Patents

Literature

36results about How to "Reduce ancillary costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for displaying a health status of hospitalized patients

InactiveUS7454359B2Minimizing adverse eventsMinimize complicationsOffice automationAlarmsGraphicsHospitalized patients

A system and method for displaying a health status of hospitalized patients. Patient data associated with hospitalized patients is selected according to display rules. A display module selects selected patient data, applies display rules to the selected patient data, and displays the selected patient data. A smart alert module generates and applies patient specific rules to other selected patient data elements. If a patient-specific rule for a hospitalized patient has been contravened, an alert is issued from the remote command center. Graphical attributes may be assigned to patients for whom an alert has been issued and to selected patient data elements that fall outside of an acceptable range. The graphical attributes determine how selected patient data appear on a display screen.

Owner:VISICU

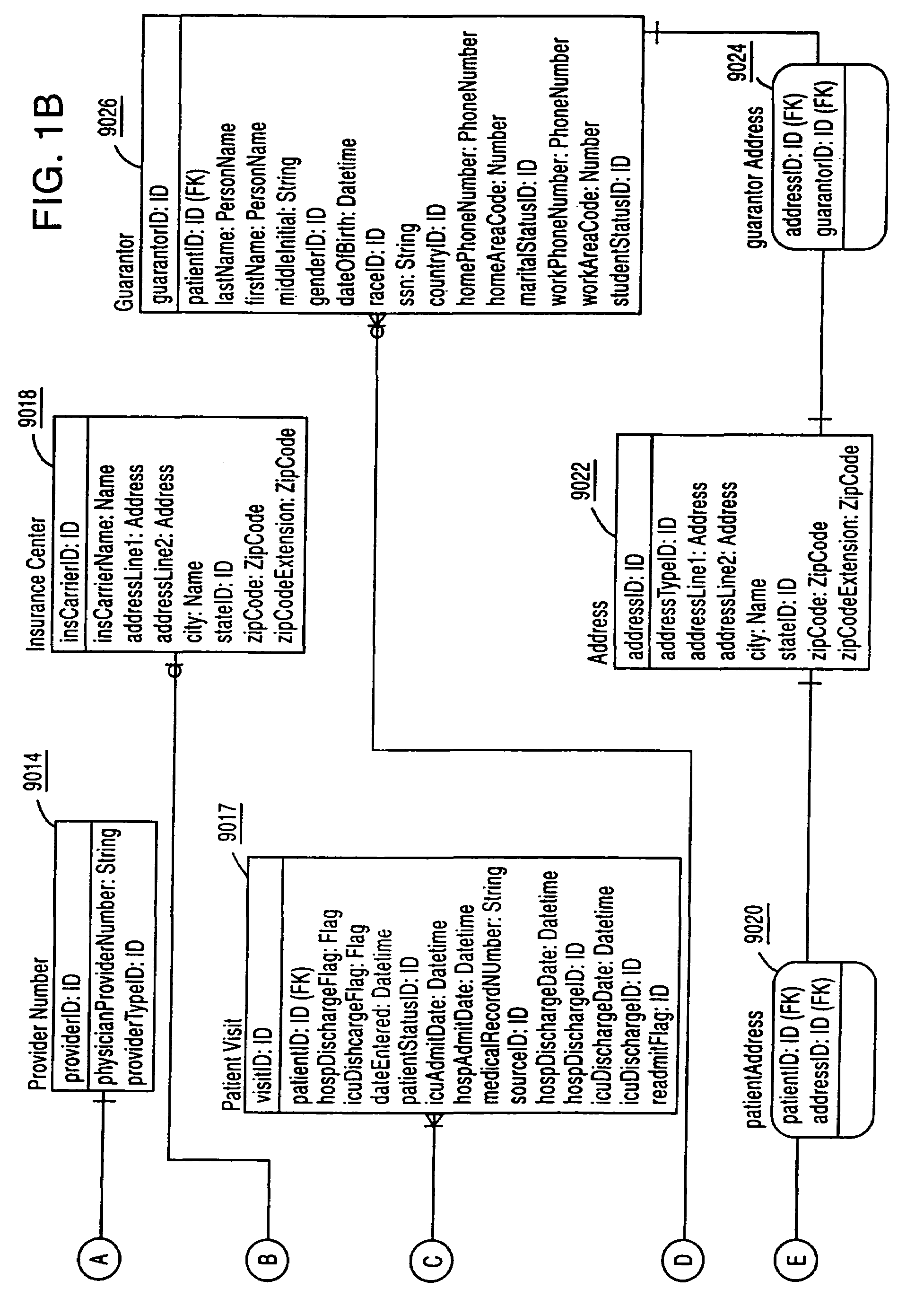

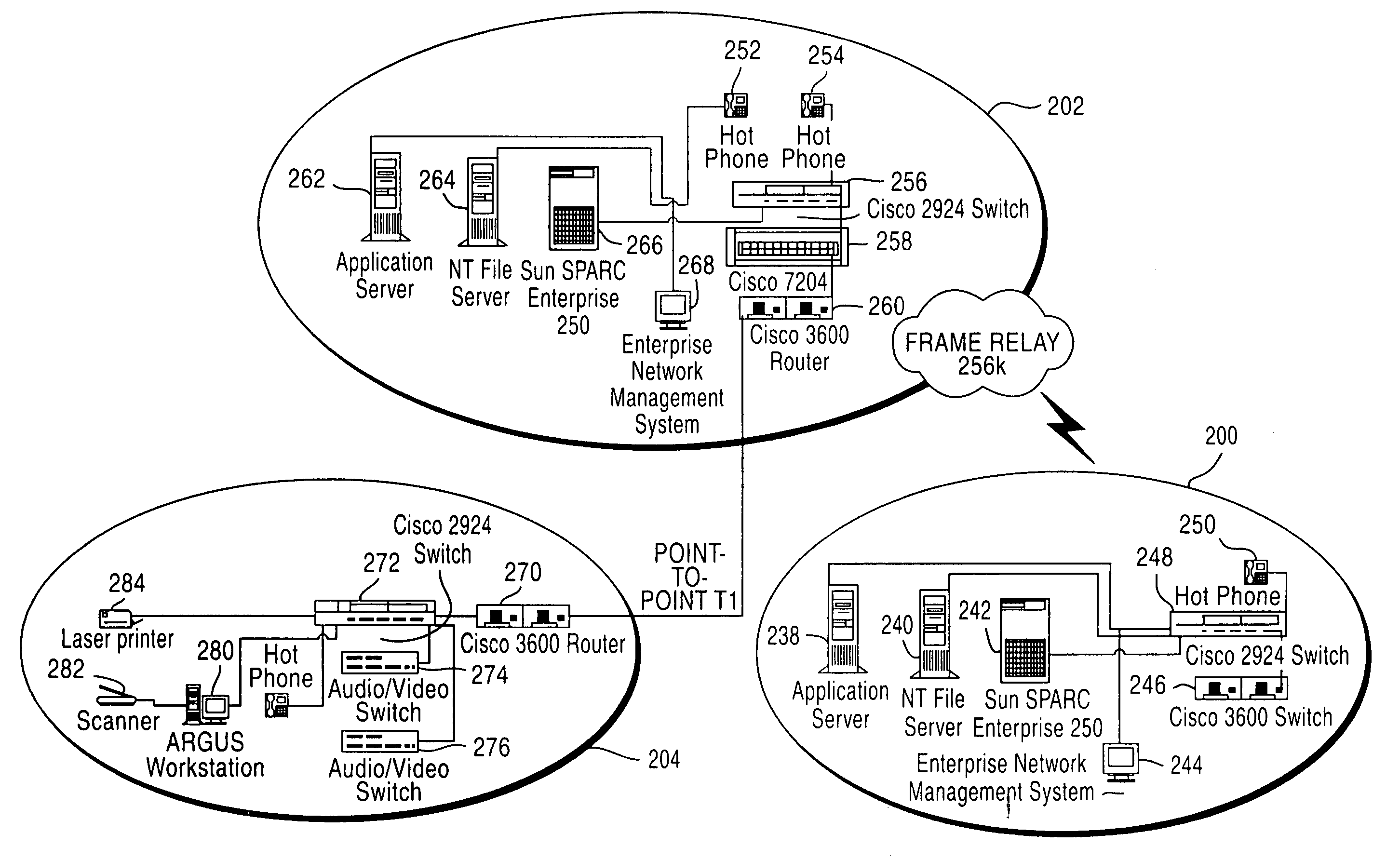

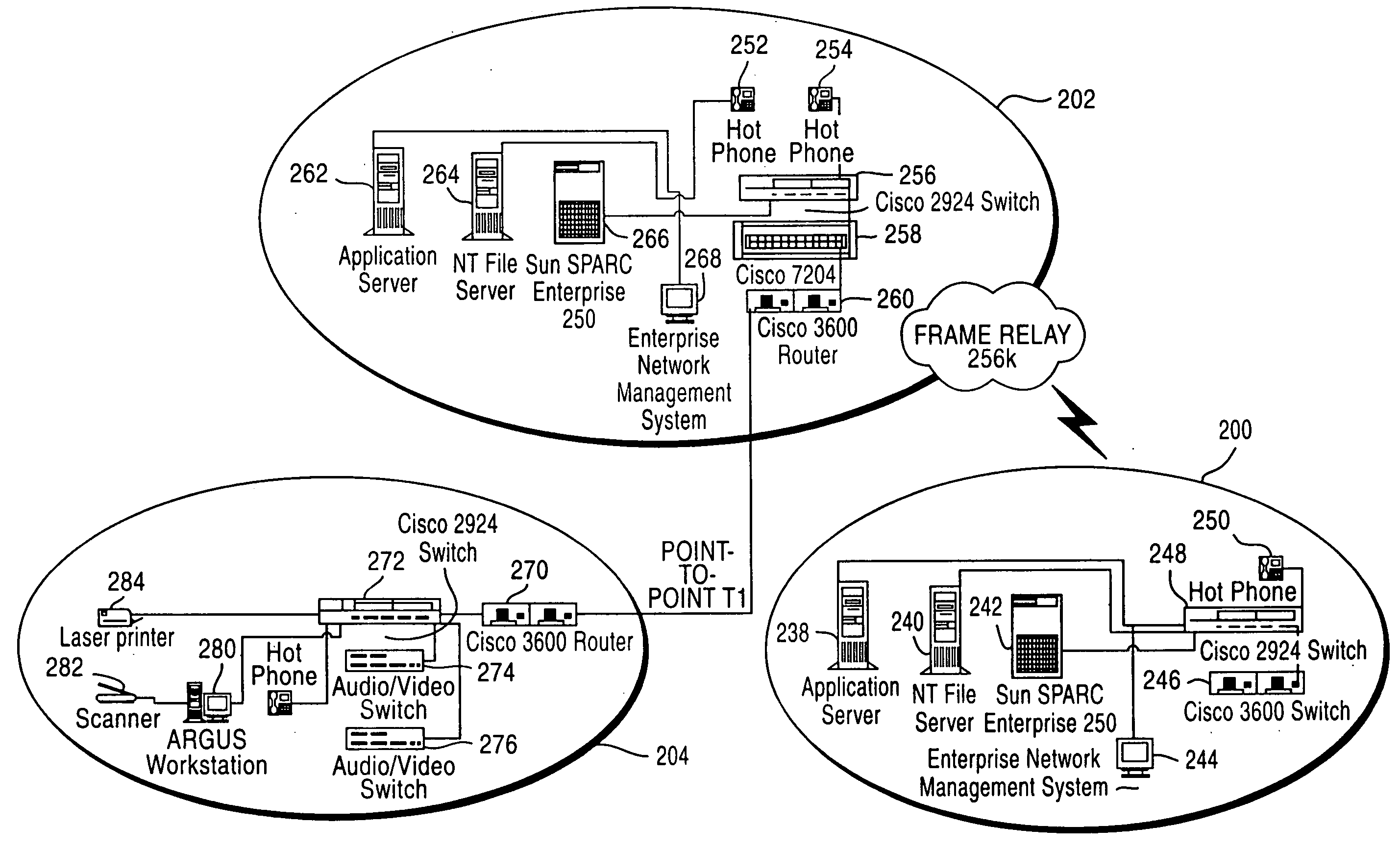

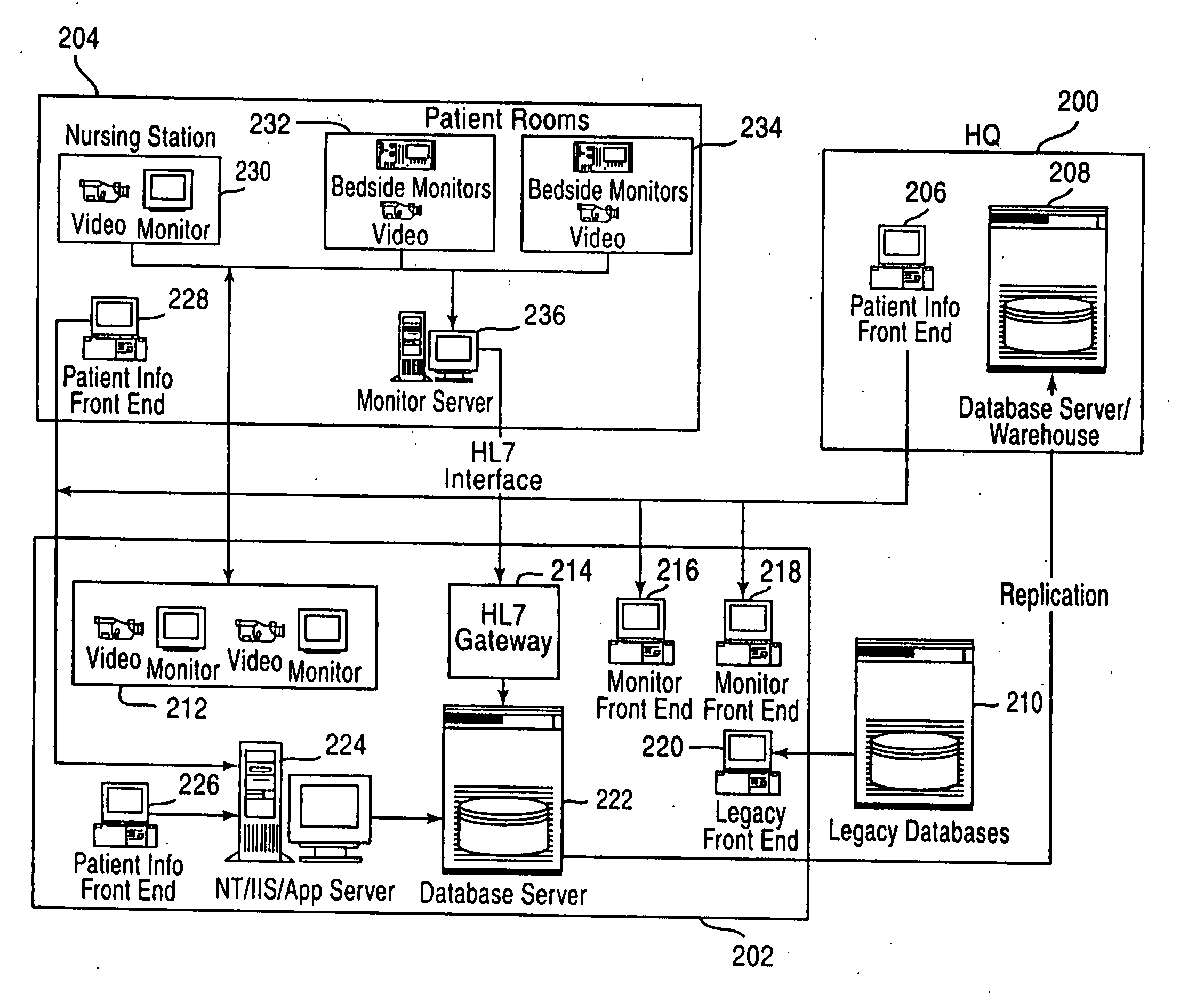

System and method for video observation of a patient in a health care location

InactiveUS7307543B2Minimizing adverse eventsMinimize complicationsElectric signal transmission systemsBilling/invoicingVisual monitoringPatient data

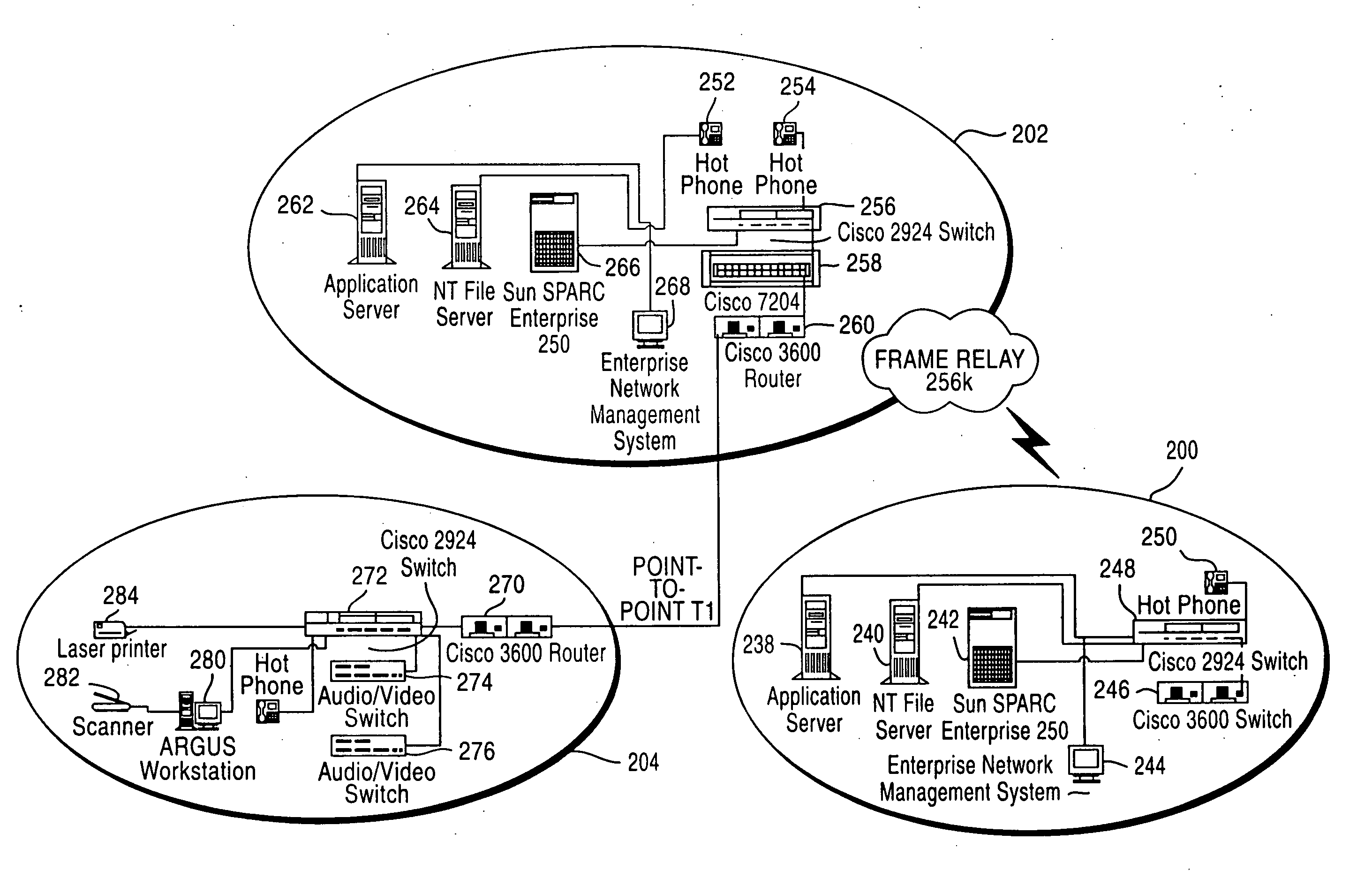

A system and method for observing patients in geographically dispersed health care locations. A patient is assigned to a health care location comprising a patient visual monitoring system, a patient audio receiver, and a patient controller. The visual monitoring system is responsive tri-axially to command signals received via a patient controller connected to the network. The patient controller sends patient imaging data and patient audio data to a remote command center via the network. A computerized patient care management system comprising the remote command center monitors patient data, patient imaging data, and patient audio data determines from the patient data, the patient imaging data, and the patient audio data if intervention with the selected patient is warranted.

Owner:VISICU +1

System and method for patient-worn monitoring of patients in geographically dispersed health care locations

InactiveUS7321862B2Minimizing adverse eventsMinimize complicationsPhysical therapies and activitiesComputer-assisted treatment prescription/deliveryMonitoring systemEmergency medicine

A patient-worn monitoring system and method for geographically dispersed health care locations. A patient-worn monitoring system comprises a network, a body-worn monitoring station, a monitoring station server, a remote command center, and a rules engine. The network comprises a first sub-network and a second sub-network. The body-worn monitoring station comprises monitoring equipment. The body worn monitoring station monitors data elements from a patient assigned to a health care location and sends monitored data elements to a monitoring station server via the first sub-network. The monitoring station server receives the monitored data elements from the body worn monitoring station and relays the monitored data elements to the remote command center via the second sub-network. The remote command center receives the monitored data elements from the monitoring station server, associates the monitored data elements with the patient assigned to the health care location, accesses patient data elements indicative of a medical condition associated with the patient, and establishes a patient-specific rule associated with the patient. The rules engine selects data elements from the monitored data elements and the patient data elements associated with the patient and applies the patient-specific rule to the selected data elements continuously and simultaneously. A determination is made whether the patient-specific rule for the patient has been contravened. An alert is issued from the remote command center in the event the patient-specific rule for the patient has been contravened.

