An Optimum Determination Method for Pipe Diversion Point Coefficients in Process Industry Production Scheduling

A technology for determining methods and shunt points, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., and can solve problems such as difficulty in calculating large-scale parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to describe the present invention more specifically, the method for optimizing and determining the coefficient of the pipe diversion point of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

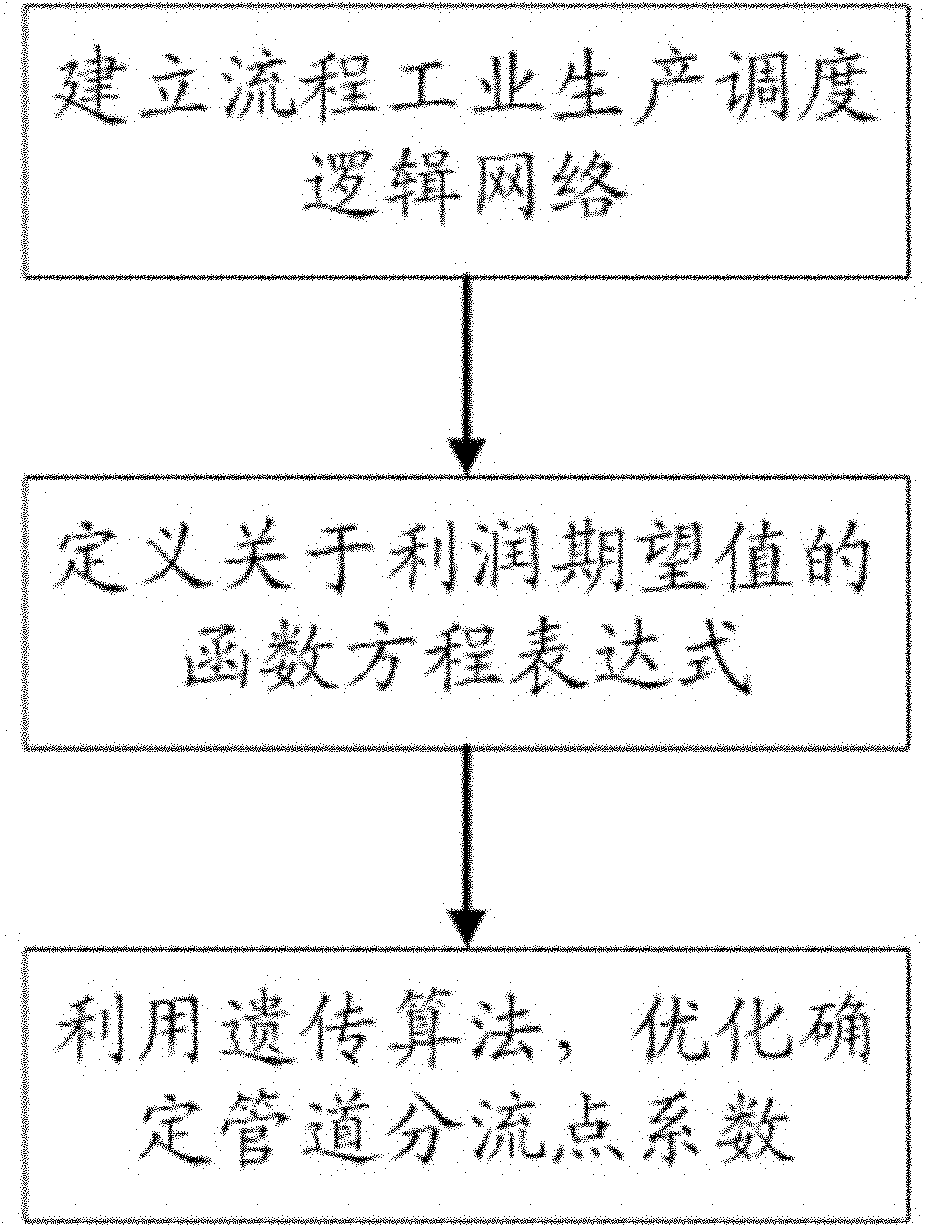

[0050] Such as figure 1 As shown, a method for optimizing and determining the coefficient of pipeline diversion points for process industry production scheduling includes the following steps:

[0051] (1) Establish the production scheduling logic network of the process industry.

