A double-cylindrical pressurized rotor balancing fixture

A rotor-balanced, double-cylinder technology, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems of surface scratches, coating surface damage, long assembly cycle, etc., to reduce assembly cycle and auxiliary costs. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

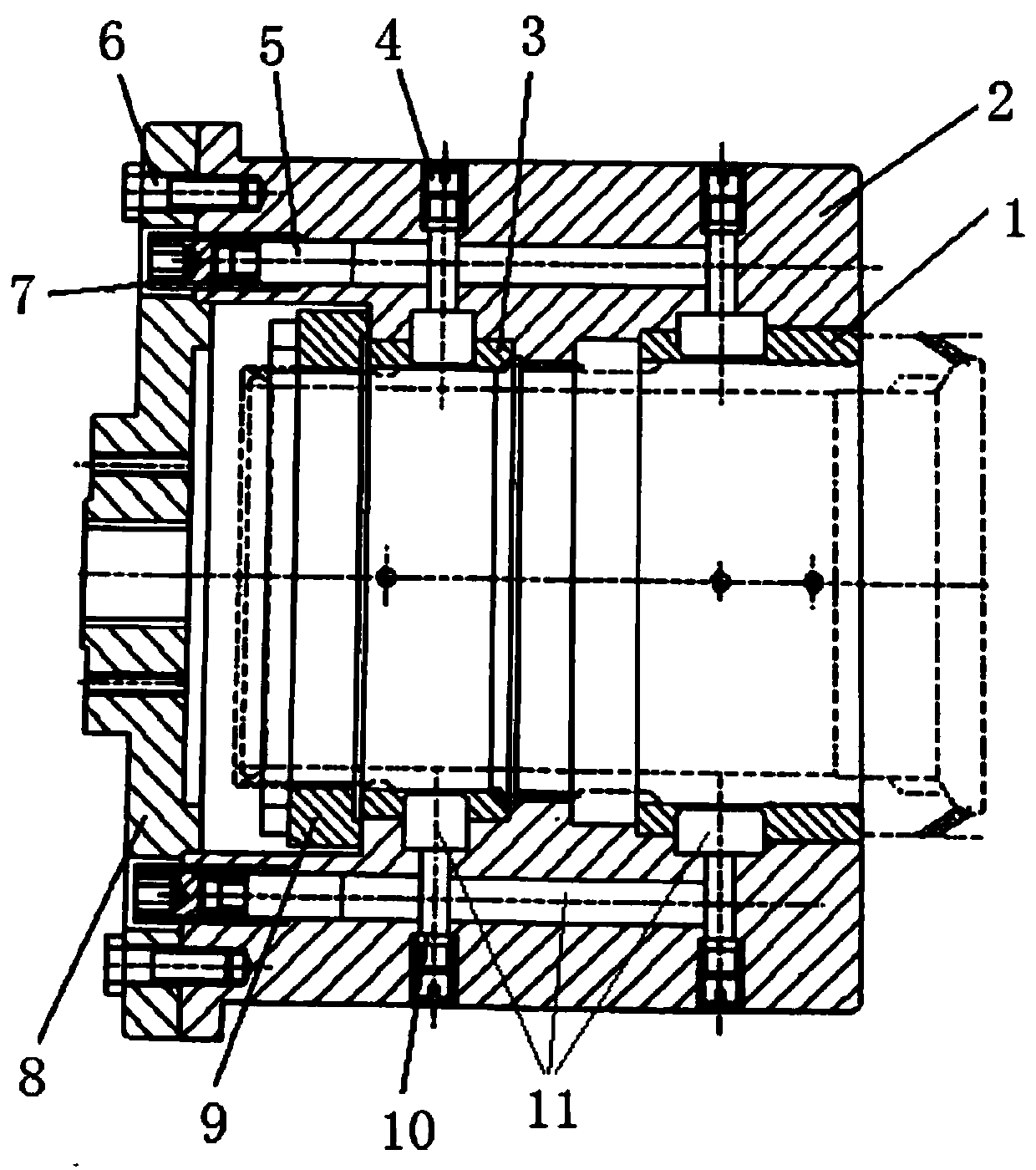

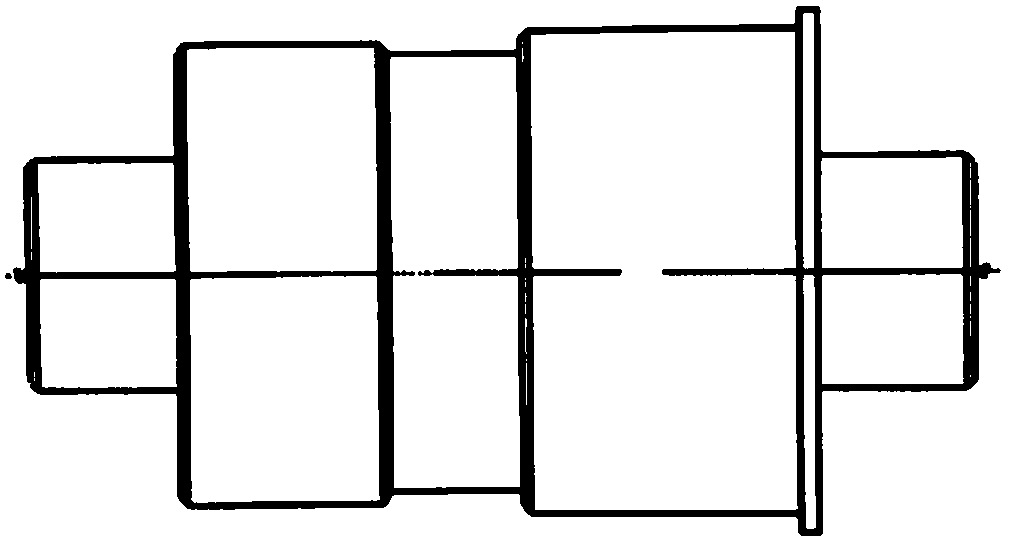

[0025] Such as Figure 1-2 Shown is a double-cylindrical pressurized rotor balancing fixture, including positioning bushing a1, balancing bushing 2, positioning bushing b3, screw a4, plunger 5, bolt 6, screw b7, adapter plate 8, and nut 9 and gasket 10;

[0026] The balance bushing 2 is in a sleeve shape, and the inner wall is provided with a plurality of installation grooves;

[0027] Fix the adapter plate 8 to the large end of the balance bushing 2 by bolts 6, and the adapter plate 8 is used for balanced rotation transmission;

[0028] The balance bushing 2 is provided with a positioning bushing a1 and a positioning bushing b3, forming a double cylinder;

[0029] The positioning bushing a1 and the positioning bushing b3 correspond to the positions of the radial installation grooves on the inner wall of the balance bushing 2 and are used for pressure clamping the front journal of the high pressure rotor; the positioning bushing a1 and the positioning bushing b3 and The high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com