Owner:VISICU

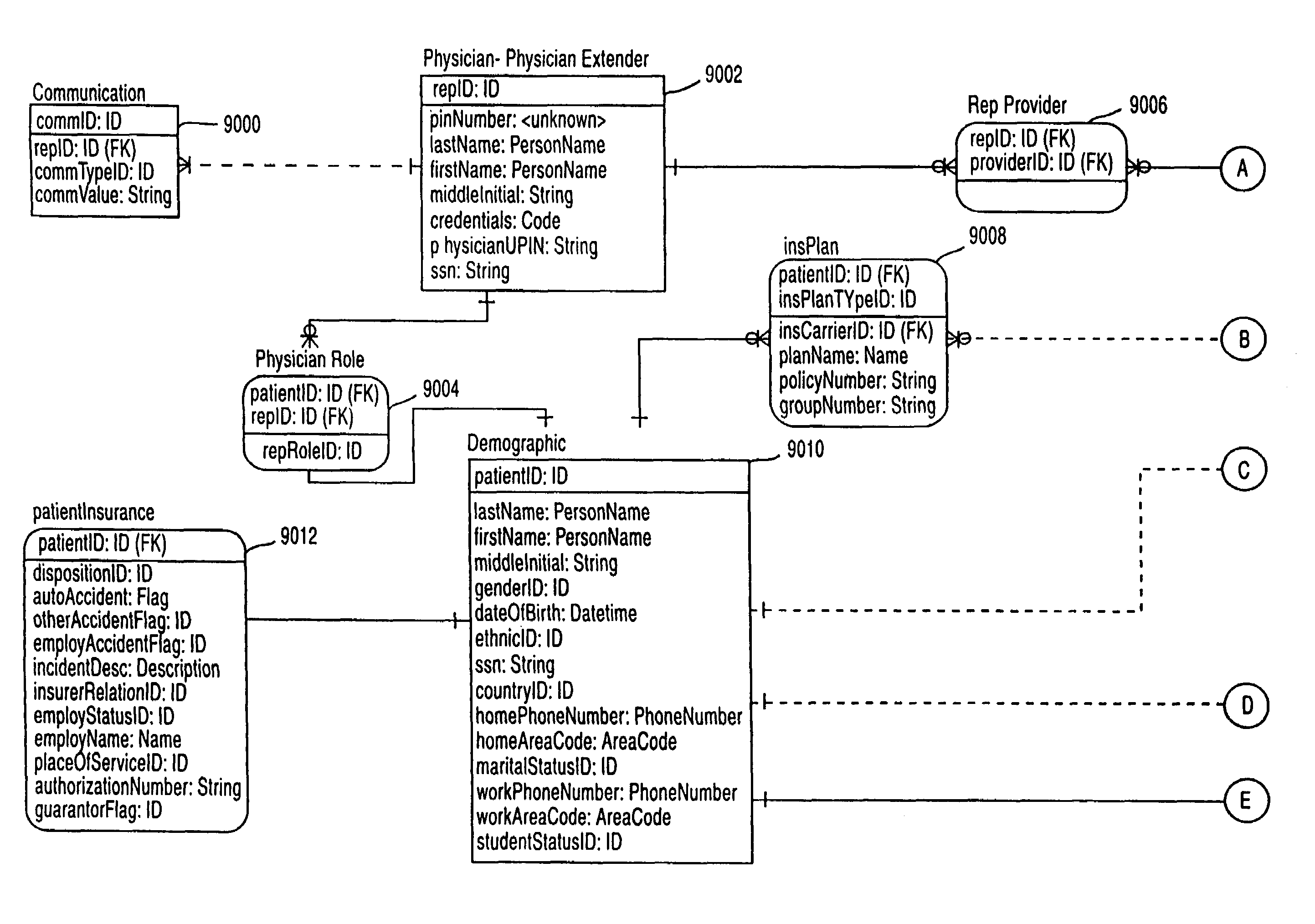

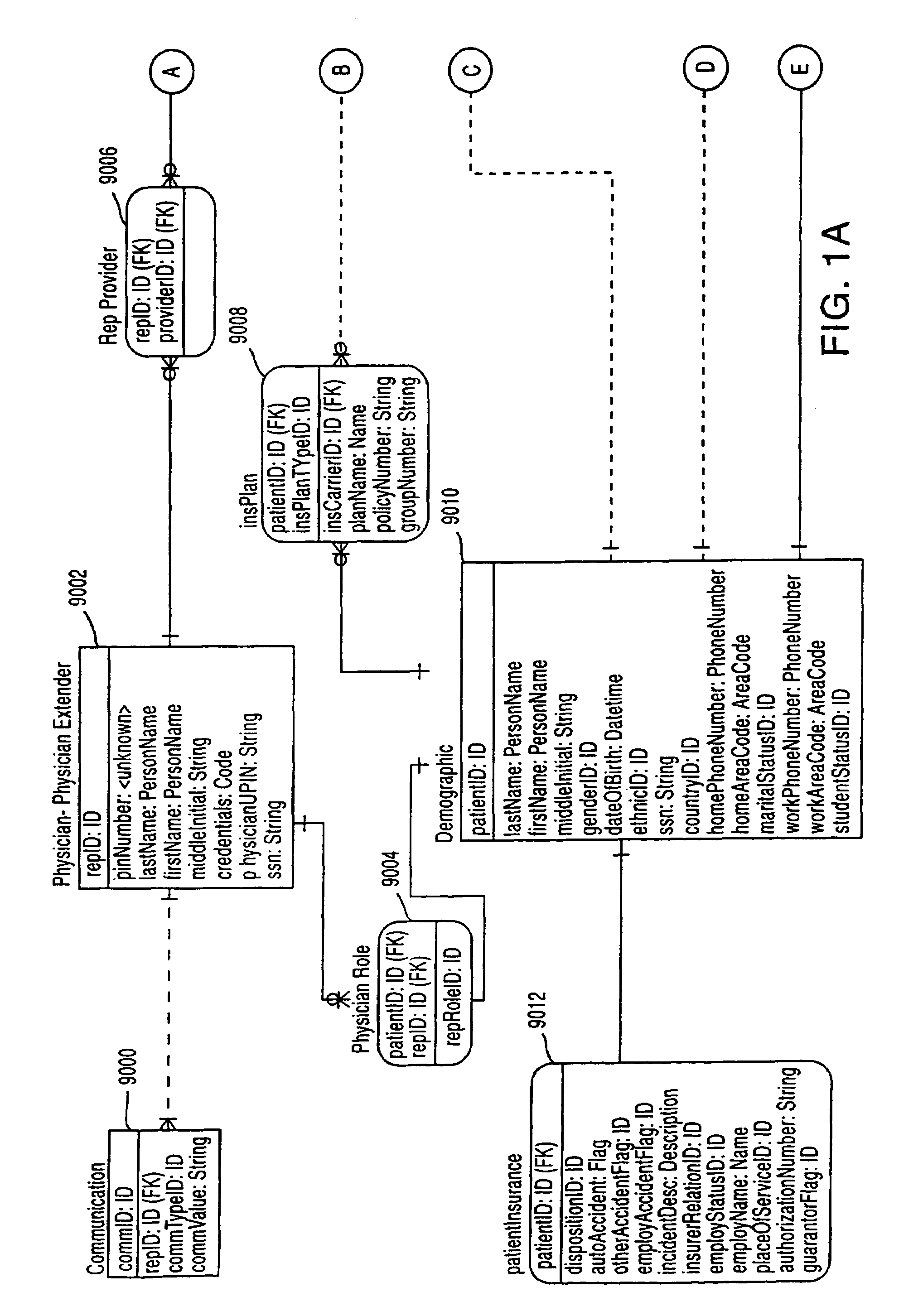

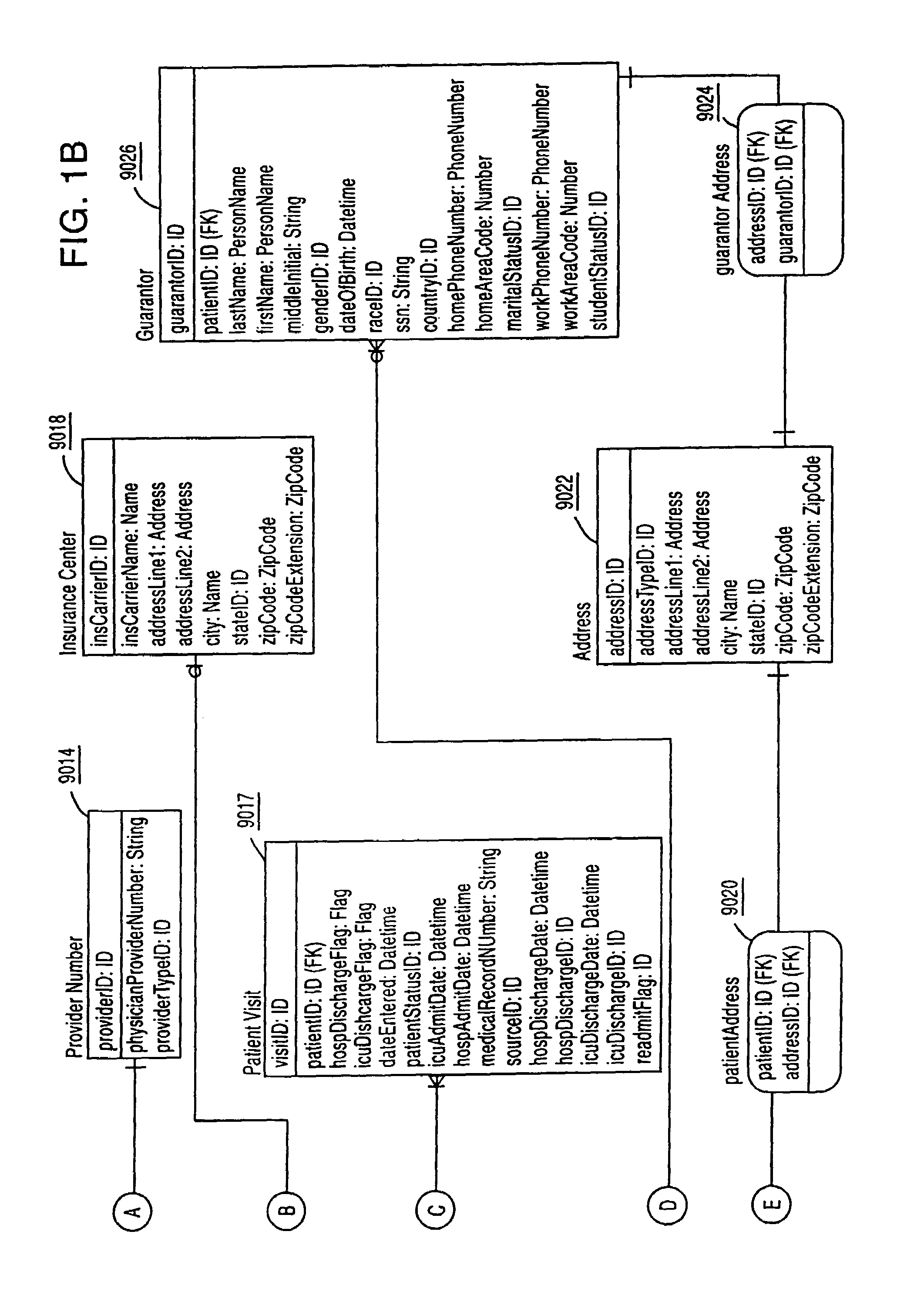

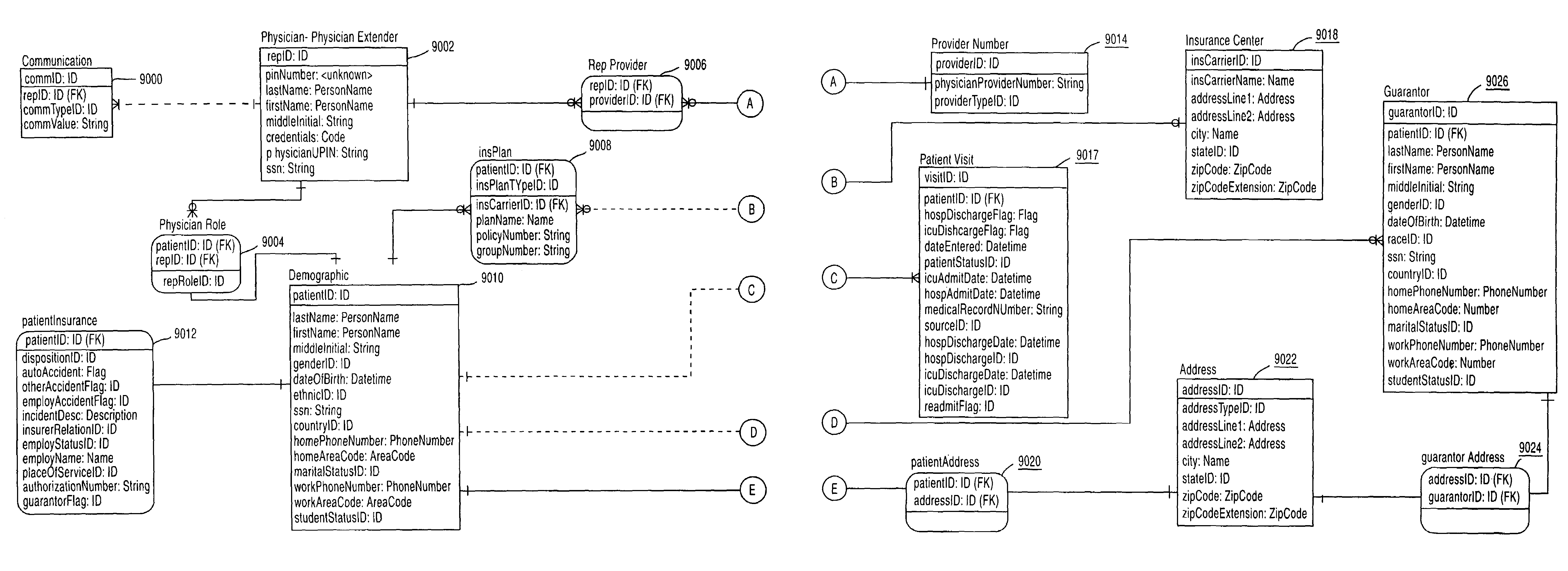

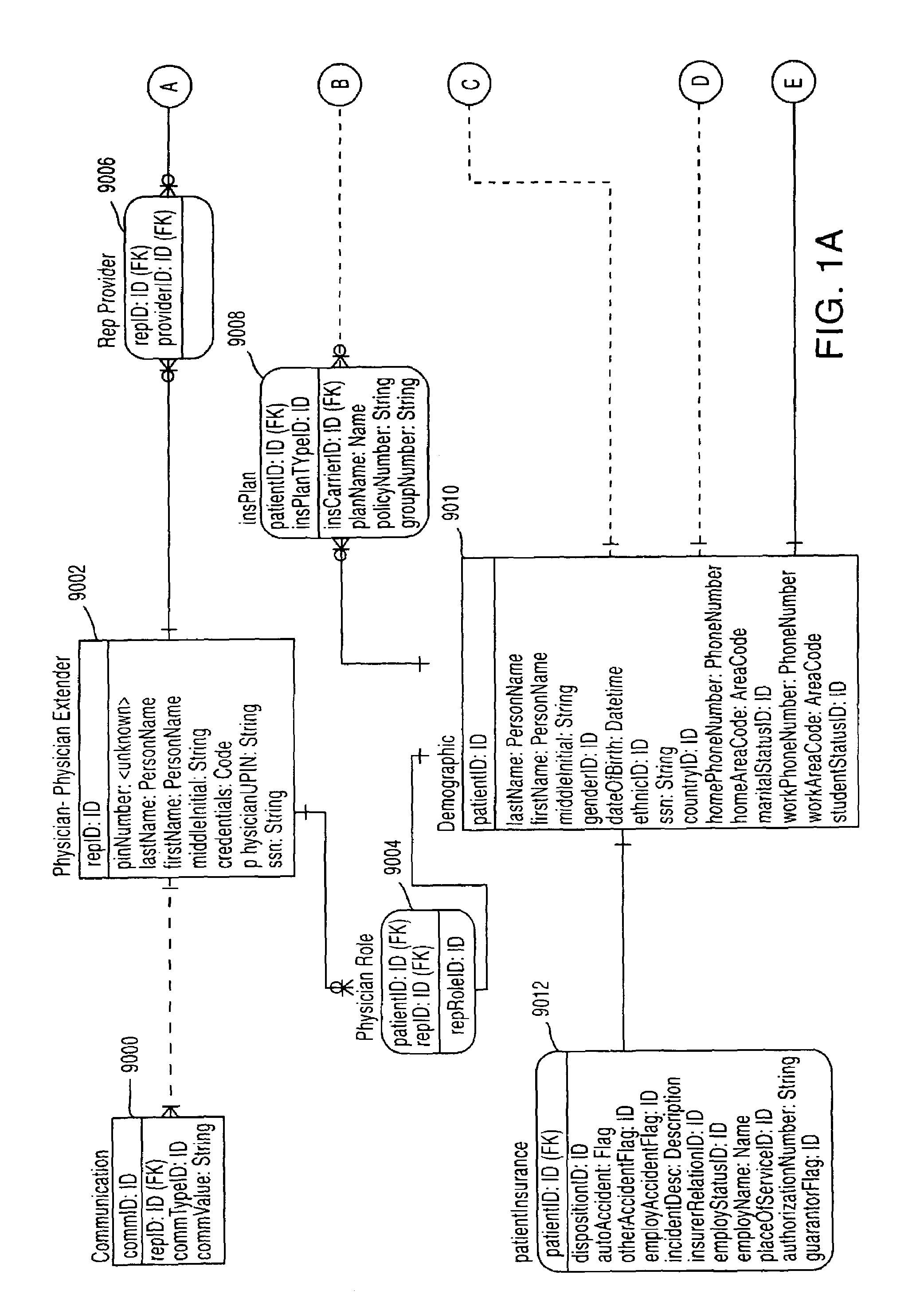

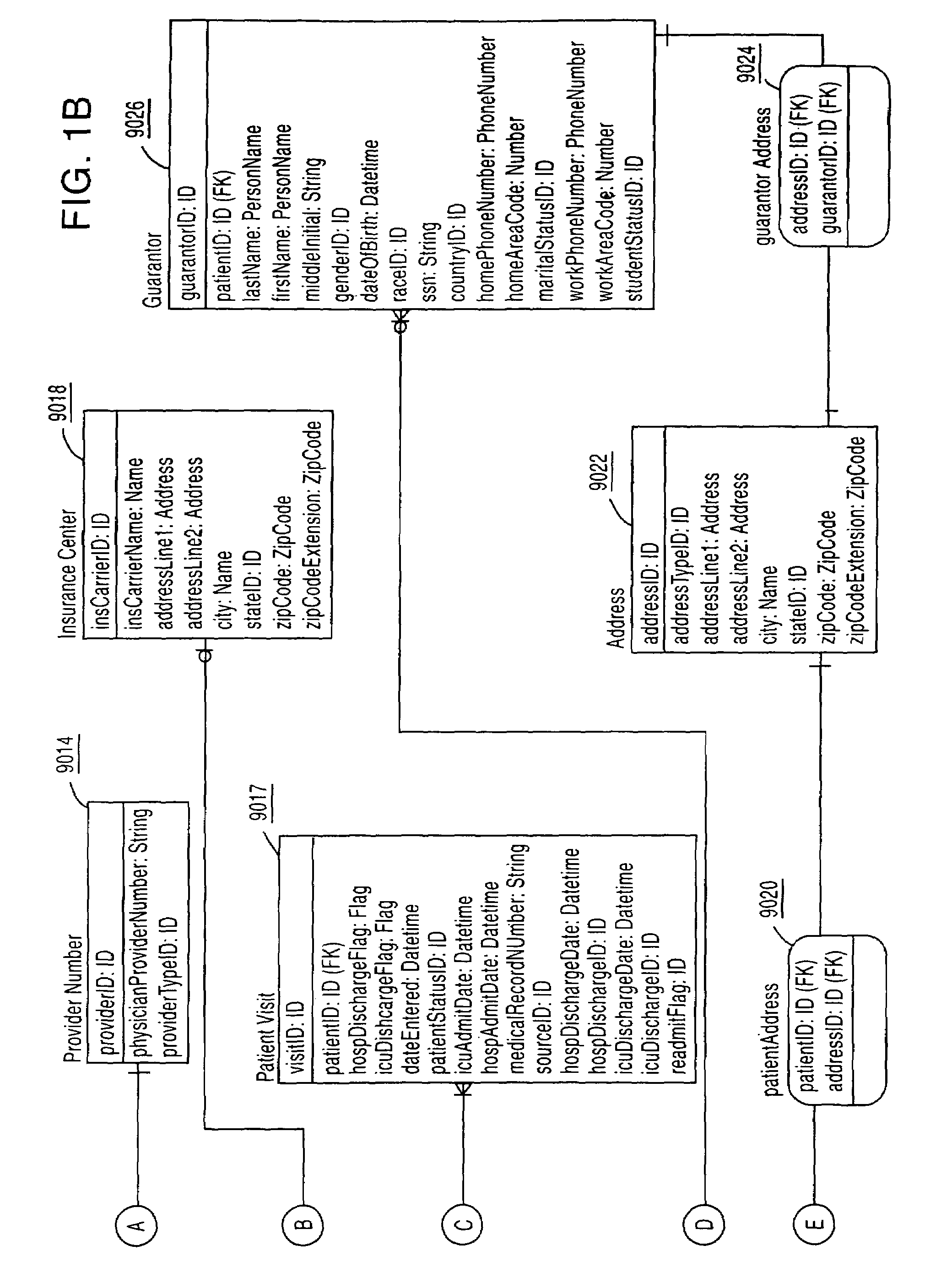

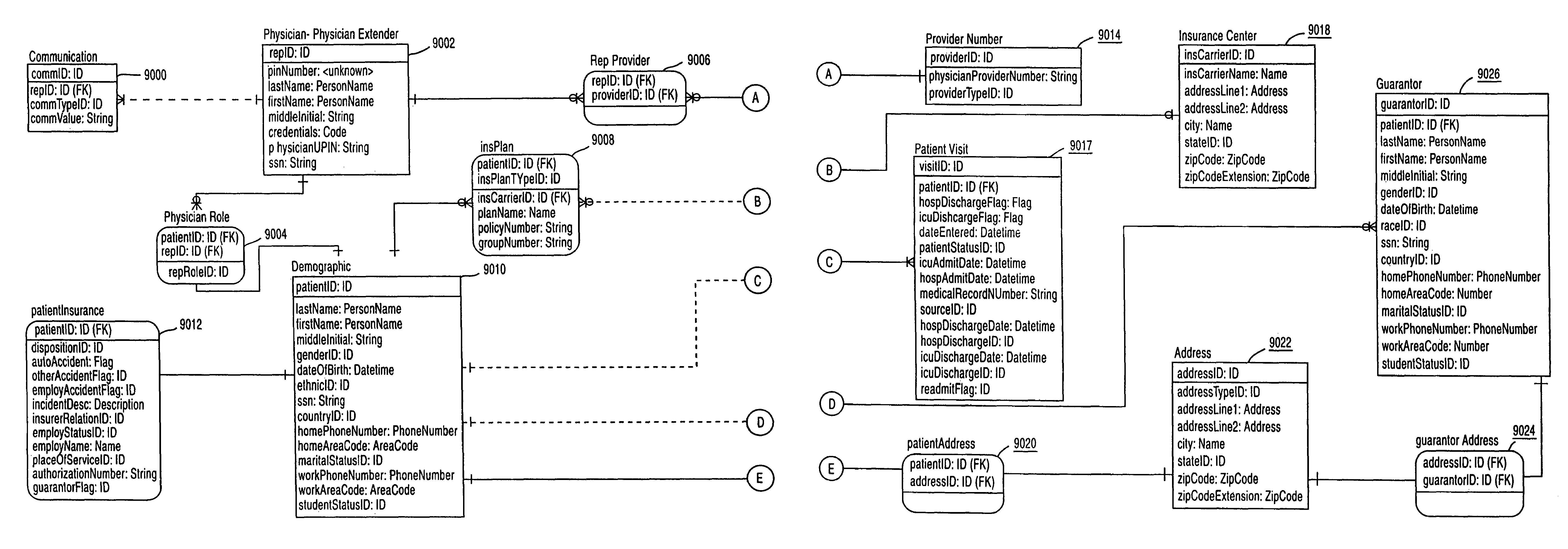

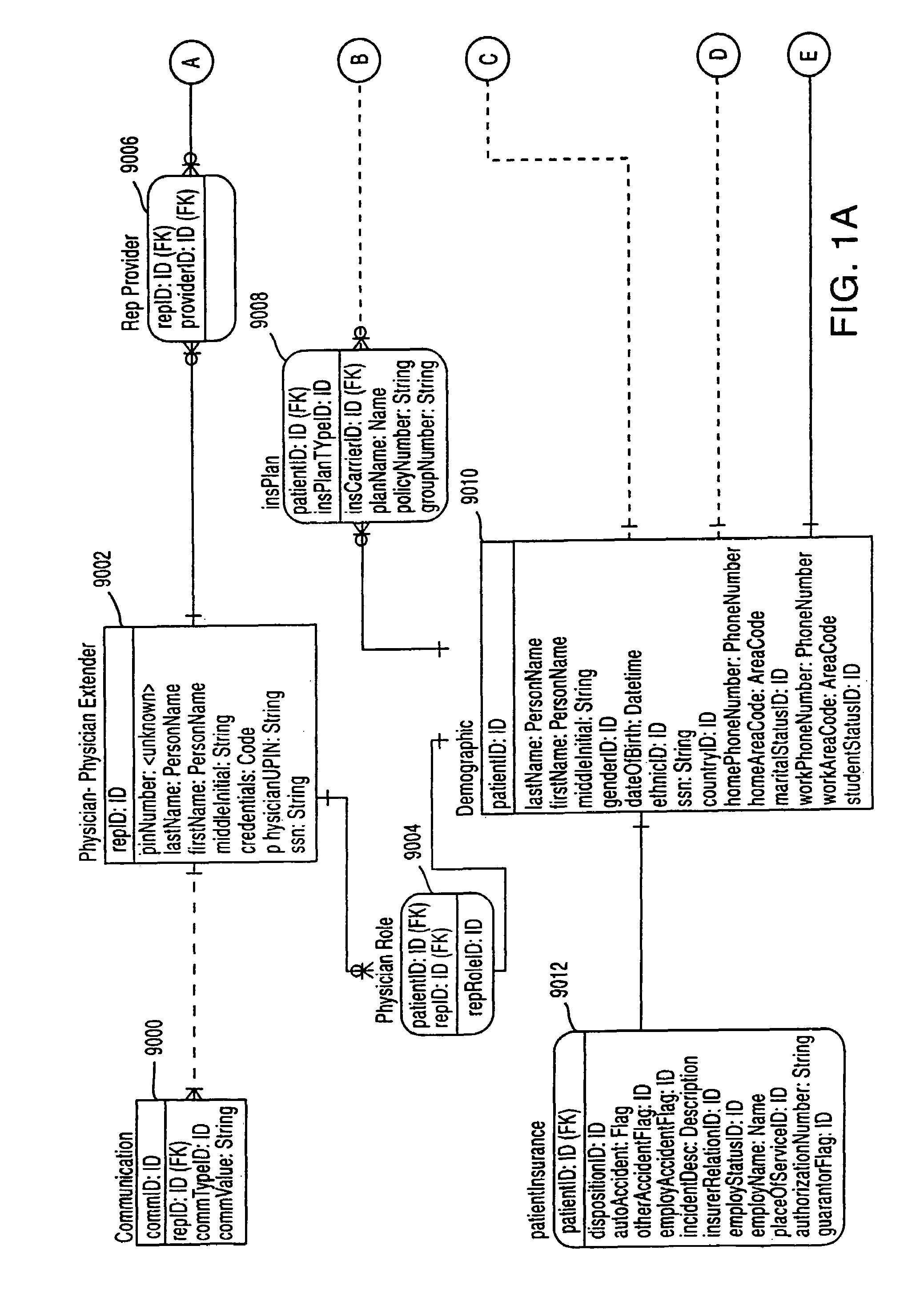

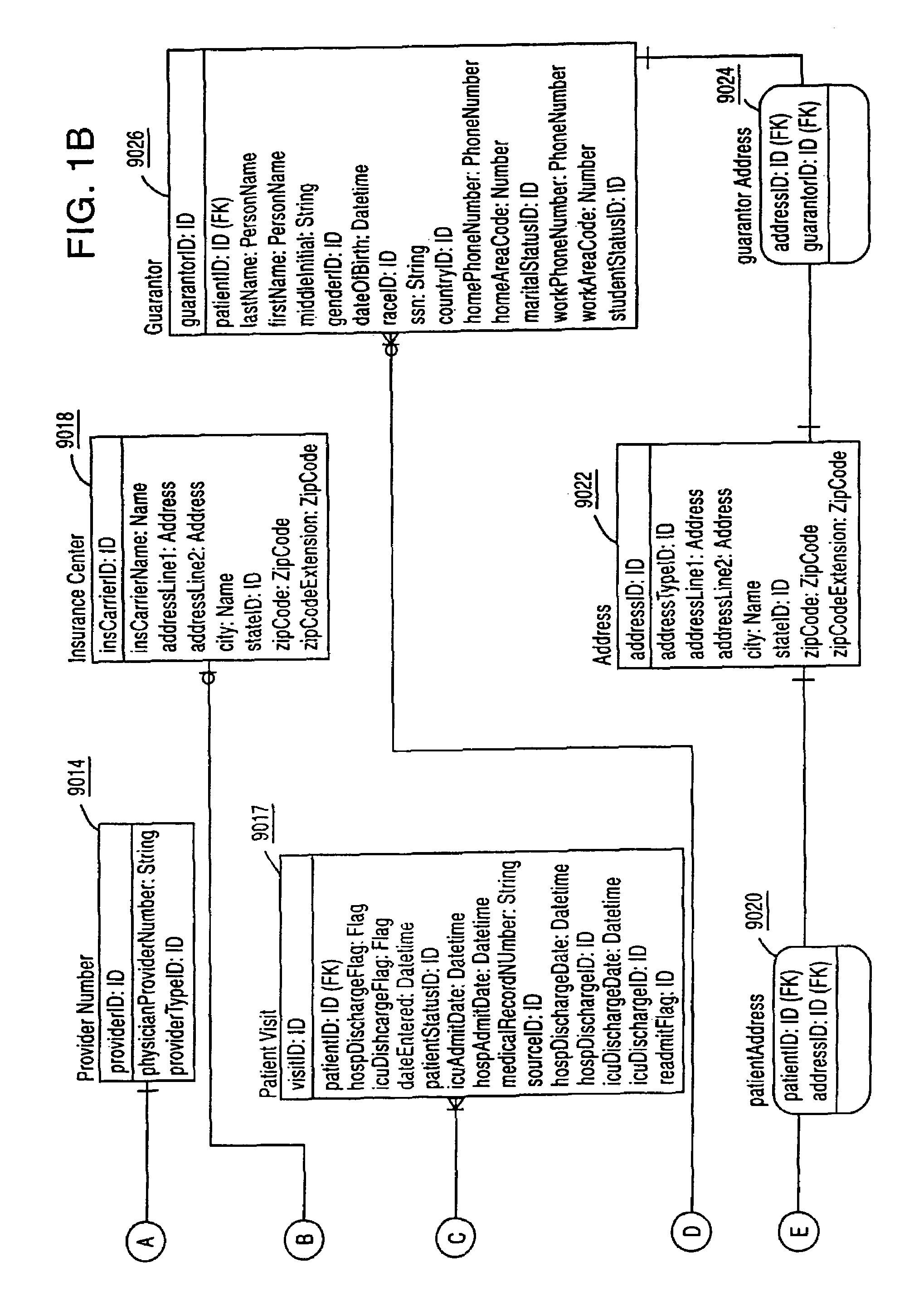

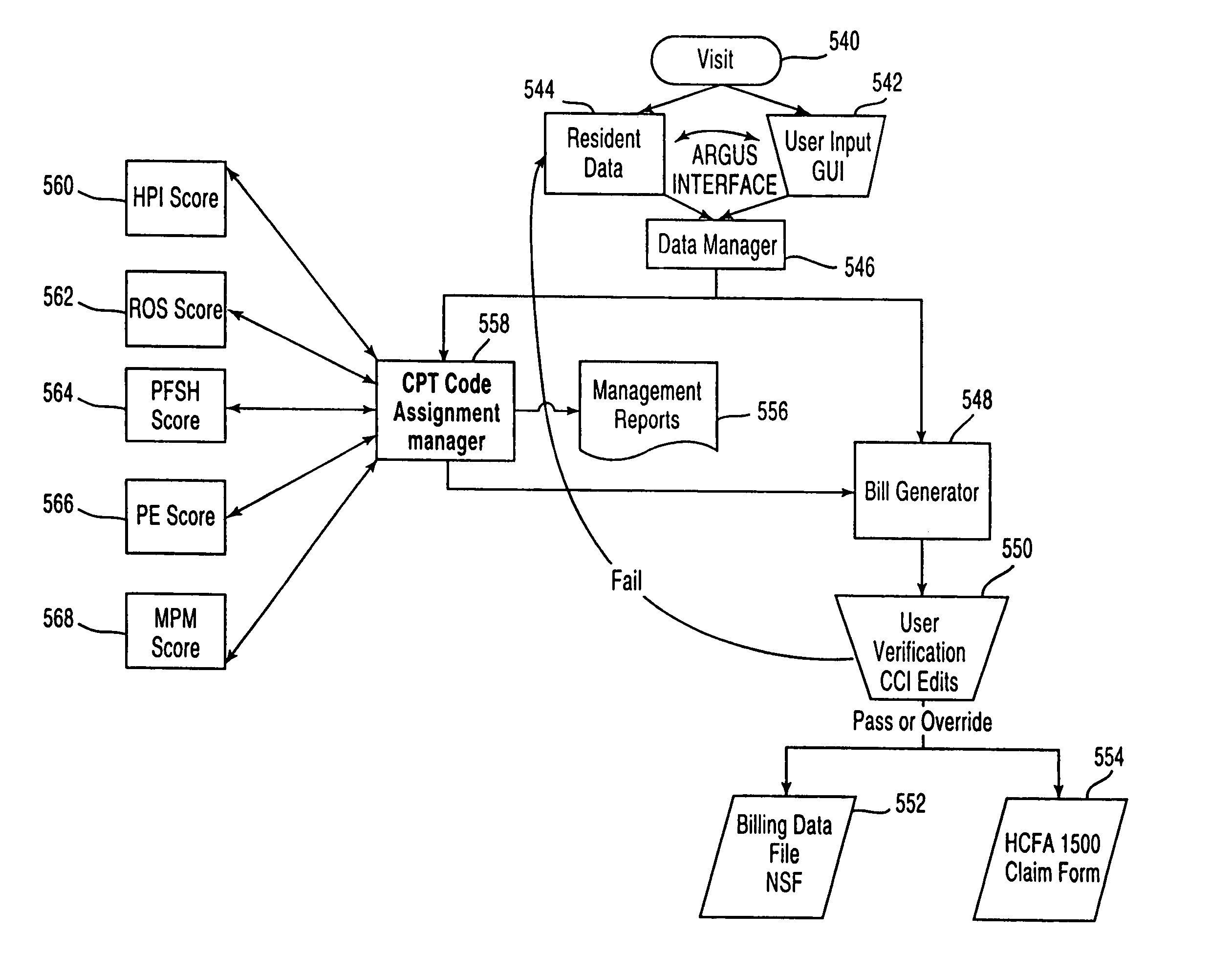