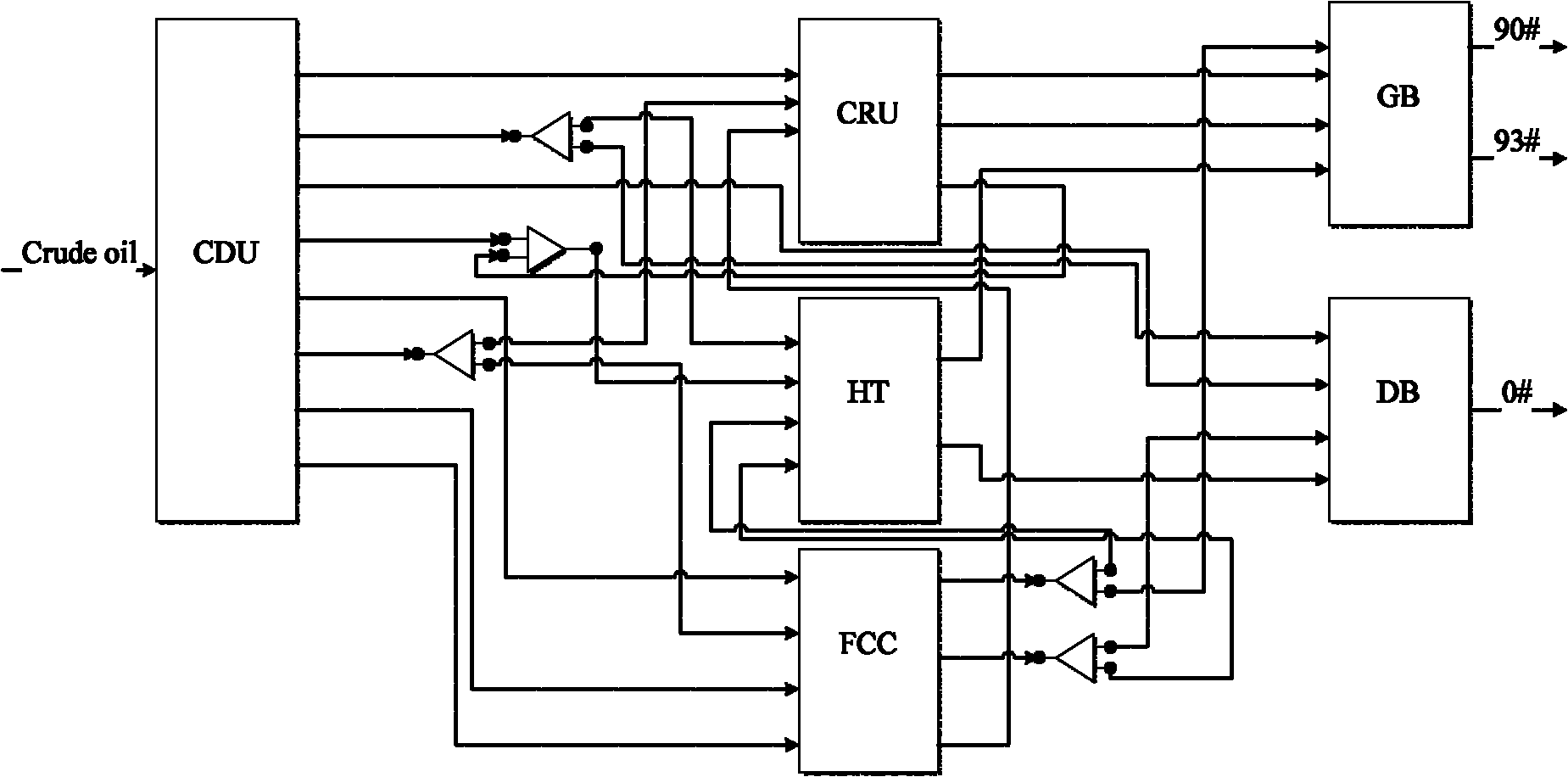

[0052] Such as figure 2As shown, taking the process industry production scheduling logic network of a petrochemical enterprise as an example, we assume the production process of the petrochemical enterprise as a fast simulator, the input variable is the optimized scheduling scheme, and the state variable is the flow through each side line The sum of the materials, the output variable is the output of 90# gasoline, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com