Road surface texturization treatment vehicle and method

A technology for texturing and processing cars, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems of easy damage of blades, short tool life, poor effect of road texture treatment, etc., and achieves simple processing and production, low input cost, Easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

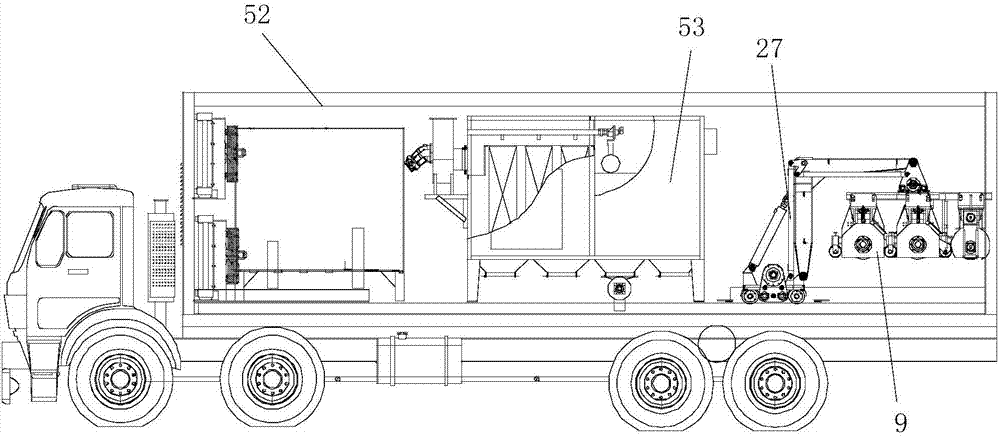

[0130] like figure 1 A road surface texturing treatment vehicle shown includes a carrier vehicle 52, a road surface texturing treatment equipment and a mobile boom 27 for translation and lifting of the road surface texturing treatment equipment, and the road surface texturing treatment equipment is installed on a mobile On the arm frame 27, the mobile arm frame 27 is installed on the carrying vehicle 52;

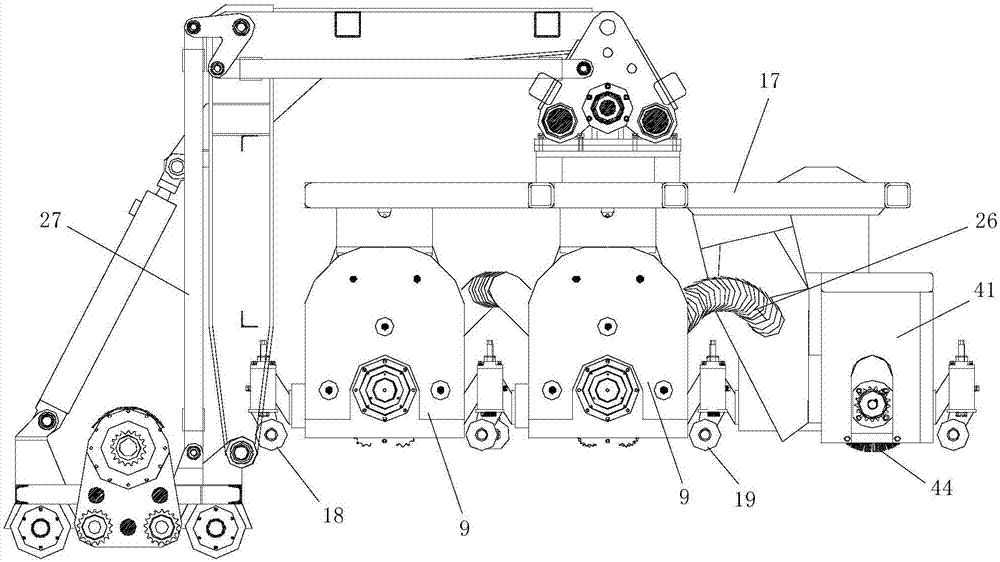

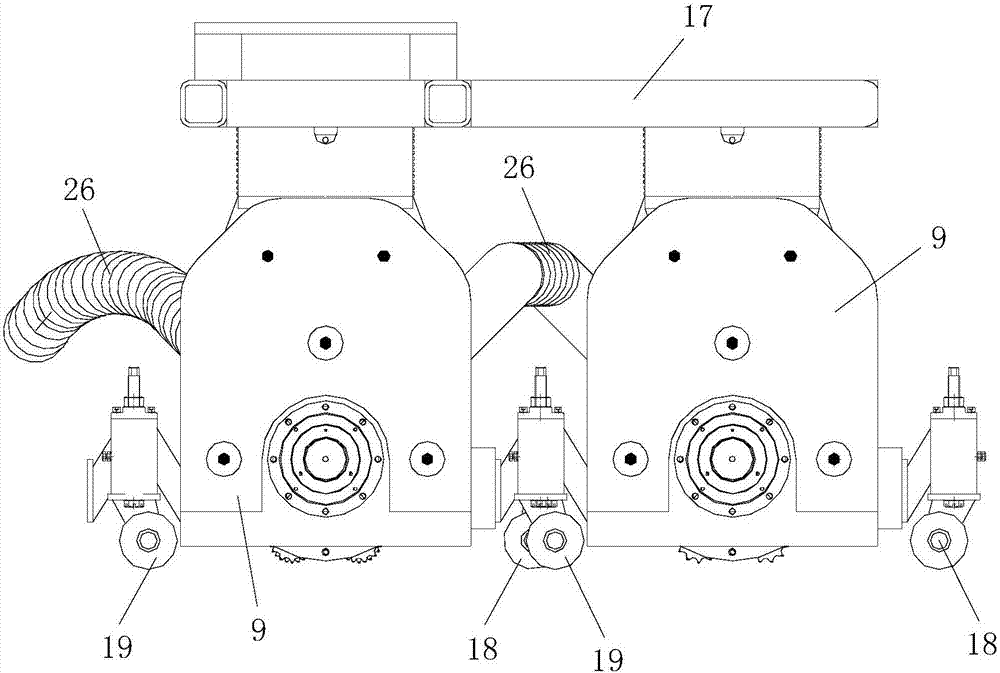

[0131] combine Picture 1-1 , Figure 1-2 , Figure 1-3 , figure 2 , image 3 , Figure 4 and Figure 5 , the road surface texturing equipment includes a road surface texturing tool assembly for texturing the processed road surface and a road cleaning device for cleaning the textured road surface to be processed, and the road cleaning device is installed Texturing the road surface on the rear side of the cutter assembly;

[0132] The road surface texturing cutter assembly includes a horizontal cutter mount 17 and three textured cutters all installed below the horizo...

Embodiment 2

[0285] like Figure 13 As shown, in this embodiment, the difference between the road surface texturing treatment vehicle used in Embodiment 1 is that the road surface texturing treatment blade 5 is a second milling cutter, and the second milling cutter includes a second gear Shape cutter head 5-3. No cutting head 5-2 is provided on the second gear-shaped cutterhead 5-3.

[0286] In this embodiment, the second gear-shaped cutter head 5 - 3 has a plurality of gear teeth evenly distributed along the circumferential direction, and the gear teeth are trapezoidal.

[0287] During actual processing, the number of gear teeth arranged on the second gear-shaped cutter head 5-3 and the arrangement position and shape of each gear tooth can be adjusted accordingly according to specific needs.

[0288] In this embodiment, the structures and connections of the remaining parts of the road surface texturing treatment vehicle are the same as those in Embodiment 1.

[0289] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com