heat treatment: Quenching temperature is 920°C±20°C, holding time is 1min / mm-4min / mm, and then water-cooled immediately until the temperature of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com