Method for machining bearing ring with installation boss and narrow and small grinding undercut

A technology for bearing rings and mounting bosses, which is applied in the field of overrun groove processing, can solve problems such as the inability to complete narrow overrun groove processing, and achieve the effects of saving production costs and auxiliary costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

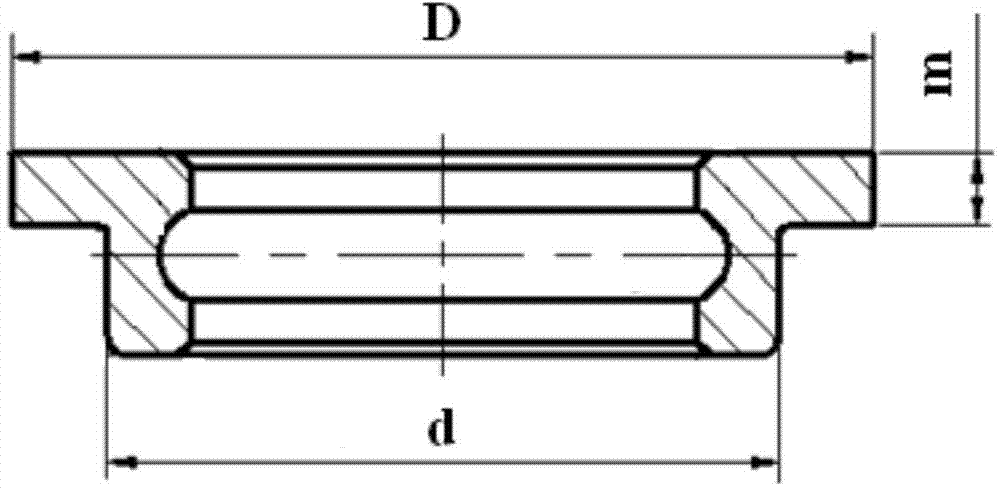

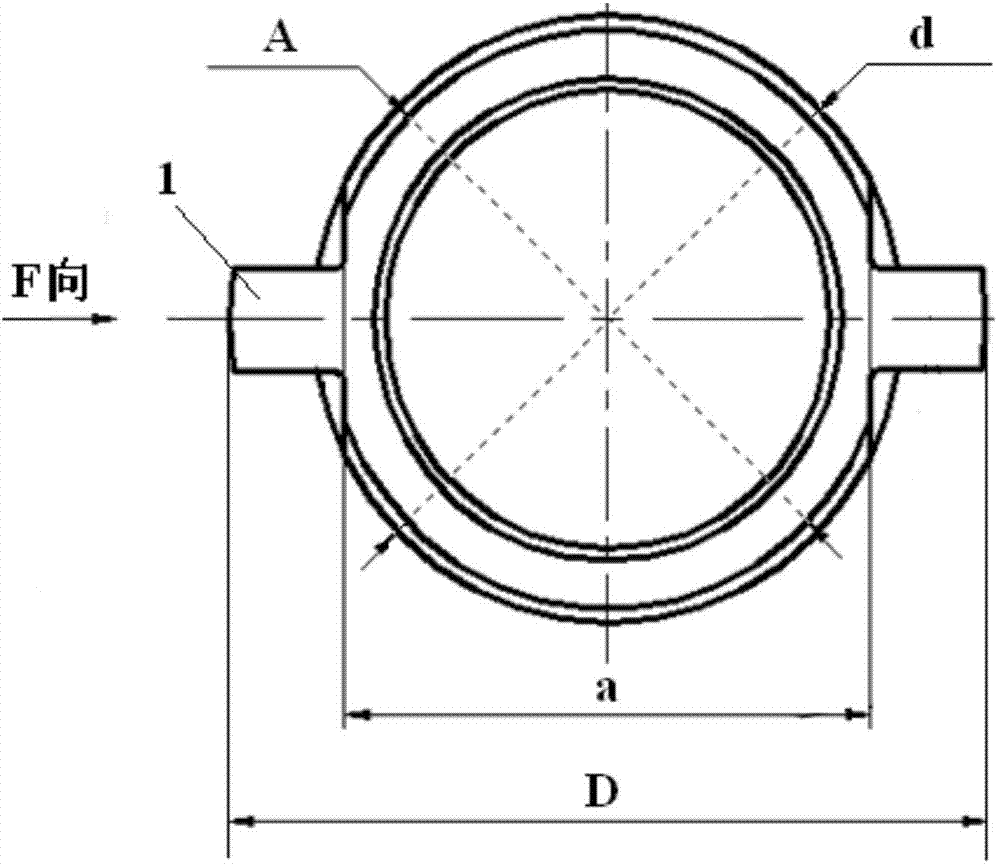

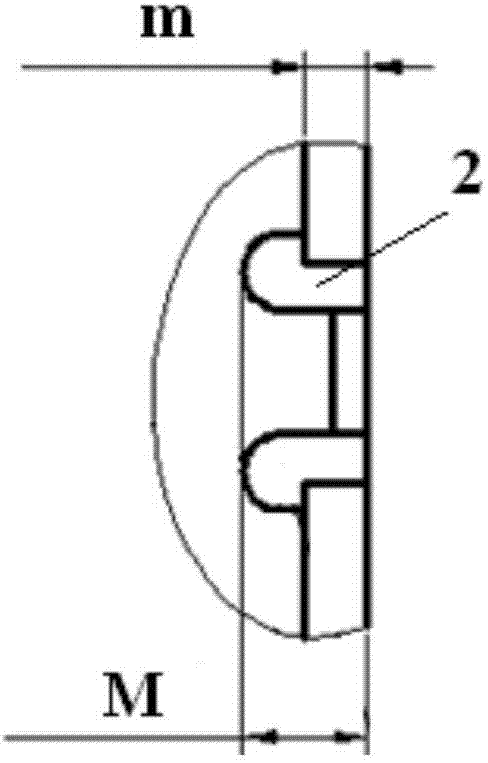

[0021] Specific implementation mode 1: This implementation mode is a processing method of a bearing ring with a mounting boss and a narrow overtravel groove, which is specifically completed according to the following steps:

[0022] 1. Rough turning forming: use a lathe to turn the ring-shaped ferrule forging into a rotary body with a stepped outer diameter to obtain a rough product of the bearing ring. The outer diameter of the upper boss of the rough product of the bearing ring is 62.3mm, and the outer diameter of the lower ring The outer diameter is 57.4mm;

[0023] 2. Tooling adjustment and clamping

[0024] ①. Use the mounting hole of φ30+0.23 and 4 screws to position and install the milling mold body on the indexing plate of the additional axis;

[0025] ②. Adjust the additional axis so that the positioning surface of the milling mold body is in a horizontal state; Two points, and the two points are 180° relative to each other on the circumference, adjust until the poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com