Method for machining lug-type notch in numerical control mode

A notch and lug technology, which is applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems of lug-type notch deformation, NC machining makes it difficult to guarantee the size of the knife and notch, and achieve tool loss Small amount, wide application range, and the effect of improving roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

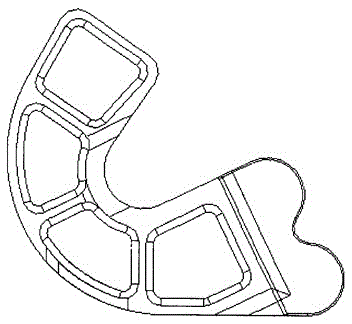

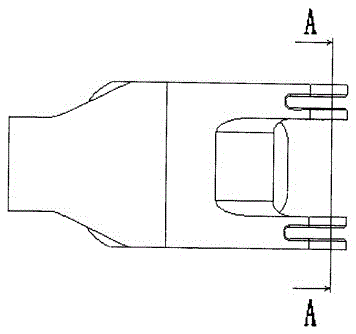

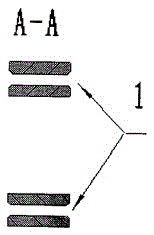

[0023] The invention relates to a method for numerically-controlled machining of a lug-type notch. The structure of the lug-type notch is as follows: figure 1 , 2 , as shown in 3; the lug-type notches are prone to deformation to varying degrees, and the main manifestations are "closing" or "opening";

[0024] 1. The state of "closed" is as follows Figure 4 As shown, that is, the width dimension 7 of the notch after rough machining is smaller than the theoretical notch width dimension 6;

[0025] For example: if the rough machining width of the notch is 40mm, and the thickness of the lugs on both sides is 10mm, the main manifestation after the phenomenon of "closing" is (the maximum lower deviation is the same value, and its value is negative): At this time, the notch The size is less than the maximum tolerance of the rough machining width of 40mm, that is, the width of the notch is "40-maximum lower deviation"; the thickness of the lug is greater than the theoretical size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com