Device for the production of cellulose staple fibers

A technology for manufacturing equipment and short fibers, which is applied in the field of manufacturing equipment for cellulose short fibers, and can solve the problems of insufficient washing, poor finishing, and poor crosslinking of short fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

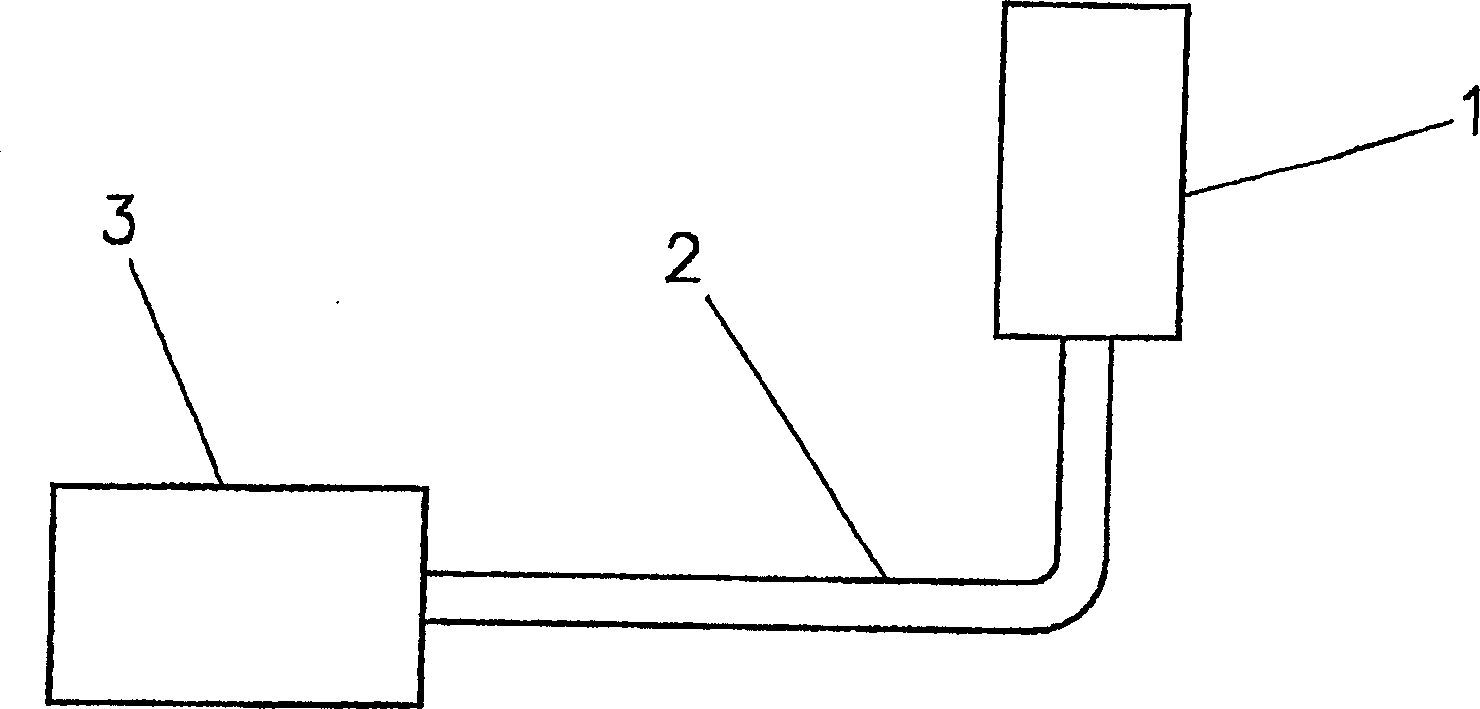

[0033] figure 1 A cutting device 1 , a liquid delivery device 2 and a fiber suspending device 3 are shown. The fibers cut into short fibers in the cutting device 1 are flushed with liquid into the liquid delivery device 2 and sent to the fiber suspension device 3 . According to the prior art, the liquid delivery device 2 is configured as a tank which is not completely filled with liquid. The fiber strands are formed in the fiber suspension device 3 and in a subsequent stage the fiber strands are cleaned and reprocessed (not shown).

