A Row Cutting Method of Double-sided Twisted Web

A technology of double-sided twisted webs and webs, applied in the directions of instruments, digital control, control/adjustment systems, etc., can solve problems such as tool limitations, and achieve the effects of low auxiliary cost, high processing efficiency, and efficient line cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

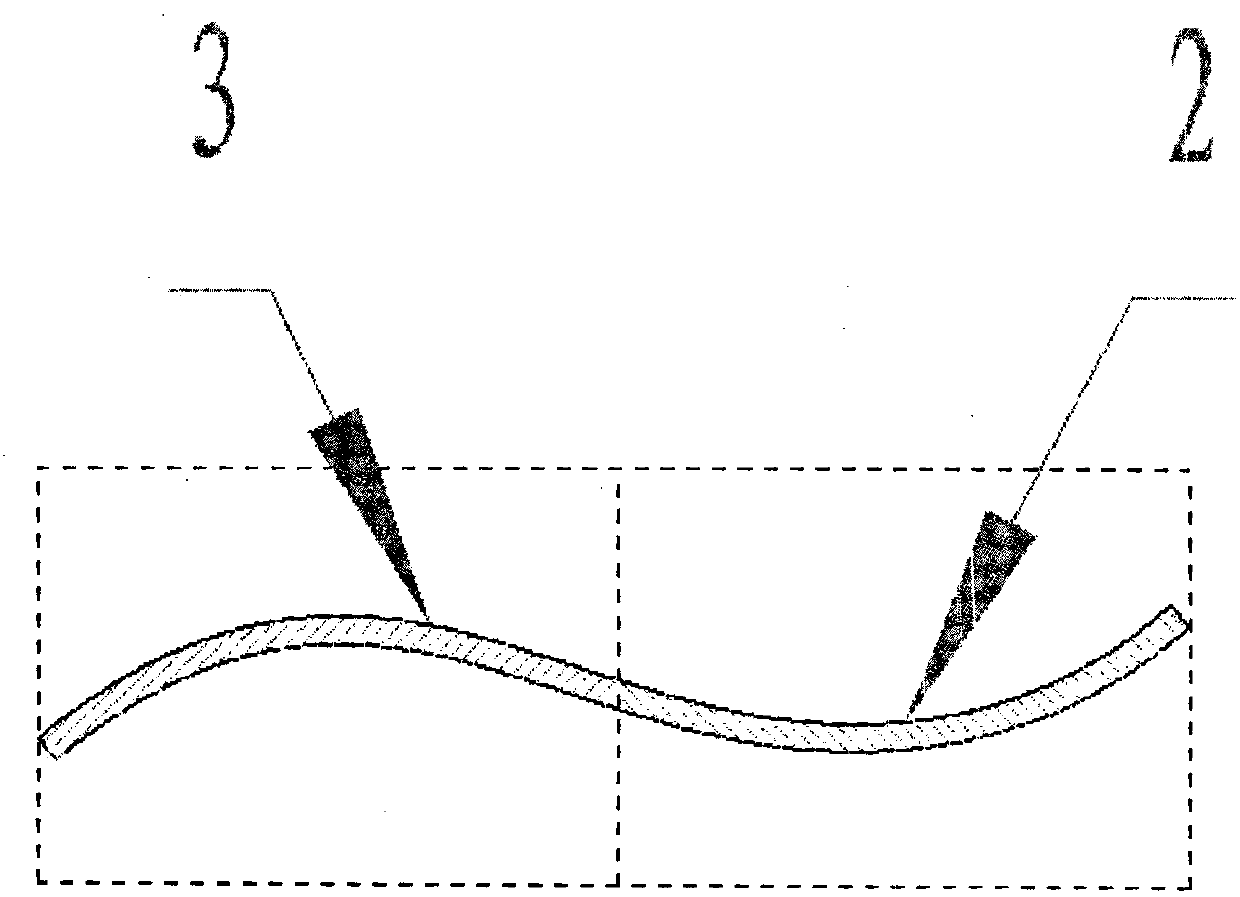

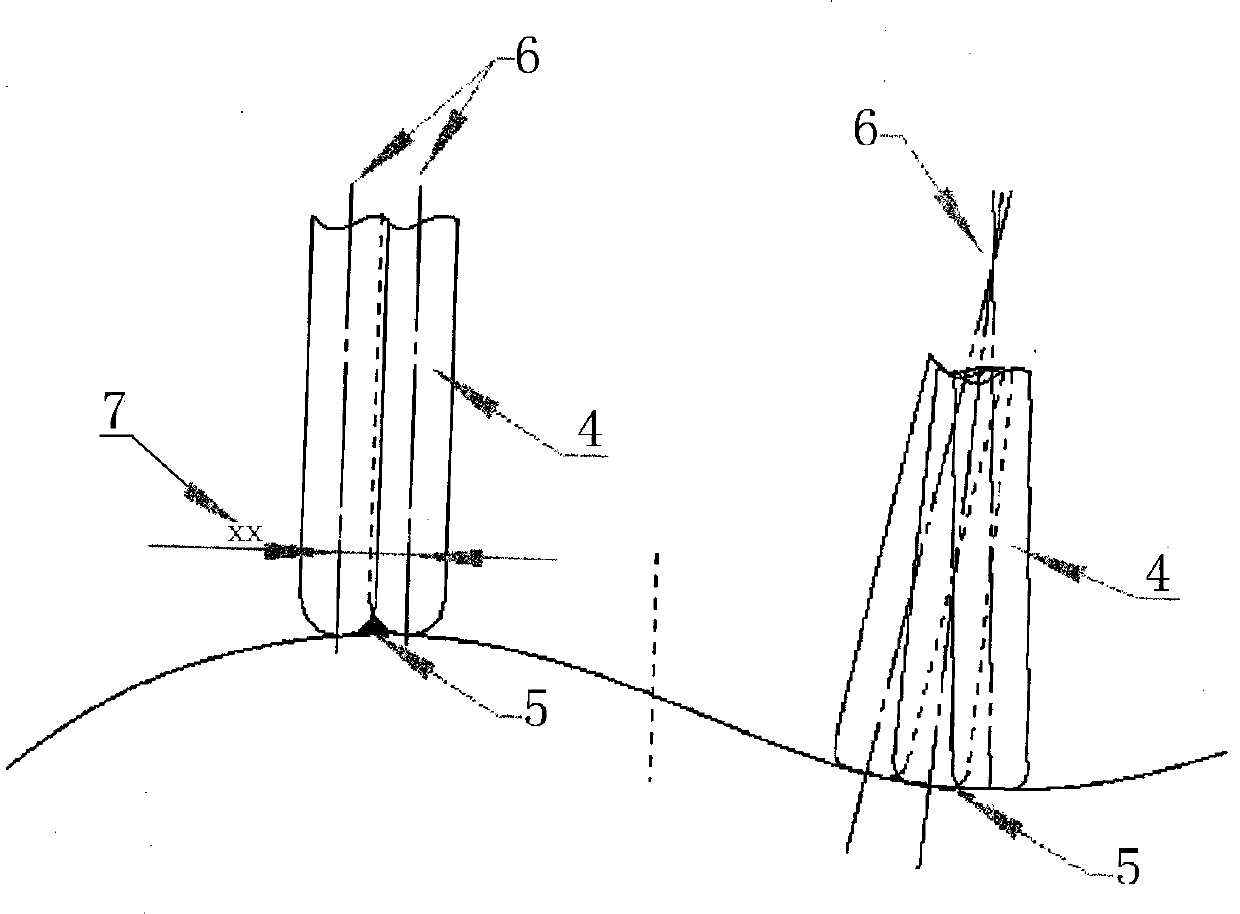

[0025] like Figure 1 to Figure 6 As shown, a line cutting method of double-sided twisted web 1 is characterized in that the following steps:

[0026] 1) According to the structural analysis of the double-sided twisted web 1, the curvature of the twisted web is calculated;

[0027] 2) Combined with the calculated curvature value, set the size of the tool 4 that needs to be selected, that is, the diameter range of the tool 4;

[0028] 3) On the basis of completing step (2), determine the value of the base R of the tool 4, and select the ratio of the base R of the tool 4 to the diameter of the tool 4 within the range of 1 / 3 to 1 / 2;

[0029] 4) Divide the processed double-sided twisted web 1 into a convex area 3 and a concave area 2, and the ratio of length to width is not less than 1;

[0030] 5) Coarse row-cut double-sided twisted web 1, leaving a margin of 0.50mm to 1.0mm on the web surface, and there is a row-cut residue between the two row-cut tracks, and the residue is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com