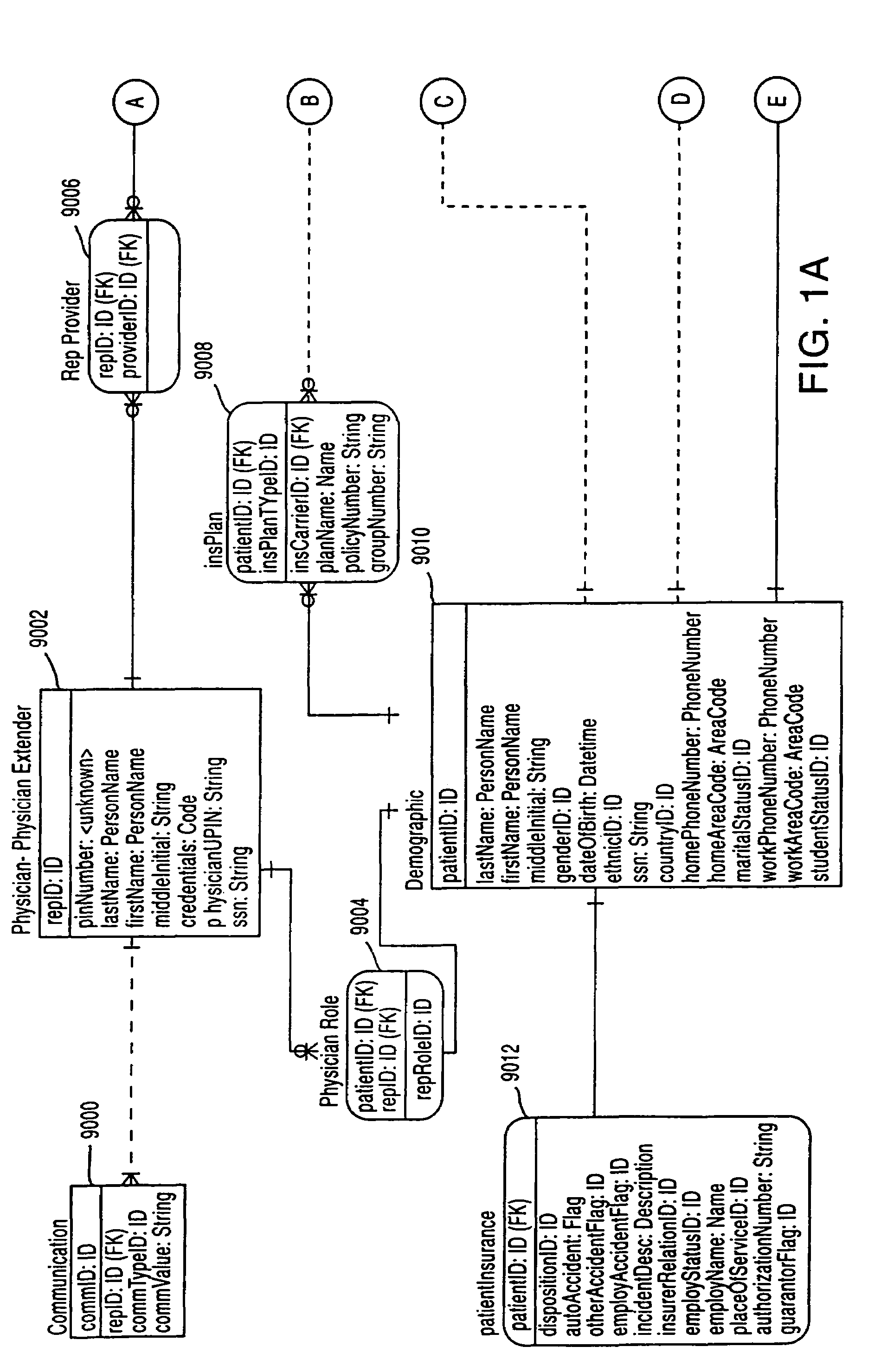

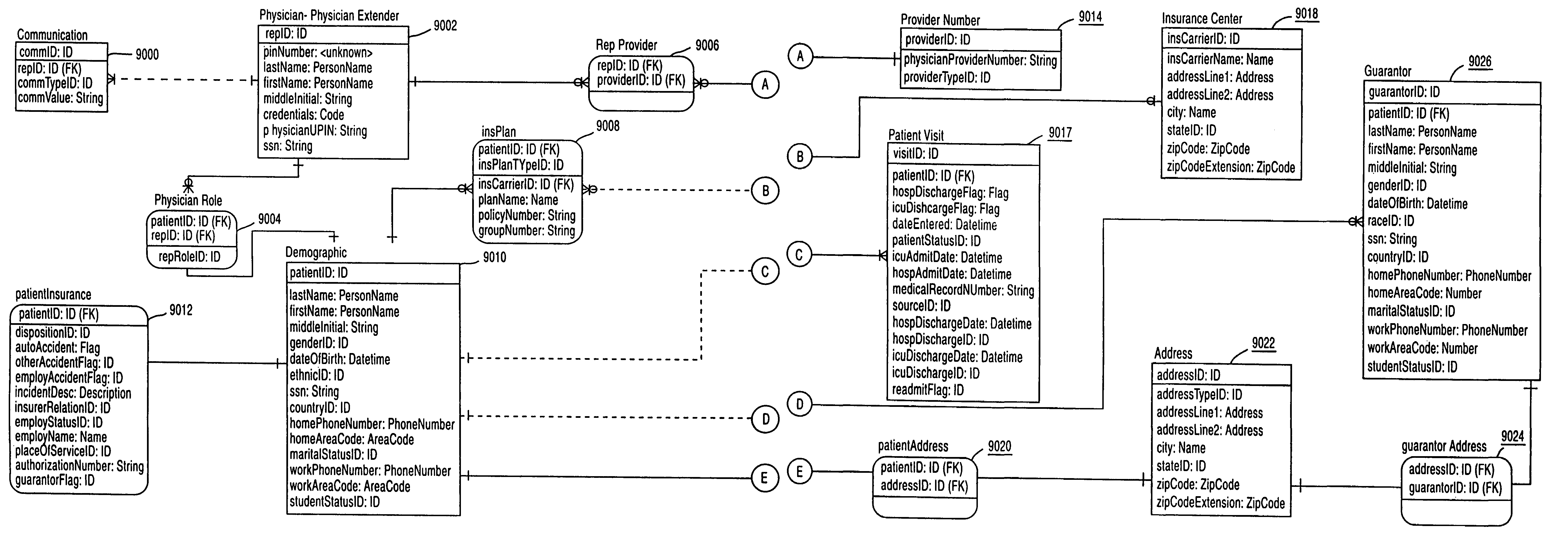

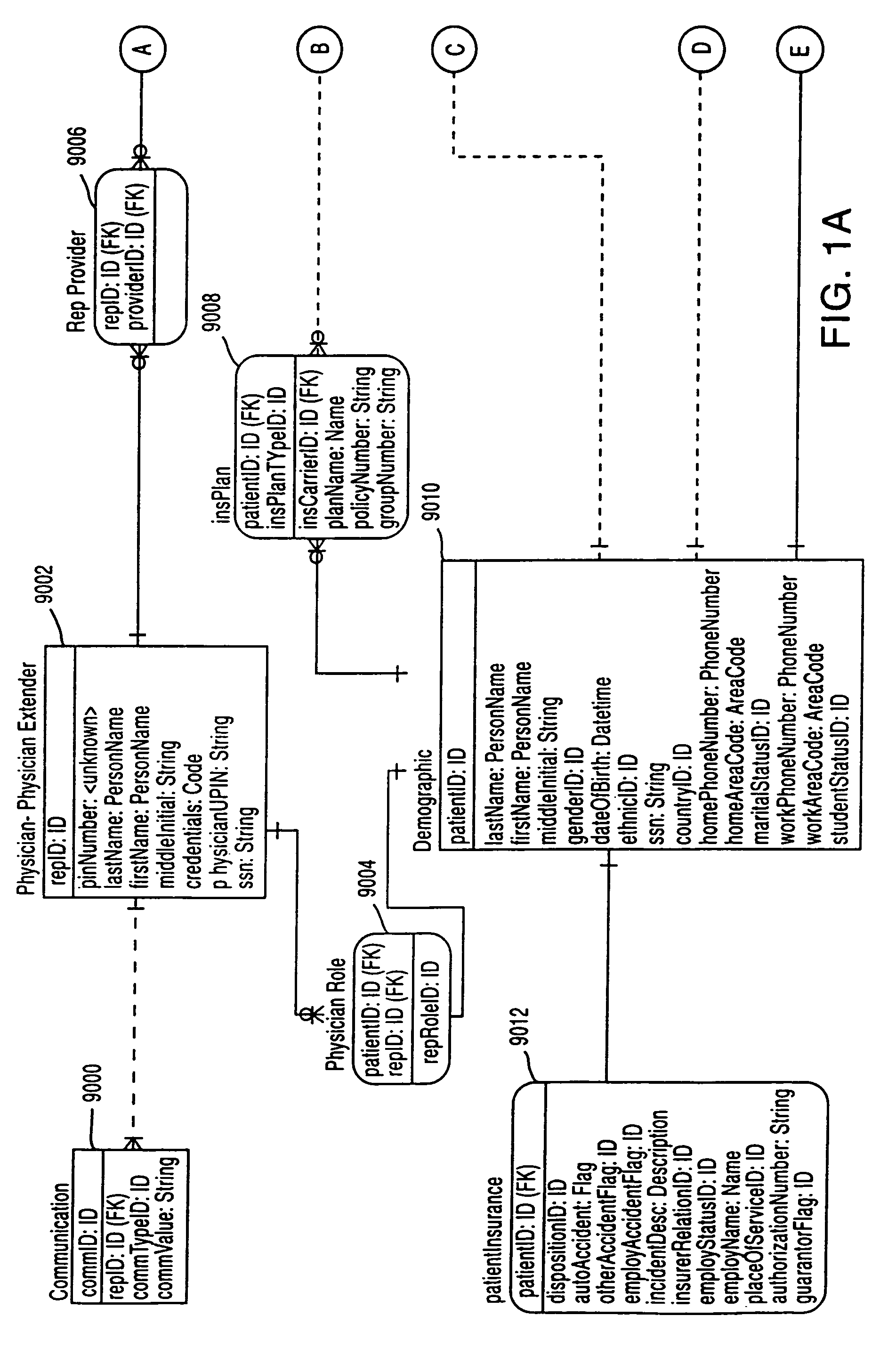

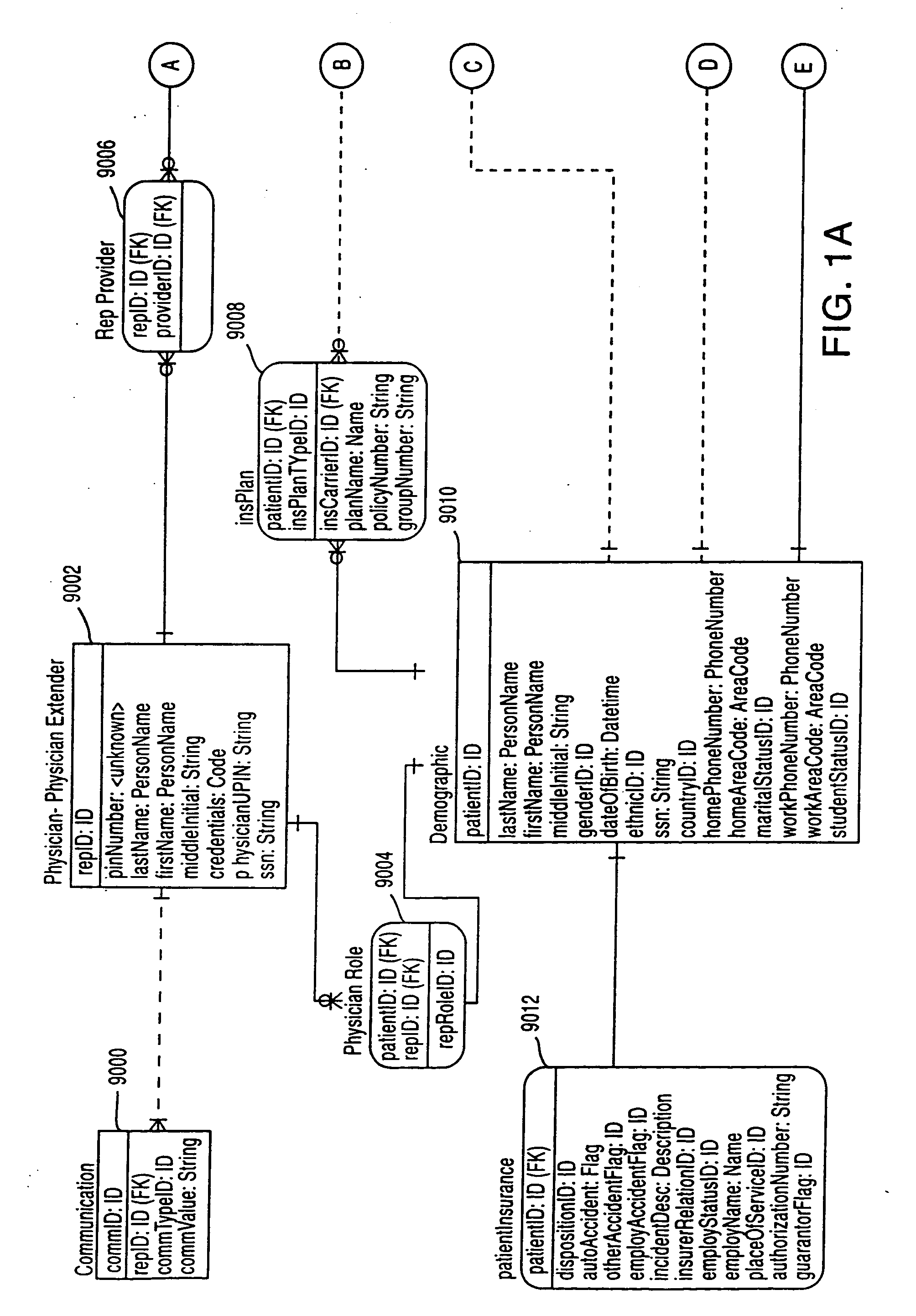

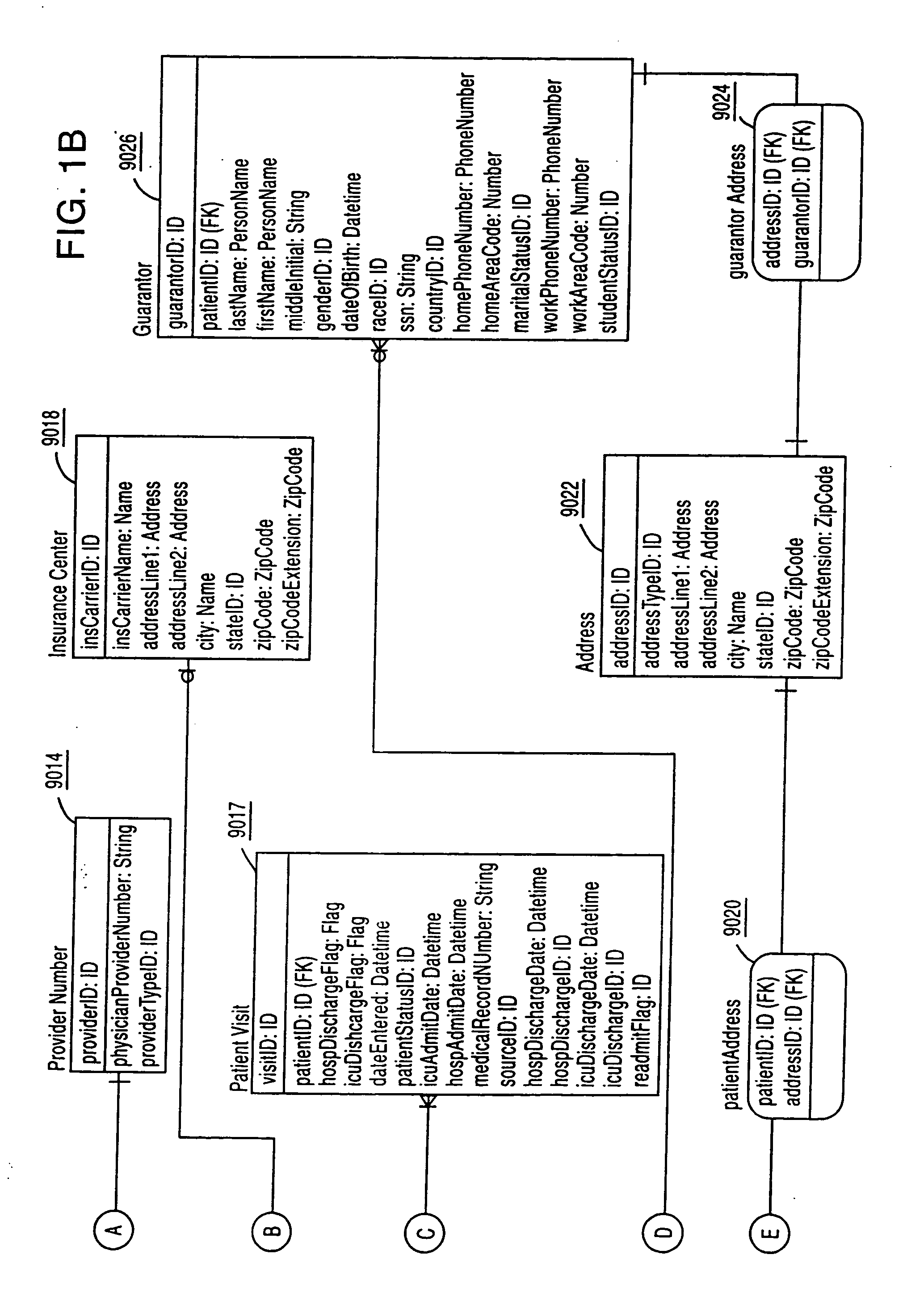

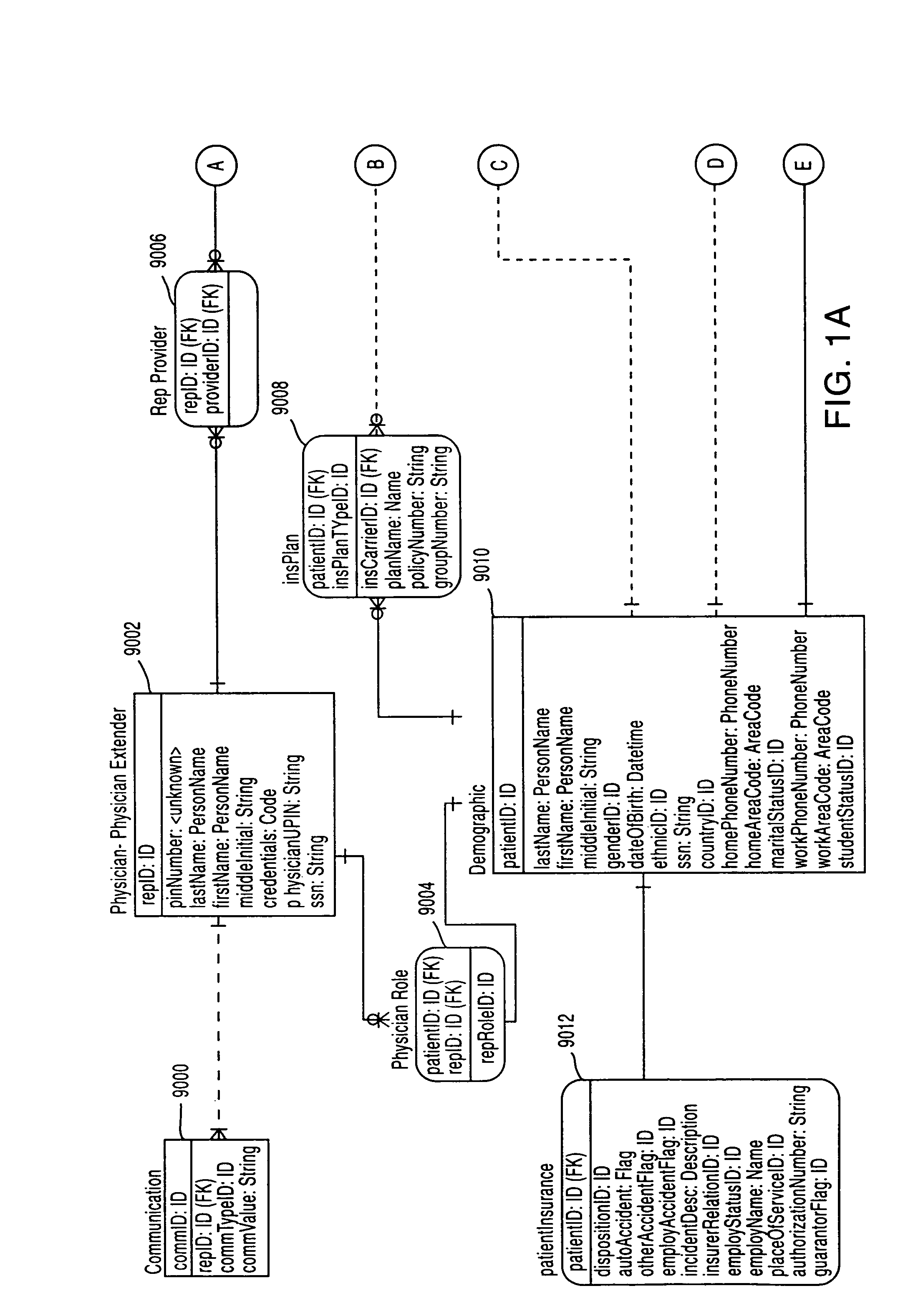

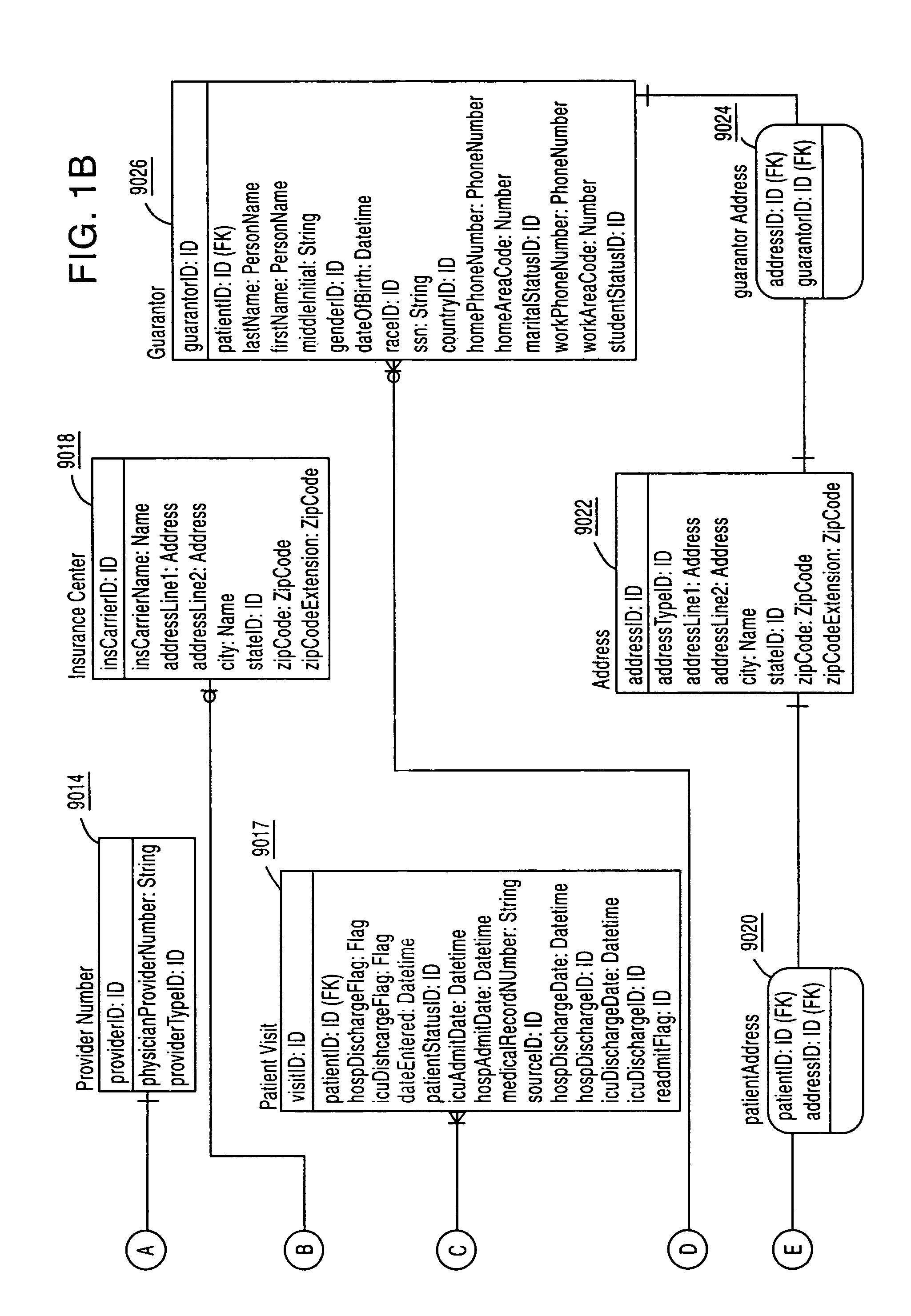

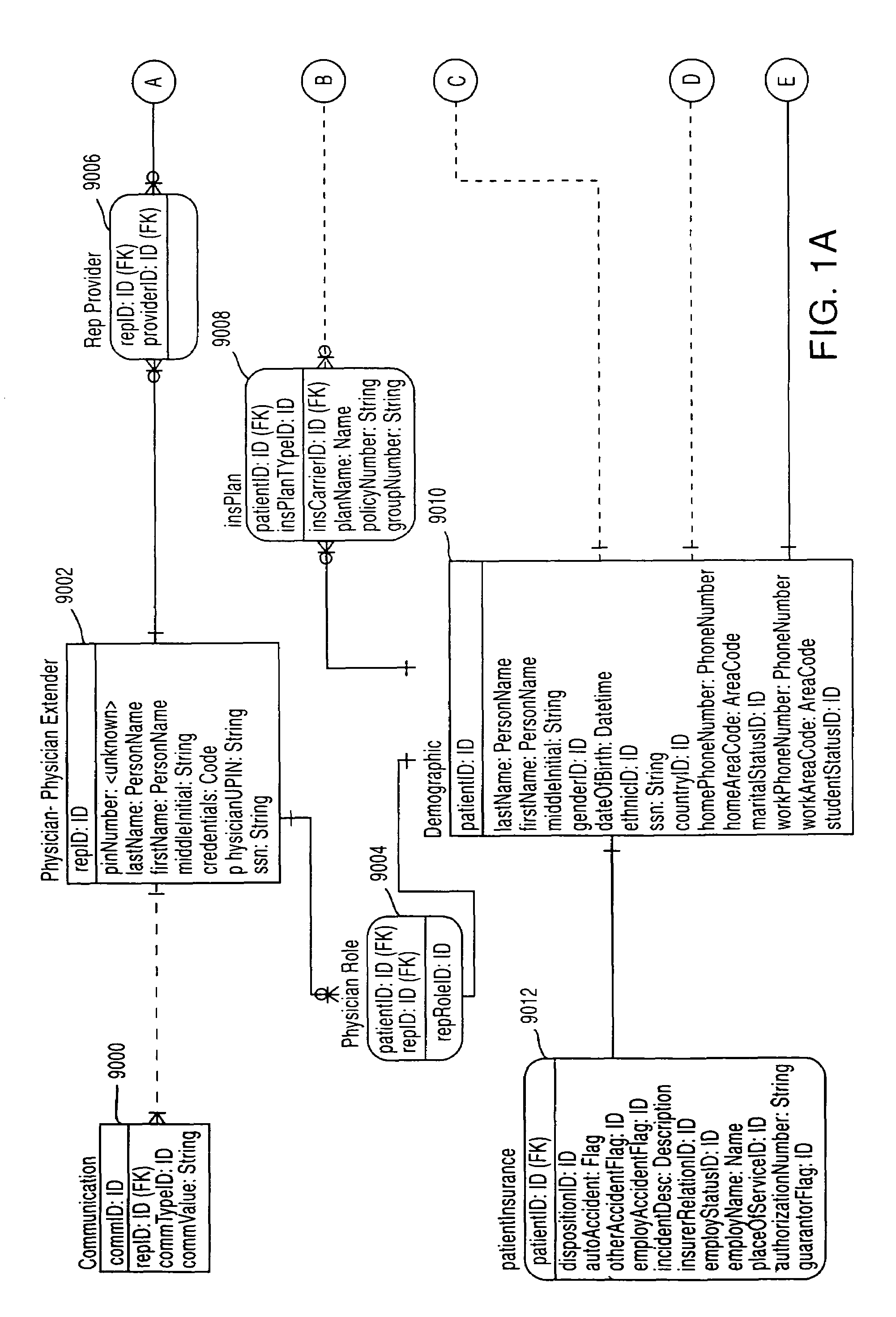

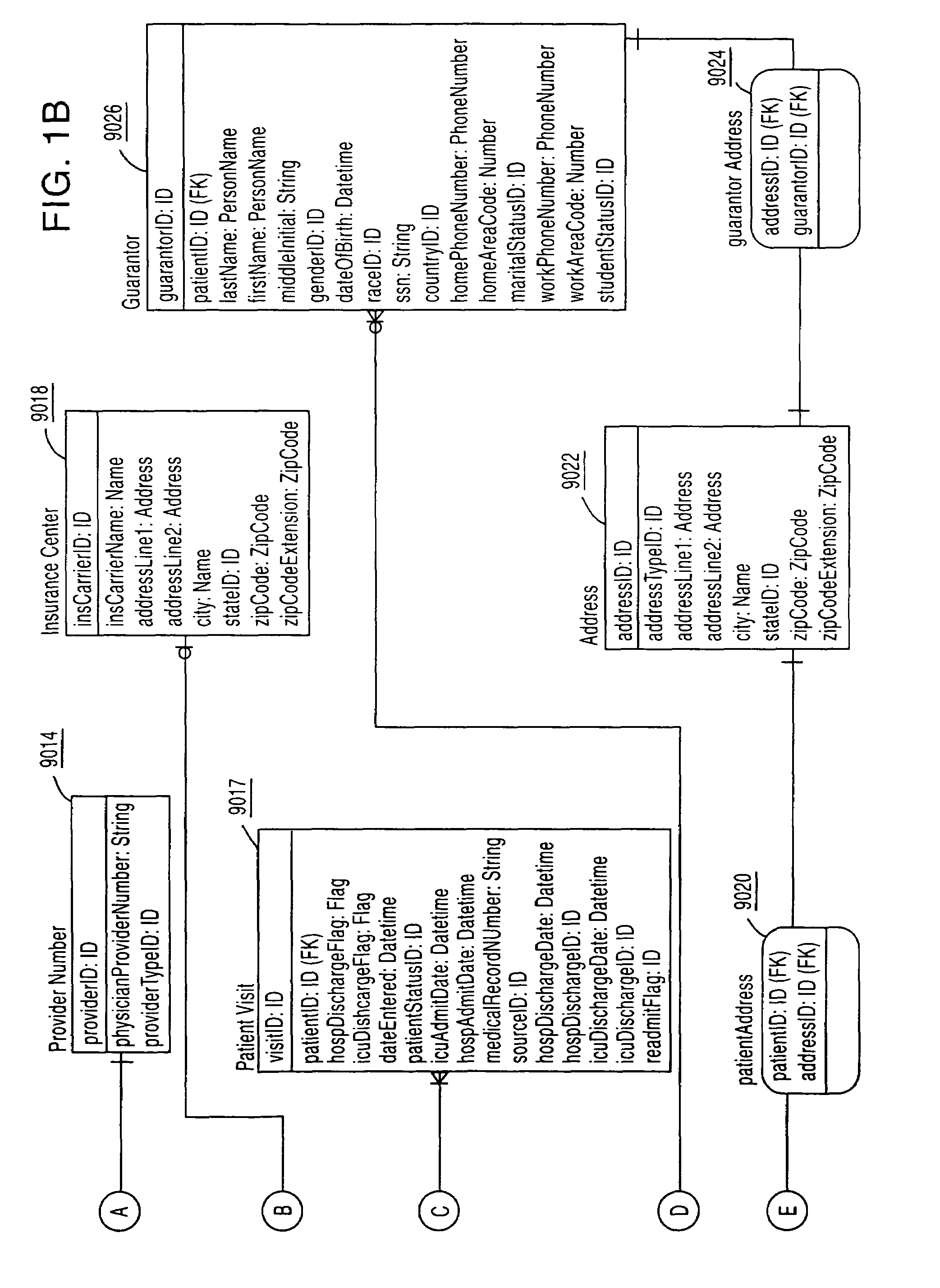

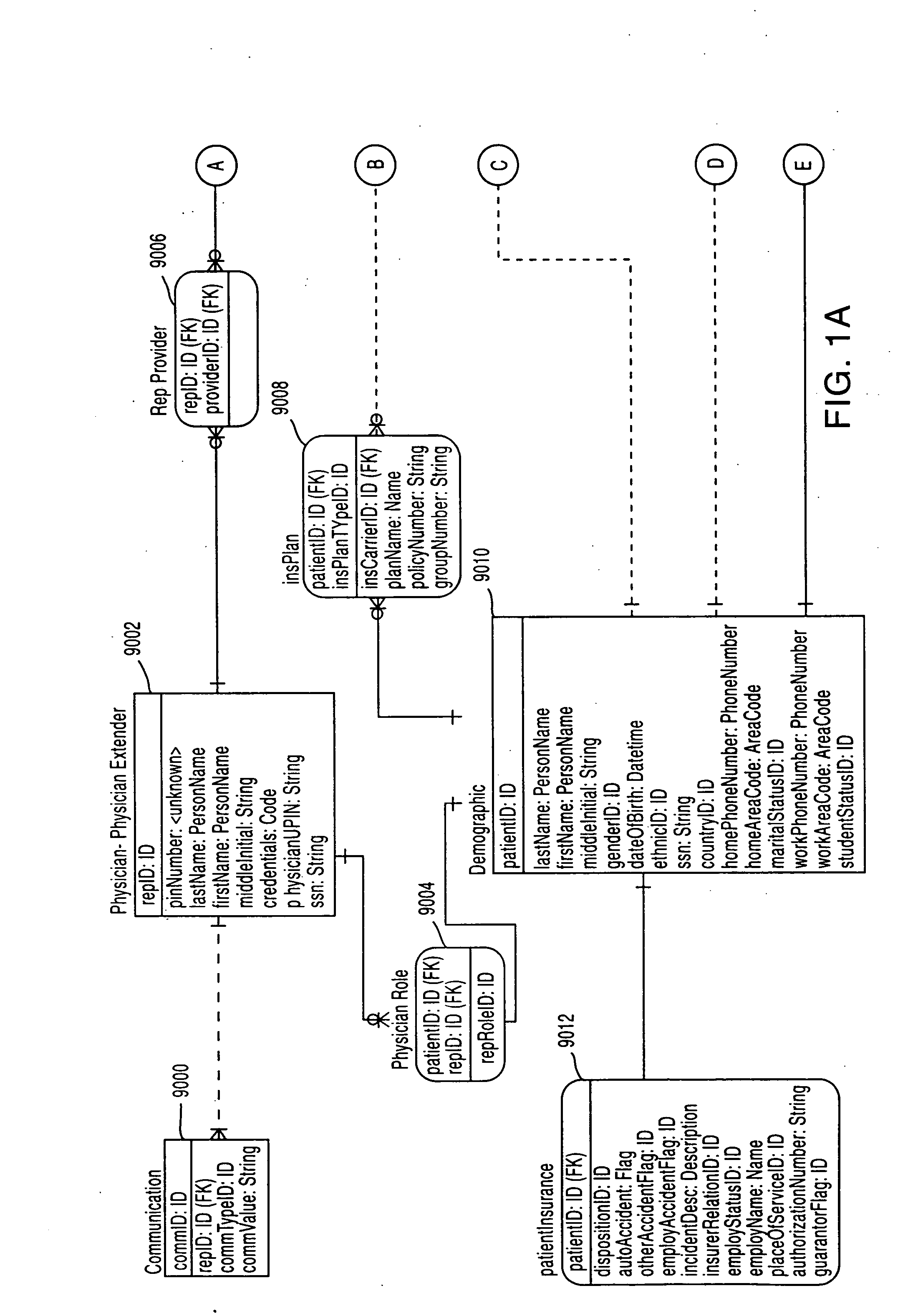

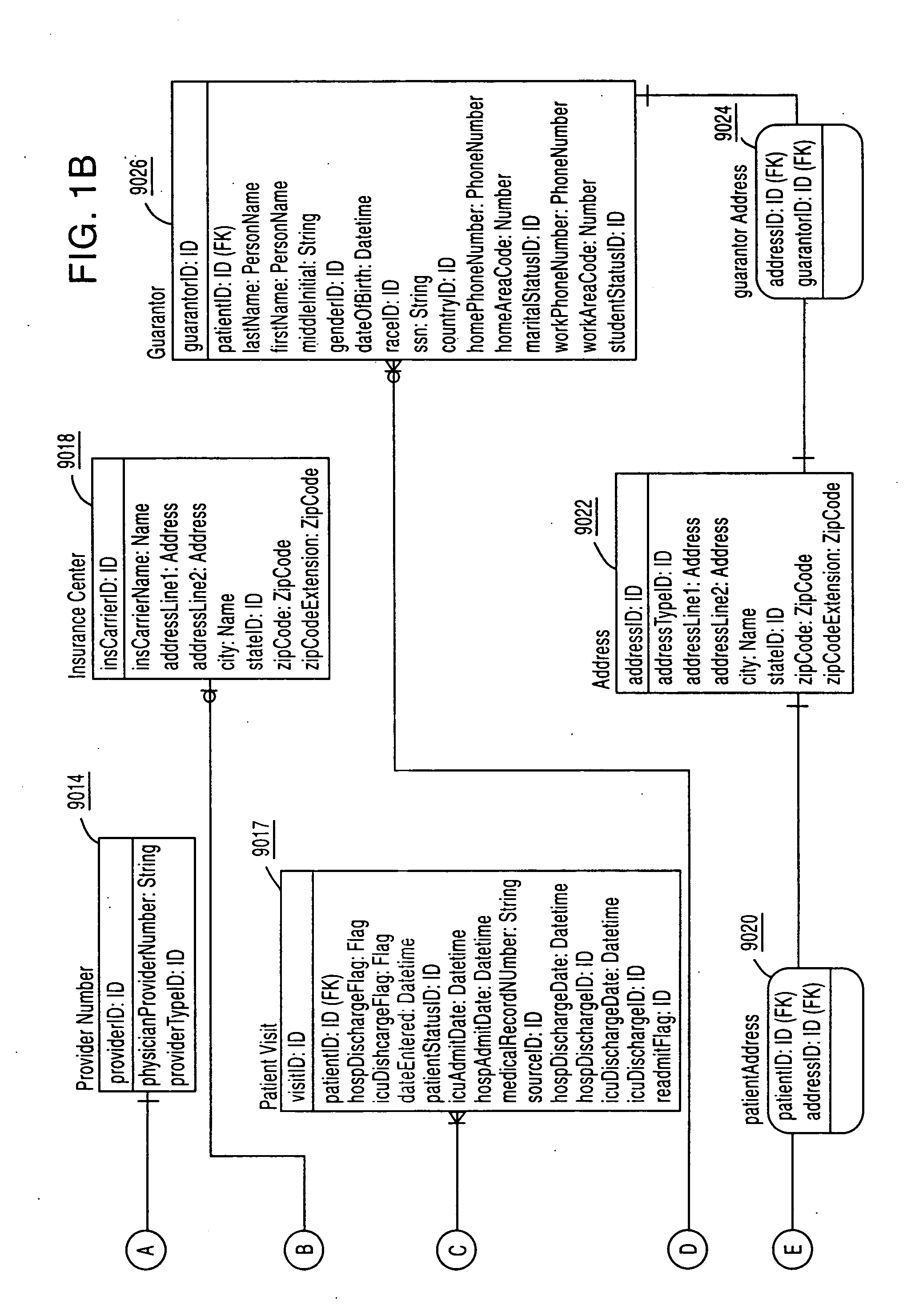

