Baffle device for sealing molten steel and fabrication method thereof as well as die applying the baffle device

A baffle device and molten steel technology, applied in the field of molds, can solve the problems of molten steel leakage, slow cooling speed of molten steel, and large auxiliary cost investment, so as to improve the ability of anti-scouring, improve the ability of anti-deformation, and reduce the auxiliary cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

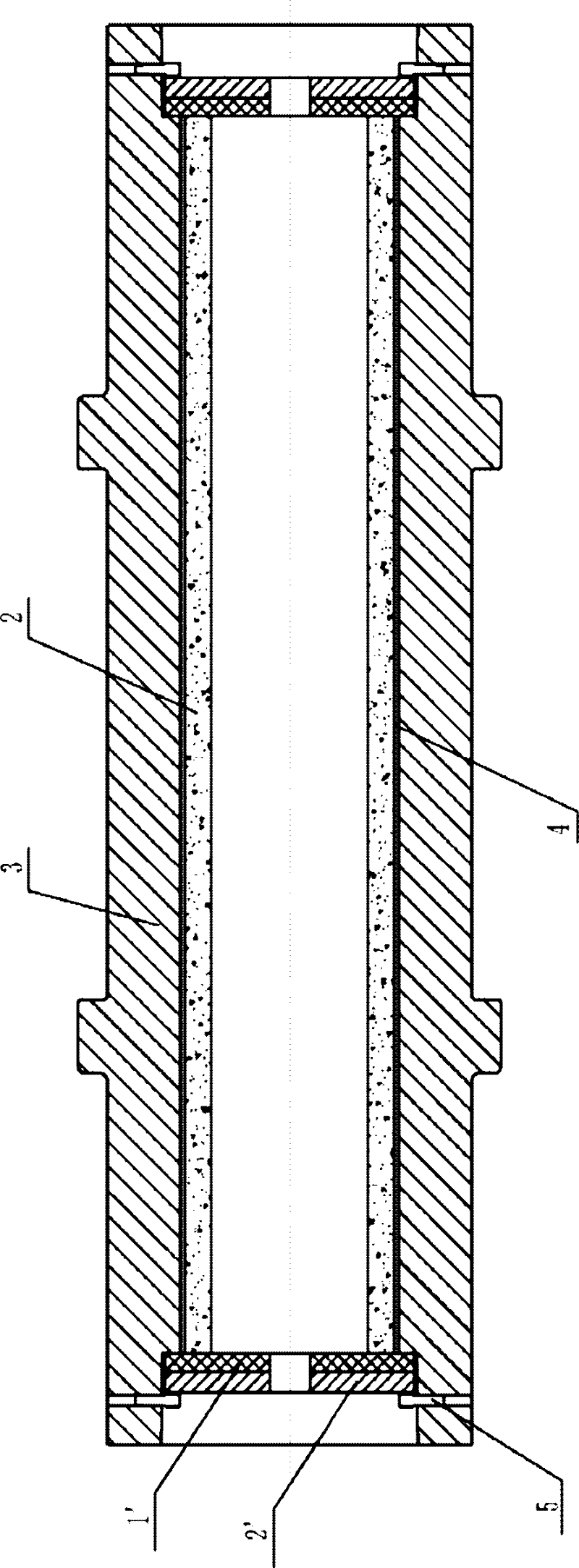

[0046] Example 1: A 27.5-inch thick-wall straight pipe for the main pipe of a nuclear power water reactor. Its specification is The material is Z3CN20-09M with a melting point of 1454°C. Casting can be successfully completed by adopting the baffle device for sealing molten steel of the present invention.

example 2

[0047] Example 2: Baosteel continuous annealing mill 1800 steering roll Thin-walled straight tube. Its specification is The material is 25CrNiSi18-9 with a melting point of 1399°C. Casting can be successfully completed by adopting the baffle device for sealing molten steel of the present invention.

