Extended box type transformer module

A transformer and box-type technology, which is applied in the direction of transformers, fixed transformers, transformer/inductor parts, etc., can solve problems such as coil defects, coil wires are not neatly wound, and low pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

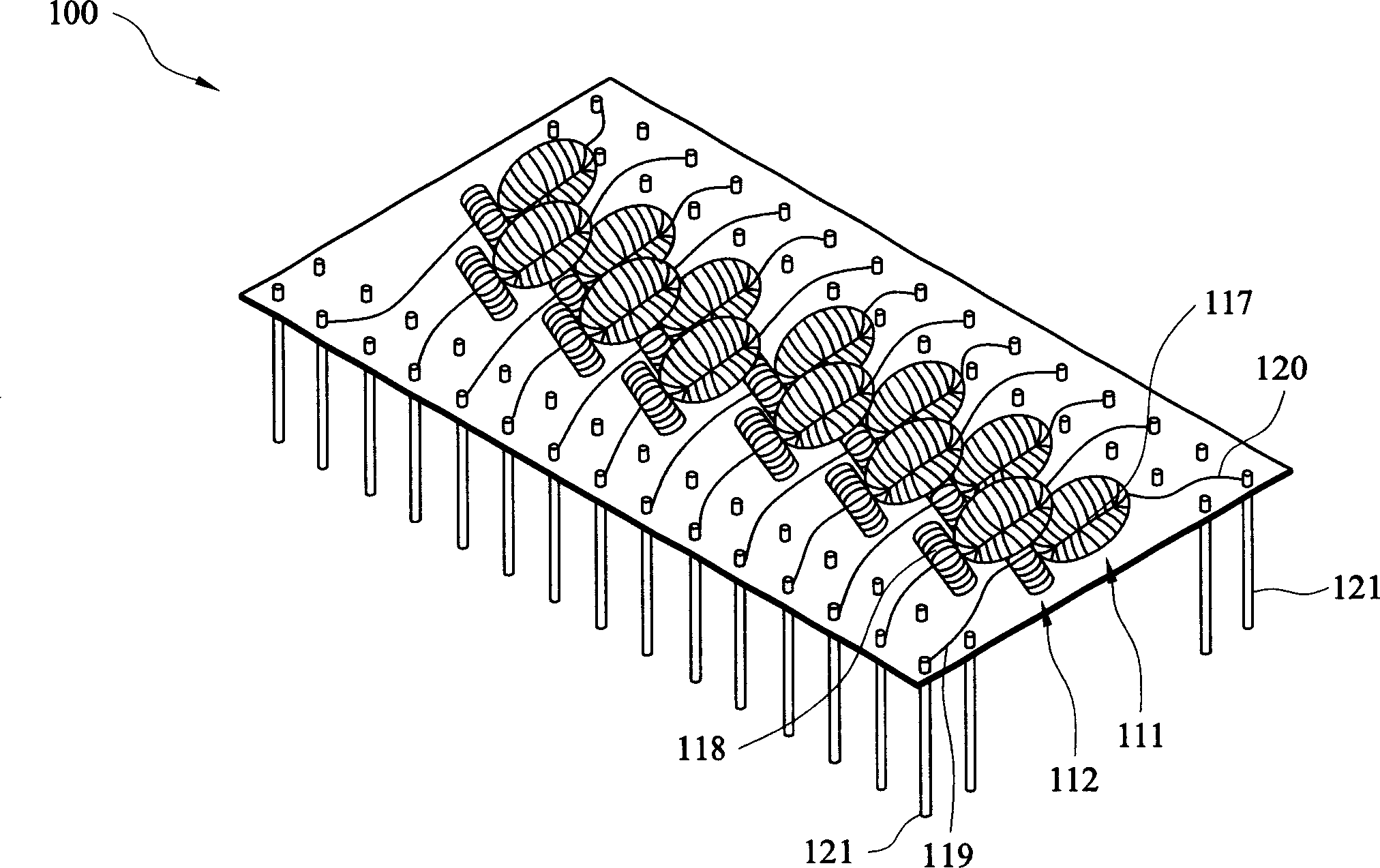

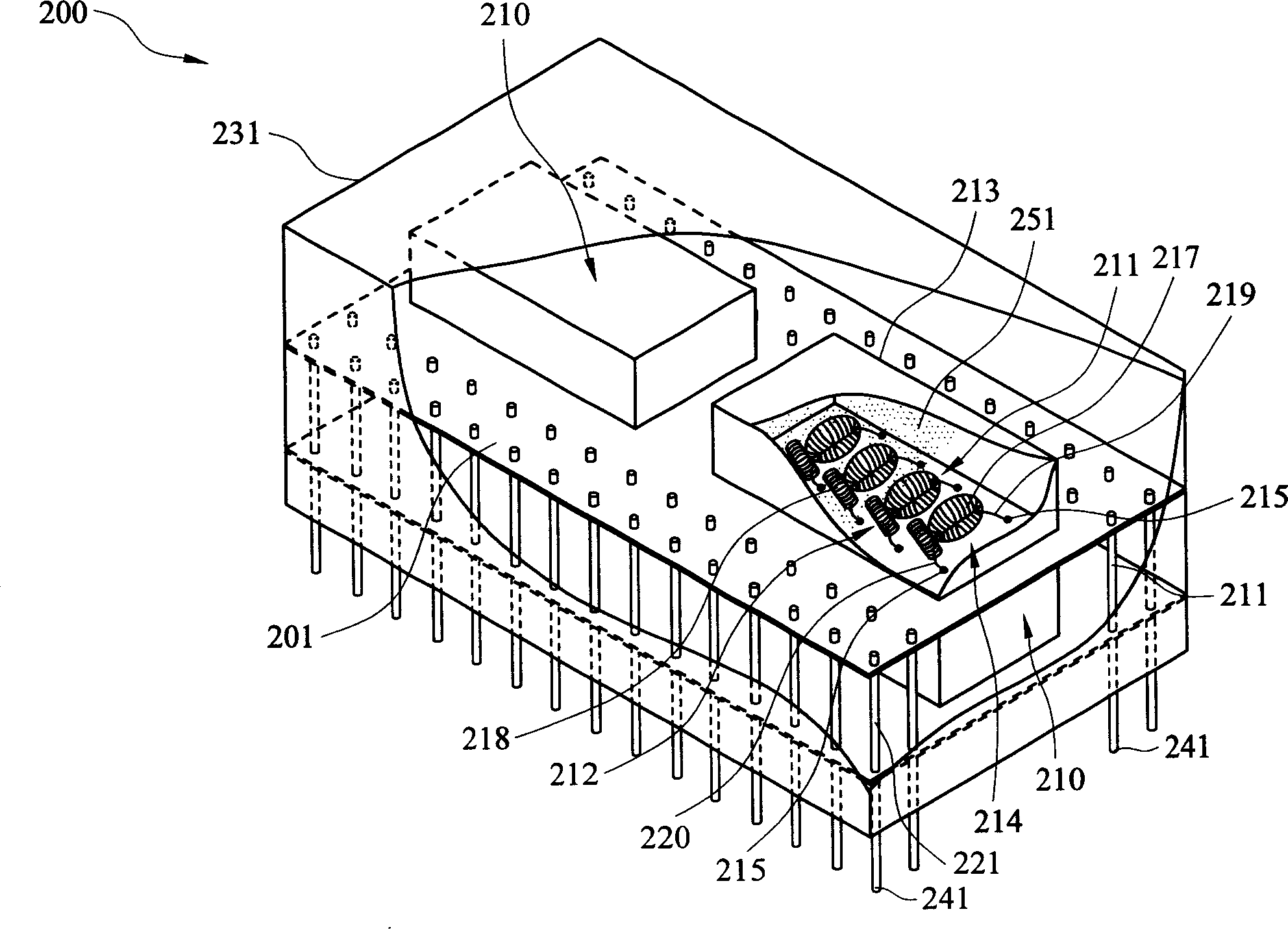

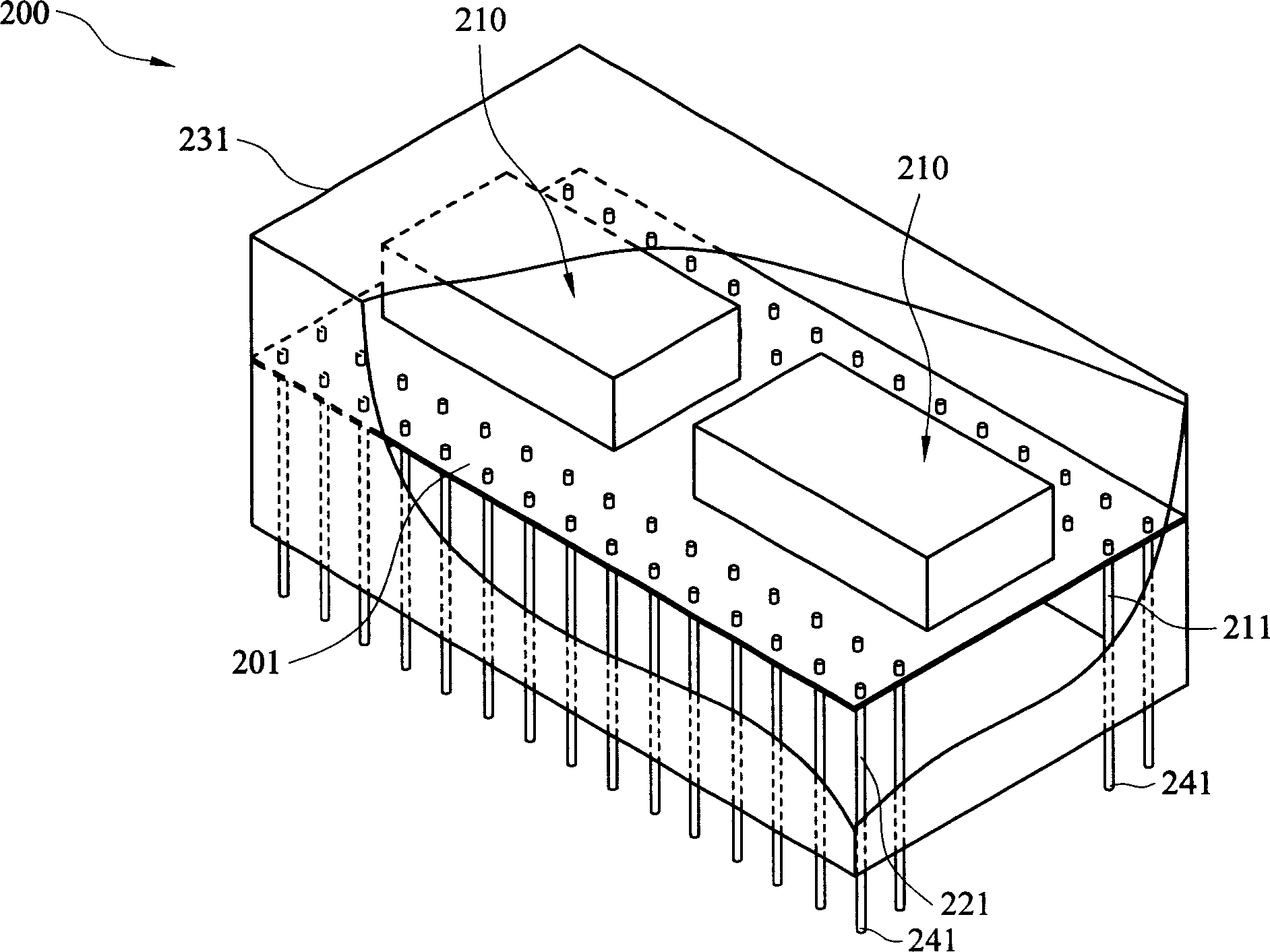

[0030] The expanded box-type transformer module of the present invention is equipped with a plurality of box-type transformers on the circuit board, and the box-type transformers and the circuit board form a stacked structure of at least one layer, thereby improving the process speed and pass rate, reducing known The appearance size of the transformer can also freely expand the transformation performance of the transformer module. The following fit Figure 2 to Figure 4 The expanded box-type transformer module of the present invention will be described in detail.

[0031] First, please refer to figure 2 , which is a three-dimensional schematic diagram illustrating an extended box-type transformer module according to a preferred embodiment of the present invention. exist figure 2 Among them, the extended box-type transformer module 200 includes at least one circuit board 201 , wherein a plurality of box-type transformers 210 and a plurality of terminals 221 electrically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com