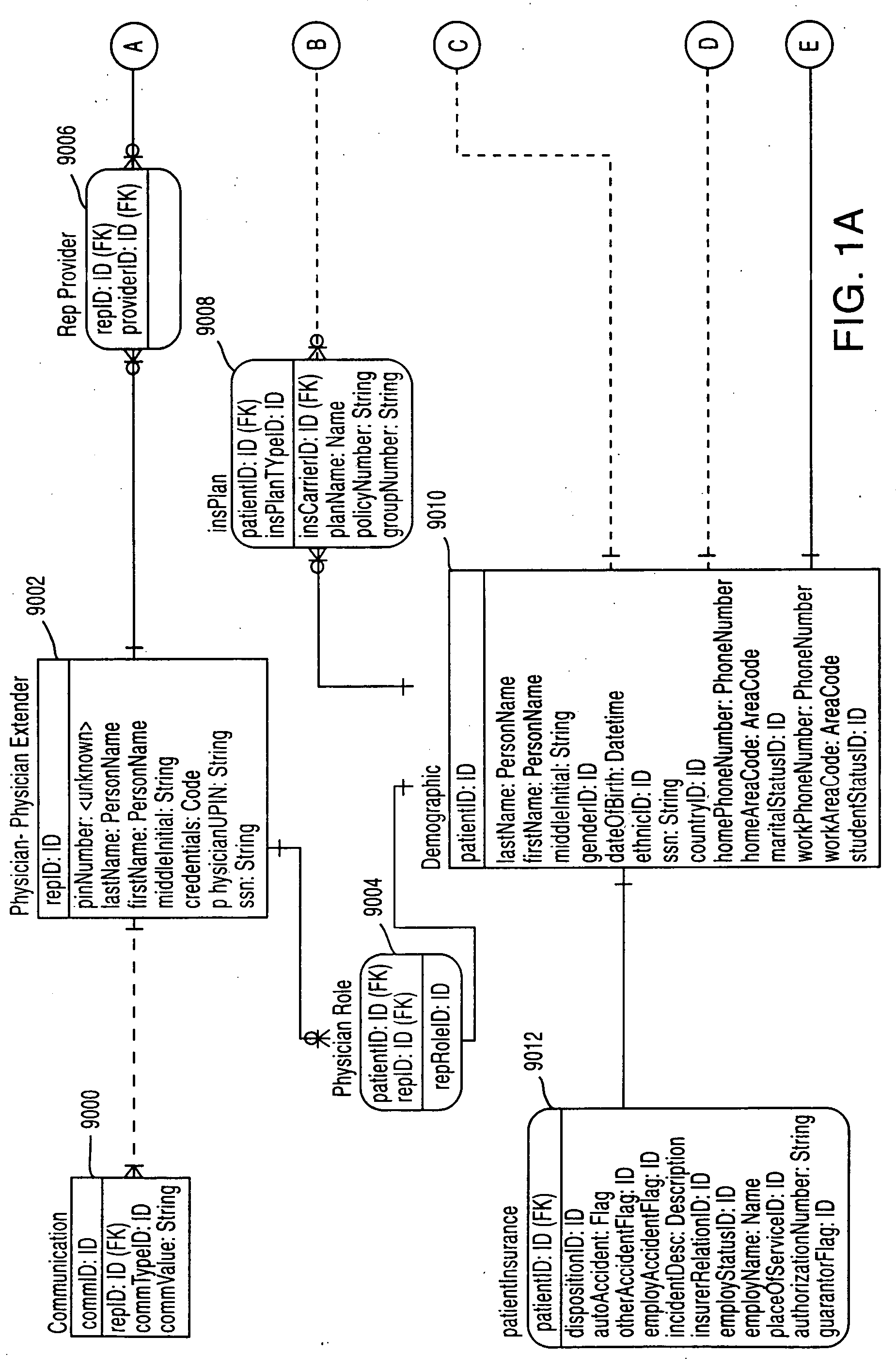

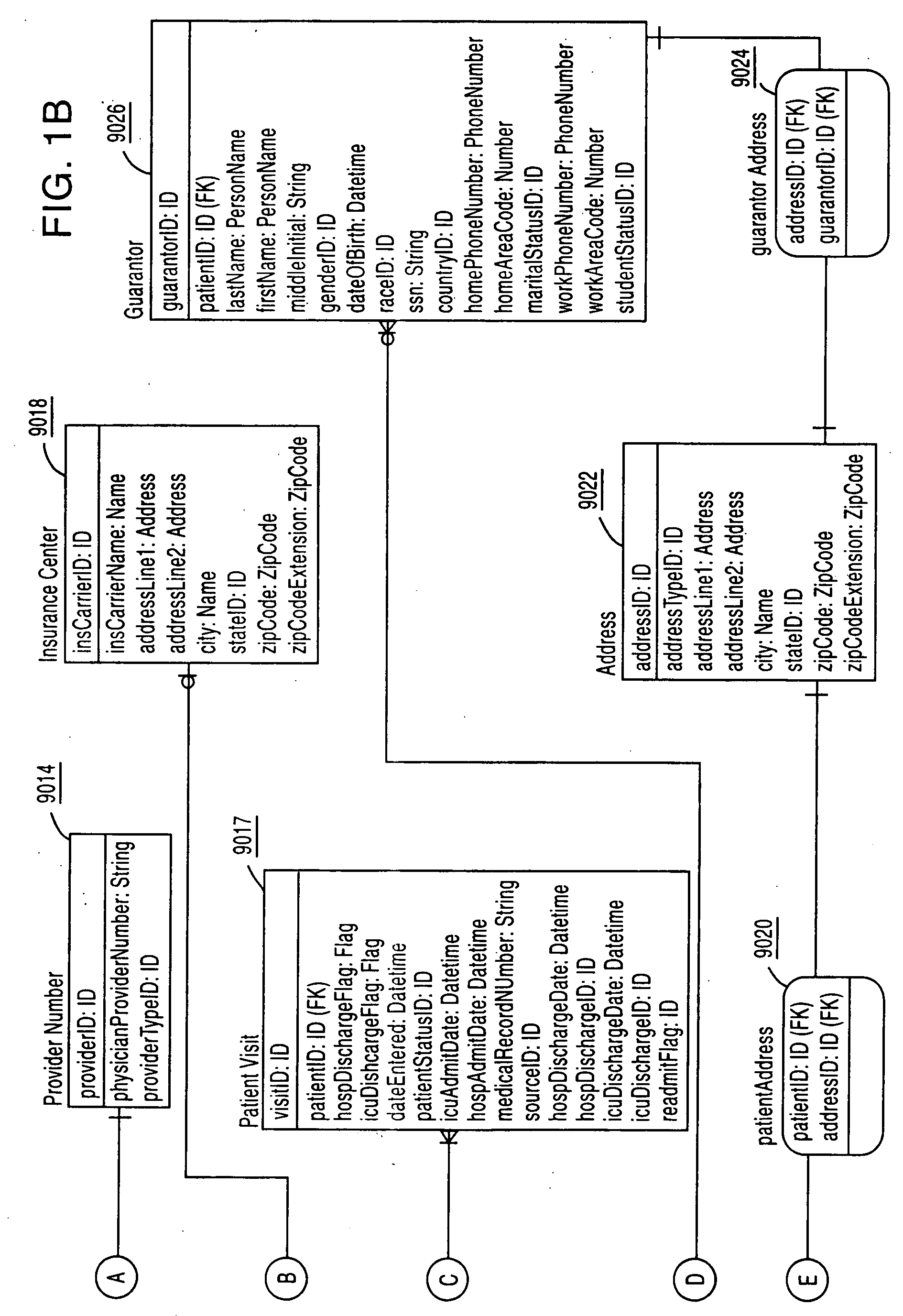

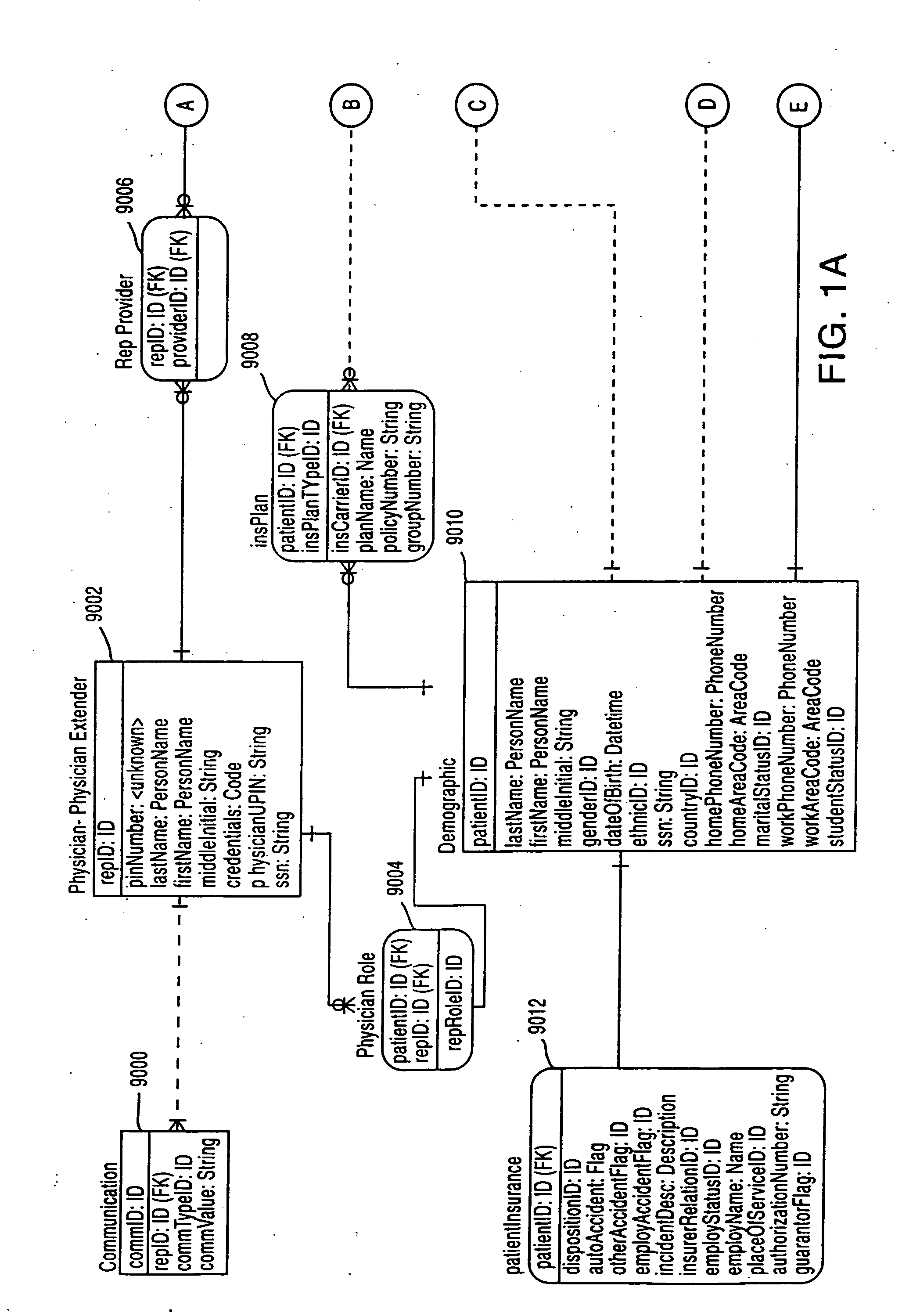

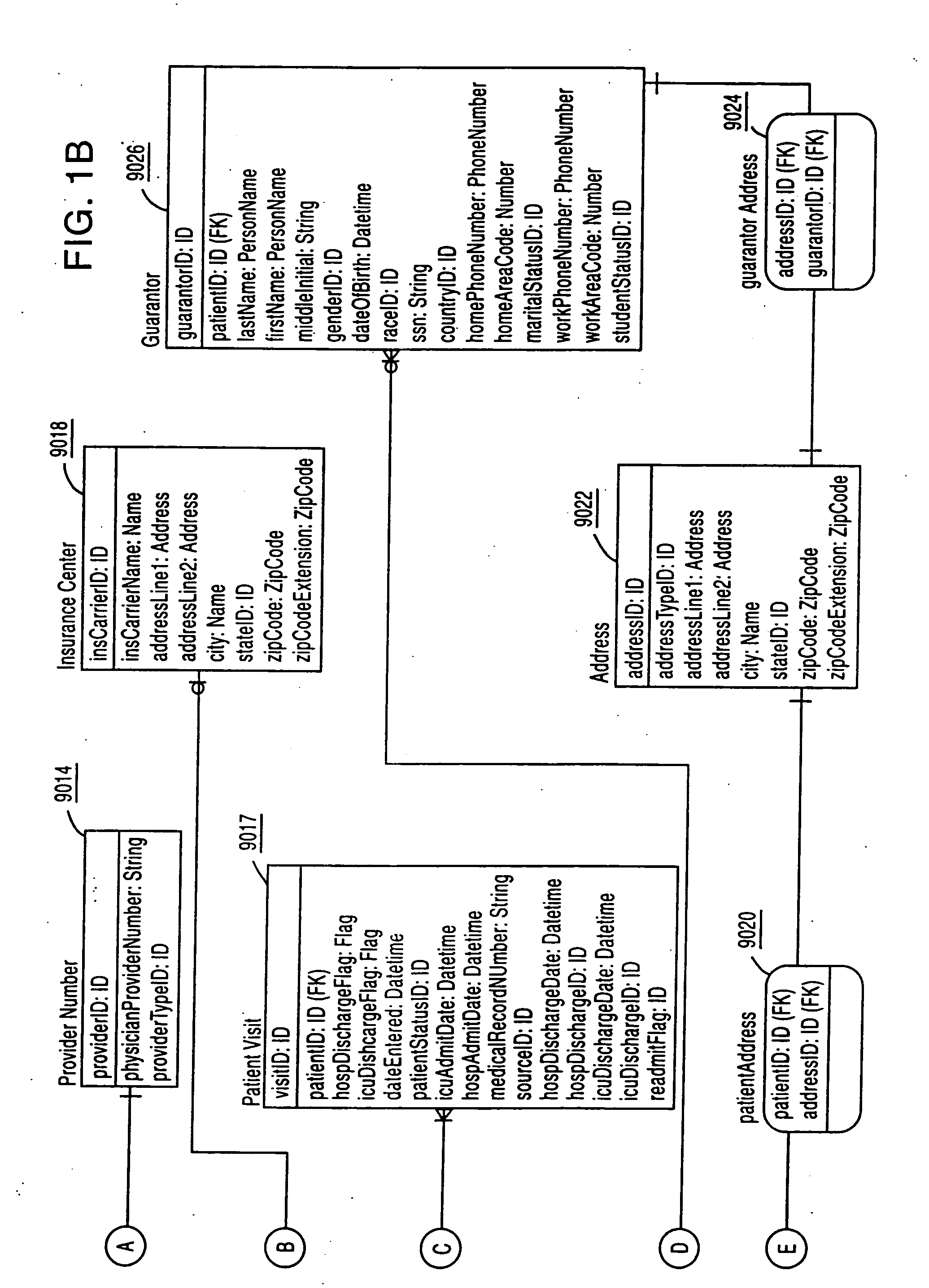

System and method for accounting and billing patients in a hospital environment

InactiveUS7467094B2Minimizing adverse eventsMinimize complicationsElectric signal transmission systemsMechanical/radiation/invasive therapiesHospitalized patientsPatient data

