Light guide module for a primary optical assembly of a motor vehicle lighting device and primary optical assembly

A technology for lighting equipment and optical components, which is applied in the field of level light, and can solve problems such as increased manufacturing costs and light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

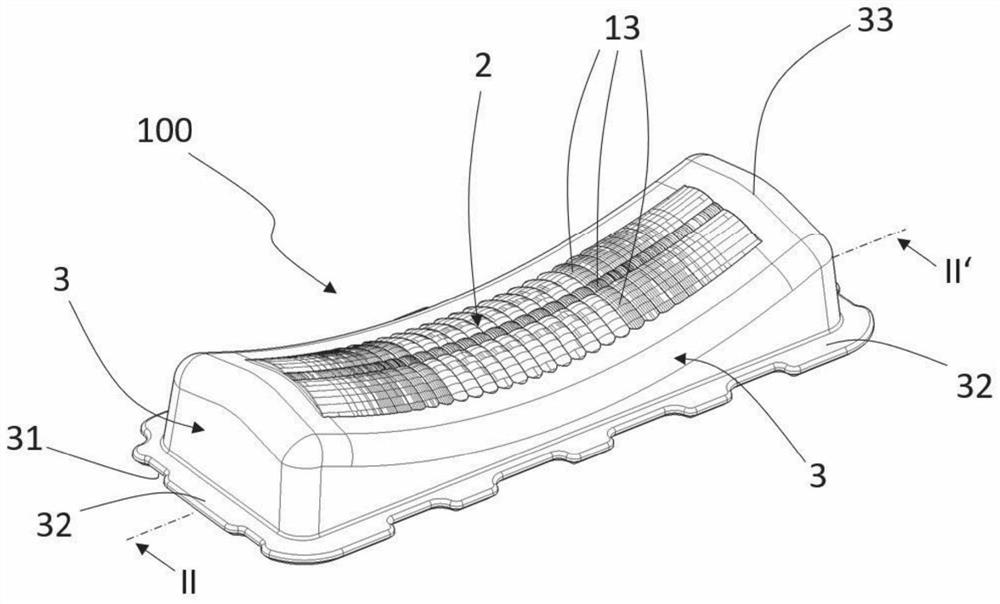

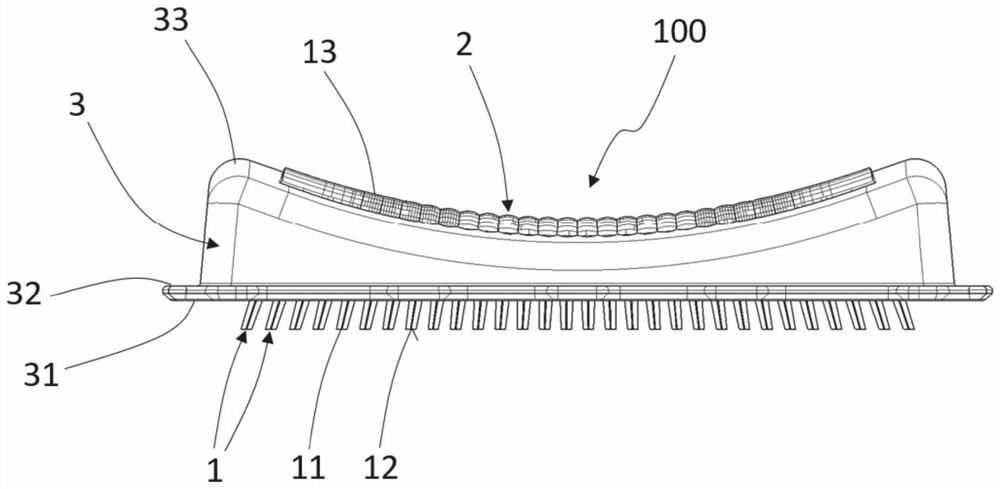

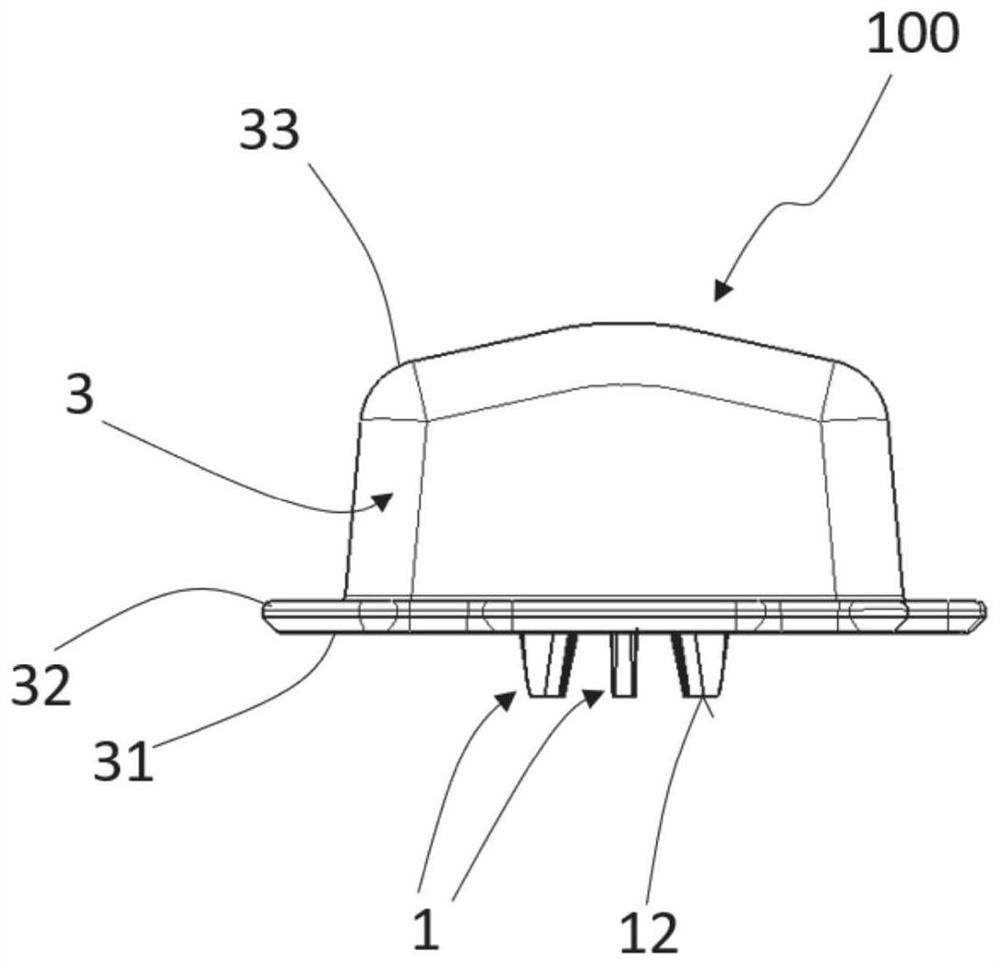

[0022]Figure 1a , 1b and 1c show a perspective view of a light conductor module 100 according to the invention, the light exit surface 2 of which is formed by the distal ends 13 of a plurality of light conductor segments 1 (for reasons of clarity, only selected The light conductor segment 1 is assigned the associated reference numerals), and the light conductor module is delimited on the edge side by a flange 3 running around in the circumferential direction.

[0023] The light conductor segments 1 are arranged next to each other in a matrix, in the example shown there are 3×30 light conductor segments 1 , which are assigned to a corresponding 3×30 LED array in the associated luminaire. The cross-section of the light guide segment 1 can be circular or oval, for example, and / or can vary along the longitudinal expansion direction of the light guide segment 100 . In particular, as in the example shown, the cross section can continue to widen between the light incoupling surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com