needle grinder

A grinding machine and needle technology, which is applied in the field of needle grinding, can solve the problems of low production efficiency of the grinding machine and uneven grinding of the needle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

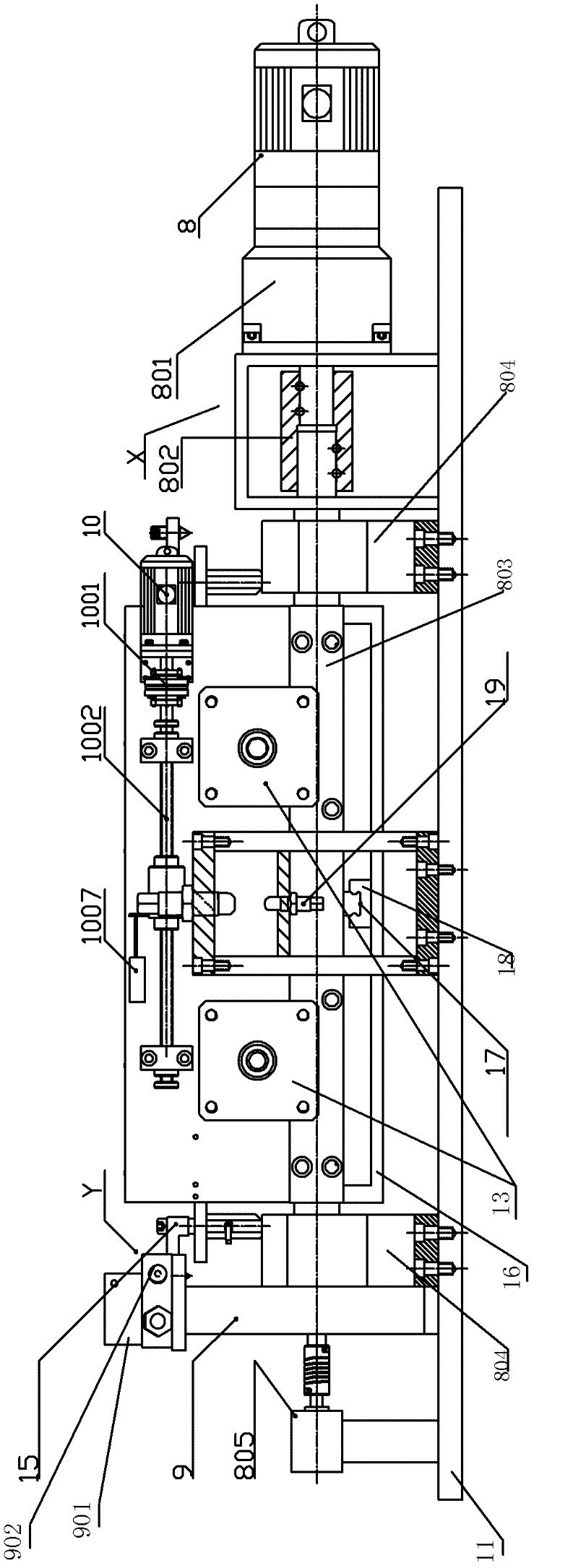

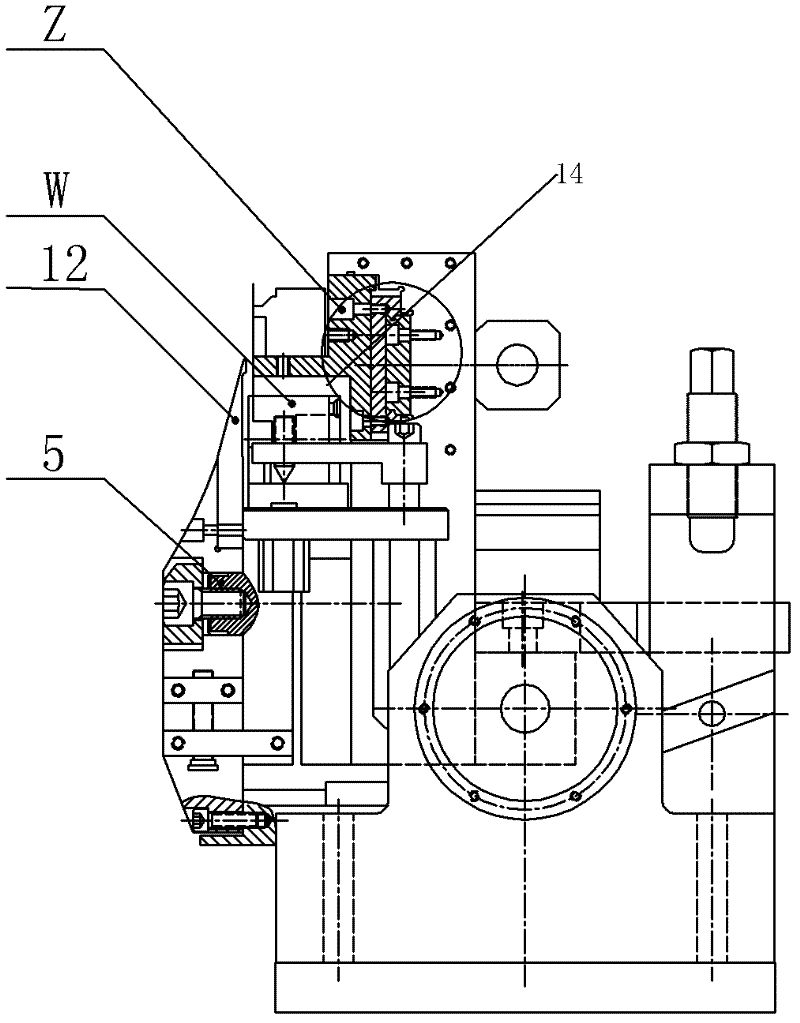

[0047] Next, a needle grinder of the present invention will be described in detail with reference to the accompanying drawings.

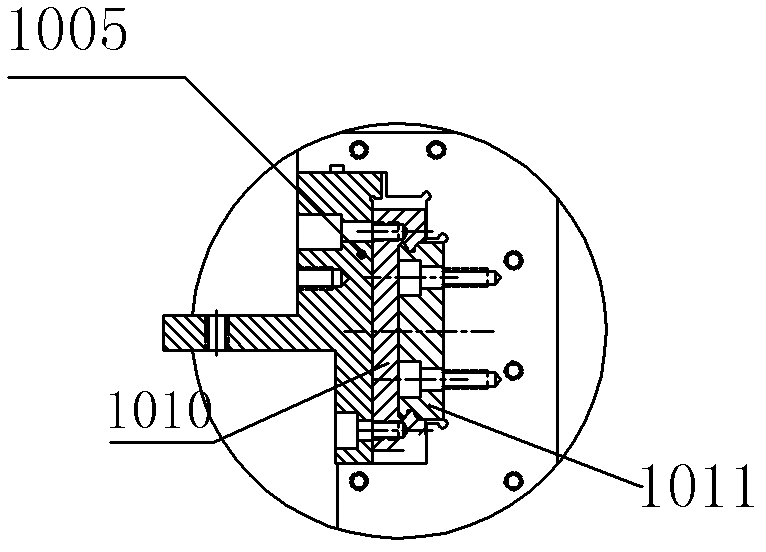

[0048] A needle grinder, comprising a frame body 11, a knife-shaped back plate 12, a main board 1008, two cylinders 13, a jig angle turning mechanism X, a needle clamp mechanism W, the two cylinder bodies are fixed on the main board, and There are through holes (not shown in the figure) corresponding to the telescopic rods of the two cylinders on the main board, and the two clamping shafts pass through a through hole to connect with the telescopic rods of one cylinder, and the clamping shafts are fixed on the rear platen by bolts superior. The top of the rear pressing plate is used to clamp the needle at the opposite position on the main board. Through the work of the cylinder, the rear pressing plate and the main board are opened to achieve the purpose of clamping the needle. The jig angle turning mechanism used to tilt the main board and the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com