Injection molding machine barrel

A material tube and material tube technology, applied in the field of plastic injection molding equipment, can solve the problems of slow temperature regulation, heat loss, low thermal efficiency, etc., and achieve the effects of fast temperature regulation, small energy loss, and high thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the above-mentioned technical scheme of the present invention and its advantages clearer and easier to understand, the preferred solution is enumerated below and described in detail as follows:

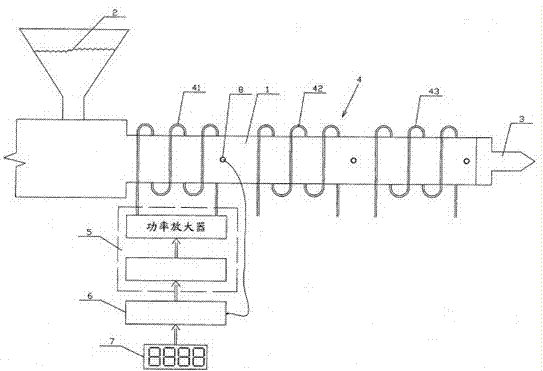

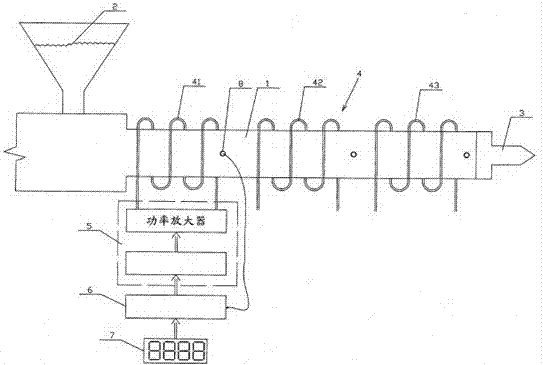

[0012] Refer to attached figure 1 :

[0013] The barrel of the injection molding machine according to the present invention includes a body 1, a feeding mechanism 2 is arranged on the body 1, a nozzle 3 is installed at the front end of the body 1, a heating coil 4 is wound on the outside of the body 1, and the heating coil 4 A high-frequency induction heater 5 is connected. The high-frequency induction heater 5 is a commercially available high-frequency induction heater, including a high-frequency oscillation generator and a power amplifier.

[0014] A plurality of heating coils 41 , 42 and 43 are wound on the barrel body 1 , and each heating coil is respectively connected to a different high-frequency induction heater. In this way, independent control of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com