Folding boring tower

A folding and drilling tower technology, applied in drilling equipment, earthwork drilling, support devices, etc., can solve the problems of increased disassembly and assembly costs, cumbersome assembly of drilling towers, and increased labor costs, so as to reduce labor costs and reduce auxiliary costs. cost, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

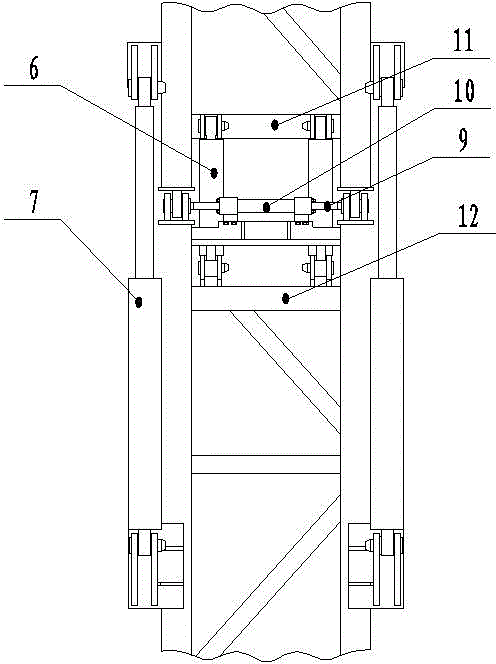

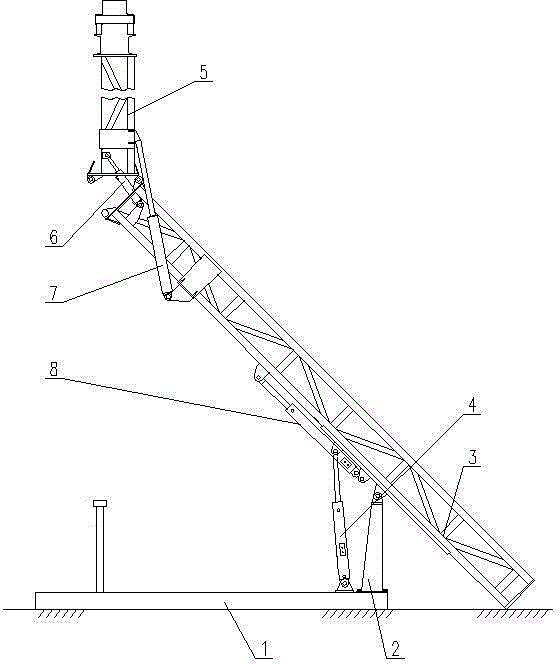

[0011] A foldable drilling tower, comprising a drilling tower support 2 arranged at the rear of the drilling rig base 1 and a tower body hinged on the drilling tower support 2, the tower body includes an upper drilling tower 5, a lower drilling tower 3 and a lifting cylinder 4. The lifting cylinder 4 is installed between the lower drilling tower 3 and the drilling rig base 1. The top of the drilling tower bracket 2 is hinged with a sliding seat, and the sliding seat is provided with slide rails for sliding the drilling tower forward and backward. The back of the drilling tower 3 is equipped with a slide rail plate that cooperates with the slide rail, and a sliding oil cylinder 8 is provided between the sliding seat and the lower drilling tower 3; a folding hinge shaft is provided on the front where the upper drilling tower 5 and the lower drilling tower 3 are connected. , the backside of the joint between the upper drilling tower 5 and the lower drilling tower 3 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com