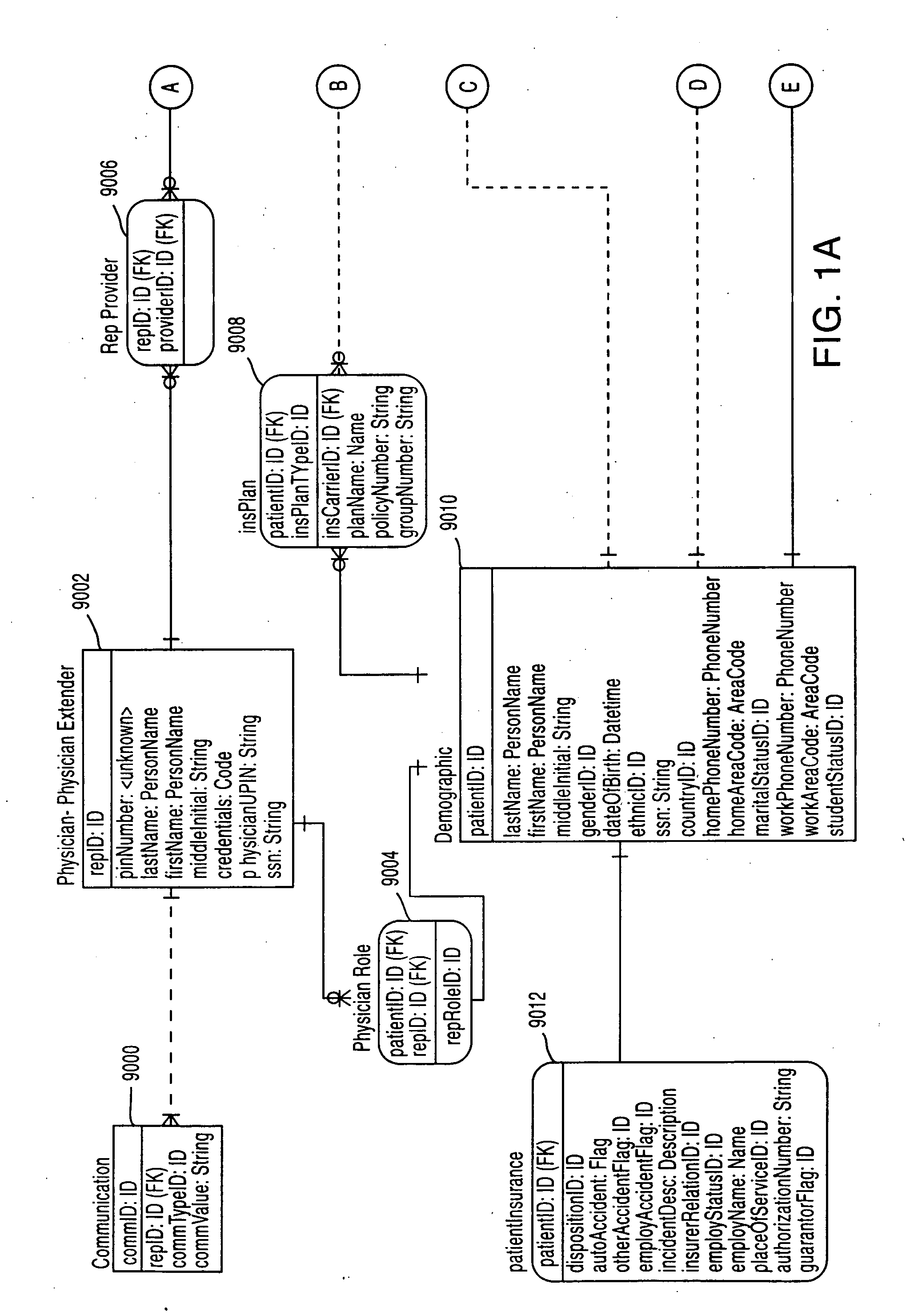

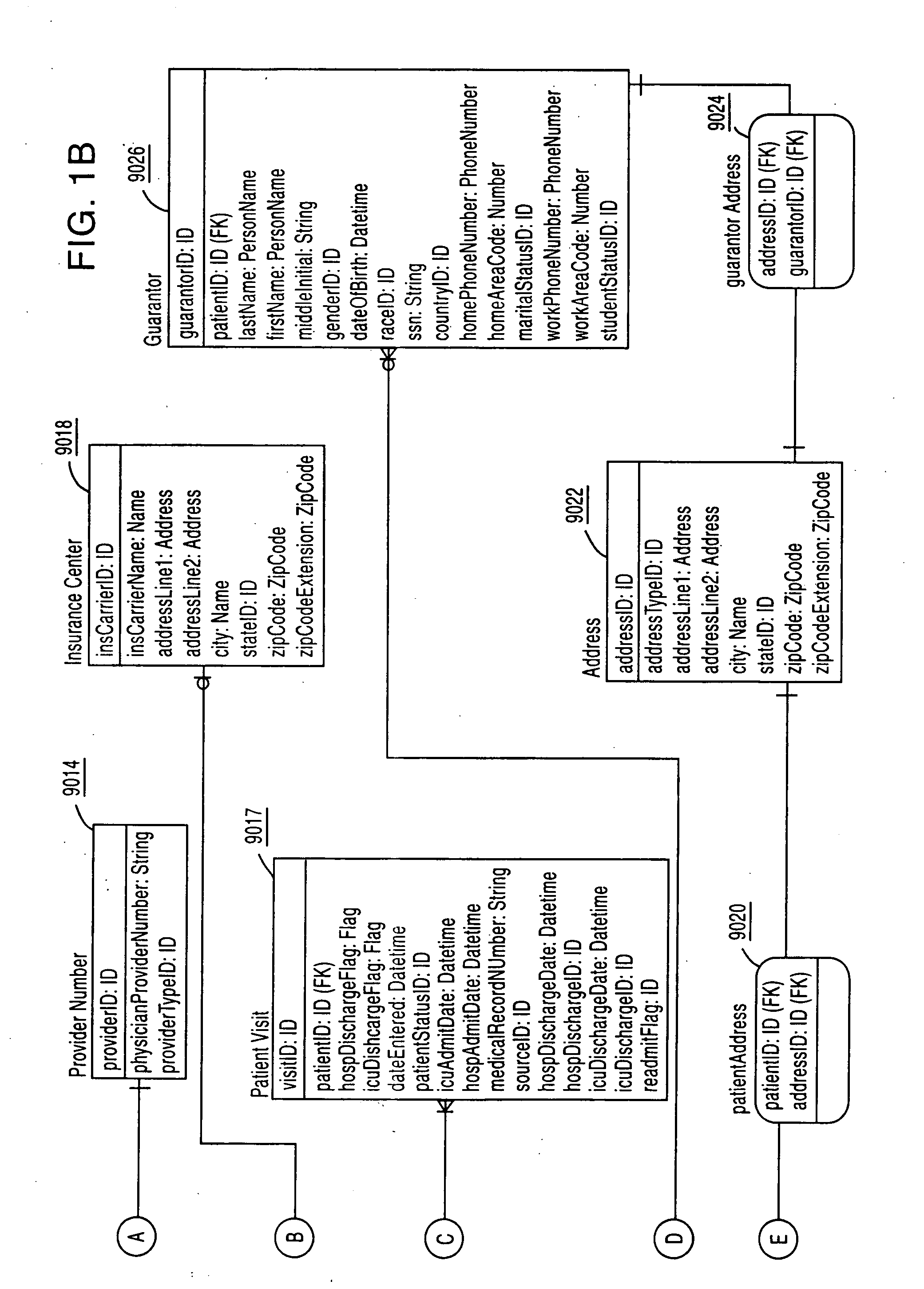

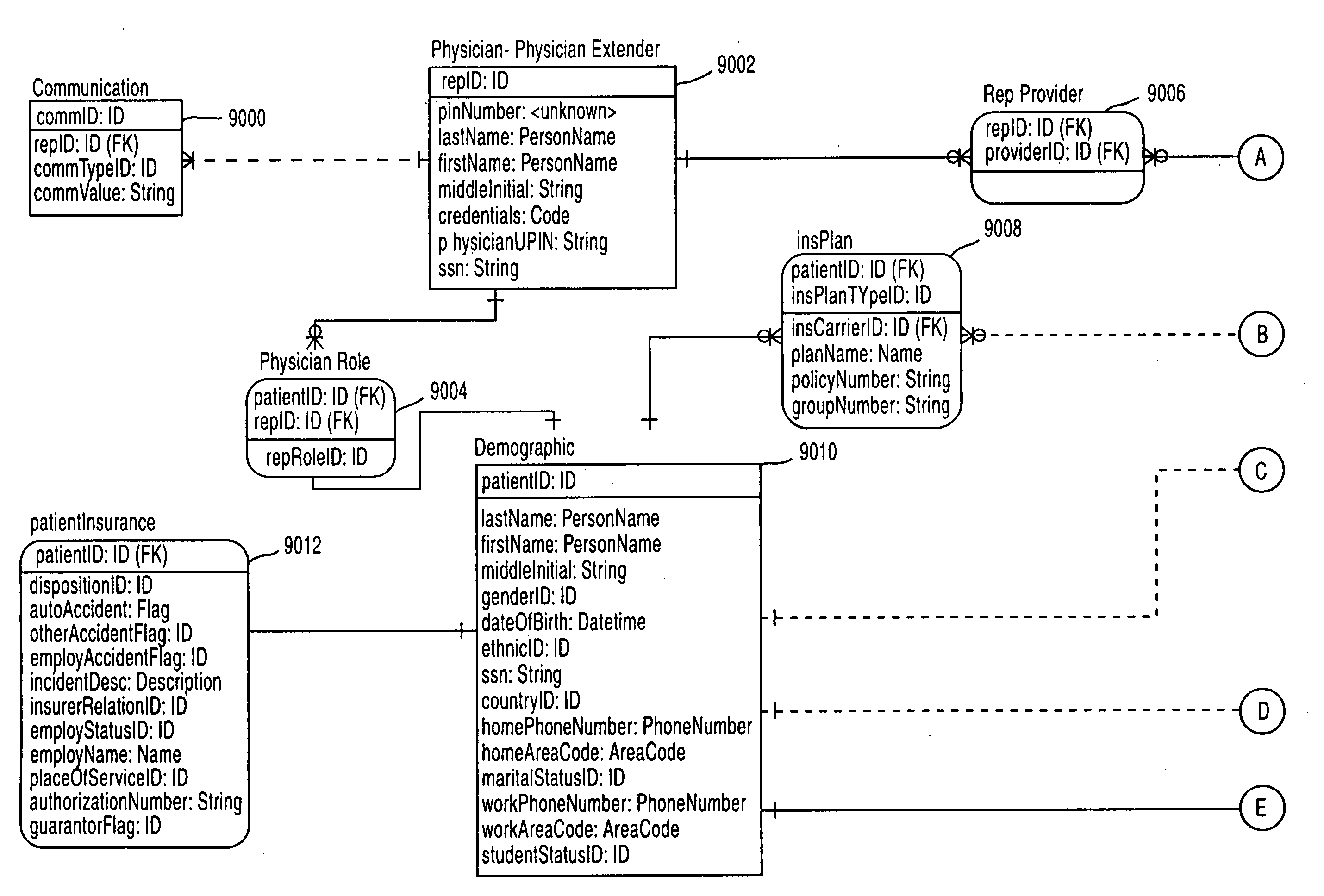

A system and method for accounting and billing patients in a hospital environment. A hospitalized patient is associated with a patient identifier. Billable services provided to the hospitalized patient are associated with the patient identifier. If the billable service is provided by a physician, a physician identifier is also associated with the billable service. The hospitalized patient is scored and a current procedural terminology (CPT) assignment manager assigns CPT codes to the billable service. A bill generator receives the patient data, patient insurance information, physician insurance information, and CPT codes and generates a bill for the billable services provided to the hospitalized patient.

Owner:VISICU

Video visitation system and method for a health care location

InactiveUS7650291B2Minimizing adverse eventsMinimize complicationsMechanical/radiation/invasive therapiesComputer-assisted treatment prescription/deliveryVisual monitoringPatient data

A video visitation system and method for dispersed health care locations. A patient data server, a teleconferencing server, a patient visual monitoring system and a visitor visual monitoring system are connected to a network. A patient data server receives patient data indicative of the condition of a patient and serves the patient data continuously and in real time to the teleconferencing server. The patient visual monitoring system acquires patient imaging data from a patient location and conveys the patient imaging data to the teleconferencing server. The visitor visual monitoring system acquires visitor imaging data from a visitor location and conveys the visitor imaging data to the teleconferencing server. The patient visual monitoring system displays the visitor imaging data and the visitor visual monitoring system simultaneously displays patient imaging data and the continuous real time feed of the patient data.

Owner:VISICU

System and method for displaying a health status of hospitalized patients

InactiveUS20060161459A9Minimizing adverse eventsMinimize complicationsOffice automationAlarmsGraphicsHospitalized patients

A system and method for displaying a health status of hospitalized patients. Patient data associated with hospitalized patients is selected according to display rules. A display module selects selected patient data, applies display rules to the selected patient data, and displays the selected patient data. A smart alert module generates and applies patient specific rules to other selected patient data elements. If a patient-specific rule for a hospitalized patient has been contravened, an alert is issued from the remote command center. Graphical attributes may be assigned to patients for whom an alert has been issued and to selected patient data elements that fall outside of an acceptable range. The graphical attributes determine how selected patient data appear on a display screen.

Owner:VISICU

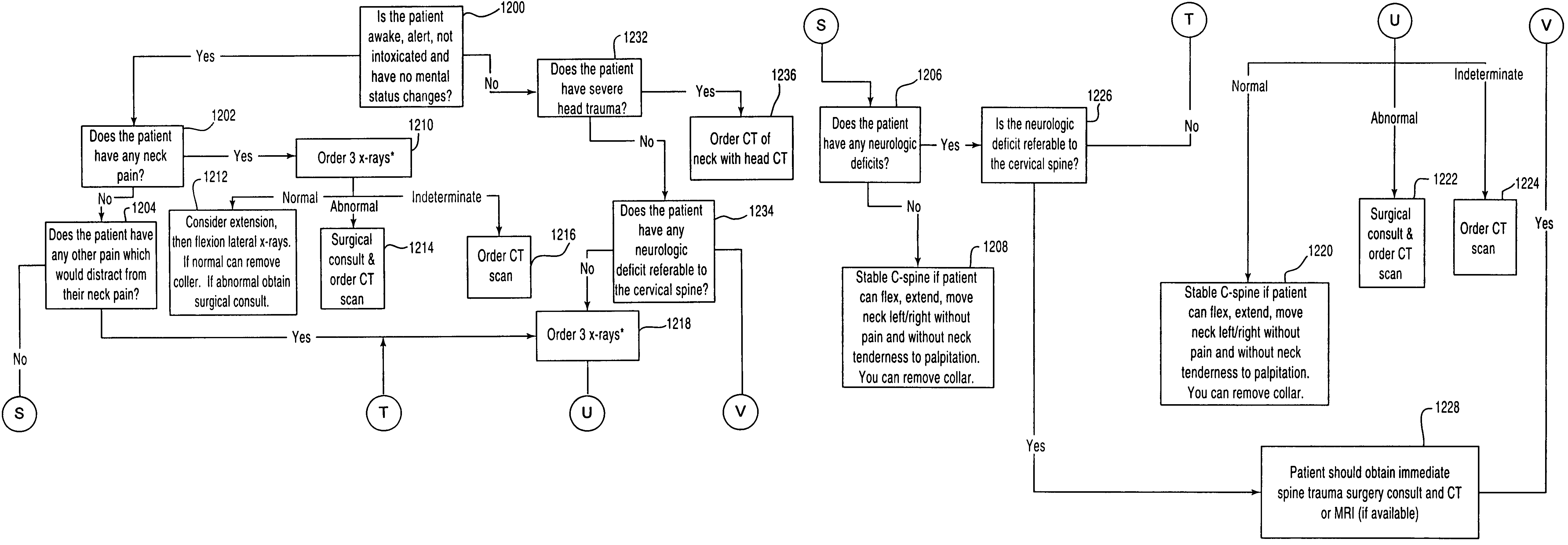

Remote command center for patient monitoring

InactiveUS8175895B2Minimizing adverse eventsMinimize complicationsMechanical/radiation/invasive therapiesComputer-assisted treatment prescription/deliveryOperative Surgical ProceduresHospitalized patients

A remote command center for providing services to geographically dispersed hospitalized patients. A datastore accessible to the remote command center receives patient data from geographically dispersed hospitalized patients. Monitored data elements of geographically dispersed hospitalized patients are also received at the remote command center and stored in the datastore. A smart alert module generates and applies patient specific rules to selected data elements. If a patient-specific rule for a hospitalized patient has been contravened, an alert is issued from the remote command center. A patient care module displays selected data elements of the hospitalized patients at the remote command center. A decision support module applies decision support algorithms to selected data elements of a hospitalized patient and to user input to provide patient care advice. Patient care advice comprises a diagnosis, a method of treatment, and a laboratory protocol. The decision support module may also write orders for medication, laboratory protocols and surgical procedures.

Owner:VISICU

System and method for observing patients in geographically dispersed health care locations

InactiveUS7411509B2Minimizing adverse eventsMinimize complicationsElectric testing/monitoringAlarmsPatient dataMonitor equipment

A system and method for observing patients in geographically dispersed health care locations. A portable monitoring station is associated with a patient assigned to a health care location. The portable monitoring station comprises monitoring equipment that monitors physiological measures of the patient. A remote command center receives the monitored data elements, accesses patient data elements indicative of a medical condition associated with the patient, and applies a patient-specific rule to selected data elements to determine whether the patient-specific rule has been contravened. The monitored equipment may further comprise video and audio equipment that captures patient video data and patient audio data and provides these data to the central command center.

Owner:VISICU

System and method for standardizing care in a hospital environment

InactiveUS20050159987A1Minimizing adverse eventMinimizing complicationAlarmsSpecial data processing applicationsMedicine.hematologyGuideline

A system and method for standardizing care in a hospital environment. Information concerning the latest care and practice standards for a given condition is provided to a decision support module. The decision support module comprises decision support algorithms that reflect a standardize guideline of practice for a particular medical condition. The general categories of cardiovascular, endocrinology, general, gastrointestinal, hematology, infectious diseases, neurology, pharmacology, pulmonary, renal, surgery, toxicology, trauma all have guidelines and practice standards associated with them. Patient data and user input are inputted to the decision support algorithm. The user may be prompted for user input, and an assessment is made of the patient so as provide patient care advice for the patient. Examples of patient care advice are a diagnosis, a method of treatment, and a laboratory protocol.

Owner:VISICU

Remote command center for patient monitoring relationship to other applications

InactiveUS20060085229A9Minimizing adverse eventsMinimize complicationsMechanical/radiation/invasive therapiesComputer-assisted treatment prescription/deliveryHospitalized patientsUser input

A remote command center for providing services to geographically dispersed hospitalized patients. A datastore accessible to the remote command center receives patient data from geographically dispersed hospitalized patients. Monitored data elements of geographically dispersed hospitalized patients are also received at the remote command center and stored in the datastore. A smart alert module generates and applies patient specific rules to selected data elements. If a patient-specific rule for a hospitalized patient has been contravened, an alert is issued from the remote command center. A patient care module displays selected data elements of the hospitalized patients at the remote command center. A decision support module applies decision support algorithms to selected data elements of a hospitalized patient and to user input to provide patient care advice. Patient care advice comprises a diagnosis, a method of treatment, and a laboratory protocol. The decision support module may also write orders for medication, laboratory protocols and surgical procedures.

Owner:VISICU

System and method for standardizing care in a hospital environment

InactiveUS20060122869A9Minimizing adverse eventsMinimize complicationsAlarmsSpecial data processing applicationsMedicine.hematologyGuideline

A system and method for standardizing care in a hospital environment. Information concerning the latest care and practice standards for a given condition is provided to a decision support module. The decision support module comprises decision support algorithms that reflect a standardize guideline of practice for a particular medical condition. The general categories of cardiovascular, endocrinology, general, gastrointestinal, hematology, infectious diseases, neurology, pharmacology, pulmonary, renal, surgery, toxicology, trauma all have guidelines and practice standards associated with them. Patient data and user input are inputted to the decision support algorithm. The user may be prompted for user input, and an assessment is made of the patient so as provide patient care advice for the patient. Examples of patient care advice are a diagnosis, a method of treatment, and a laboratory protocol.

Owner:VISICU

Video visitation system and method for a health care location

InactiveUS20060064324A1Minimizing adverse eventsMinimize complicationsMechanical/radiation/invasive therapiesComputer-assisted treatment prescription/deliveryVisual monitoringPatient data

A video visitation system and method for dispersed health care locations. A patient data server, a teleconferencing server, a patient visual monitoring system and a visitor visual monitoring system are connected to a network. A patient data server receives patient data indicative of the condition of a patient and serves the patient data continuously and in real time to the teleconferencing server. The patient visual monitoring system acquires patient imaging data from a patient location and conveys the patient imaging data to the teleconferencing server. The visitor visual monitoring system acquires visitor imaging data from a visitor location and conveys the visitor imaging data to the teleconferencing server. The patient visual monitoring system displays the visitor imaging data and the visitor visual monitoring system simultaneously displays patient imaging data and the continuous real time feed of the patient data.

Owner:VISICU

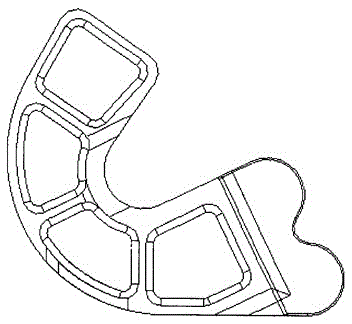

Method for machining lug-type notch in numerical control mode

ActiveCN105537657AEffectively \"shut up\"Effective \"opening\" phenomenonMilling equipment detailsNumerical controlEngineering

The invention discloses a method for machining a lug-type notch in a numerical control mode, and belongs to the technical field of mechanical machining. The method comprises the steps that 1, the structural form of the lug-type notch of a part is analyzed; 2, processes for machining the notch are selected; 3, the form and specification of a T-shaped tool for rough machining and the form and specification of a T-shaped tool for fine machining are selected; 4, a numerical control machining procedure is programmed; 5, the processes are detected, if an opening is formed at the notch, the fine machining procedure is adjusted according to a difference value between the size of the opening and the theoretical size of the notch, a step 7 is performed, if a necked opening is formed at the notch, the size of the necked opening is recorded, and according to a different value between the theoretical size of the notch and the size of the necked opening, a step 6 is performed to trim the size of the notch; 6, an up milling procedure is performed for the necked opening, and after the size is qualified, the step 7 is performed; 7, fine machining is performed on the size of the notch; 8, the size of the notch obtained through fine machining is detected. Accordingly, numerical control machining of the lug-type notch is achieved, and the advantages of being high in machining efficiency for lug-type notch structural parts, little in tool loss amount, low in assistance cost and wide in application range are achieved.

Owner:SHENYANG AIRCRAFT CORP

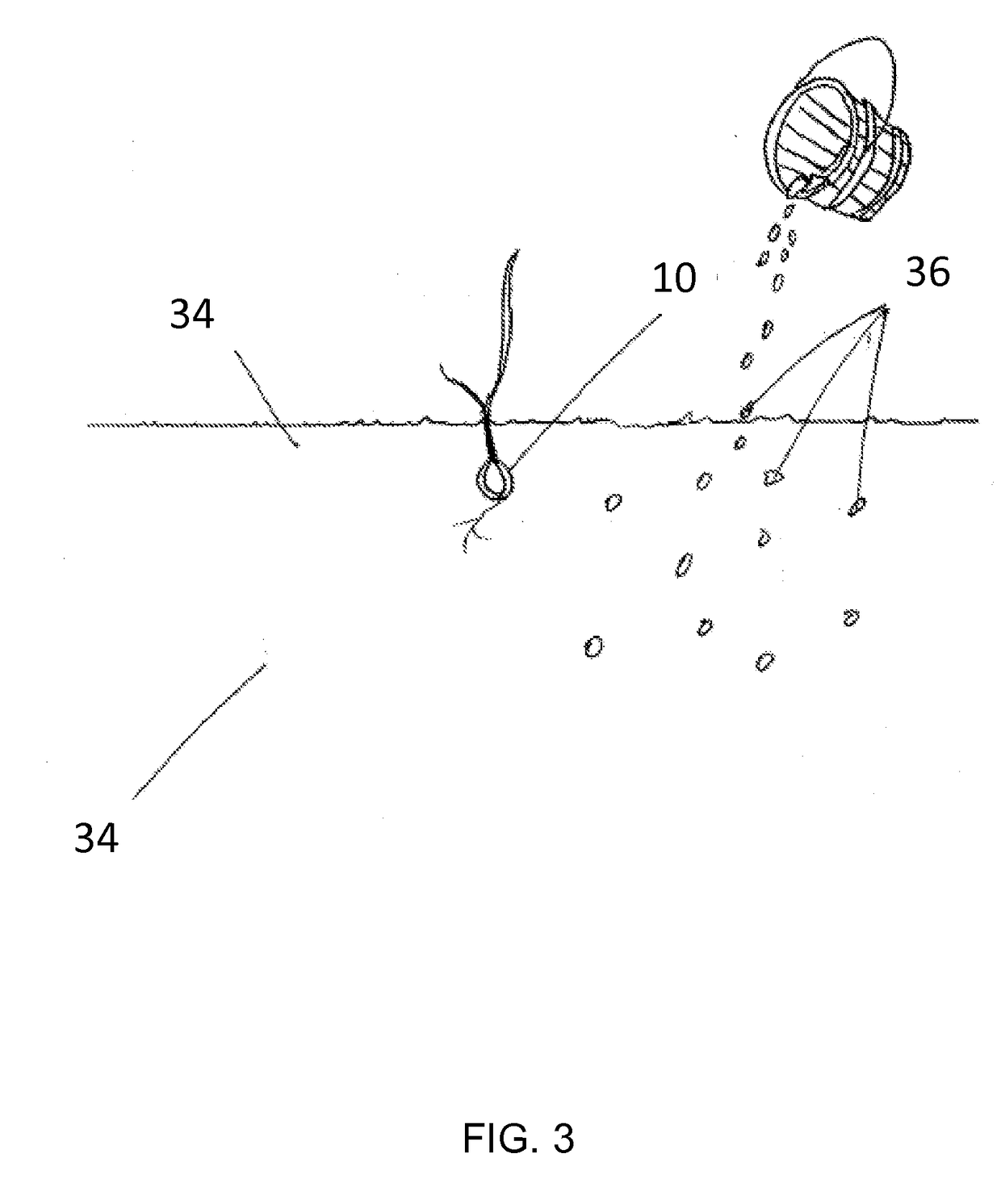

Seed composition and method to improve germination and emergence under adverse soil conditions

InactiveUS20170086488A1Good energyMaximize use of waterSeed coating/dressingFood scienceSURFACTANT BLENDGermination

A seed composition, system, and method of improving seed germination, emergence, and seedling development are provided. The seed composition includes a seed, a binder, and a surfactant forming a first layer. The seed composition can have a second layer composed of a diatomaceous earth, lime, or clay and a binder and a third coating that includes a surfactant.

Owner:AQUATROLS CORP OF AMERICA INC

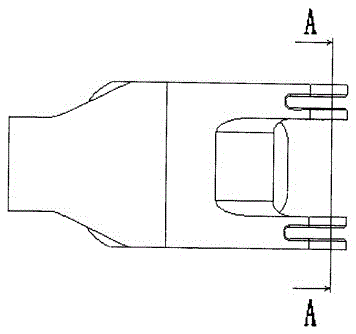

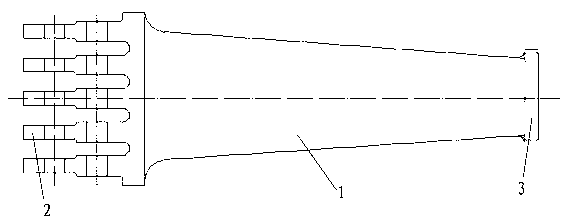

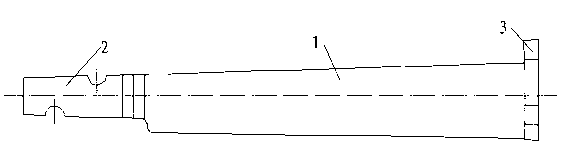

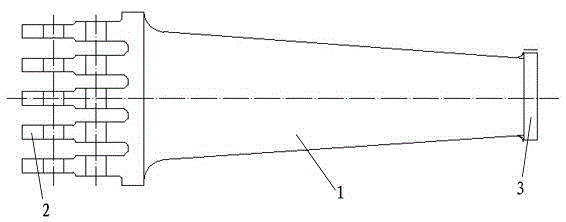

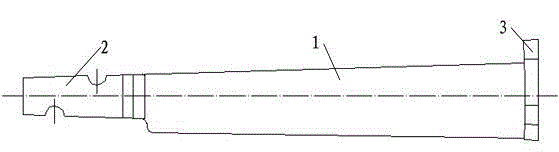

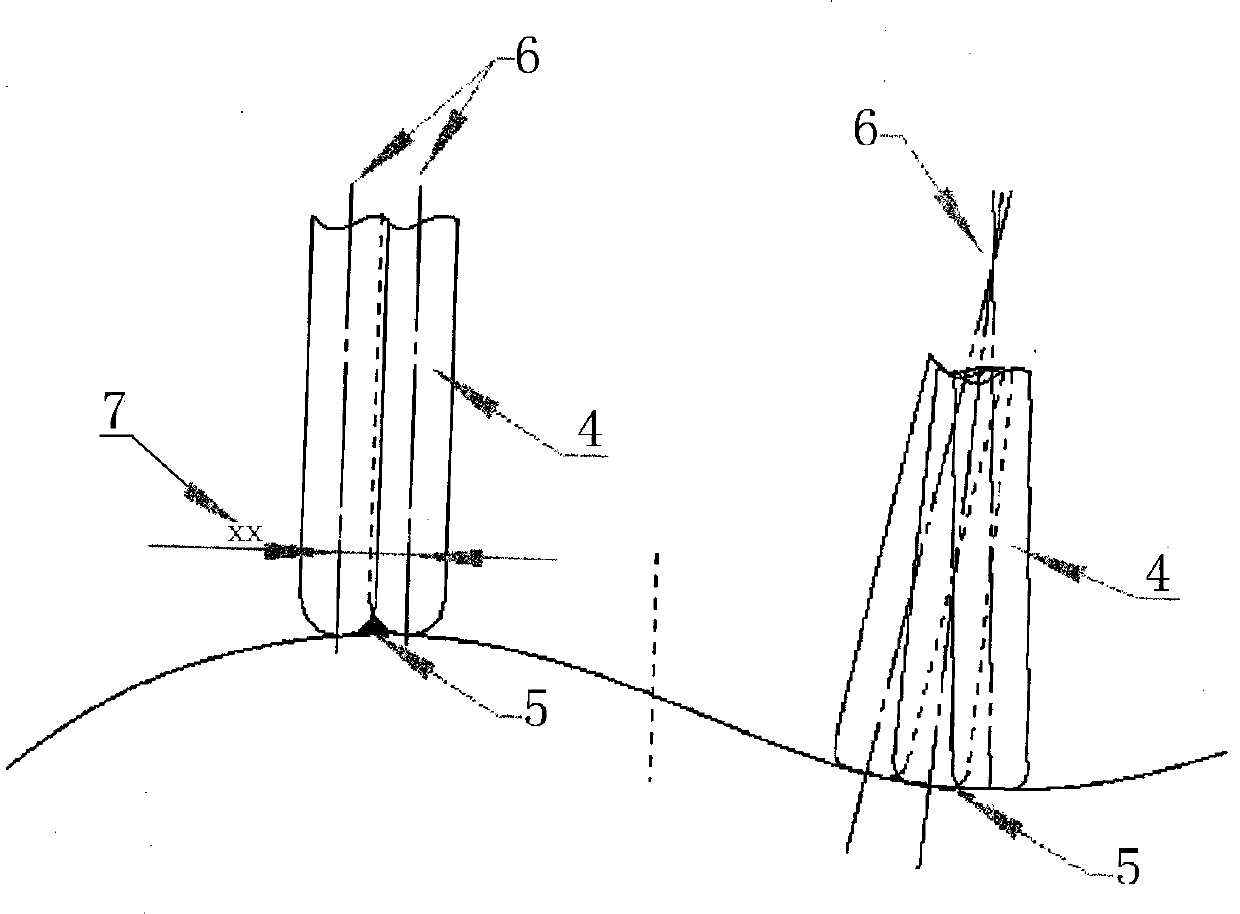

Processing method of five-fork blade-root moving blades with own shrouds

ActiveCN103203490AAvoid deformationLess effective cuttingMilling equipment detailsProcess engineeringMachine tool

