Stretching-straightening device for online heating-straightening process of magnesium alloy extrusion material

A heating device and a technology for extruding materials, applied in the field of material processing, can solve problems such as bending and instability, and achieve the effects of improving the quality of profiles, simplifying operations, and avoiding thermal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

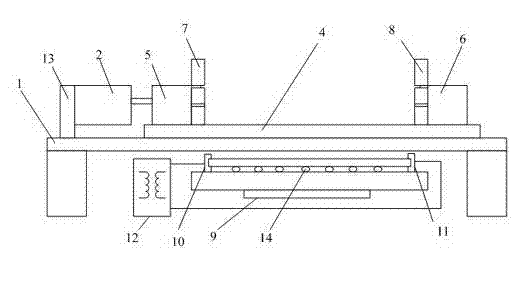

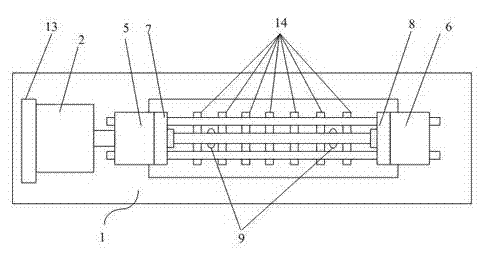

[0037] Such as figure 1 , 2 As shown, the stretching straightening device for the magnesium alloy extruded material online heating straightening process of the present invention includes a stretching straightening device and a heating device;

[0038] The stretching and straightening mechanism includes a frame 1, a stretching drive mechanism 2 and a clamping drive mechanism. The frame is provided with double rails 4, and the rails are provided with chucks I 5 and II 6 that are slidably matched with the surface of the rails.

[0039] In this embodiment, the stretching driving device 2 is a hydraulic stretching oil cylinder, which is arranged on the frame 1 at the end position corresponding to one end of the double rails, and the stretching rod of the stretching oil cylinder is fixedly connected to the chuck 15. Under the action of the stretching drive device 2, the chuck 15 slides back and forth along the track direction; one end of the frame 1 is provided with a support plate...

Embodiment 2

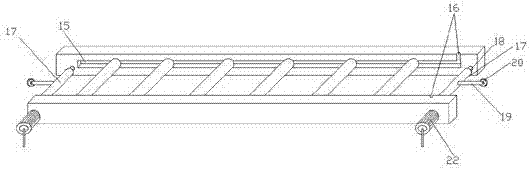

[0047] Such as image 3 , 4 As shown, the difference between this embodiment and Embodiment 1 is that the insulating roller is arranged between the double rails, and the installation method is that guide grooves 15 extending horizontally along the length direction are respectively provided on the opposite inner sides of the double rails, and the insulating rollers The two ends of the idler are respectively embedded in the guide groove for fixing, and at least one guide groove on one side is provided with at least one notch 16 for loading or removing the insulating idler; through such a structure, the idler can be easily removed , installed, and the installation density of insulating rollers can be adjusted according to the length specification of the material to be straightened.

[0048] The lifting mechanism includes two lifting rollers 17. The lifting rollers 17 are installed on the edges of the two ends of the guide grooves on both sides in a manner parallel to the axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com