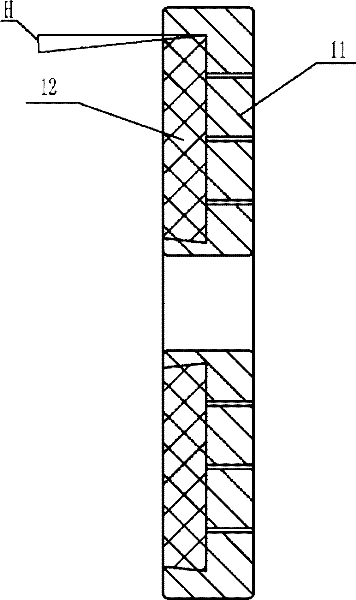

[0048] The method step of making the baffle device of sealing molten steel of the present invention is as follows:

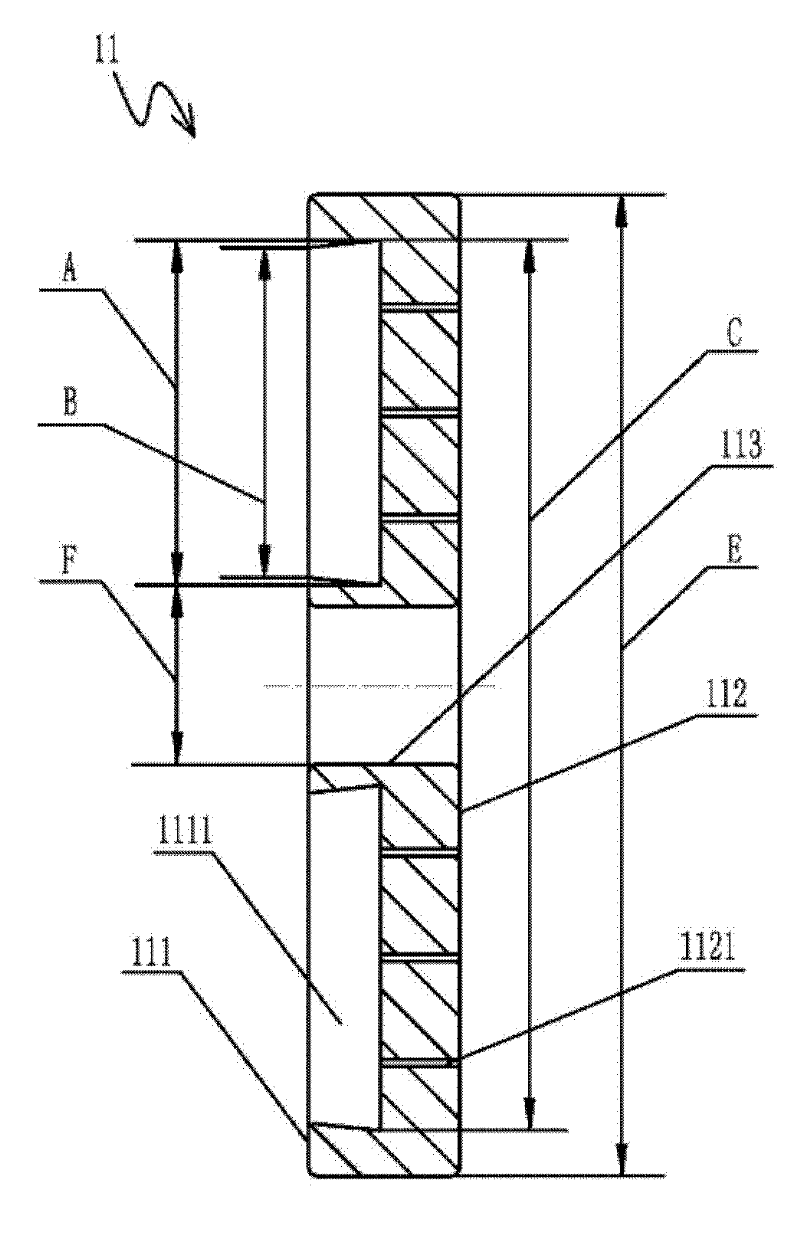

[0049] (1) Selecting a steel plate with a predetermined thickness as the steel plate part, and an annular inverted cone dovetail groove is provided on the first side of the steel plate part;

[0050] (2) Fill the refractory filler into the inverted cone dovetail groove of the steel plate, and preheat it by baking;

[0051] (3) Coating is applied to the surface of the steel plate portion and the refractory filler and dried.

[0052] In addition, several air holes are provided on the second side of the steel plate part, and the air holes connect the inverted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com