The invention discloses a processing method of five-fork blade-root moving blades with own shrouds, belonging to the technical field of blade processing. The processing method comprises: step 1, clamping blades, step 2, roughing, step 3, semi-refining, step 4, refining, step 5, positioning a steam-out side of a shoulder of the blade root, a steam-out side of a shroud and a back radial surface of the blade root, selecting a cutter with cutting edges matching with five-fork blade root lines, with a rotating speed being 25-30 r / min, a feeding speed being 12.5 mm / min, a feed amount being 0.5-0.8 mm, and performing fine milling for the five-fork blade root lines of the blade along a linear direction. According characteristics of the five-fork blade-root moving blades with own shrouds, positioning reference surface during processing is unified, a one-time clamping is used to complete processing of each part, thereby effectively preventing accumulative errors, increasing processing precision, optimizing integration processing, shortening processing periods of products, reducing required amount of machine tool, and reducing production cost.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

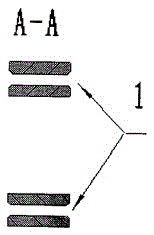

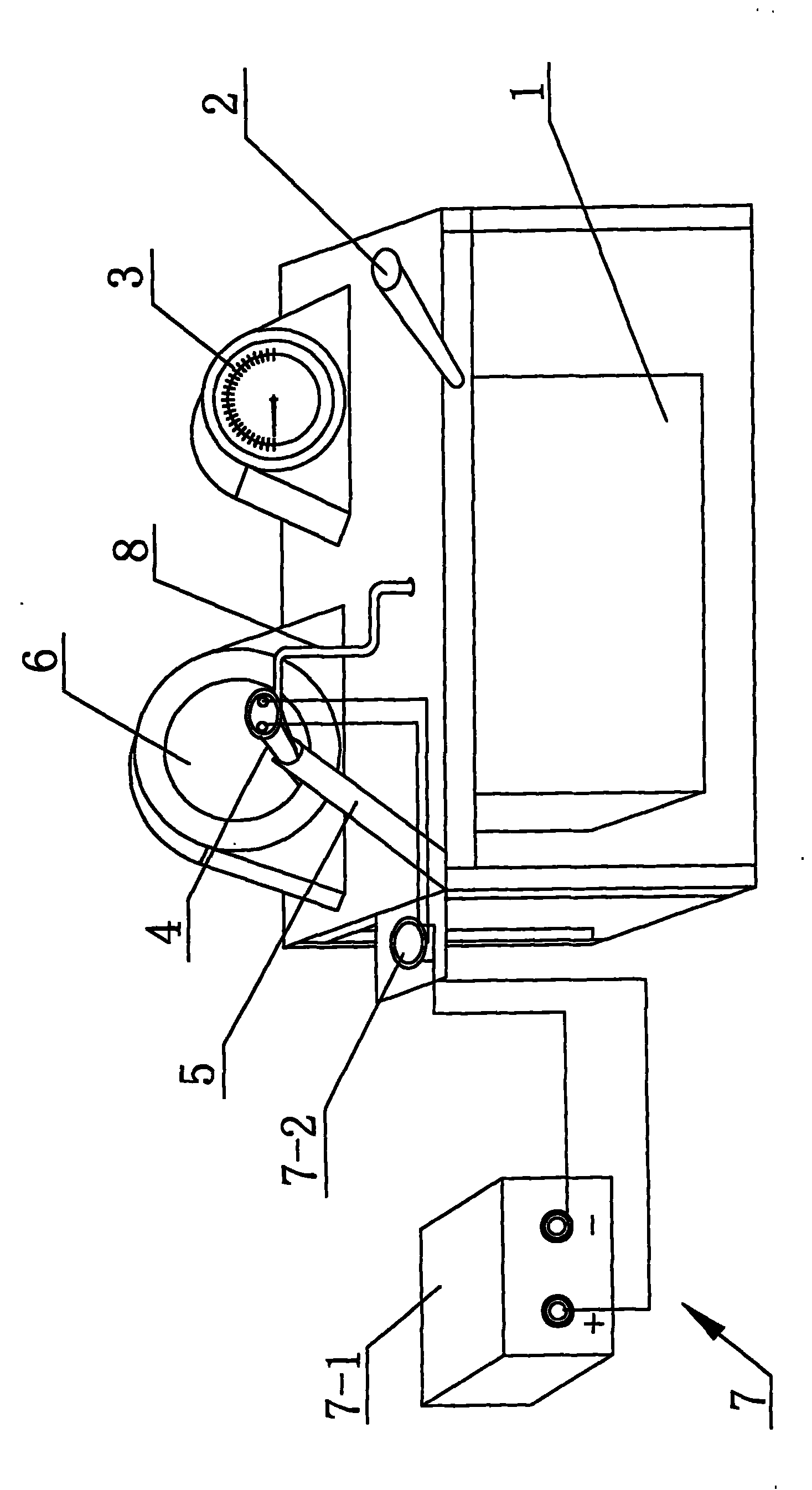

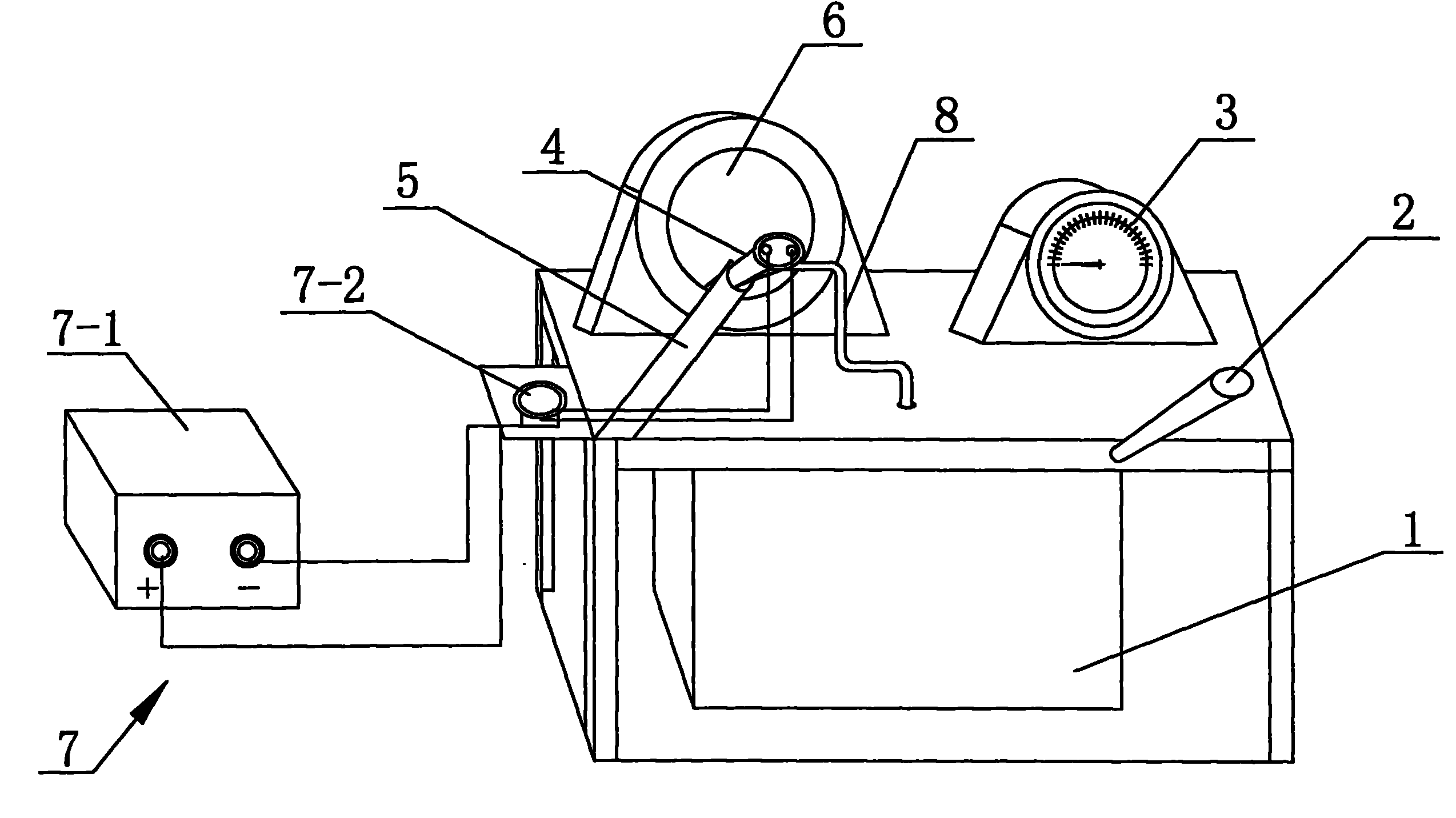

Simple electronic control fuel injector testboard

InactiveCN101886598AReduce ancillary costsSave time resourcesEngine testingFuel injection apparatusFuel tankElectric control

The invention relates to a simple electronic control testboard, which comprises a fuel tank; a pressure operating rod for providing pressure for test fuel is arranged on the fuel tank; the fuel tank is provided with a pressure gauge and a mounting bracket used for mounting the fuel injector; and the fuel injector is connected with the fuel tank and a test fuel recovery unit through a fuel pipe. The simple electronic control testboard is characterized in that the test system also comprises an electronic control mechanism for controlling the atomization of the fuel injector. By adopting the structure, an operator can operate the pressure operating rod and a motor switch simultaneously, and observes whether the fuel injector injects fuel and the fuel atomizing condition at any time so as to determine whether the fuel injector fails. Therefore, a trouble that the fuel injector is brought to a monitoring station specially is eliminated, and the supplementary cost is reduced. The conventional fuel injector testboard is modified; the modification cost is reduced to the maximum on the premise of not wasting resources, and the simple electronic control testboard is easy to promote and use in various service stations; besides, the simple electronic control testboard can complete tests and obtain test results in short time, so the time and human resource are saved.

Owner:BRITISH JOINT VENTURE PERKINS ENGINES TIANJIN

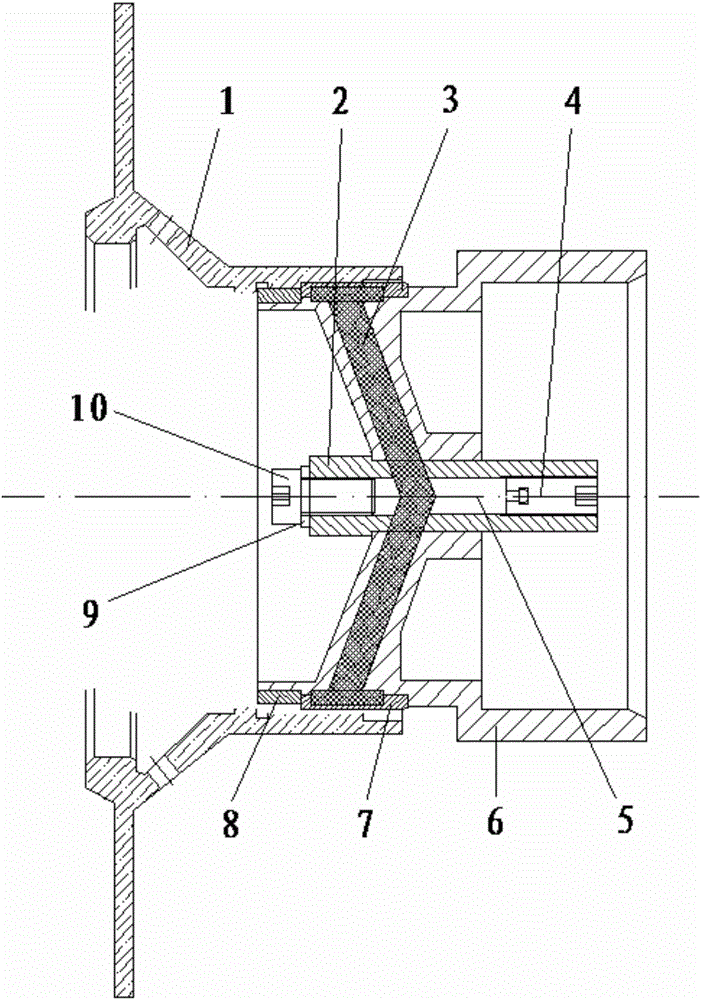

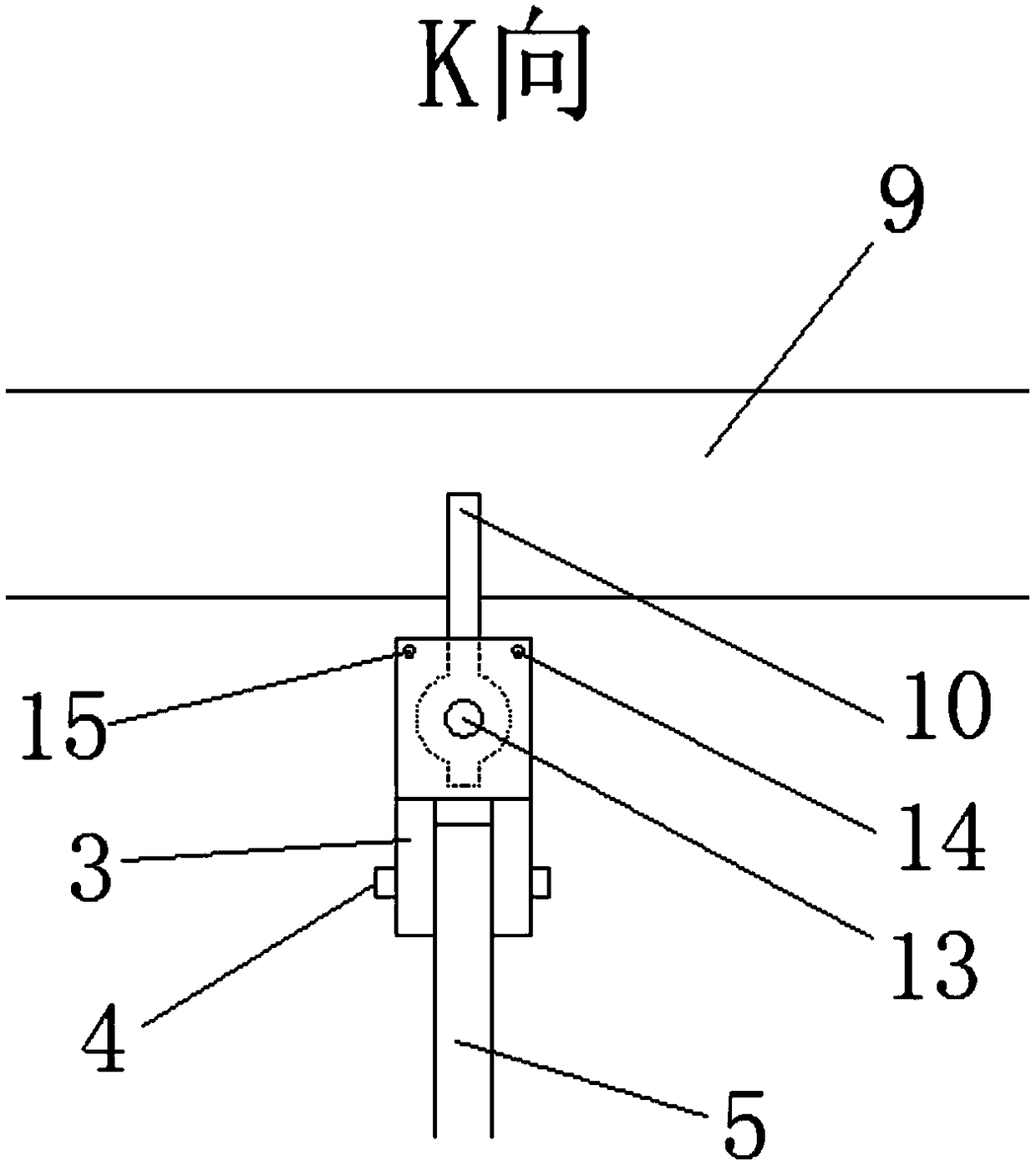

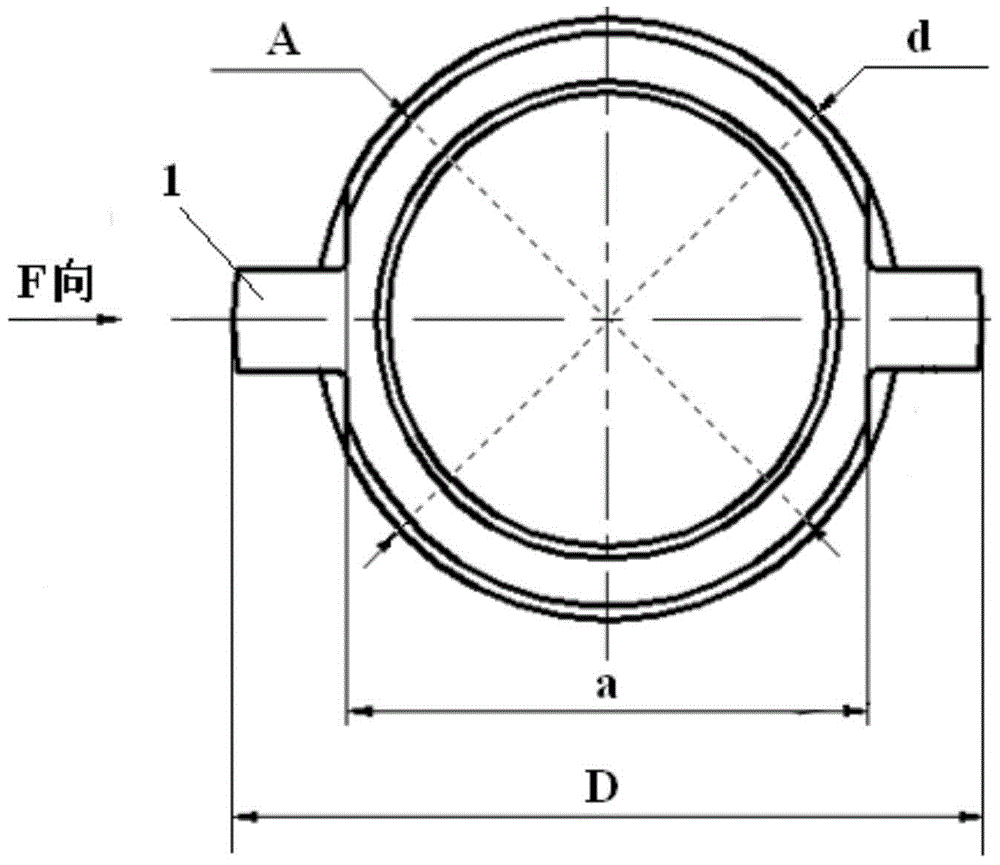

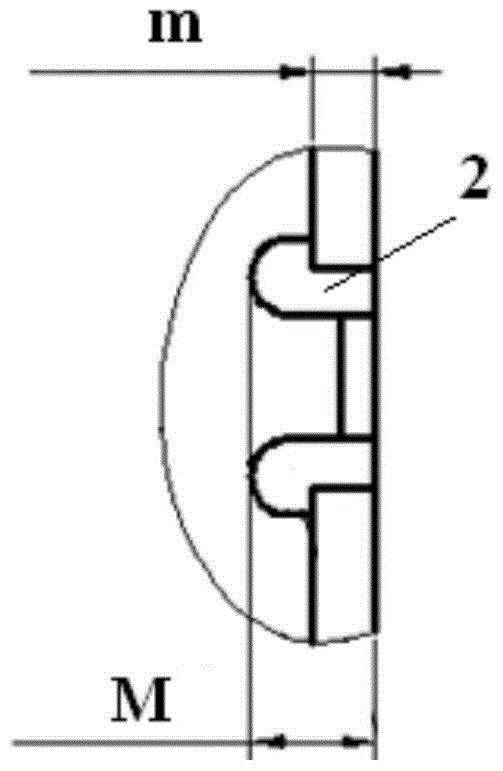

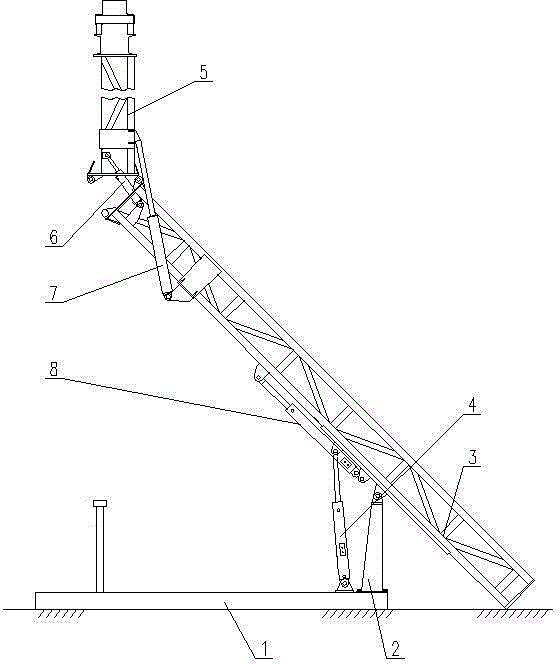

Hydraulic supporting clamp for rotor processing

InactiveCN106736732ASimple structureImprove practicalityWork holdersPositioning apparatusEngineeringMechanical engineering

The invention discloses a hydraulic supporting clamp for rotor processing. The hydraulic supporting clamp for rotor processing comprises a liner (2), liquid plastic (3), a first screw (4), a plunger (5), a positioning sleeve (6), a liner (7), a retaining sleeve (8), a composite cushion ring (9) and a second screw (10), wherein the positioning sleeve (6) is a main body structure part and is composed of a small end ring and a large end ring; the small end ring and the large end ring are coaxially integrated; the inner side of the large end ring is matched with a processing equipment supporting structure; and an outer side groove of the small end ring supports the liner (7). The hydraulic supporting clamp for rotor processing is simple in structure, high in practicability, short in design and manufacturing period, low in cost, convenient to use and easy to operate, can accurately position a machine element, lowers auxiliary cost brought by a conventional tool and improves the assembly efficiency.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

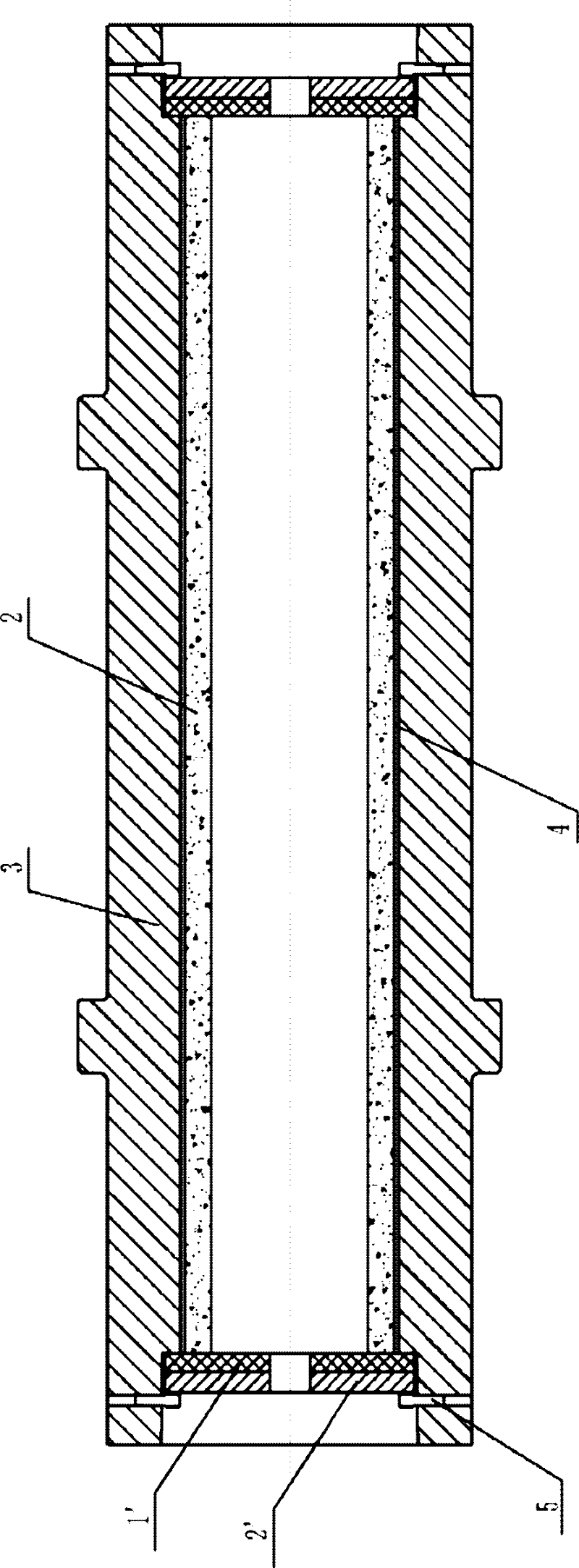

Baffle device for sealing molten steel and fabrication method thereof as well as die applying the baffle device

ActiveCN102266930BImprove anti-scourabilityImprove vibration resistanceMolten steelTemperature resistance

Owner:JIANGSU BIAOXIN KUBOTA IND

Processing method of five-fork blade-root moving blades with own shrouds

ActiveCN103203490BImprove appearance qualityReduce in quantityMilling equipment detailsProcess engineeringMachine tool

The invention discloses a processing method of five-fork blade-root moving blades with own shrouds, belonging to the technical field of blade processing. The processing method comprises: step 1, clamping blades, step 2, roughing, step 3, semi-refining, step 4, refining, step 5, positioning a steam-out side of a shoulder of the blade root, a steam-out side of a shroud and a back radial surface of the blade root, selecting a cutter with cutting edges matching with five-fork blade root lines, with a rotating speed being 25-30 r / min, a feeding speed being 12.5 mm / min, a feed amount being 0.5-0.8 mm, and performing fine milling for the five-fork blade root lines of the blade along a linear direction. According characteristics of the five-fork blade-root moving blades with own shrouds, positioning reference surface during processing is unified, a one-time clamping is used to complete processing of each part, thereby effectively preventing accumulative errors, increasing processing precision, optimizing integration processing, shortening processing periods of products, reducing required amount of machine tool, and reducing production cost.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

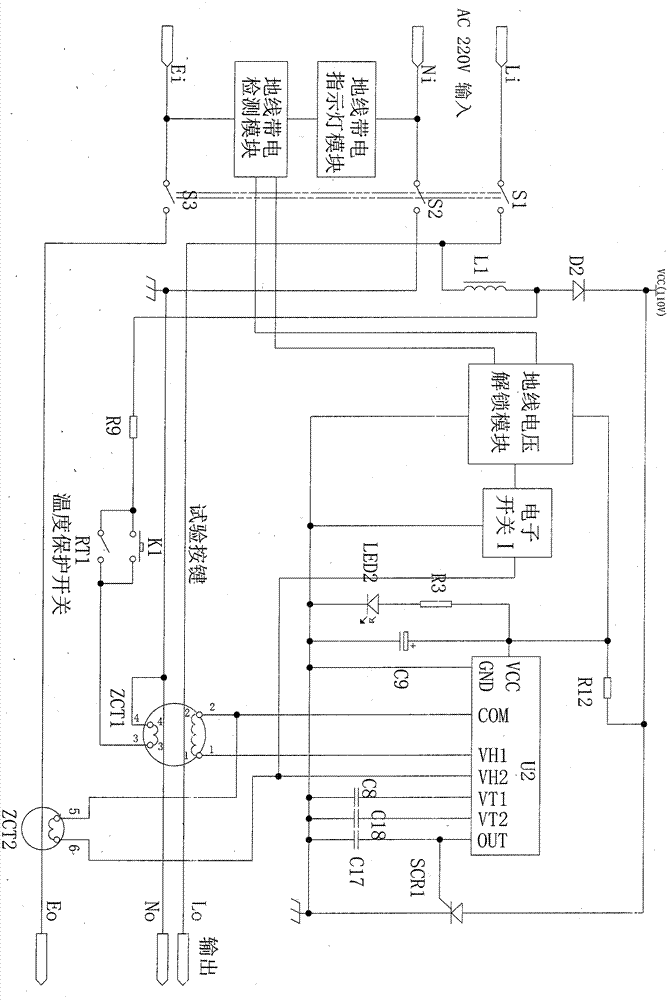

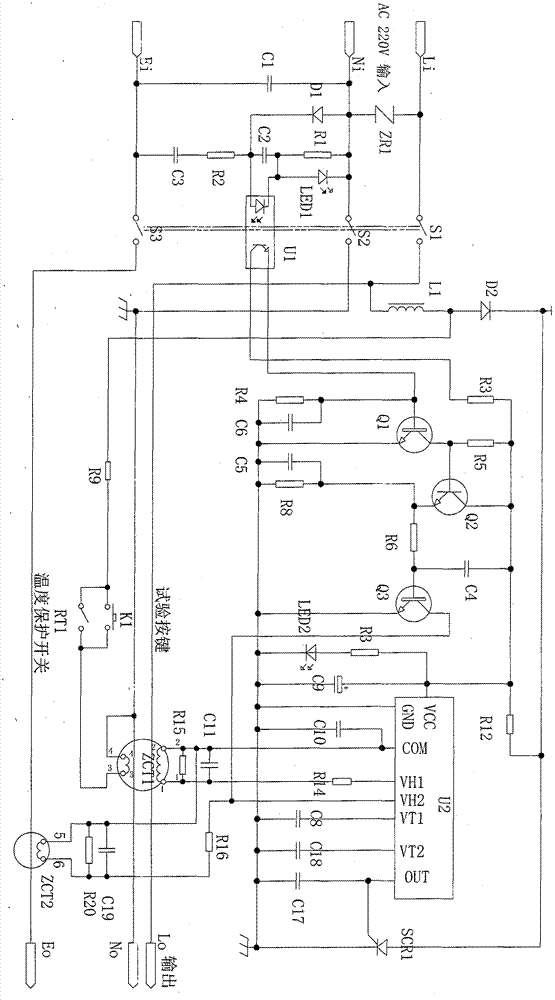

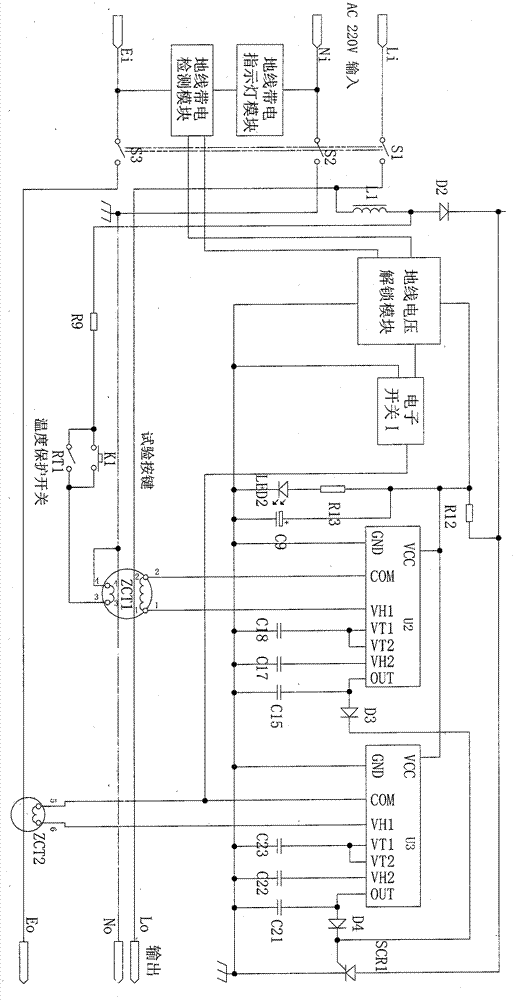

Control method of grounding wire current locking type electric leakage protector

InactiveCN106981859ASolve a large number of customer complaintsReduce ancillary costsEmergency protective arrangements for automatic disconnectionThree levelElectronic switch

The invention relates to the field of an electric leakage protector, in particular to a control method of a grounding wire current locking type electric leakage protector. The control method involves a detection loop, an electronic switch I, an electronic switch II, an electric leakage protection chip U2, an electric leakage protection chip U3, a grounding wire live-line detection module, a grounding wire voltage unlocking module, a grounding wire live-line indication lamp module and a temperature protection switch. The control method has the beneficial effects that the problem of non-locking error tripping is solved by the control method of the grounding wire current locking type electric leakage protector, and the auxiliary cost brought by installation insulation needed for a non-locking type three-level electric leakage and breakage protector used for matching of the whole machine is reduced. According to the control method, the grounding wire current protection function is automatically opened and closed by automatically detecting the size of a voltage of an Ei-Ni end of a plug, the problem of a large amount of customer complaints caused by a power utilization environment in the market is solved, moreover, the industry of the electric leakage protector is introduced to a new field of intelligent control, and the electric leakage protector is safer and more humanized.