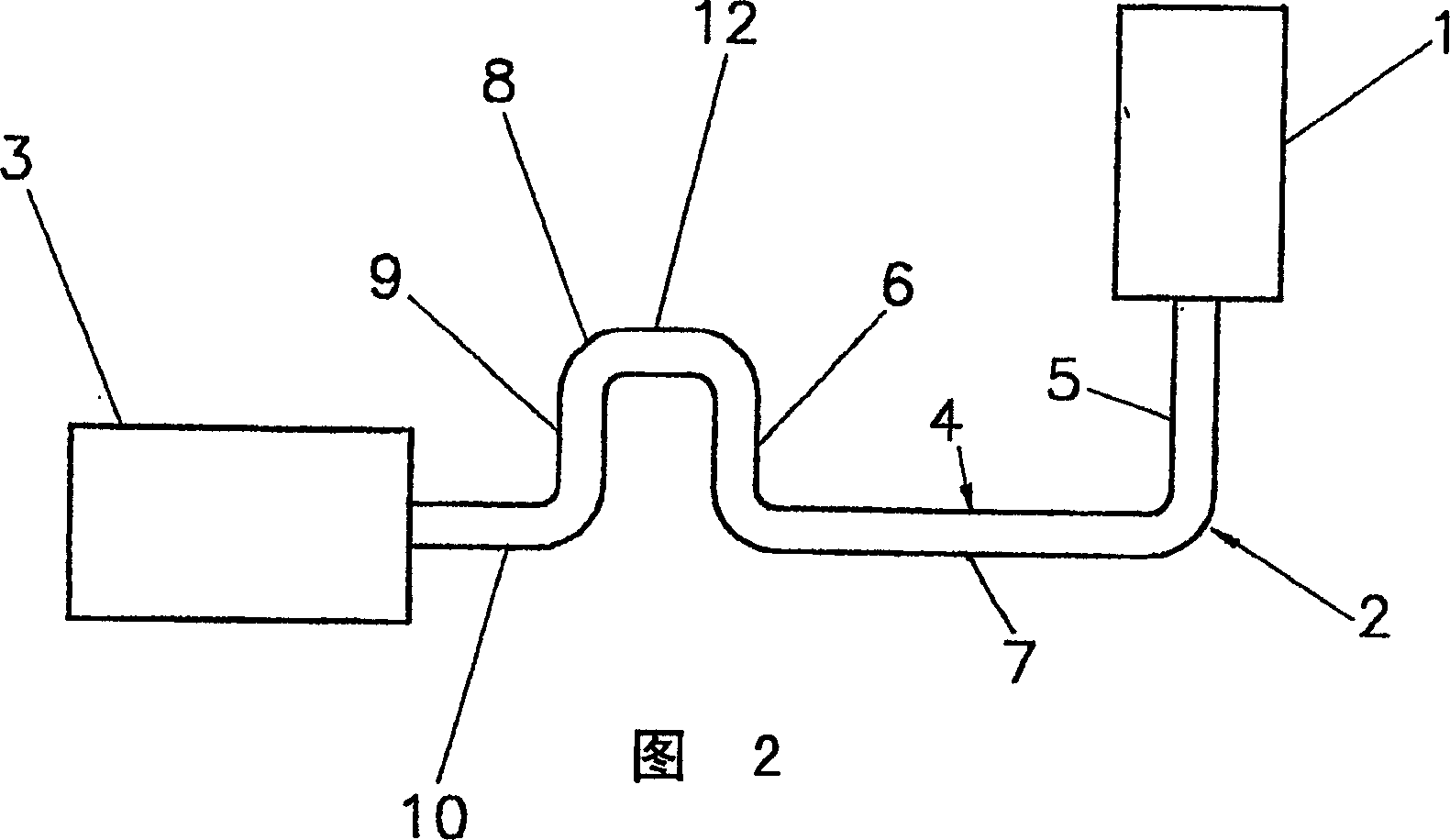

[0034] According to a preferred embodiment of the device according to the invention, as shown in FIG. 2 , the liquid delivery device 2 has a siphon-shaped part 4 which is configured with two branches 5 , 6 . Between the two branches of substantially equal length there is provided a substantially horizontally extending intermediate portion 7 whose length is equal to a multiple of the length of the downwardly extending branch 5 .

