Simple electronic control fuel injector testboard

An electronically controlled fuel injection and test bench technology, which is applied in the testing of machine/structural components, engine testing, instruments, etc., can solve problems such as inability to provide power supply and inability to detect in time, and achieve easy popularization and use, reduce auxiliary costs, The effect of saving time and human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

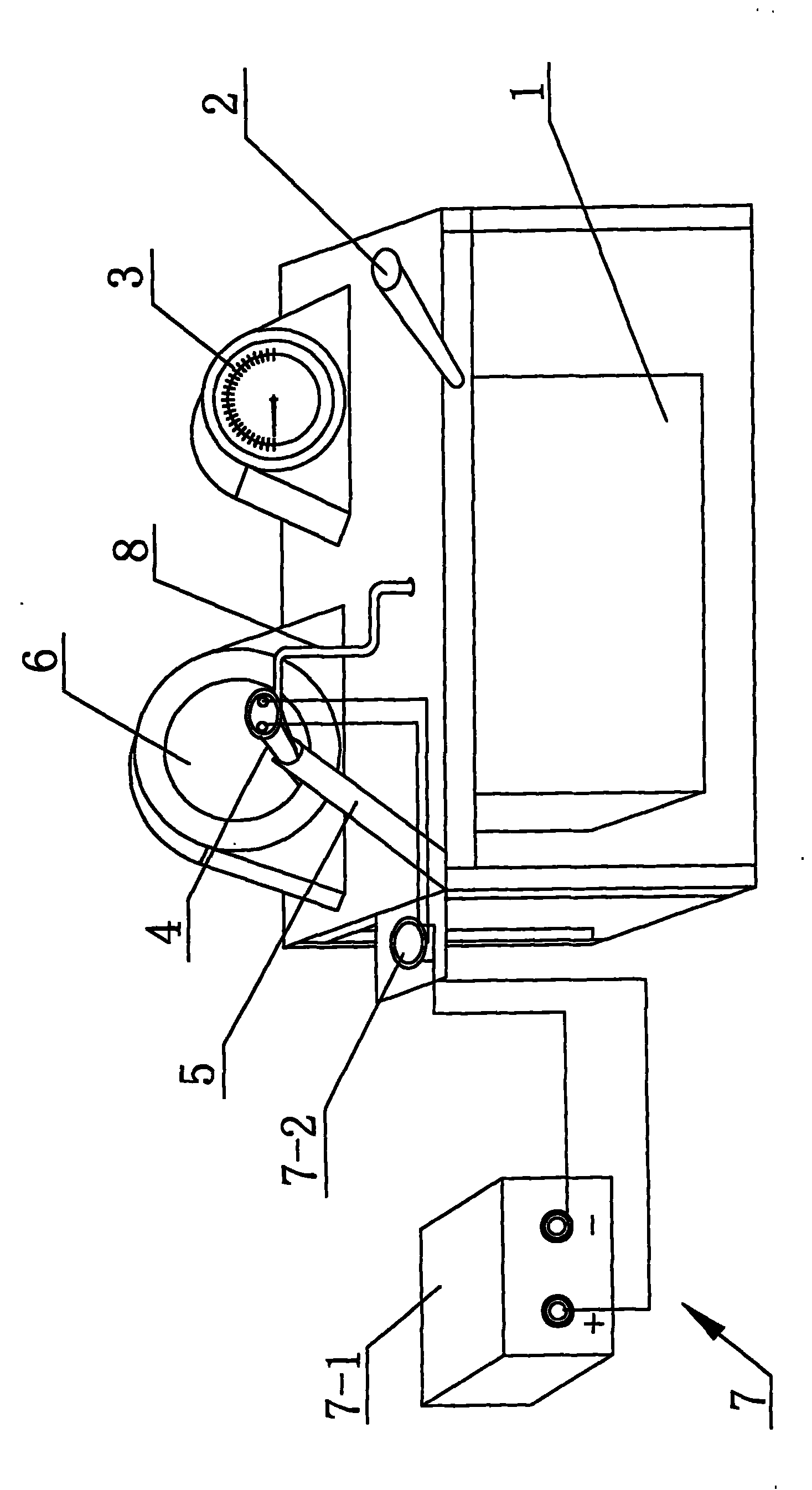

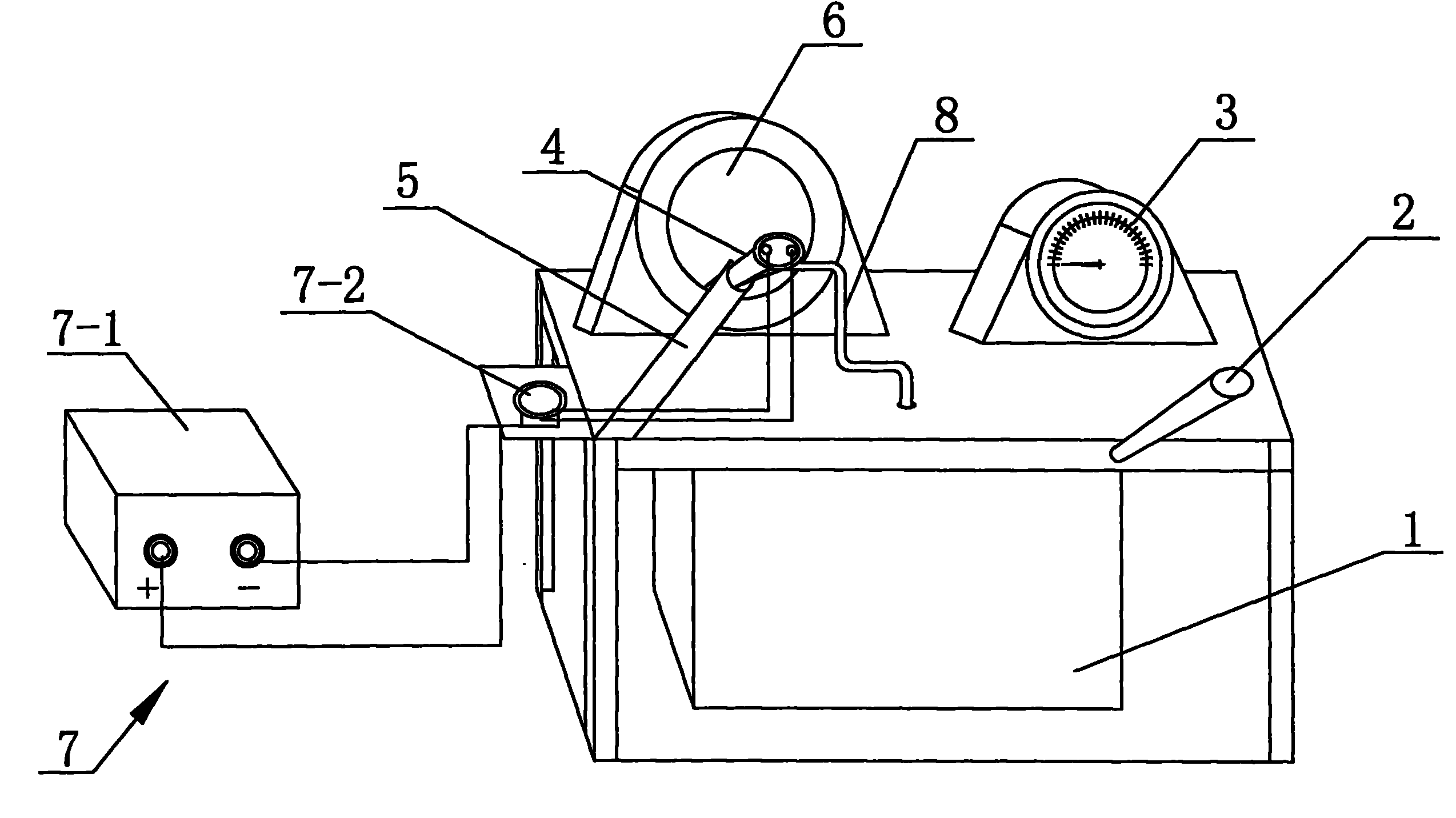

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0014] see figure 1 , a simple electronically controlled fuel injector test bench, the test system includes a fuel tank 1 for storing test oil, a pressure operating rod 2 for providing pressure for the test oil is installed on the fuel tank 1, and a pressure gauge 3 is installed on the fuel tank 1 for use The installation bracket 5 of the fuel injector 4 is installed. The fuel injector is connected to the fuel tank 1 and the test oil recovery device 6 through the oil pipe 8. The test oil recovery device adopts a recovery device that is more common in the market. The test oil is recovered and reused, and the above-mentioned structure belongs to the main structure of the known fuel injector test bench; the present invention also includes an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com