Owner:浙江诚富电器科技有限公司

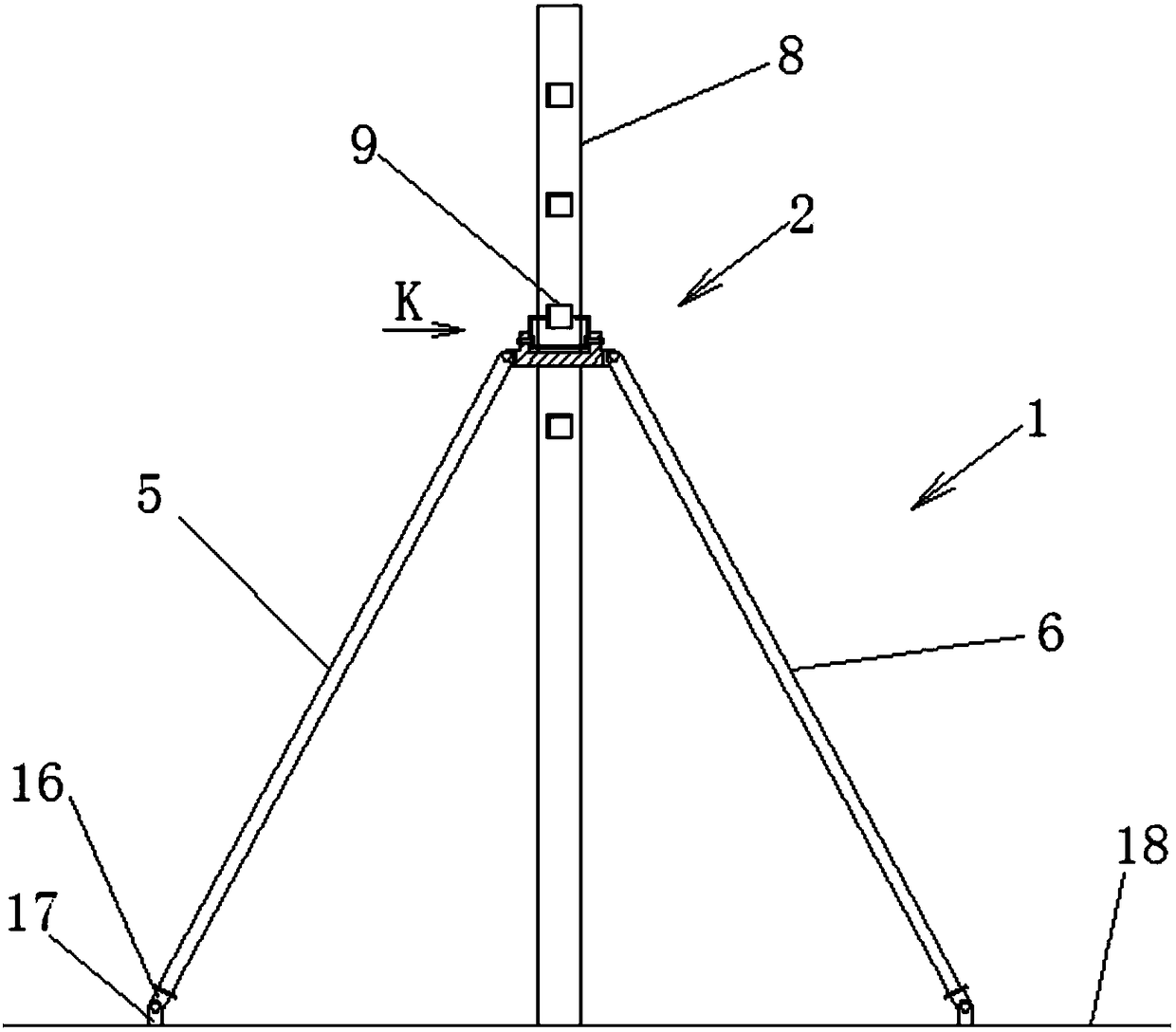

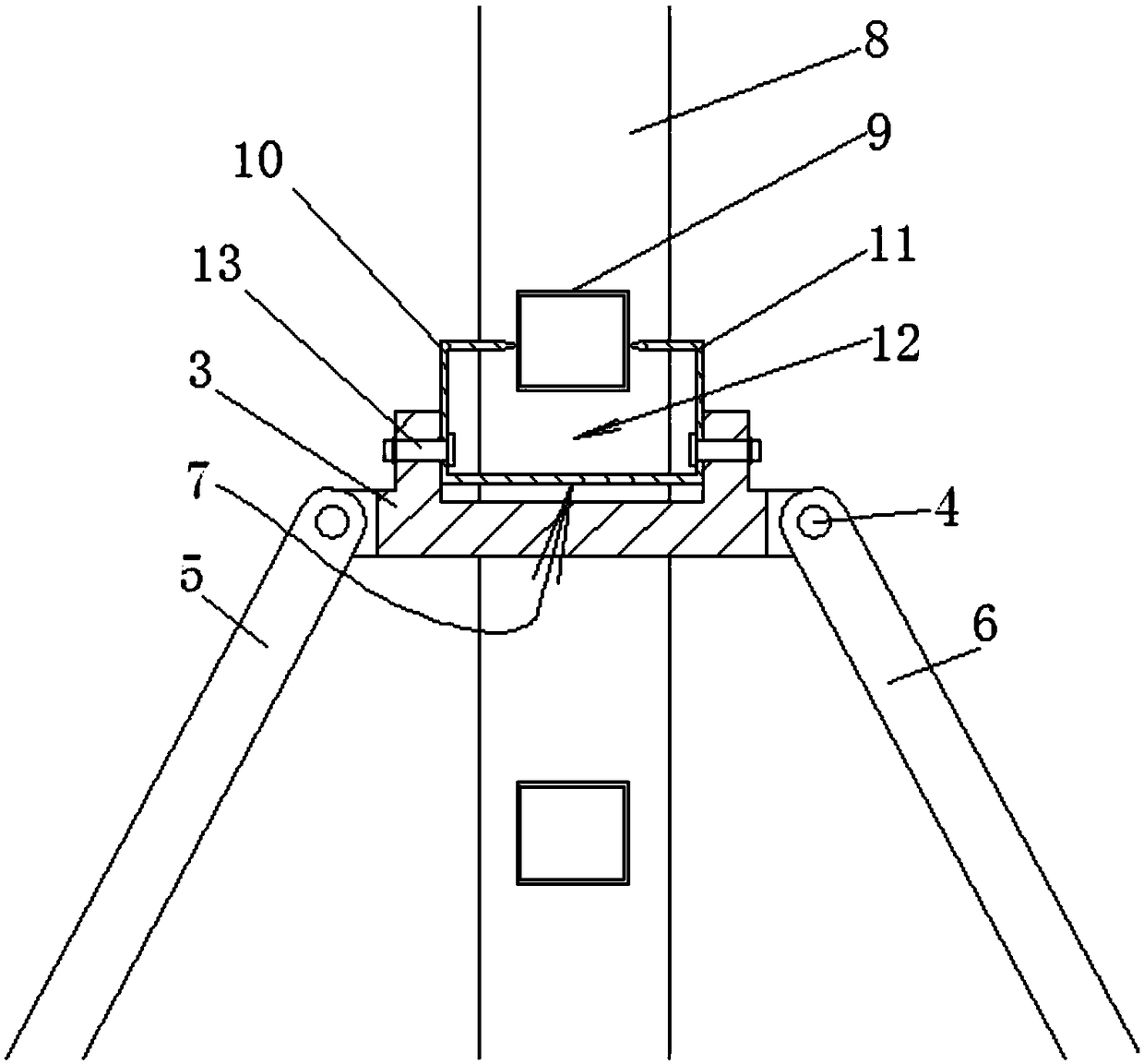

Supporting tool for spraying zinc to surface of fence small assembly of ship deck

The invention relates to the technical field of ship manufacturing, and discloses a supporting tool for spraying zinc to the surface of a fence small assembly of a ship deck. The supporting tool for spraying zinc to the surface of the fence small assembly of the ship deck comprises a supporting rack and a lateral limiting device, wherein the lateral limiting device is arranged on the upper portionof the supporting rack and is used for preventing the fence small assembly from tilting leftwards or rightwards; the supporting rack comprises a seat block; the left side and the right side of the seat block are separately connected with a left supporting rod and a right supporting rod through hinges; the upper end of the seat block is connected with the lateral limiting device; and the lateral limiting device comprises a connecting arm, a left bent catch pawl and a right bent catch pawl, the connecting arm is arranged horizontally, the left bent catch pawl and the right bent catch pawl are arranged at the two ends of the connecting arm, extend upwards and are used for limiting the left side surface and the right side surface of a handrail in the fence small assembly; and a gap for zinc spraying to the handrail is formed between the connecting arm and the handrail. The zinc spraying quality and efficiency are improved, and meanwhile, the cost for supporting auxiliary materials is saved.

Owner:CHENGXI SHIPYARD

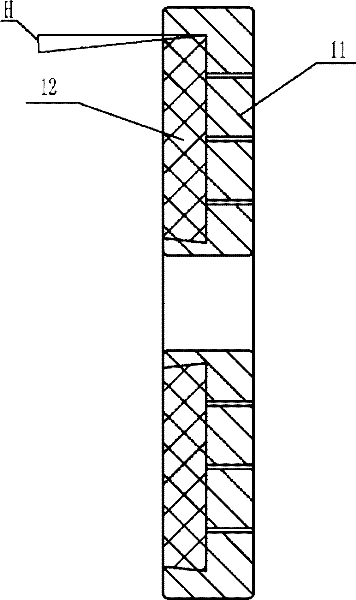

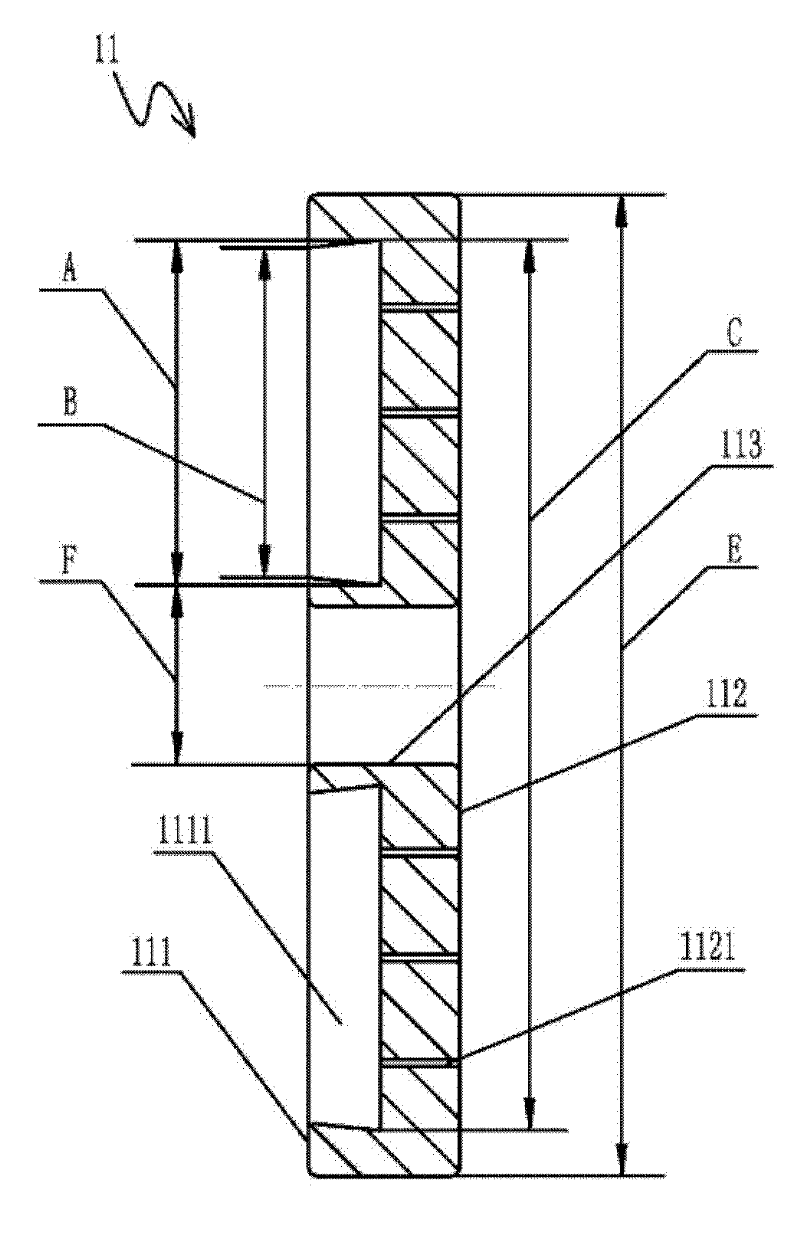

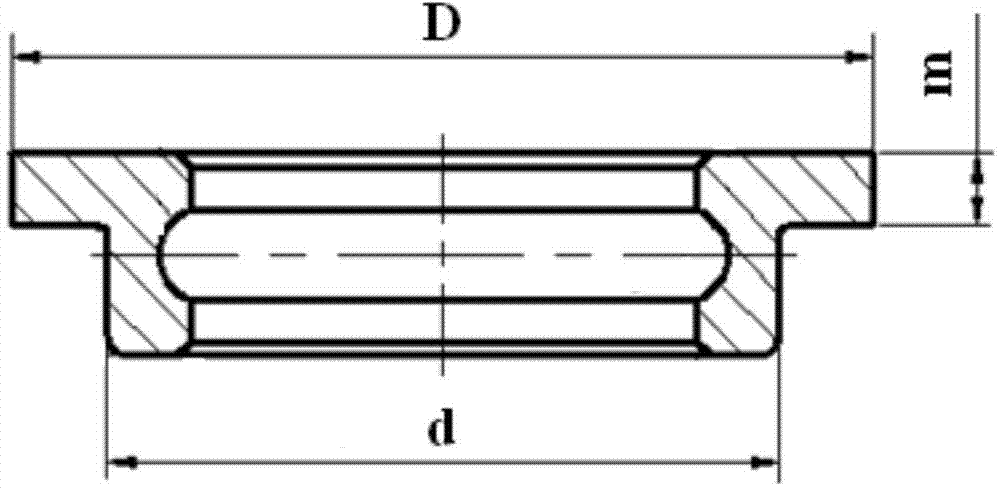

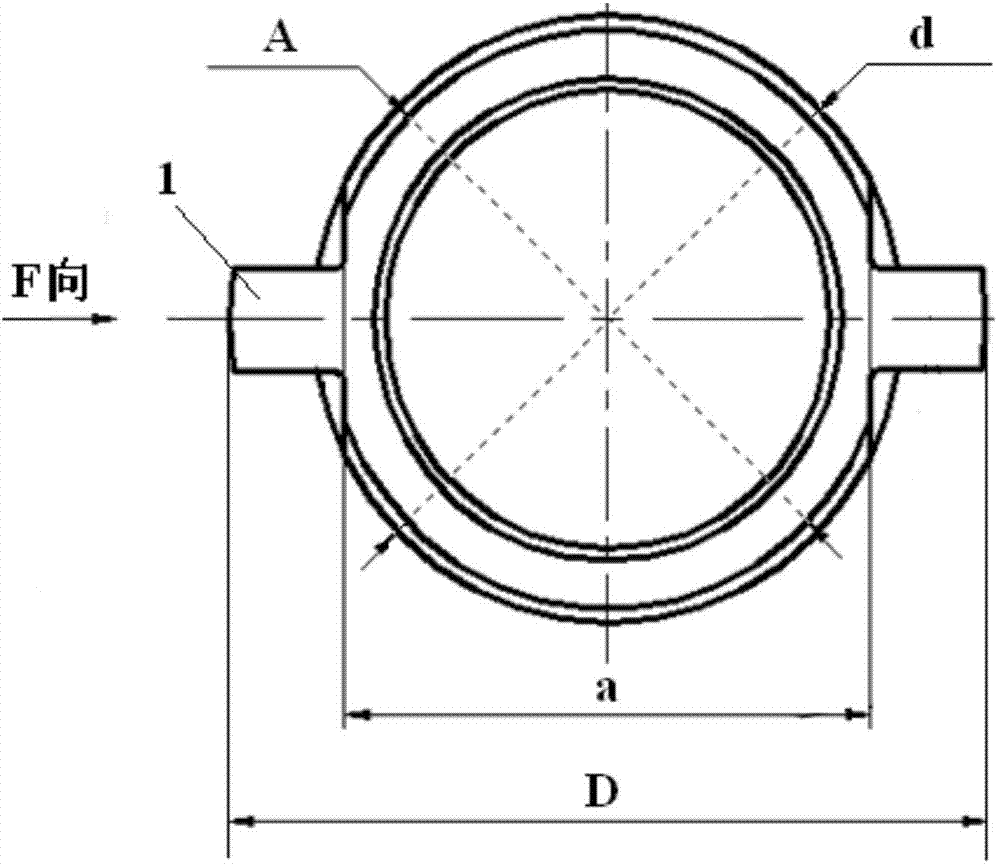

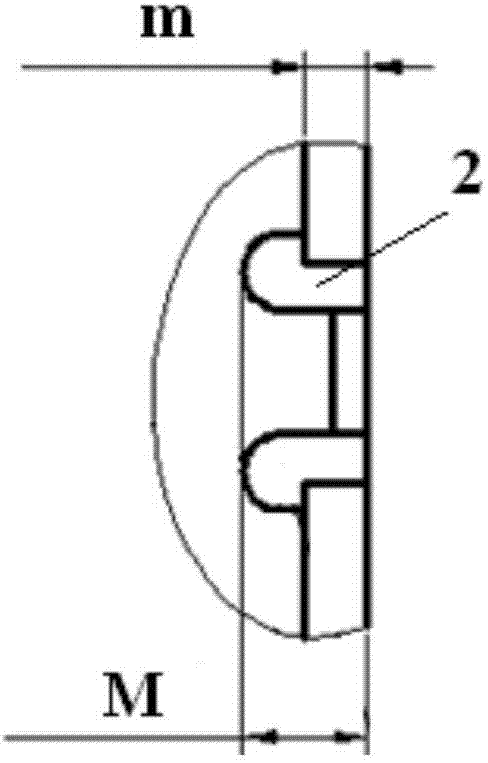

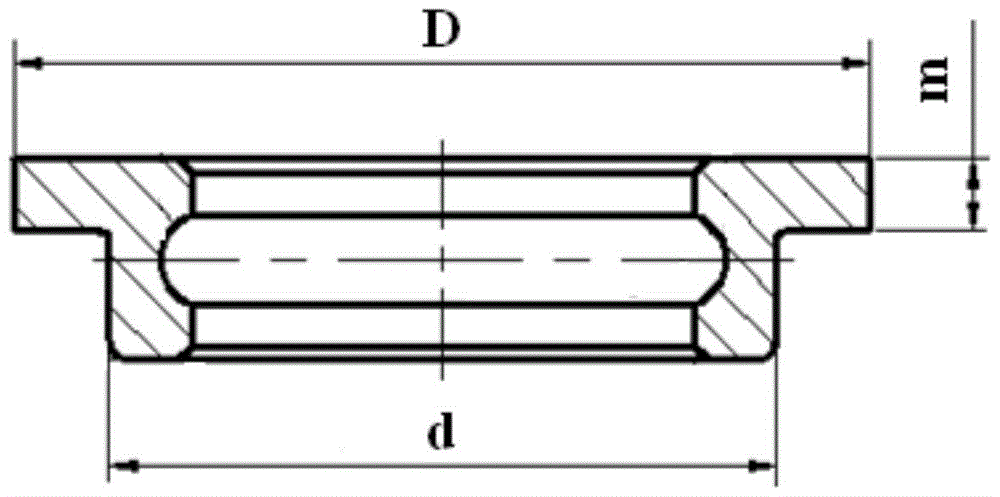

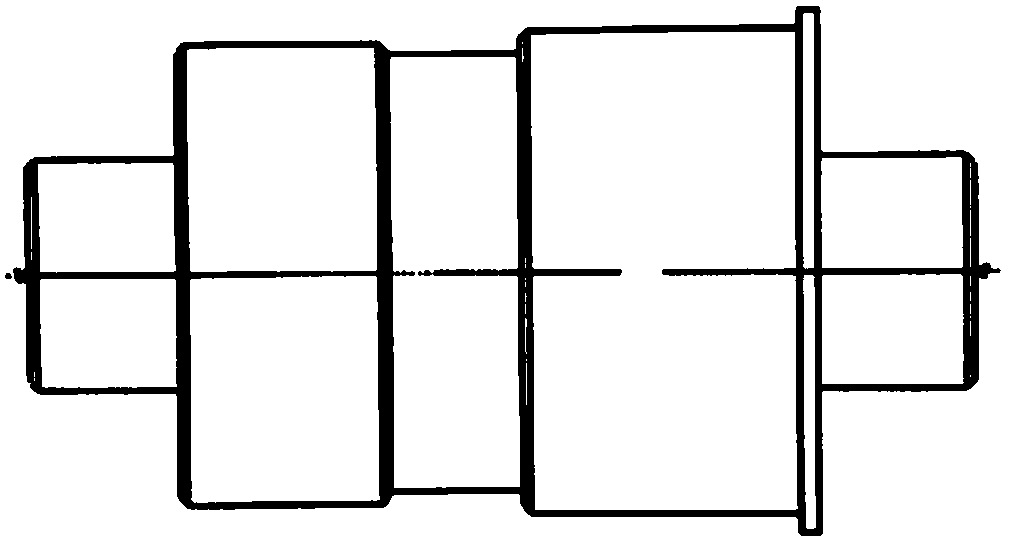

Method for machining bearing ring with installation boss and narrow and small grinding undercut

The invention discloses a method for machining a bearing ring with an installation boss and a narrow and small grinding undercut, and relates to a method for machining the grinding undercut. The method aims at solving the problem that at present, the narrow and small grinding undercut cannot be machined. The method for machining the bearing ring with the installation boss and the narrow and small grinding undercut comprises the steps of firstly, carrying out rough turning forming, and obtaining a rough bearing ring body; secondly, adjusting and clamping a tool; and thirdly, carrying out milling forming, and obtaining the bearing ring with the installation boss and the narrow and small grinding undercut. The method has the advantage that the production cost is saved. According to a convention technological process, two-time clamping machining is needed, and after a milling mold is used, machining can be completed only through one-time clamping. Compared with the prior art, the tool cost, the man hour cost, the electricity cost and the auxiliary cost can be saved by 50 percents. The method is mainly used for machining the bearing ring with the installation boss and the narrow and small grinding undercut.

Owner:AVIC HARBIN BEARING

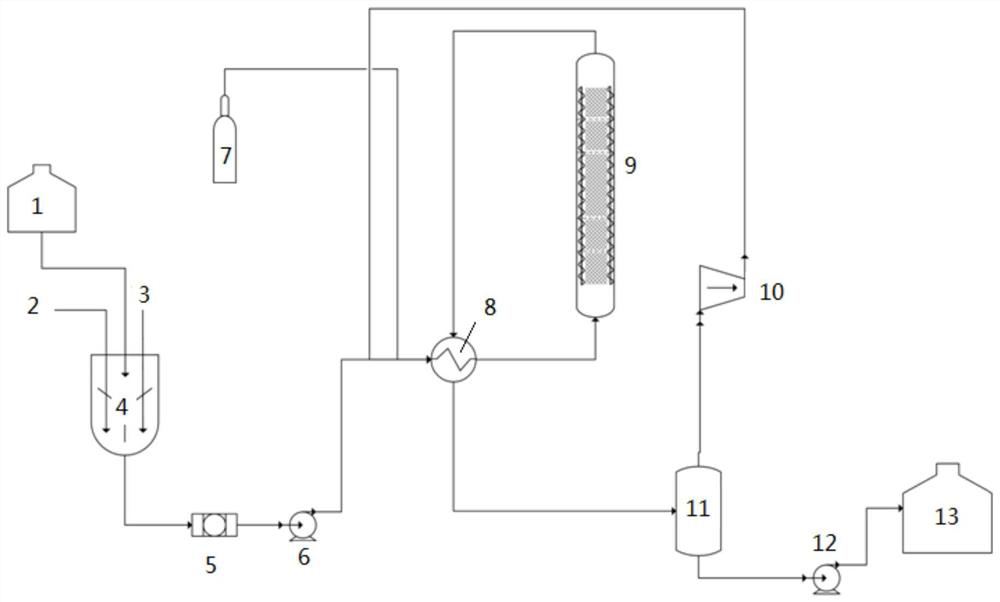

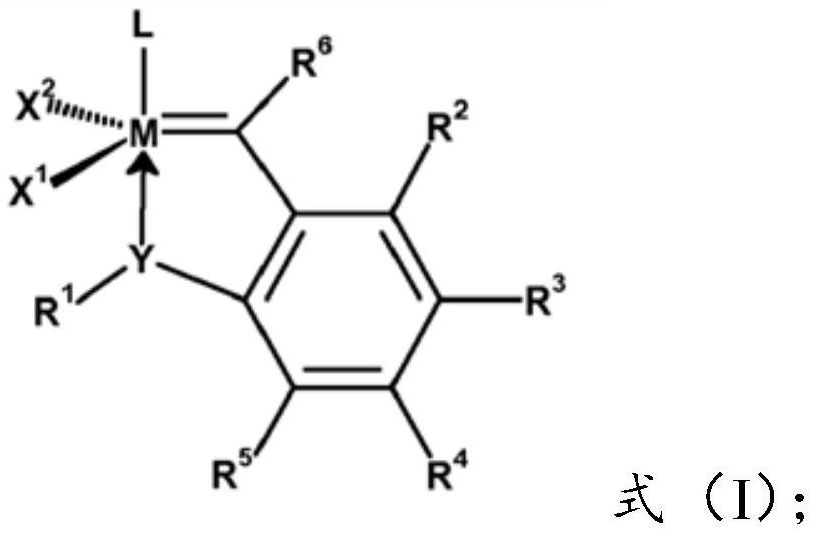

Continuous hydrogenation production device and production method for carbon-carbon double bonds in unsaturated polymer

ActiveCN111889035AAchieving selective hydrogenation reactionsImprove stabilityChemical/physical processesPtru catalystHydrogenation reaction

The invention provides a continuous hydrogenation production method for carbon-carbon double bonds in conjugated diene latex. The method comprises the following steps: mixing conjugated diene latex and an assistant in a raw material pretreatment kettle to obtain a mixture; filtering the mixture, mixing with hydrogen generated by a hydrogen generation device, preheating by a preheater, and reactingin a hydrogenation reactor to obtain a hydrogenated copolymer, wherein a supported catalyst is arranged in the hydrogenation reactor, the supported catalyst comprises a carrier and an active component, the active component is a group VIII metal compound shown as a formula (I), the hydrogenated copolymer is subjected to heat exchange through the raw material preheater and gas-liquid separation through the gas-liquid separation tank, and hydrogenated copolymer latex at the bottom of the tank is conveyed to the product tank through the product conveying pump. A specific heterogeneous hydrogenation catalyst is adopted, and devices such as a fixed bed reactor are combined so that conjugated diene selective hydrogenation reaction can be efficiently realized, and a high-hydrogenation-degree product can be obtained. Thea continuous hydrogenation mode is used so that the production efficiency and the process safety are improved.