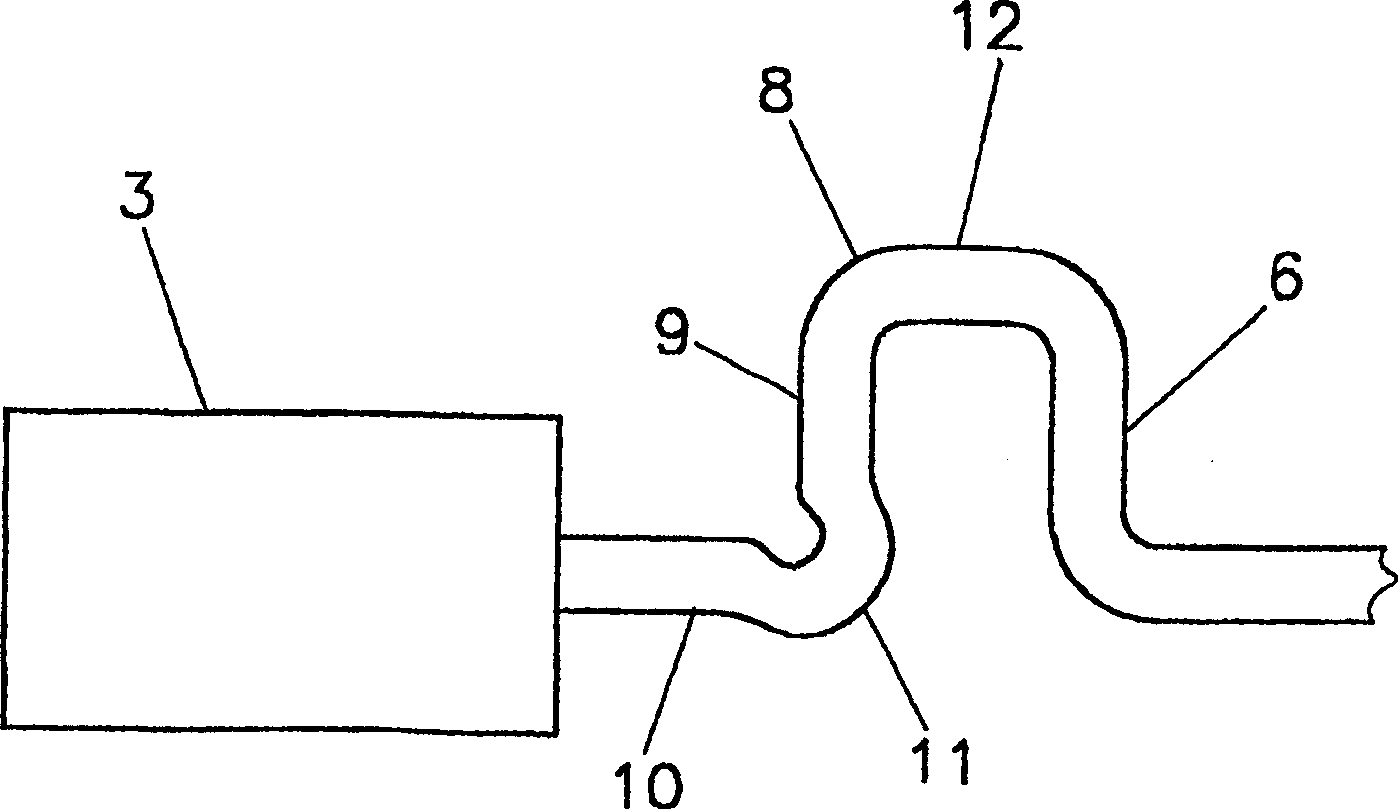

[0035] At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com