Hydraulic supporting clamp for rotor processing

A hydraulic support and rotor technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, metal processing equipment, etc., can solve the problems of long assembly and disassembly preparation period, complex process realization, and difficulty in fixing processing equipment, etc., to achieve design and manufacturing The effect of short cycle, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

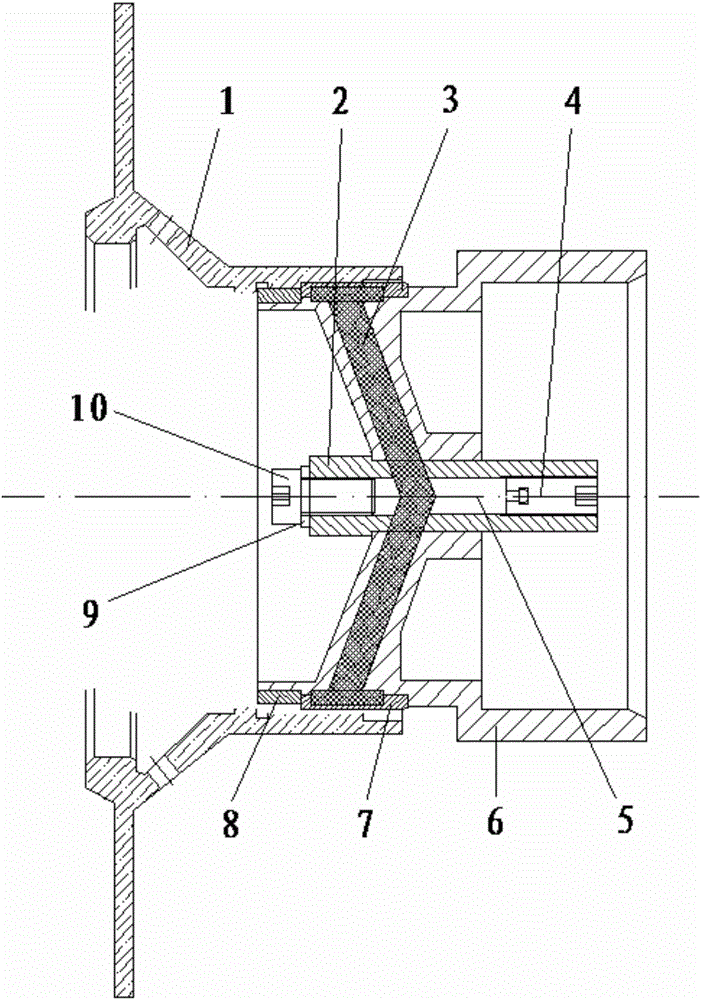

[0016] The hydraulic support fixture for rotor processing is composed as follows: bushing 2, liquid plastic 3, first screw 4, plunger 5, positioning sleeve 6, bushing 7, retaining sleeve 8, composite washer 9 and second screw 10; , the positioning sleeve 6 is a main structural part. The positioning sleeve 6 includes a small end ring and a large end ring. The support structure is matched, the outer groove of the small end ring supports the bushing 7, the bushing 7 is fixed on the small end ring of the positioning sleeve 6 through the stop sleeve 8, and the stop sleeve 8 is assembled to the small end of the positioning sleeve 6, after assembly Fix the bushing 7 on the positioning sleeve 6, and seal the groove cavity formed by the two pieces. The outer side of the bushing 7 and the inner hole of the rear shaft of the high-vortex rotor 1 are mating surfaces. The bushing 2 is assembled on the center of the positioning sleeve 6, and the inner hole of the bushing 2 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com