Owner:山东京博中聚新材料有限公司 +2

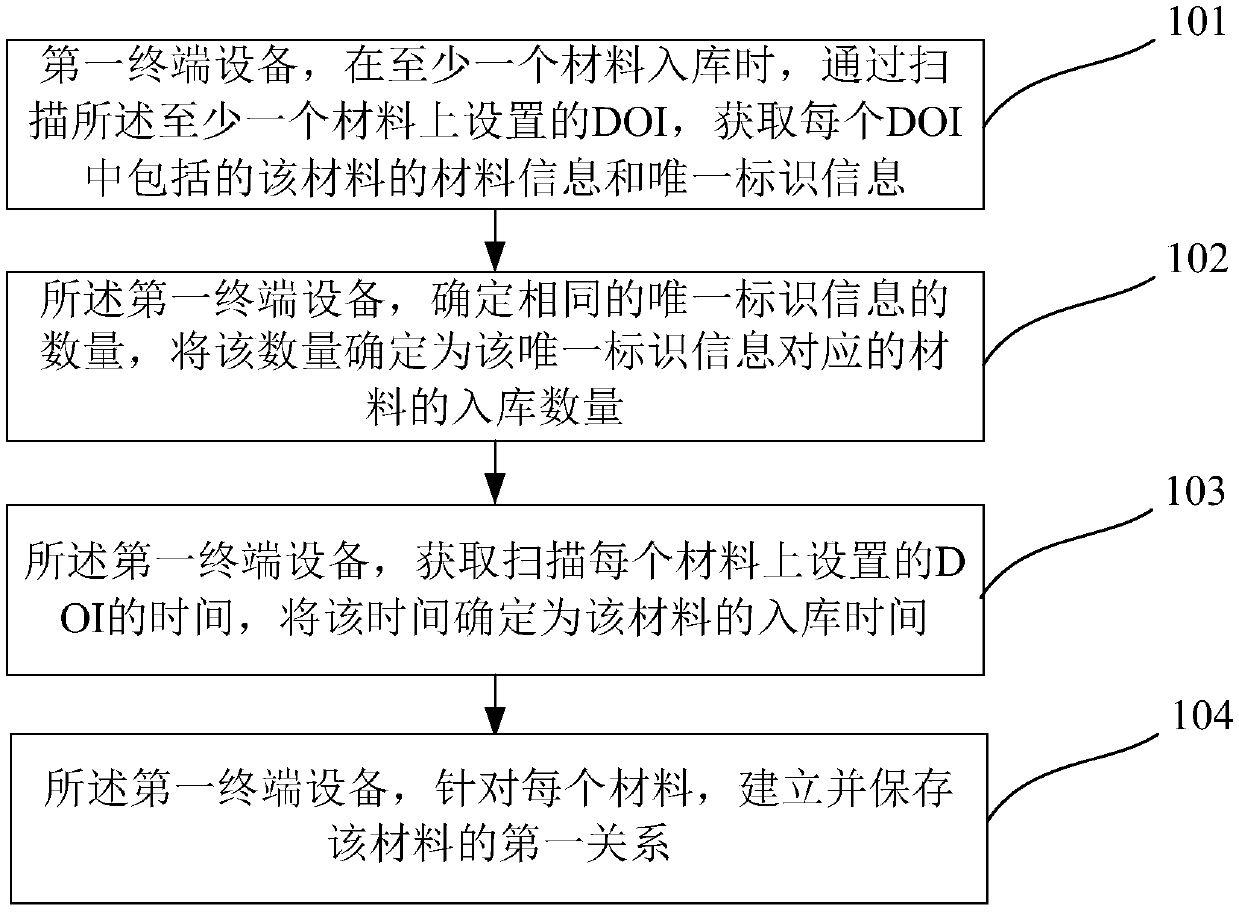

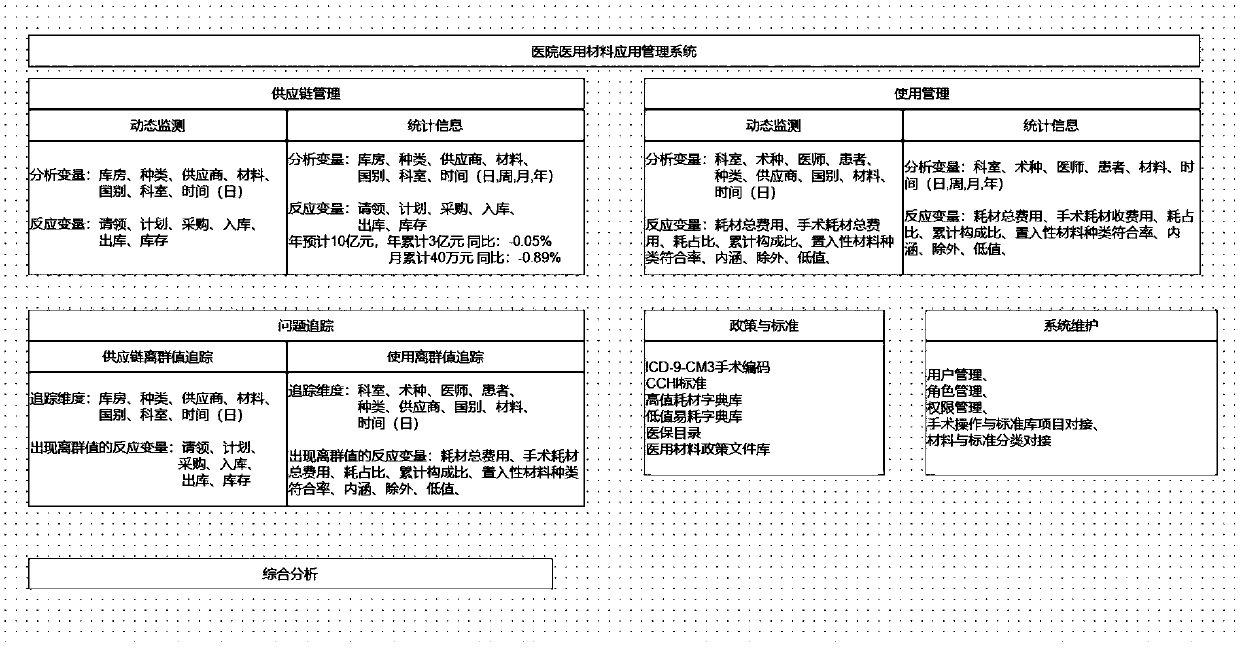

An information processing method and system

InactiveCN109102225AReduce ancillary costsImprove interoperabilityLogisticsFirst relationshipDigital object

A method and a system for processing information are disclosed. The method comprises: as at least one material is stored, scanning the digital object unique identifier DOI set on the at least one material, obtaining material information and unique identification information of the material included in each DOI, determining the same amount of unique identification information, determining the quantity as the stock-in quantity of the material corresponding to the unique identification information, getting the time to scan the DOI set on each material, the time being determined as the warehousingtime of the material, and a first relationship of the material being established and stored for each material, wherein the first relationship of each material is a one-to-one correspondence relationship of at least one of unique identification information, material information, warehousing quantity, and warehousing time of the material, thereby improving the convenience of managing the material.

Owner:京弘达(上海)医疗技术有限公司

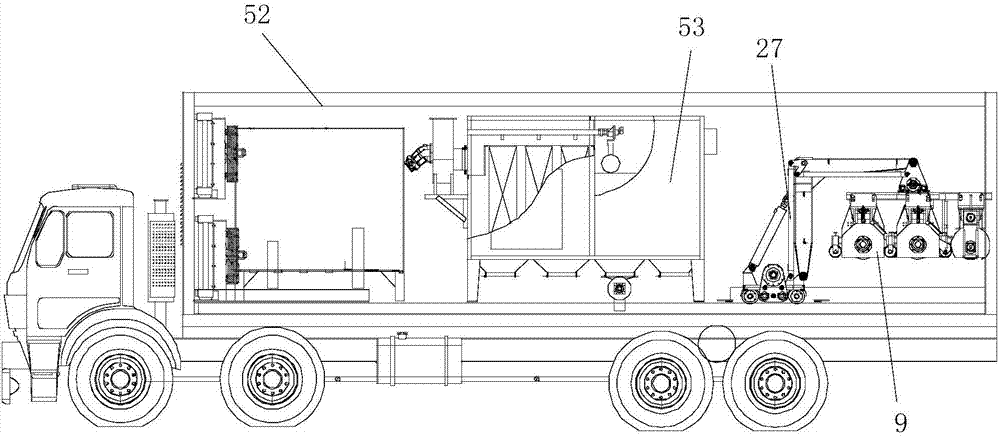

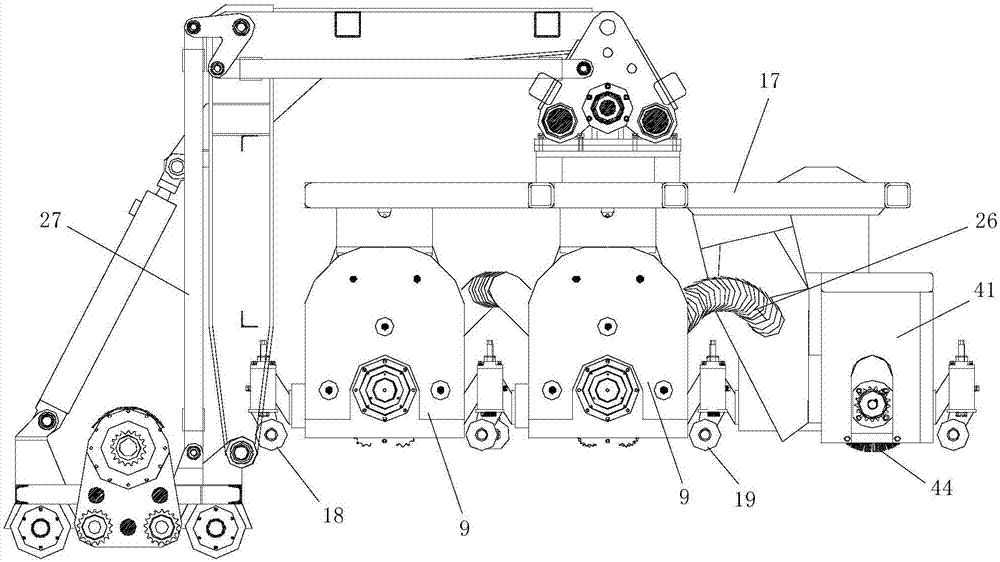

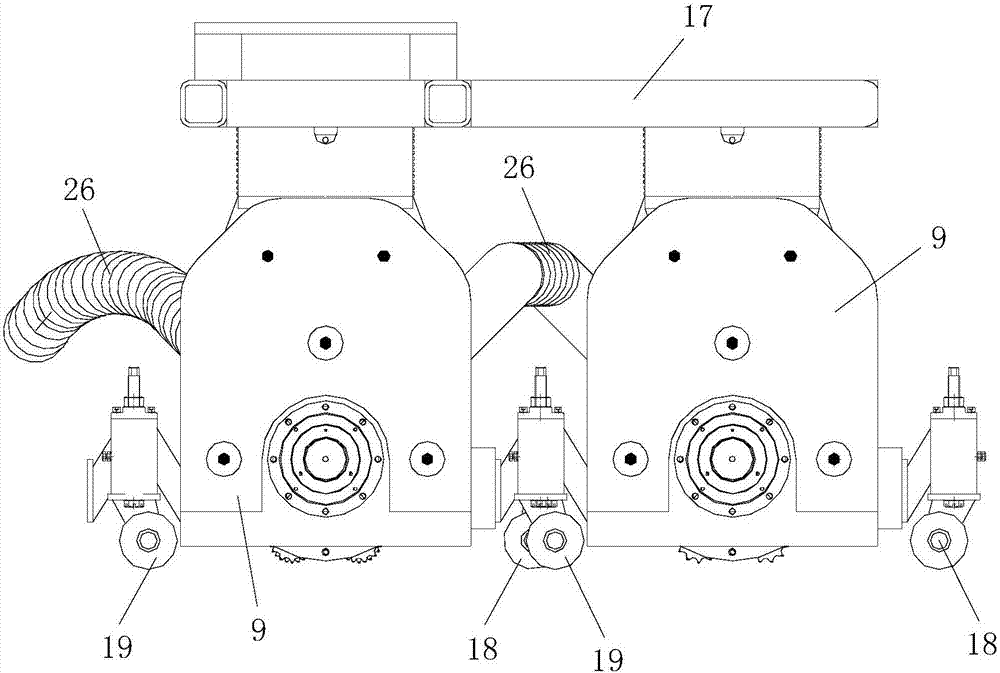

Road surface texturization treatment vehicle and method

ActiveCN106988194ASimple structureReasonable designFinal product manufactureRoads maintainenceRoad surfaceTreatment Vehicle

The invention discloses a road surface texturization treatment vehicle and method. The treatment vehicle comprises a bearing vehicle body, road surface texturization treatment equipment and a movable arm frame for translation and lifting of the road surface texturization treatment equipment, the movable arm frame is mounted on the bearing vehicle body, and the road surface texturization treatment equipment is located behind the bearing vehicle body; the road surface texturization treatment equipment comprises a road surface texturization treatment tool assembly and a road surface sweeping device, and the road sweeping device is mounted on the rear side of the road surface texturization treatment tool assembly; and the movable arm frame comprises an arm frame body, a horizontally movable mechanism and a lifting mechanism; and the method comprises the steps of (1) movable arm frame mounting, (2) bearing vehicle body in-place movement; (3) road surface texturization treatment tool assembly alignment adjustment and (4) road surface texturization treatment. The road surface texturization treatment vehicle and method are reasonable is design, easy and convenient to use and operate and good in service effect and can come into service only by being mounted on horizontally movable equipment, road surface texturization treatment can be easily, conveniently and quickly conducted, and the texturization treatment effect is good.

Owner:西安远景智创道路工程有限公司

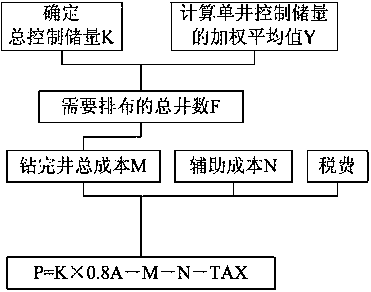

Evaluating and analyzing method for shale gas reservoir exploration economical efficiency

The invention discloses a method for evaluating and analyzing the economics of shale gas reservoir development. By subtracting the total cost of drilling and completion from the theoretical total income, subtracting the auxiliary cost, and subtracting taxes and fees, the net profit of the income minus the cost is obtained. According to the positive, negative and size of P value, the economics of the shale gas reservoir is evaluated on this basis, which provides an economical evaluation method for shale gas development.

Owner:郭强

Processing Method of Bearing Ring with Mounting Boss and Narrow Outrunning Groove

The invention discloses a method for machining a bearing ring with an installation boss and a narrow and small grinding undercut, and relates to a method for machining the grinding undercut. The method aims at solving the problem that at present, the narrow and small grinding undercut cannot be machined. The method for machining the bearing ring with the installation boss and the narrow and small grinding undercut comprises the steps of firstly, carrying out rough turning forming, and obtaining a rough bearing ring body; secondly, adjusting and clamping a tool; and thirdly, carrying out milling forming, and obtaining the bearing ring with the installation boss and the narrow and small grinding undercut. The method has the advantage that the production cost is saved. According to a convention technological process, two-time clamping machining is needed, and after a milling mold is used, machining can be completed only through one-time clamping. Compared with the prior art, the tool cost, the man hour cost, the electricity cost and the auxiliary cost can be saved by 50 percents. The method is mainly used for machining the bearing ring with the installation boss and the narrow and small grinding undercut.

Owner:AVIC HARBIN BEARING

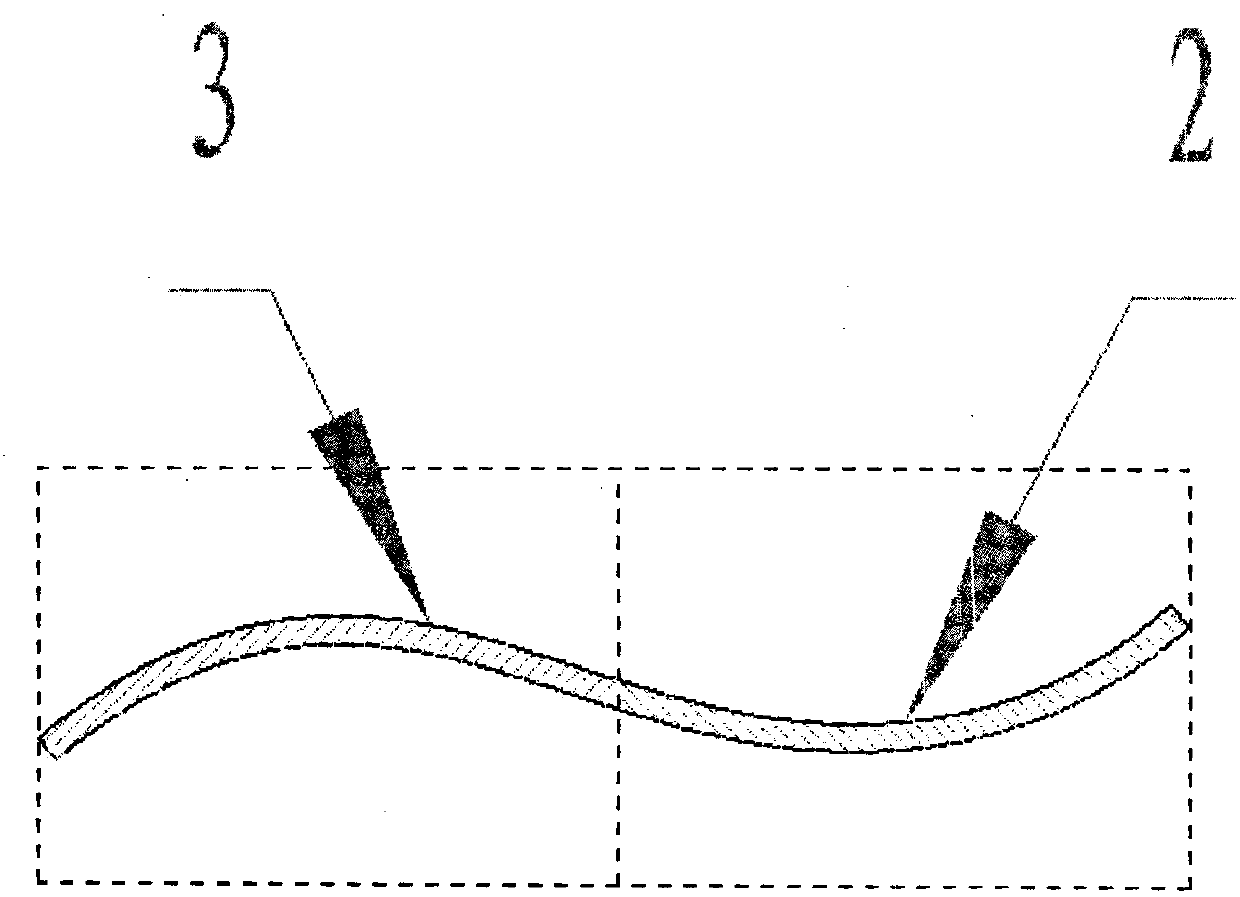

A Row Cutting Method of Double-sided Twisted Web

ActiveCN105302064BImprove surface roughnessReduce lossNumerical controlMachine partsSurface roughness

The invention relates to a stroke milling method of a double-surface twisted web. Through curvature calculation, cutter selection, recessed surface area and convex surface area selection, rough stroke milling and fine stroke milling, high-efficiency stroke milling of a double-surface twisted web is achieved. The surface roughness of a machined part can be improved, the machining efficiency is high, cutter losses are small, auxiliary costs are low, and the application range is wide.

Owner:SHENYANG AIRCRAFT CORP

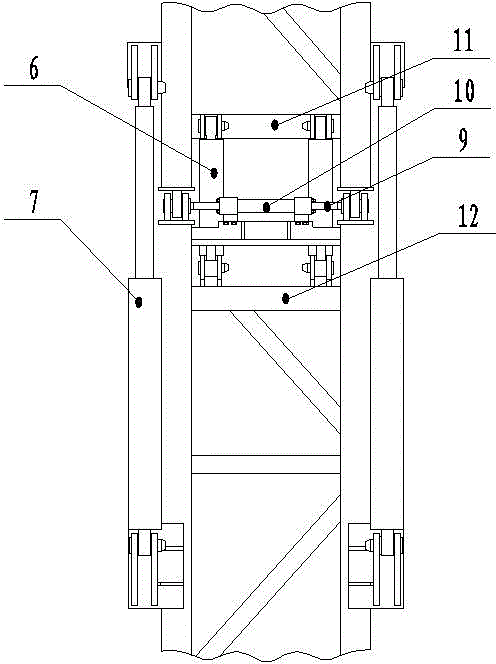

Folding boring tower

The invention relates to a folding boring tower which comprises a boring tower support arranged on the rear part of a rig substructure and a tower body articulated on the boring tower support, wherein a tower body comprises an upper section boring tower, a lower section boring tower and a tower rising oil cylinder, and the tower rising oil cylinder is arranged between the lower section boring tower and the rig substructure; the top end of the boring tower support is articulated with a sliding seat, a sliding oil cylinder is arranged between the sliding seat and the lower section boring tower, the front of a joint of the upper and lower section boring towers is provided with a folding articulated shaft, and the back surface of the joint of the upper and lower section boring towers is provided with positioning holes which are mutually matched; and an automatic plug pin mechanism matched with the positioning holes is arranged on the upper section boring tower or the lower section boring tower, and a double cylinder mutual assistance mechanism is arranged between the upper and lower boring towers. The folding boring tower provided by the invention adopts the double cylinder mutual assistance mechanism, the tower body can automatically complete spread or fold, the automatic degree is increased, and the performance of a boring apparatus is improved; and the sliding seat and the sliding oil cylinder are adopted to match, the work force and a lifting device are not needed in a tower rising process, the auxiliary expenses in a construction process is greatly reduced, and the work efficiency is improved.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

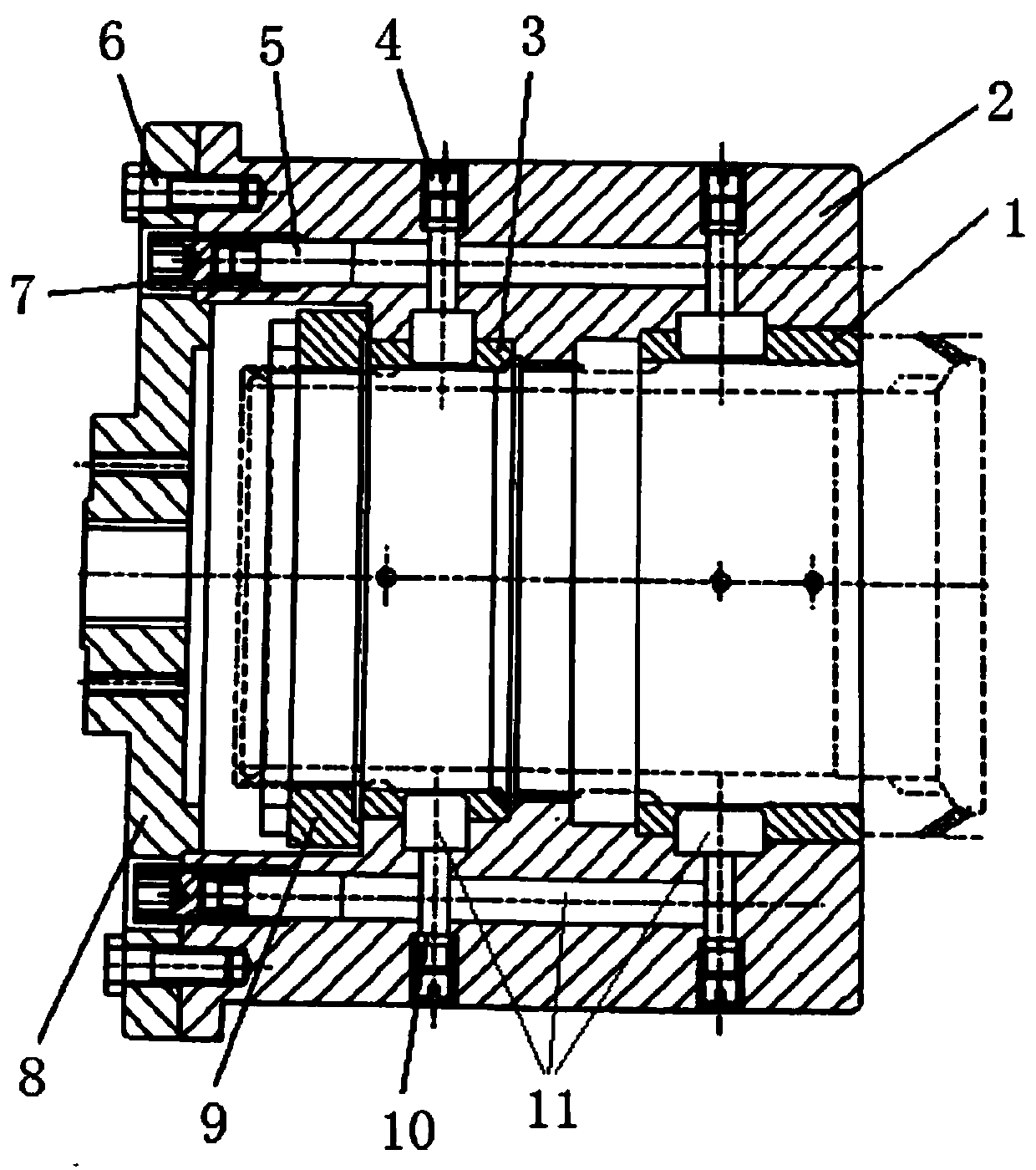

A double-cylindrical pressurized rotor balancing fixture

The invention discloses a double-cylindrical-surface pressurizing type clamp for rotor balancing. The clamp comprises a positioning bushing a, a balancing bushing, a positioning bushing b, screws a, plungers, a bolt, screws b, an adapting plate, a nut and gaskets. The balancing bushing is in the shape of a sleeve, and a plurality of mounting grooves are formed in the inner wall of the balancing bushing. The adapting plate is fixed to the large end of the balancing bushing through the bolt, and the positioning bushing a and the positioning bushing b are arranged in the balancing bushing to formdouble cylindrical surfaces. The positioning bushing a and the positioning bushing b correspond to the mounting grooves in the radial direction of the inner wall of the balancing bushing in position.The plungers are poured into the mounting grooves in the radial direction of the inner wall of the balancing bushing. Each screw b is arranged at the upper end of the corresponding plunger, the nut is screwed on a part and clamped on the inner wall of the balancing bushing, and thus device movement is prevented. The inner wall of the balancing bushing is further provided with cavity channels communicating with the positioning bushing a and the positioning bushing b. The screws a penetrate through the outer wall of the balancing bushing and abut against the cavity channels. The gaskets are arranged between the screws a and the cavity channels. The cavity channels are filled with liquid plastic.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com